Overview

Design Resources

Design & Integration File

• Schematic• Bill of Materials

• Gerber Files

• Layout Files (Allegro)

• Assembly Drawing Download Design Files 1.72 M

Evaluation Hardware

Part Numbers with "Z" indicate RoHS Compliance. Boards checked are needed to evaluate this circuit.

- EVAL-ADICUP360 ($60.92) EVAL-ADICUP360

- EVAL-CN0396-ARDZ ($101.52) EVAL-CN0396-ARDZ

Device Drivers

Software such as C code and/or FPGA code, used to communicate with component's digital interface.

AD779x Linux GitHub Driver Source Code

AD779x GitHub no-OS Driver Source Code

Features & Benefits

- Dual electrochemical gas sensor

- Temperature compensation

- 16-bit digitization

Product Categories

Markets and Technologies

Parts Used

Documentation & Resources

-

EVAL-CN0396-ARDZ Shield - Hardware User Guide10/16/2018WIKI

-

CN0396: Dual Electrochemical Gas Sensor with Temperature Compensation (Rev. 0)10/27/2016PDF215 K

Circuit Function & Benefits

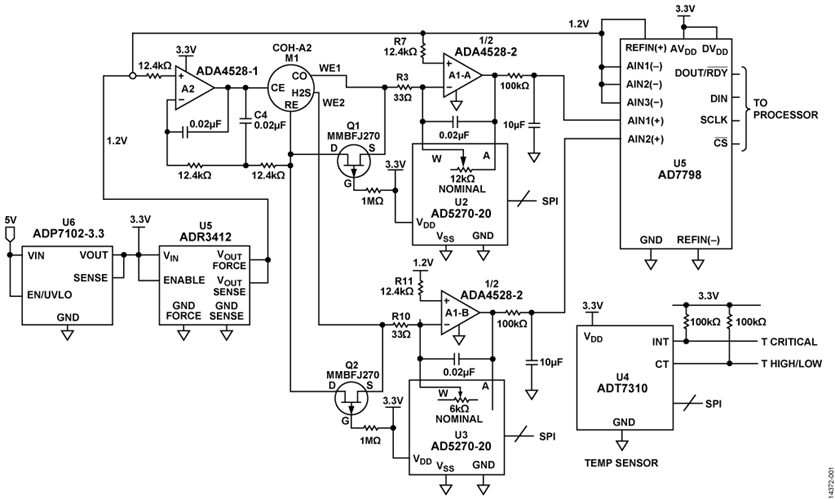

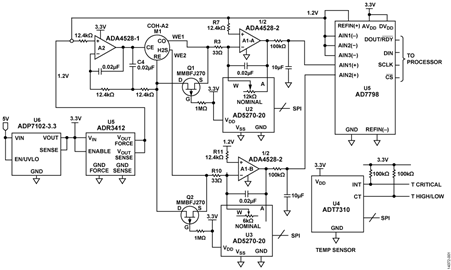

The circuit shown in Figure 1 is a portable gas detector, using a 4-electrode electrochemical sensor, for simultaneous detection of two distinct gases. The potentiostatic circuit uses an optimum combination of components designed to provide single-supply, low power, and low noise performance, while offering a high degree of programmability to accommodate a variety of sensors for different types of gases.

Electrochemical sensors offer several advantages for instruments that detect or measure the concentration of many toxic gases. Most sensors are gas specific and have usable resolutions under one part per million (ppm) of gas concentration.

The Alphasense COH-A2 sensor, which detects carbon monoxide (CO) and hydrogen sulfide (H2S), is used in this example.

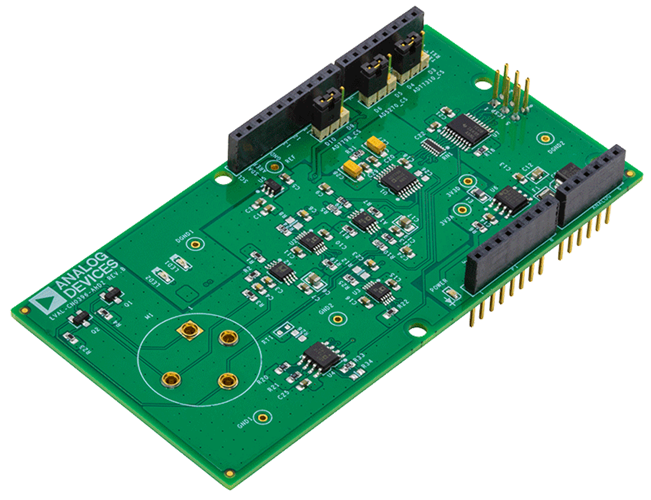

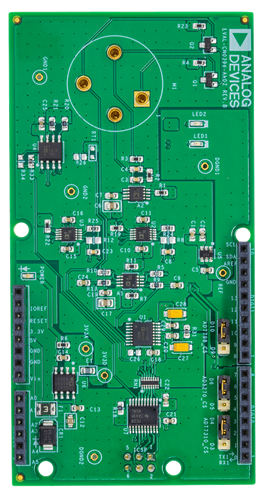

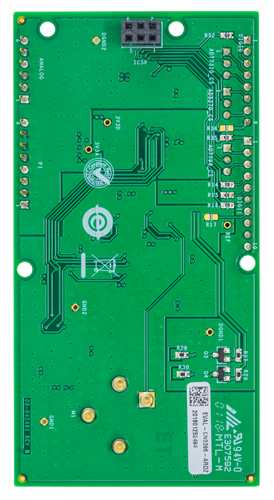

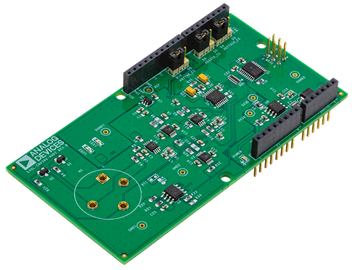

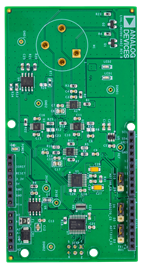

The EVAL-CN0396-ARDZ printed circuit board (PCB) is designed in an Arduino-compatible shield form factor and interfaces to the EVAL-ADICUP360 Arduino-compatible platform board for rapid prototyping.

Circuit Description

Figure 2 shows a simplified schematic of an electrochemical sensor measurement circuit.

Electrochemical sensors work by allowing gas to diffuse into the sensor through a membrane and by interacting with the working electrode (WE). The sensor reference electrode (RE) provides feedback to Amplifier U2-A, which maintains a constant potential with the WE terminal by varying the voltage at the counter electrode (CE). The direction of the current at the WE terminal depends on whether the reaction occurring within the sensor is oxidation or reduction. For a carbon monoxide sensor, oxidation takes place; therefore, the current flows into the working electrode, which requires the counter electrode to be at a negative voltage (typically 300 mV to 400 mV) with respect to the working electrode. The op amp driving the CE terminal must have an output voltage range of approximately ±1 V with respect to VREF to provide sufficient headroom for operation with different types of sensors (Alphasense Application Note AAN-105-03, Designing a Potentiostatic Circuit).

For 4-electrode electrochemical gas sensors, there are two working electrodes (shown as WE1 and WE2 in Figure 1). Each WE responds to a certain gas. In this example, the Alphasense COH-A2 sensor is used. One working electrode responds to CO, while the other responds to H2S. The sensors are designed such that special chemical filters prevent one gas from affecting the other electrode. The two working electrodes share a common RE and CE electrode.

The current into the WE terminal is less than 100 nA per ppm of gas concentration for CO and less than 1000 nA per ppm for H2S; therefore, converting this current into an output voltage requires a transimpedance amplifier with a very low input bias current. The ADA4528-1/ADA4528-2 op amp has CMOS inputs with a maximum input bias current of 220 pA at room temperature, making it a very good fit for this application. The ADA4528-1/ADA4528-2 is an auto-zero amplifier, which has a maximum offset voltage of 2.5 μV at room temperature and an industry leading 5.6 μV/√Hz of voltage noise density.

The ADR3412 voltage reference establishes the 1.2 V pseudo ground reference for the circuit, which allows single-supply operation while consuming very little quiescent current (100 μA maximum). The ADR3412 has 0.1% accuracy and 8 ppm/°C drift.

Amplifier A2 sinks enough current from the CE terminal to maintain a 0 V potential between the WE terminals and the RE terminal on the sensor. The RE terminal is connected to the inverting input of Amplifier A2; therefore, no current flows in or out of it. This means that the current comes from the WE terminal, and it changes linearly with gas concentration.

The A1-A and A1-B transimpedance amplifiers convert the sensor currents into voltages proportional to the gas concentration.

The sensor selected for this circuit is an Alphasense COH-A2 carbon monoxide (CO) and hydrogen sulfide (H2S) sensor. Table 1 shows the typical specifications associated with this type of sensor.

The gases that can be measured using this circuit and compatible sensors are toxic. Take extreme care when testing this circuit. Take note of the exposure limits and safety precautions when handling gases such as carbon monoxide and hydrogen sulfide.

| Parameter | Value |

| Carbon Monoxide (CO) | |

| Sensitivity | $50\text{ nA/ppm}$ to $100\text{ nA/ppm}$ |

| Response Time ($t_{90}$ from $0\text{ ppm}$ to $400\text{ ppm}$) | $< 35\text{ sec}$ |

| Measurement Range (Guaranteed) | $0\text{ ppm}$ to $1000\text{ ppm}$ |

| Overrange Limit | $2000\text{ ppm}$ |

| Hydrogen Sulfide ($H_2S$) | |

| Sensitivity | $600\text{ nA/ppm}$ to $1000\text{ nA/ppm}$ |

| Response Time ($t_{90}$ from $0\text{ ppm}$ to $20\text{ ppm}$) | $< 30\text{ sec}$ |

| Measurement Range (Guaranteed) | $0\text{ ppm}$ to $200\text{ ppm}$ |

| Overrange Limit | $400\text{ ppm}$ |

The output voltage of the transimpedance amplifier is

where:

IWE is the current into the WE terminal.

RAW is the transimpedance feedback resistor (shown as the

AD5270-20 U2 and U3 digital rheostat in Figure 1).

The maximum response of the COH-A2 sensor for CO gas is 100 nA/ppm, and its maximum input range is 1000 ppm. For the H2S gas, the maximum response is 1000 nA/ppm, and the maximum input range is 200 ppm. These values result in a maximum output current of 100 μA and 200 μA for CO and H2S electrodes, respectively. The transimpedance amplifier feedback resistors determine the maximum input voltage to the analog-to-digital converter (ADC).

Equation 2 shows the calculation for output voltage of the TIA for the CO electrode.

Applying 1.2 V to VREF of the AD7798 allows a usable range of ±1.2 V at the output of the transimpedance amplifiers, A1-A and A1-B. Selecting nominal feedback resistors of 12 kΩ for the CO channel and 6 kΩ for the H2S channel gives a maximum output voltage of approximately 2.4 V for both sensor types. The exact values of the resistors are determined by a single-point calibration in a gas of known concentration.

The AD5270-20 digital rheostat is used for the feedback resistor in both channels and has a maximum resistance value of 20 kΩ. There are 1024 resistance positions, resulting in resistance step sizes of 19.5 Ω. The 5 ppm/°C resistance temperature coefficient of the AD5270-20 is better than that of most discrete resistors, and its 1 μA of supply current is a very small contributor to the overall power consumption of the system.

Temperature Compensation

The ADT7310 is a 16-bit, digital serial peripheral interface (SPI) temperature sensor with an accuracy of ±0.5°C. In this circuit, it is used to monitor the temperature of the environment. The temperature data can be used to correct for the effects of temperature changes on the performance of the gas sensor.

It is recommended to position the temperature sensor close to the gas sensor. The sensitivity of gas sensors (expressed as nA/ppm) changes by typically 0.1%/°C to 0.3%/°C with respect to the room temperature sensitivity (Alphasense Application Note AAN-110, Environmental Changes: Temperature, Pressure, Humidity).

The ADT7310 measures the ambient temperature and sends the result to a microprocessor over an SPI interface. The corrections are then carried out in the software using a lookup table or an equation.

Always consult the manufacturer to obtain the temperature correction data for the specific sensor used in a system.

Noise Performance

The output impedance of the sensor WE terminals is a parallel combination of a relatively large capacitance and resistance. The capacitance causes the noise gain of the amplifier to increase as the frequency increases, thereby increasing the output noise. The R3 and R10 resistors are in series with the sensor output impedance and keep the noise gain (NG) of the TIAs at a reasonable level. Selecting the optimum value of this resistor is a compromise between the fastest response time when exposed to high concentrations of gas (low R3, R4, and high noise gain) and low noise (high R3, R4, and low noise gain). For the example shown in Equation 3 and Equation 4, R4 = 33 Ω, which results in a noise gain of 365 in the CO channel and 183 in the H2S channel, neglecting the output impedance of the WE terminals:

The input noise of the transimpedance amplifier appears at the output, amplified by the noise gain. For this circuit, only low frequency noise is of interest because the frequency of operation of the sensor is very low. The ADA4528-2 has a 0.1 Hz to 10 Hz input voltage noise of 97 nV p-p.

The 12.4 kΩ resistors, R7 and R11, each contribute approximately 294 nV p-p over the 0.1 Hz to 10 Hz bandwidth.

Therefore, the total input noise is the rss value of 97 nV p-p and 294 nV p-p, or 309 nV p-p.

Reflected to the output by the noise gains results in 365 × 309 nV = 113 μV p-p in the CO channel and 183 × 309 nV = 57 μV p-p in the H2S channel.

Because this noise is low frequency 1/f noise, the noise is very difficult to filter. However, because the sensor response is also slow, it is possible to use a very low frequency, low-pass filter (100 kΩ/10 μF) with a cutoff frequency of 0.16 Hz and a time constant of 2.2 sec. Even with this large time constant, the effect of the filter on the sensor response time is negligible when compared to the approximate 30 sec response time of the sensor.

The 0.16 Hz filter reduces the CO and H2S output noise from 113 μV p-p and 57 μV p-p to approximately 14.3 μV p-p and 7.2 μV p-p, respectively.

The theoretical noise free code resolution of the system in each channel measured at the output of the 0.16 Hz filter can be calculated as follows:

These calculations assume that there is no noise contribution from the sensor itself. In practice, the equivalent CO sensor rms noise is specified to be less than 0.5 ppm (for full scale = 1000 ppm), and the H2S sensor less than 0.05 ppm (for full scale = 200 ppm).

Final system tests including the sensor were conducted on the CO channel, and the peak-to-peak noise was measured to be approximately 4 LSBs, for a full scale of 216−1 = 32,768, which gives

One important characteristic of electrochemical sensors is their very long time constant. When first powered up, it can take several minutes for the output to settle to its final value. When exposed to a midscale step in concentration of the target gas, the time required for the sensor output to reach 90% of its final value can be in the order of 25 sec to 40 sec. If the voltage between the RE terminal and the WE terminal has a sudden change in magnitude, it can take several minutes for the output current of the sensor to settle. This long time constant also applies when cycling power to the sensor. To avoid long start-up times, the Q1 and Q2 P-channel JFETs short the RE terminals to the WE terminals when the supply voltage drops below the gate-to-source threshold voltage (~2.0 V) of the JFETs.

Power Consumption

The circuit is powered by a 3.3 V supply coming from an ADP7102-3.3 LDO. The current from the output of the LDO was measured to be 4.5 mA. The system was configured as shown in Table 2. With the ADC, digital rheostat, and temperature sensor placed in their power-down modes and the amplifier supplies disabled, the system only consumes 17 μA maximum.

| Device | Configuration |

| AD7798 (Low Power 24-Bit ADC) |

* Buffers: **Enabled** (High input impedance) * Gain: **1** * Mode: **Continuous conversion** * Update Rate: **4.17 Hz** (Optimized for 50 Hz/60 Hz rejection) |

| AD5270-20 (Digital Rheostat) |

* Operating Mode: **Normal mode** * R-performance: **Disabled** * Function: Precise TIA gain control |

| ADT7310 (High Accuracy Temperature Sensor) |

* Conversion Rate: **1 SPS mode** * Resolution: **16-bit** * Function: Gas sensor temperature compensation |

System Gas Concentration Measurements

A calibrated gas chamber was used to make concentration measurements with the CN-0396 circuit. Figure 3 shows the measured concentration as a function of the chamber concentration. The sensor manufacturer recommends a single-point calibration at 400 ppm concentration for the CO sensor. The data shows that the full-scale gain error is approximately 80 ppm due to the inherent sensor error and the accuracy of the gas chamber calibration.

A complete set of schematics, bill of material, and layout files for the EVAL-CN0396-ARDZ board is available in the CN-0396 Design Support package.

Common Variations

Electrochemical sensors operate with very small amounts of current, making them well suited for portable, battery-powered instruments. If lower power is required, the ADA4505-2 amplifier has a maximum input bias current of 2 pA and consumes only 10 μA per amplifier. However, the noise of the ADA4505-2 is greater than that of the ADA4528-2.

The ADR291 precision voltage reference consumes only 12 μA and can be substituted for the ADR3412, if lower power is required.

For embedded applications, the Analog Devices, Inc., family of microcontrollers such as the ADuCM360 feature an on-board, 24-bit, Σ-Δ ADC and internal voltage reference. This can lower the number of components and power consumption of the system.

For 3-electrode electrochemical toxic gas sensing design, see the Circuit Note CN-0357.

Circuit Evaluation & Test

The circuit shown in Figure 1 uses the EVAL-CN0396-ARDZ circuit evaluation board and the EVAL-ADICUP360 development board. In addition, the EVAL-CN0396-ARDZ comes in an Arduino shield form factor, making it possible to use pin-compatible developments boards for evaluation and prototyping.

The CN-0396 demo software (see the CN-0396 User Guide) allows the EVAL-ADICUP360 board to configure and read data from the EVAL-CN0396-ARDZ evaluation board. This data can be displayed using a serial port terminal program on a PC.

Equipment Needed

The following equipment is needed:

- PC with a USB port and Windows® 7 (32-bit) or higher

- EVAL-CN0396-ARDZ circuit evaluation board

- EVAL-ADICUP360 development board

- USB-A to USB micro cable

- 7 V to 12 V power supply

- CN-0396 demo software (see the CN-0396 User Guide)

- Serial terminal software (PuTTY, Tera Term, or similar)

- 4-electrode electrochemical gas sensor (CO and H2S sensor is provided with the evaluation board)

- Environmental chamber

- Calibration gases

- Precision current source (alternative to actual sensor and gases)

Getting Started

A detailed user guide for the EVAL-CN0396-ARDZ is available at www.analog.com/CN0396-UserGuide. Consult this user guide for all aspects of hardware and software operation.

A detailed user guide for the EVAL-ADICUP360 platform board is also available at www.analog.com/EVAL-ADICUP360.

Set the jumpers on the EVAL-ADICUP360 board to the positions indicated in the CN-0396 User Guide.

Download the CN-0396 demo code to the EVAL-ADICUP360 board using the Eclipse IDE and DEBUG USB connection.

Install the gas sensor on the EVAL-CN0396-ARDZ board through the sockets provided. Connect the EVAL-CN0396-ARDZ board to the EVAL-ADICUP360 using the mating headers.

Connect the USER USB port of the EVAL-ADICUP360 to the PC. On the PC, start the preferred serial terminal software and connect to the EVAL-ADICUP360 serial port to begin reading the data.

Other processors can also be used to test and evaluate the EVAL-CN0396-ARDZ board; however, the software and drivers may not be provided.

Functional Block Diagram

A functional block diagram of the test setup is shown in Figure 4. A complete schematic of the evaluation board is contained in the CN-0396 Design Support package, including layout, Gerber files, and a bill of materials.

Power Supply Configuration

When connected appropriately to the EVAL-ADICUP360 platform board, the EVAL-CN0396-ARDZ evaluation board receives the necessary voltage to power the circuitry from the EVAL-ADICUP360 board.

Test

To measure gas concentration, position the system in the environment to be measured. The data coming from the ADC must be converted into a voltage value. The ADC input voltage, together with the rheostat resistance value and sensor sensitivity, is used to compute the gas concentration. The performance of the circuit can be tested without a gas chamber by using a precision current source to simulate the sensor output current, as shown in Figure 5. The test must be conducted with the sensor inserted so that the circuit impedance and voltage levels are correct.

Figure 6 shows a photo of the EVAL-CN0396-ARDZ board.