MAX17851

推荐用于新设计SPI至UART安全监控桥

可充当冗余微控制器的超快BMS通信接口

- 产品模型

- 2

概述

- 支持Maxim的电池管理UART协议

- 满足ASIL D功能安全要求

- 经过简化的主机报告实现片内通信自动验证

- 提供故障类型和故障位置的不间断菊花链故障轮询

- 带冗余菊花链控制器的集成系统看门狗

- 可编程系统恢复

- 用于菊花链配置的可编程存储器

- 可编程接触器控制

- 集成了在微控制器处于睡眠模式时进行电池平衡的功能

- 具有可编程中断的安全长期平衡监控

- UART波特率可编程至高达4Mbps

- SPI接口速率高达10MHz

- 采用1.71V至5.5V电源供电

- 超低静态电流

- 工作温度范围:-40°C至+125°C

MAX17851 SPI至UART安全监控桥将通信从SPI格式转换为通用异步接收器/发射器(UART)格式,专为与Maxim的电池管理数据采集系统进行接口而设计。 安全监控桥可在单菊花链和双菊花链系统架构中以高达4Mbps的波特率实现稳健的通信。高吞吐速率、双UART系统可以在1173us内读取96节电池的电压。

UART符合汽车安全完整性等级(ASIL) D系统的ISO26262标准,可通过嵌入式UART通信锁步安全措施状态机(LSSM)检测消息损坏、延迟、丢失和插入。{{max_num}} 会自我验证消息有效载荷内的所有通信,以简化主机微控制器上的软件开发。

此外,MAX17851会监控主机微控制器以检测任何故障。如果与主机发生通信故障,MAX17851会首先尝试自动恢复通信。如果不成功,它将接管控制权。然后,MAX17851可以选择性地重新配置菊花链网络,以继续监控电池状况。 这有利于保持安全的系统操作。 最后,MAX17851会在电池状况超出编程范围时提供接触器信号,使整个系统进入故障安全状态。

应用

- 电池管理系统(BMS)

- 电动和混合动力汽车(EV/HEV)

- 储能系统(ESS)

参考资料

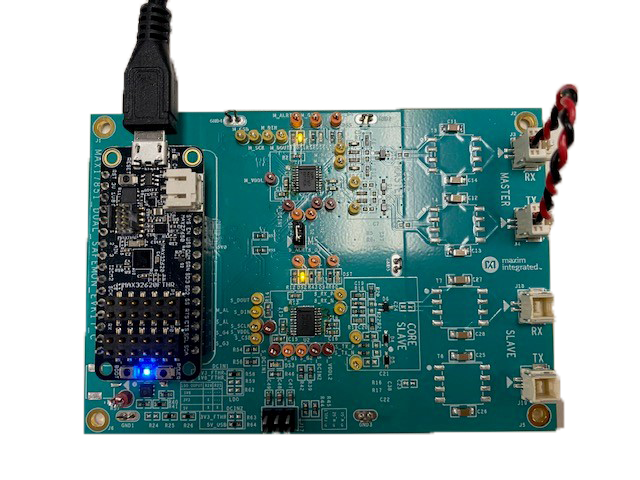

视频 1

ADI 始终高度重视提供符合最高质量和可靠性水平的产品。我们通过将质量和可靠性检查纳入产品和工艺设计的各个范围以及制造过程来实现这一目标。出货产品的“零缺陷”始终是我们的目标。查看我们的质量和可靠性计划和认证以了解更多信息。

| 产品型号 | 引脚/封装图-中文版 | 文档 | CAD 符号,脚注和 3D模型 |

|---|---|---|---|

| MAX17851AUP/V+ | TSSOP_4.4 / TSSOP_6.1 | ||

| MAX17851AUP/V+T | TSSOP_4.4 / TSSOP_6.1 |

这是最新版本的数据手册

评估套件

最新评论

需要发起讨论吗? 没有关于 MAX17851的相关讨论?是否需要发起讨论?

在EngineerZone®上发起讨论