要約

With the increasing influx of diagnostics devices in the market, it is incumbent of analog power system designers to innovate and create a synergic combination of power management and optical sensor solutions, which guarantee the lowest power consumption and the smallest form factor without compromising on the fidelity of the sensor measurements. This application note focuses on the personal pulse oximeter design requirements with the spotlight on the correlation between their power requirements, serviced with Single-Inductor Multiple-Output (SIMO) Power Management Integrated Circuits (PMICs), and the Signal-to-Noise Ratio (SNR) characteristics of the optical sensor module inside these vital monitors.

Introduction

Covid-19 in 2020 brought a paradigm shift in the world of wellness. People across different age groups now continuously track and monitor their vital signs like SpO2, Heart Rate (HR), and VOx levels as a part of their lifestyle routine. With the advent of so many wellness trackers, smartwatches, heart rate monitors, and personal pulse oximeters, the concept of human vital monitoring has moved away from the doctor's clinic to our wardrobes. With the increasing influx of these diagnostics devices in the market, it is incumbent of analog semiconductor companies like Maxim Integrated to innovate and create a synergic combination of power management and optical sensor solutions, which can guarantee the lowest power consumption and smallest form factor without compromising on the fidelity of the sensor measurements. This application note focuses on the personal pulse oximeters with the spotlight on the correlation between their power requirements and the Signal-to-Noise Ratio (SNR) characteristics of the optical sensor module inside these vital monitors. The application also discusses how Maxim Integrated, with its Single-Inductor Multiple-Output (SIMO) Power Management Integrated Circuits (PMICs) help the pulse oximeter manufacturers prepare for the ever-shrinking battery power consumption and system Figure-of-Merit (FoM) requirements in their next product iteration.

Pulse Oximetry

Pulse oximetry is a noninvasive measurement of blood oxygenation (SpO2). The measurement is based on a technique called Photoplethysmography (PPG). This technique can be classified as transmissive or reflective:

- In transmissive pulse oximetry, the photodiode and (Light-Emitting Diode) LED are placed on opposite sides of the human body (e.g., finger). The body tissue absorbs some of the light, and the photodiode collects the remaining light that passes through the body.

- In reflective pulse oximetry, the photodiode and LED are on the same side. The photodiode here collects the light reflected from underneath the skin.

Figure 1. Transmissive (Left) vs Reflective (Right) PPG techniques for pulse oximetry measurements.

Pulse oximetry is based on three main principles:

- Absorbance of transmitted/reflected light by pulsatile arterial blood.

- Different absorbance characteristics of HbO2 and RHb for different light wavelengths (red vs. infrared).

- Direct correlation between transmitted/reflected light and the PPG signal current generated at the photodiode.

The optical module is a crucial subsystem in the personal pulse oximeter system architecture. A typical optical module is designed with three programmable high current LED drivers (red, IR for SpO2, and green for HR) on the transmitter side, and a high-efficiency PIN photodiode with an optical readout channel on the receiver side.

Figure 2. Sequence timing for RED and IR LED pulse in pulse oximetry.

An optical sensor module (refer to MAXM86161) can be configured to pulse the LED drivers sequentially, taking measurements at multiple wavelengths (infrared, red) in pulse oximetry measurements. Figure 2 illustrates the optical timing mode when SpO2 is measured with IR and red LEDs. When SpO2 is measured with IR and red LEDs, the optical sampled and digitized photodiode current appear at the receiver side, following the same sequence. The ambient light pulse sample is not illustrated here as the topic of ambient light sampling requires more deliberation, which is beyond the scope of this application note.

Power Management Requirements

The frequency, pulse width, and pulse amplitude of each LED pulse (Figure 3) can be modulated to extend the battery life of the personal pulse oximeter. Consequently, the resultant average ILED current can vary depending on the full-scale peak LED current settings (ranging from 30mA to 120mA). Keeping these variables in context, it is essential to maintain the LED bias rail (VLED) output within the output ripple and undershoot/overshoot (during any LED pulsing) specifications. Any unwarranted noise at the VLED bias rail can inject subsequent noise at the photodiode receiver end, introducing optical measurement error and degrading the overall system accuracy and SNR performance.

A typical personal pulse oximeter consists of the following subsystems:

Figure 3. Personal pulse oximeter subsystems.

Most commercially available personal pulse oximeters operate off rechargeable Li+ secondary cell or easy-to-replace primary cells like CR3032, with the operating voltage range between 3V to 4V. However, a single battery (secondary or primary) cannot regulate all the subsystems in a personal pulse oximeter to their optimal voltage ratings.

The system needs a power management solution, which can ensure all subsystems get the correct input bias voltage supplies, with no cross talk among them. That is where the Maxim Integrated MAX77643, an easy-to-configure, > 93% efficient SIMO PMIC, which can boost, buck, and buck-boost the battery voltage over a wide range of output voltages - 0.5V up to 5.5V, across three output channels, all while using just a single inductor, serves the purpose. With only a single inductor supporting multiple output channels, MAX77643, like other SIMO PMICs, guarantees the lowest Bill-of-Material (BOM) and an ultra-compact power stage Printed Circuit Board (PCB) real estate compared to any conventional discrete power management solution, allowing the system designers to just focus on optimizing PPG algorithms and the form factor of the personal pulse oximeter.

Refer to the SIMO Whitepaper for more details on the SIMO architecture.

The integrated optical sensor modules are designed to operate from 3.0V to 5.5V (VLED) single-supply voltage range. Any of the multiple switching buck-boost output channels of the low-power SIMO PMIC MAX77643 (SBB0 selected in Figure 3) can be programmed through I2C (or with an OTP factory setting) to easily support the required VLED supply range.

The MAX77643, with the inherently stable constant ON-time control scheme as a part of the SIMO architecture, ensures no unwarranted noise gets coupled to the VLED output rail during the ILED steady-state setting or during any transient LED pulse.

When operating in steady-state at a nominal peak ILED setting, a high amplitude ripple at VLED output rail introduces low-fidelity LED pulses, degrading the sensor measurements. At even lower average ILED conditions (during low-peak ILED setting, low LED ON pulse-width, or low LED pulse repetition rate), an additional introduction of low-frequency output ripple burst due to the MAX77643 selectable low-power mode of operation to extend the battery life, can further exacerbate the optical measurements.

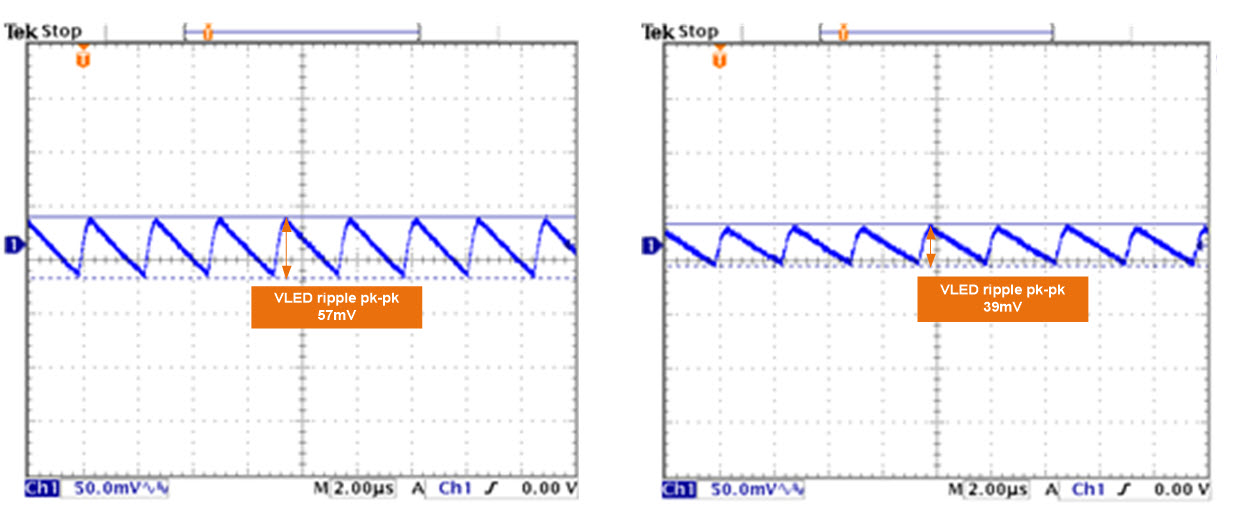

The MAX77643, operating with SIMO architecture and programmable peak current settings, ensures the VLED output ripple remains at less than 60mV (across load and output capacitors settings (approximately 50% lower than the optical module VLED ripple requirements)). Also, the output ripple burst frequency stays at ~50kHz, even during the low-power mode of operation for the light load ILED setting to conserve battery power.

Figure 4 shows the VLED output ripple measurements with MAX77643.

Figure 4. VLED ripple at ILED = 100mA (left) with 2 x 10µF COUT capacitors and VLED ripple at ILED = 100mA (right) with 1 x 10µF COUT capacitor (right).

During the transient operation, the LED ON pulse-width can be anywhere between ~20µs to ~120µs. This ON pulse-width includes the LED pulse blanking delay, starting from the onset of the LED pulse to the beginning of the PD (Analog-to-Digital Converter) ADC integration time, TINT. A longer LED ON pulse-width can improve the system SNR performance but reduce battery operation lifetime. At the onset and during such LED ON pulse, the MAX77643 delivers ultra-fast response to the ILED transient and ensures the VLED voltage remains within the undershoot/overshoot specification.

Figure 5 shows a typical output load transient behavior where the ILED toggles between no load and 93mA. The VLED is set to 3.0 V. The VLED is seen quickly settling to a steady value (the VLED undershoot measures 138mV only, even when the low-power mode is enabled with the MAX77643, ensuring the VLED does not drop below 2.7V, the minimum compliant voltage for the RED LED) in less than 14µs (with low-power mode enabled with the MAX77643; in the low-power disabled mode, the VLED output settling time is less than 8µs and the undershoot value less than 22mV). The consistent ultra-fast load transient response and fast settling time ensure that no DC offset pushing the VLED outside the minimum compliance is introduced, keeping the ILED setting intact and preventing any consequent sensor measurements.

Figure 5. Low-power mode enabled (left) vs. low-power mode disabled (right) (in the MAX77643)

Impact of SIMO PMICs on System SNR

Figure 2 shows the red and IR LEDs on the transmitter side are driven sequentially and alternately with a low repetition rate and variable duty cycle depending on the system requirement (pulse oximeter sleep-mode and active-mode). As highlighted before, to ensure the accuracy of the optical sensor measurements during the operation, the ILED currents must be precise and have minimal noise because any noise in the frequency bandwidth of interest negatively impacts the SNR of the entire system.

At the photodiode (PD) receiver side in the optical sensor module, the reflected and modulated RED and IR lights are converted into PD current and consequently to a voltage. This voltage is sent through a high-resolution, optimal sampling rate and high SNR ADC to be processed further in the digital domain.

As noted in Table 1, the MAX77643 when powering up the MAX86171, the latest AFE for pulse oximetry and heart rate monitoring from Maxim Integrated, ensures that the sensor's system SNR performance matches the data sheet typical operating characteristics closely with any degradation.

| MAX86171 | SNR (dB) | SNR12 (dB) | SNR4 (dB) |

| PMIC – MAX77643 | 90.9 | 97.2 | 101.9 |

The SNR data point (90.9 dB) is the basic SNR ratio measured with the MAX86171 without any band-pass filtering, with the target PD current at 30µA (IFS) and the ADC integration time, TINT (part of the LED ON pulse-width setting) clamped at 117.1µs. An additional signal filtering algorithm between the optical sensor module and micro may be warranted for more accurate measurements. These filters are responsible for removing the higher frequency noise while retaining the useful frequency components of the signal, improving the SNR further. The typical PPG signal bandwidth can be as narrow as < 15Hz. The SNR12 data point (97.2 dB) in Table 1 is the SNR logged with the MAX86171 when the measured signal is filtered further by a bandpass filter with the passband set between 0.5Hz and 12Hz. Similarly, the SNR4 data point (101.9 dB) is a measure of the MAX86171 SNR when the measured signal is further filtered by a bandpass filter with the passband set between 0.5Hz and 4Hz.

This data further confirms that the MAX77643, like other PMICs with SIMO architecture (MAX17270, MAX77650, MAX77654, and MAX77655) can support any optical sensor module or optical AFE when it comes down to sensor measurement accuracy across different operating conditions.

Summary

This application note highlights the combination of a SIMO PMIC powering the optical sensor module and other peripherals in the personal pulse oximeter, while maintaining the system accuracy and SNR performance, in detail. The SIMO PMIC family ensures the optical sensor modules in the ever-shrinking personal pulse oximeter designs see a regulated VLED bias, remain within their transmitter LED bias voltage specifications under all operating conditions, are not burdened by additional passives in the power stage, and do not need to compete with power management components for premium PCB real estate.