Precision ADCs

Precision ADCs

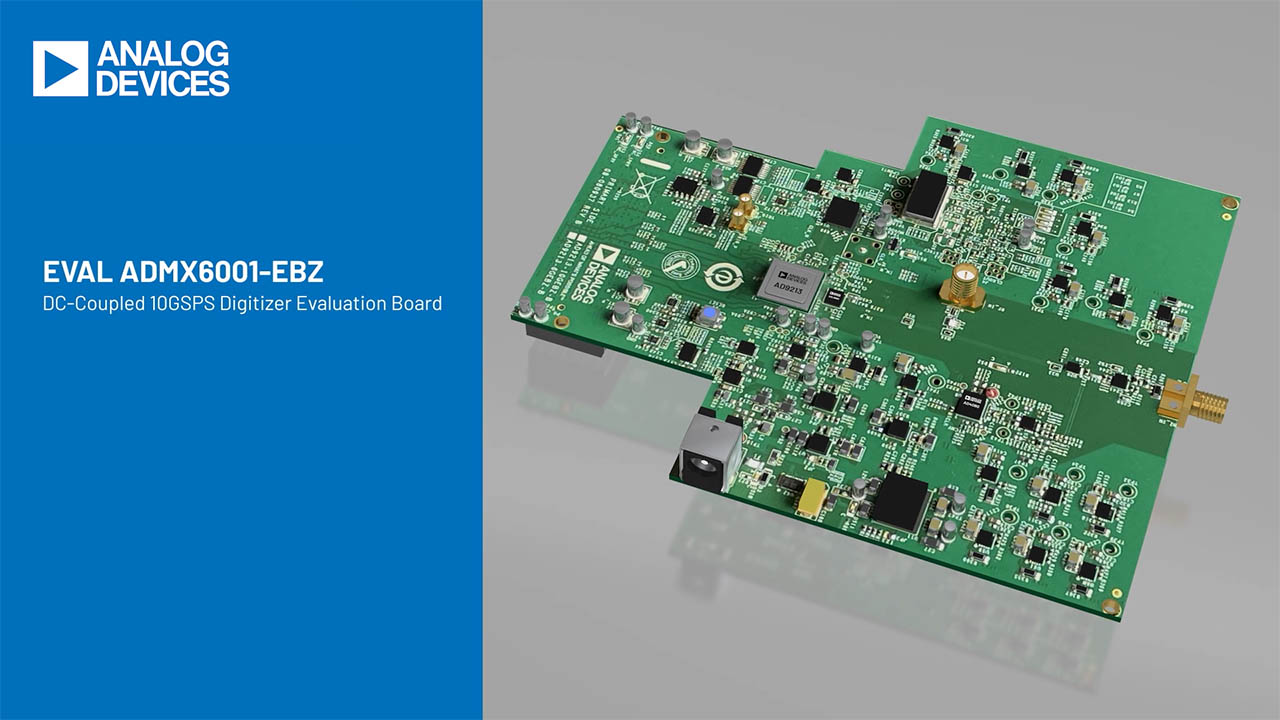

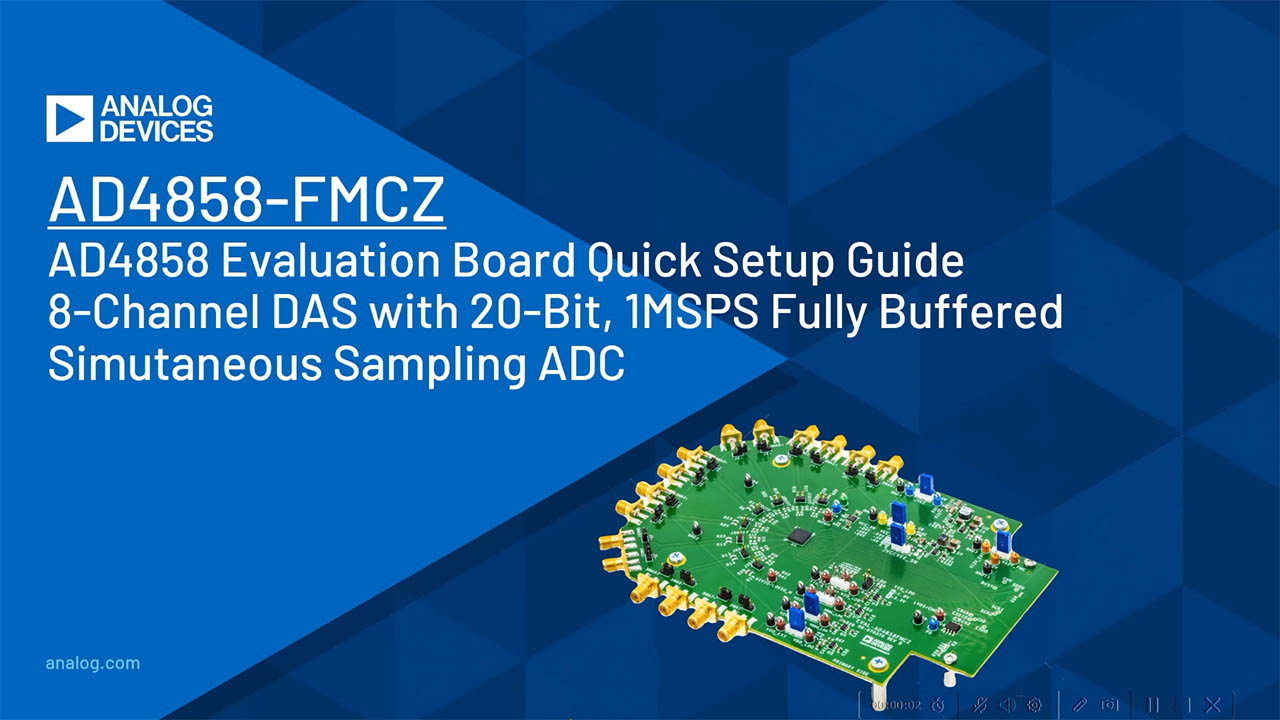

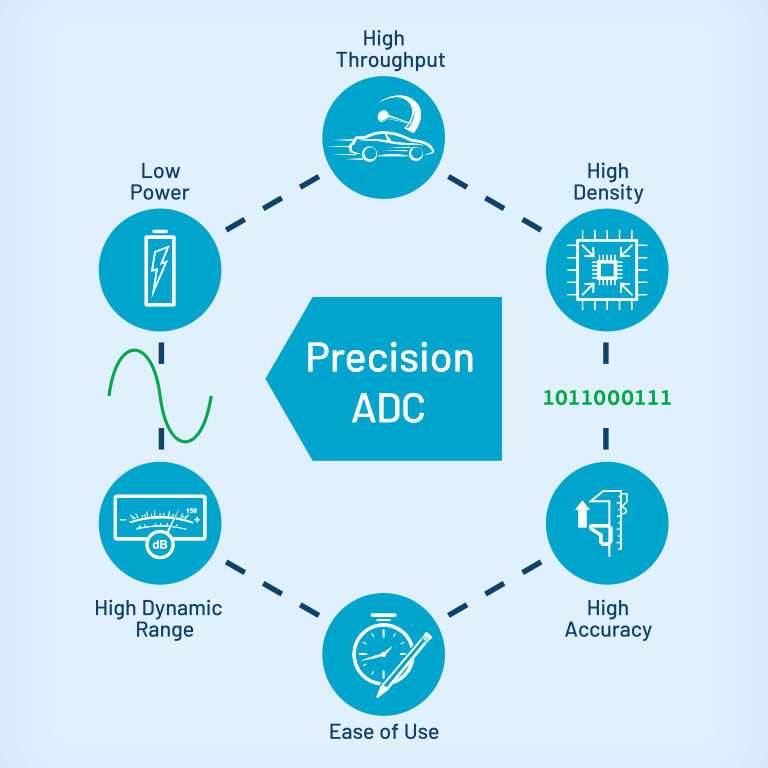

Analog Devices provides an unrivaled portfolio for precision analog-to-digital converters (ADCs). When you select an ADI precision ADC, you are selecting from the industry-leading portfolio in AC and DC performance, power, speed, and size, with products ranging from 8-bit to 32-bit resolution. Products are available in a range of architectures, including successive approximation (SAR) ADCs, Σ-Δ modulators, and isolated ADCs.

Analog Devices provides an unrivaled portfolio for precision analog-to-digital converters (ADCs). When you select an ADI precision ADC, you are selecting from the industry-leading portfolio in AC and DC performance, power, speed, and size, with products ranging from 8-bit to 32-bit resolution. Products are available in a range of architectures, including successive approximation (SAR) ADCs, Σ-Δ modulators, and isolated ADCs.

Precision ADC Selection Guide

{{modalTitle}}

{{modalDescription}}

{{dropdownTitle}}

- {{defaultSelectedText}} {{#each projectNames}}

- {{name}} {{/each}} {{#if newProjectText}}

-

{{newProjectText}}

{{/if}}

{{newProjectTitle}}

{{projectNameErrorText}}