Learn more about our new, streamlined product navigation and improved parametric search tables enabling faster product selection.

Magnetic Sensors

Magnetic Sensors

Magnetic sensors are devices that detect and measure magnetic fields around permanent magnets, current conductors, and electrical devices. As the world becomes increasingly electrified, demand for improved positional and current sensing has grown in turn. ADI MagIC+™ breakthrough multiturn sensing technology operates with zero-power, enabling more space-efficient solutions. ADI MagIC+™ magnetic sensors create more accurate solutions. Analog Devices’ magneto resistive sensing technologies, signal conditioning capabilities, and deep domain expertise are enabling new, innovative, and high performance sensing solutions for both position and current measurements across a broad range of applications and markets.

Magnetic sensors are devices that detect and measure magnetic fields around permanent magnets, current conductors, and electrical devices. As the world becomes increasingly electrified, demand for improved positional and current sensing has grown in turn. ADI MagIC+™ breakthrough multiturn sensing technology operates with zero-power, enabling more space-efficient solutions. ADI MagIC+™ magnetic sensors create more accurate solutions. Analog Devices’ magneto resistive sensing technologies, signal conditioning capabilities, and deep domain expertise are enabling new, innovative, and high performance sensing solutions for both position and current measurements across a broad range of applications and markets.

What if we had the power to be powerless?

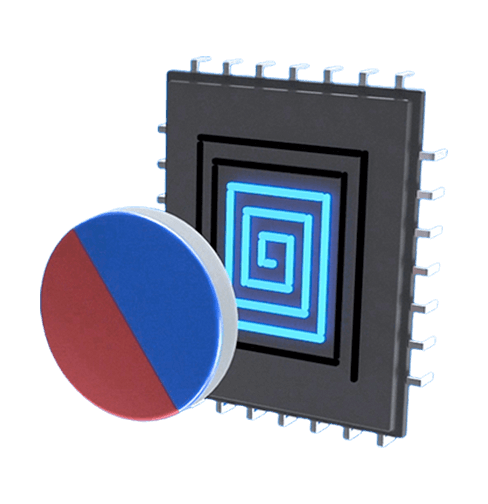

What if we had the power to be powerless? It’s not a contradiction, but it may as well be magic. The ADMT4000 true power-on multiturn sensor is blurring the lines of what we previously thought to be possible in the realm of magnetic field sensors, and more specifically for magnetic position sensing.

ADI MagIC+ Multiturn Sensor

The unique true power-on multiturn technology offered by the ADI MagIC+ group can track rotations of a magnet without power or contact. This removes the need for battery backups, linear transducers or gearing in applications where motor rotations need to be measured in the absence of power. System advantages include eliminating the need for homing and calibration which can reduce factory downtime and cost, or provide robust safety features with a single chip solution.

ADI MagIC+ Multiturn Sensor

The unique true power-on multiturn technology offered by the ADI MagIC+ group can track rotations of a magnet without power or contact. This removes the need for battery backups, linear transducers or gearing in applications where motor rotations need to be measured in the absence of power. System advantages include eliminating the need for homing and calibration which can reduce factory downtime and cost, or provide robust safety features with a single chip solution.

{{modalTitle}}

{{modalDescription}}

{{dropdownTitle}}

- {{defaultSelectedText}} {{#each projectNames}}

- {{name}} {{/each}} {{#if newProjectText}}

-

{{newProjectText}}

{{/if}}

{{newProjectTitle}}

{{projectNameErrorText}}