High Speed Low Power RS485 Transceivers with Integrated Switchable Termination

High Speed Low Power RS485 Transceivers with Integrated Switchable Termination

2006-06-01

Introduction

The LTC2859 and LTC2861 combine a logic-selectable integrated termination resistor with a rugged 20Mbps RS485/RS422 transceiver, providing a single die impedance-matched network solution in a tiny package. The low power driver features logic-selectable reduced-slew rate mode for operation below 250kbps with low EMI emissions. The 1/8-unit load receiver provides a failsafe output over the full RS485 common mode range for up to 256 nodes. Both receiver inputs and driver outputs feature robust ESD protection exceeding ±15kV. The half duplex LTC2859 is available in a 3mm × 3mm DFN, while the full duplex LTC2861 is available in both 4mm × 3mm DFN and 16-pin SSOP packages (see photo in Figure 1). Block diagrams for the LTC2859 and LTC2861 are shown in Figure 2.

Figure 1. Photograph of the LTC2861 SSOP, LTC2861 4mm × 3mm DFN, and LTC2959 3mm × 3mm DFN packages.

Figure 2. Block diagrams of the LTC2859 and LTC2861.

Switchable Termination

RS485 transceivers typically communicate over twisted-pair cables with characteristic impedance ranging from 100Ω to 120Ω. Proper termination of the cable is important to minimize reflections that can otherwise corrupt the data. The termination usually consists of discrete resistors that have the same resistance as the characteristic impedance of the cable, connected differentially across the cable at both ends. When using LTC2859/LTC2861 transceivers, however, no external resistors are necessary. These devices have an integrated 120Ω resistor on the receiver inputs that can be enabled logically to terminate the cable where needed. Figure 3 shows an example of a properly connected network using LTC2859 transceivers with integrated termination resistors enabled on the two end devices. Short connection to the intermediate stages along the cable should be maintained as these stubs will produce unwanted reflections.

Figure 3. A properly connected RS485 network using LTC2859 transceivers with selectable terminators.

To illustrate the importance of proper termination placement in an RS485 system, consider the network of Figure 3 where four LTC2859 transceivers are spaced equidistantly along three hundred feet of cat5e cable. Signals are driven from node 1 and received at node 4. The integrated termination resistors in the LTC2859 devices are switched in or out at various locations along the cable to illustrate the effect of termination placement on the received waveforms. No external resistors are used.

With proper resistive termination applied at the ends of the line (nodes 1 and 4) the received waveform has clean transitions, as shown in Figure 4a. If the end resistive termination is moved from node 4 to nodes 2 or 3, the waveforms of figures 4b and 4c result, respectively. It is clear that placement of termination resistors can have a large impact on the signal integrity.

(a).

(b).

(c).

Figure 4. Differential received signals at node 4 from network in Figure 3. properly terminated with termination at nodes 1 and 4 (a). Improperly terminated with termination at nodes 1 and 2 (b), and nodes 1 and 3 (c).

The termination resistor in the LTC2859 and LTC2861 is enabled by pulling the termination enable (TE) pin high. The resistor is disconnected when the termination enable is pulled to a logic low or the device is unpowered. Figures 5 (a), (b), and (c) show the resistance is maintained well over temperature, common mode voltage, and frequency.

(a).

(b).

(c).

Figure 5. LTC2859 termination resistance vs temperature (a), common mode voltage (b), and frequency (c).

The inclusion of a selectable 120Ω resistive termination on the LTC2859 and LTC2861 is a significant advantage over other RS485 transceivers. When modifications or additions are made to an RS485 network, the required termination changes can be made by logical control of the termination enable pin on the desired transceiver. This can be done through the use of a simple jumper or through higher level system control where manual intervention is prohibitive. A valuable benefit is that every node in the network is capable of providing termination without the use of external resistors, making network re-configuration more manageable.

Controller based configuration of a network with the aid of switchable termination can be extended beyond simple network additions and reductions to include fault protection as well. RS485 networks supporting bus lengths up to 4000 feet are at risk of breaks or disconnects in the cabling that can interrupt service. Figure 6 shows a dual-master controlled ring network making use of the LTC2859 logic-controlled termination to protect against such open cable faults.

Figure 6. Line break-tolerant RS485 topology.

When a break in a network is detected, through loss of response from one or more nodes, the master controller enters a low data rate mode. Even though the break imposes a severe impedance mismatch, low data rate communication is still possible up to the point of the break (as a rule of thumb, communication without termination is possible if the two-way cable propagation delay is less than 10% of the bit time). Each sequentially addressed transceiver on the network is polled by the masters to determine where the break has occurred. If the network is constructed of LTC2859 and LTC2861 transceivers with selectable termination, the masters can instruct the two nodes on either side of the line break to enable termination resistance. The two master controllers may now access each node of the bus at high data rates until physical repairs have been made. An XOR of the RO pin from each transceiver on the master controller can optionally reduce the I/O pin count to the micro controller.

Driver

The LTC2859/LTC2861 drivers can deliver RS485/RS422 signals up to 20Mbps. Figure 7 shows waveforms of the part operating at the maximum data rate. The LTC2859/LTC2861 also feature a reduced-slew rate mode (SLO mode), which is entered by setting the SLO pin to a logic low level.

Figure 7. Driver outputs toggling at the maximum data rate of 20Mbps.

SLO mode increases the driver transition time to reduce high frequency EMI emissions from equipment and cables. In this mode the driver data rate is limited to about 250kbps. Slew limiting also mitigates the adverse affects of improper line termination and long stubs.

Figure 8 shows single-ended and differential driver outputs in normal and SLO mode with corresponding frequency spectrums operating at 250kbps. SLO mode significantly reduces the high frequency harmonics.

Figure 8. Time and frequency domain waveforms of the LTC2859 driver output in normal and reduced-EMI SLO mode.

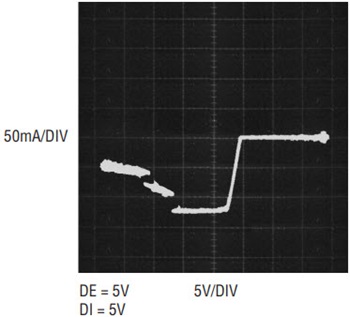

The LTC2859 and LTC2861 drivers feature current limiting that protects them from faults such as shorting the outputs to the power supply or ground. Short circuit current is limited to below the ±250mA RS485 standard, with typical clamp currents of ±150mA. If fault voltages are greater than approximately ±10V, currents are reduced further to limit power dissipation. The LTC2859 and LTC2861 also feature thermal shutdown protection, disabling the part if a fault condition causes it to overheat. Figure 9 shows the driver output I-V characteristic when driven by a curve tracer. Overcurrent protection engages on the positive and negative sweeps limiting the driver output current.

(a).

(b).

Figure 9. Curve traced I-V characteristic of the LTC2861 driver output showing current limiting. (a) Pin is driven low by the LTC2861 driver. (b) Pin is driven high by the LTC2861 driver.

Receiver

The LTC2859 features a low power receiver using just 540µA of current (typical). The LTC2859/LTC2861 failsafe feature guarantees the receiver output to be a logic HIGH state when the inputs are shorted, open, or terminated, but not driven for more than about 3µs. The delay prevents signal zero crossings from being interpreted as a shorted input and causing RO to go inadvertently high. This failsafe feature is guaranteed to work for inputs spanning the entire common mode range of –7V to +12V.

The receiver output is internally driven high (to VCC) or low (to ground) with no external pull-up needed. The RO pin of the disabled receiver becomes high impedance with leakage of less than ±1µA for voltages within the supply range.

Conclusion

Improperly terminated RS485 cabling can severely distort signals leading to losses in data integrity. Correcting network termination without logic-selectable termination often requires physical inspection of expansive networks. The inclusion of selectable termination resistance on the rugged LTC2859 and LTC2861 provide complete solutions to RS485 networking with next-generation remote network tuning capability.

关于作者

Steven Tanghe is an Engineering Design Manager at Analog Devices based in Burlington, Vermont. He has a Ph.D. from the University of Michigan in electrical engineering and MEMs. Steven joined Analog Devices (Linear Techno...