摘要

We discuss the challenge of implementing a small and efficient power management system for battery-operated devices. A tailored approach to integration is introduced which exploits the space and power efficiency of the SIMO architecture by selectively integrating, into a single PMIC, the necessary building blocks to support the given level of complexity. We apply the SIMO technology to three different portable applications. For each case, the SIMO PMIC is customized to the application and yields the best possible result for minimum PCB size and long battery life.

Introduction

The wireless IoT industry is producing copious quantities of battery-operated devices (Figure 1). While the basic battery management system is well understood, the specific configuration varies with battery technology (primary, secondary, chemistry, or form factor) and load constraints (voltage, current, or noise sensitivity). With all these variables it seems that we should be resigned to a discrete approach to the system implementation: one ad-hoc IC for each building block, such as in the typical system shown in Figure 2. However, this approach clashes with another important requirement of these portable and lightweight devices, specifically small size. This design solution reviews three very different portable applications and shows that even when multiple building blocks are required, a tailored integration approach to power management, built around the SIMO core converter, can easily solve this dilemma.

Figure 1. IoT devices wirelessly connect.

An Integrated Approach to Power

For portable power management, the SIMO architecture addresses the inefficiencies in power and size faced by conventional solutions that use multiple switching regulators with associated inductors or linear regulators.

In a previous article, we reviewed the fundamentals of single-inductor-multiple-output (SIMO) switching regulator architecture and the advantages it provides when applied to a wireless hearable system. In that article, we showed conclusively that a SIMO solution delivers significantly more power in a smaller space, compared to other approaches, enabling longer battery life and smaller form factors. That comparative analysis will not be repeated here.

While a SIMO converter IC is a big step forward in integration, additional functions may be needed to address more complex systems. This raises the question: is it possible to integrate a core SIMO converter together with varying levels of ancillary functions, thus preserving the ability to confine the entire power management system within a single IC?

In the following case studies, we tackle this question while applying the SIMO technology to three very different portable applications.

Typical Rechargeable Battery System

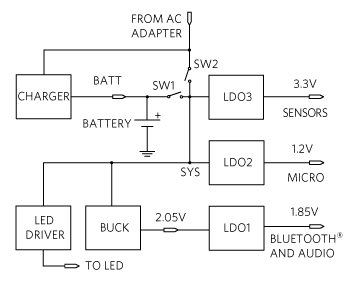

Figure 2 shows a typical rechargeable battery system implementation. The AC adapter charges the battery via the CHARGER when present, while powering the loads via SW2. In the absence of the adapter, the battery takes over, powering the system via SW1. Space and cost constraints typically impose the use of multiple LDOs, with a single switching regulator (BUCK) that delivers power to the heaviest load. One or more LED drivers may be needed for IR remote control or RGB signaling.

Figure 2. Typical hearable power flow diagram.

In the following sections, we will customize this system to three different applications.

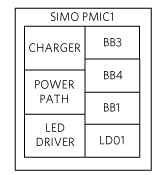

SIMO PMIC Rechargeable Battery System

In Figure 3, a fully integrated SIMO PMIC approach to a rechargeable battery system is shown. It efficiently services two of the loads with two buck-boost switching regulators (BB3, BB2), in place of LDOs (LDO3, LDO2 in Figure 2). The third buck-boost regulator (BB1) covers for the BUCK in Figure 2. LDO1 is integrated for noise-sensitive loads. The LED driver is also integrated. Finally, the charger and switches of Figure 2 are integrated in the charger and power path blocks of Figure 3.

The power efficiency and size advantage of using a SIMO switching regulator vs. a linear regulator solution is obvious. The use of buck-boost switching converters, which regulate even when the input voltage falls below the output voltage, squeezes the last drop of energy out of the battery.

Figure 3. Rechargeable battery system with SIMO PMIC1.

Case Study: Rechargeable Remote Control

For these systems, the use of a SIMO PMIC such as the MAX77278 is ideal. The PMIC incorporates a linear charger (375mA), a triple-output SIMO buck-boost converter (300mA total), an LED driver (425mA), and an LDO (50mA). A bidirectional I2C interface allows for configuring and checking the status of the device.

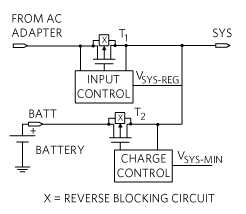

Figure 4 shows the implementation of the charger and switches in the PMIC. A Smart Power Path circuitry distributes power between the system (SYS) and the battery. The input control loop, in the presence of power from the AC adapter, regulates the system voltage (SYS) to 4.5V (VSYS-REG). In this phase, the charger (transistor T2 and its associated control) is powered from the SYS pin and charges the battery. In the absence of input power from the AC adapter, the battery powers the IC blocks and the system loads via T2. This configuration is more silicon-efficient than the one in Figure 2 because T2 serves double-duty as both a pass transistor for the linear charger (AC adapter present) and as a switch (no AC adapter).

Figure 4. Smart power path.

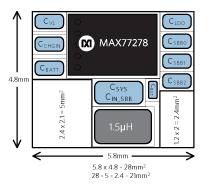

Thanks to its SIMO switching regulators and its efficiently biased LDO, the small PMIC (packaged in a 2.15mm x 3.15mm x 0.5mm WLP) delivers power with minimum losses in a PCB space of 21mm2 that is less than half that of a typical implementation. The solution layout in Figure 5 accounts for all the passive and active components.

Figure 5. SIMO PMIC1 solution (21mm2).

In addition, the PMIC draws only 300nA in standby mode, at least twice better than other available solutions. This ability and its efficiency gain save valuable battery life and helps reduce the system size by using the smallest battery possible while prolonging the use time between each charge.

SIMO PMIC Non-Rechargeable Battery System

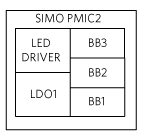

In Figure 6, a simpler PMIC2 captures all the necessary functions for a non-rechargeable battery.

Figure 6. Non-rechargeable battery system with SIMO PMIC2.

Case Study: Non-Rechargeable Activity Monitors

Activity monitors and insulin pens employ LEDs to perform a variety of functions and are typically powered by AA and AAA cylindrical cells. Smart insulin dosage devices help load the insulin pen with the right amount of insulin and signal the end of loading by turning on an LED. Activity monitors, like physical activity, seizure, and sleep monitors, are worn on the wrist like watches. The light from LEDs, tuned to various frequencies, penetrates the skin. Photodetectors pick up the reflected signal modulated by blood flow and body tissue and provide information about the patient’s physical activity like heart rate, motion, and ventilation.

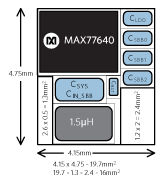

For these devices, a SIMO PMIC such as the MAX77640 is ideal. The PMIC in Figure 7 incorporates a triple-output SIMO buck-boost converter (300mA total), three LED drivers (3.2mA each), and an LDO (150mA). A bidirectional I2C interface allows for configuring and checking the status of the device.

This PMIC (in a 2.15mm x 2.75mm x 0.7mm WLP) delivers power while occupying minimal PCB space (16mm2). The solution layout in Figure 7 accounts for all the passive and active components.

Figure 7. SIMO PMIC2 solution (16mm2).

In addition, the PMIC draws only 300nA in standby mode and 5.6µA in active mode.

SIMO Small Non-Rechargeable Battery System

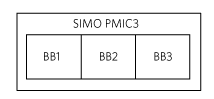

In Figure 8, a stripped down PMIC3 integrates three buck-boost regulators for the simplest and smallest non-rechargeable implementations.

Figure 8. Non-rechargeable battery system with SIMO PMIC3.

Case Study: Coin-Cell Powered Sensors

Humidity and other IoT sensors require small, robust power management systems for the smallest size and longest possible operation and shelf life.

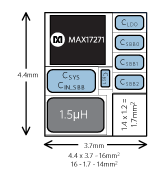

A SIMO PMIC such as the MAX17271 with low quiescent current is ideal for these applications. The PMIC incorporates a triple-output SIMO buck-boost converter (300mA total). A bidirectional I2C interface allows for configuring and checking the status of the device.

This PMIC (housed in a 1.77mm x 1.77mm x 0.5mm WLP) delivers power with minimum PCB space occupancy (14mm2). The solution layout in Figure 9 accounts for all the passive and active components.

Figure 9. SIMO PMIC3 solution (14mm2).

In addition, the PMIC draws only 330nA in standby mode and 1.5µA in active mode.

Conclusion

We discussed the challenge of implementing a small and efficient power management system for battery-operated devices. A tailored approach to integration was introduced which exploits the space and power efficiency of the SIMO architecture by selectively integrating, into a single PMIC, the necessary building blocks to support the given level of complexity.

We applied the SIMO technology to three different portable applications. For each case, the SIMO PMIC was customized to the application and yielded the best possible result for minimum PCB size and long battery life.

The MAX77278 PMIC, which integrates a linear charger, smart power path, a triple-output SIMO buck-boost converter, an LED driver, and an LDO, was shown to be an ideal solution for rechargeable applications.

The MAX77640, which integrates a triple-output SIMO buckboost converter, three LED drivers, and an LDO, provided a tailored solution for non-rechargeable applications.

The MAX17271 PMIC, which integrates a triple-output SIMO buck-boost converter, was tailored to small, stripped down applications.

This tailored approach to power management makes the most of space and power efficiency advantages of the SIMO architecture to deliver the smallest, most efficient power management solution for portable applications.