概览

设计资源

描述

工业4.0标志着第四次工业革命,其特点是分布式、智能化控制系统。工业4.0摆脱了过去体积笨重、集中式的可编程逻辑控制器,允许工厂高度可配置、高度模块化,支持的传感器输入数量大幅增加,输出较之前更高。超小尺寸PLC,或称之为微型PLC,是工业4.0工厂的核心,以极小尺寸封装提供高性能,功耗极低。MAXREFDES61是Analog的微型PLC、四通道模拟输入卡。

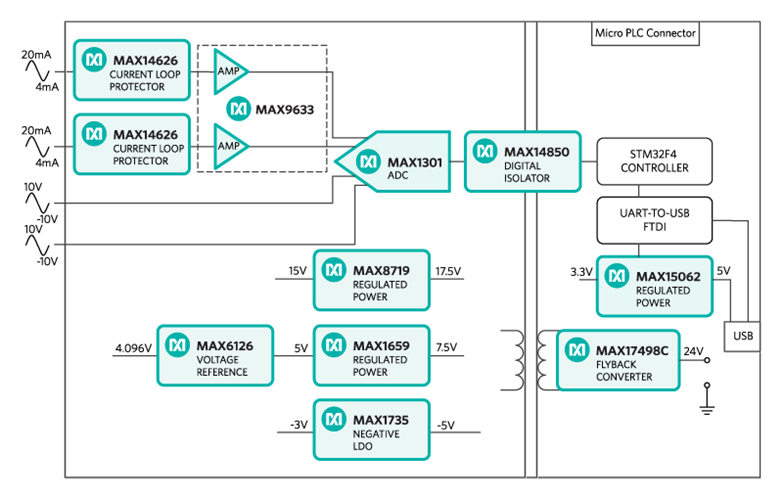

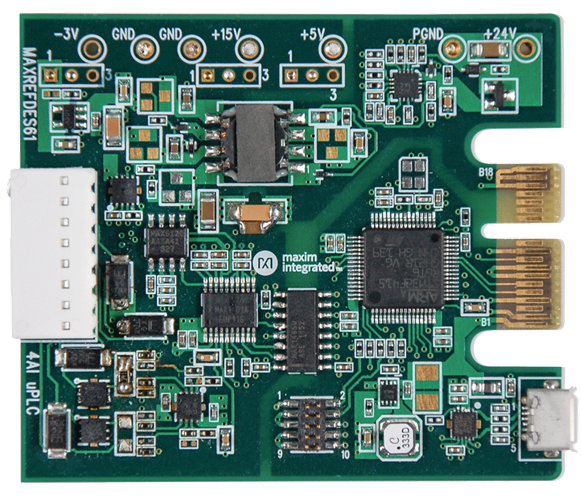

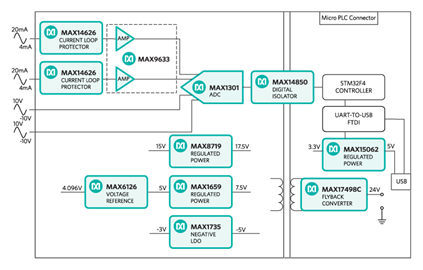

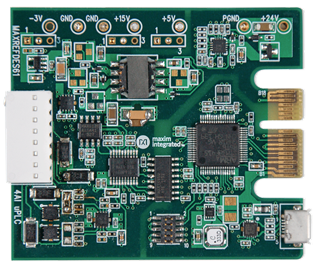

MAXREFDES61具有16位高精度、四通道模拟输入,电源和数据隔离。其中两路输入通道支持-10V至+10V电压信号,另两路输入支持4mA至20mA电流信号。MAXREFDES61设计集成双通道、低噪声、低失真缓冲器(MAX9633);16位、4通道、多量程输入ADC (MAX1301);两片高电压、4–20mA电流保护器(MAX14626),用于电流输入通道;超高精度4.096V电压基准(MAX6126);600VRMS数据隔离(MAX14850);STM32F4微控制器;FTDI USB-UART桥;高效DC-DC转换器(MAX15062);以及隔离/稳压+15V、+5V和-3V电源(MAX17498C/MAX8719/MAX1659/MAX1735)。整个系统的功耗通常小于500mW,适合用于信用卡大小的空间。用于工业、微型PLC领域时,MAXREFDES61可用于任何要求高精度模/数转换的应用。图1所示为系统方框图。

图1. MAXREFDES61#参考设计方框图。

优势和特点

- 高精度

- -10至+10V ±20%电压输入

- 4至20mA +20%电流输入

- 隔离电源和数据

- 微型PLC规格

- 器件驱动器

- C语言源代码示例

- 测试数据

详情

The power requirement is shown in Table 1.

| Power Type | Input Voltage (V) | Input Current (mA, typ) |

|---|---|---|

| On-board isolated power | 24 | 20 |

Note: STM32 and FTDI are powered by USB separately.

The MAX1301 (U1) is a highly integrated, 16-bit, 4-channel ADC with a selectable multirange input feature. The ADC also has integrated analog input buffers with a 17kΩ input. The ADC’s reference input is driven by an ultra-high-precision 4.096V voltage reference, the MAX6126 (U3), with 0.02% initial accuracy and a 3ppm/°C maximum temperature coefficient (tempco). Channel 0 and channel 1 are used for the 4–20mA current loop input, and channel 2 and channel 3 are used for the ±10V voltage input.

The current input circuit consists of two MAX14626 (U4, U5) high-voltage current protectors and a MAX9633 (U2) dual low-noise low-distortion op amp. The MAX14626 protects the current input circuit from high input current. The MAX9633 and the 499Ω sensing resistors convert the 4–20mA signals to 0V to 10V signals to match the input range of channel 0 and channel 1 of the ADC.

MAXREFDES61# uses the ultra-efficient MAX17498C (U13) to generate the isolated +17.5V, +7.5V, and -5V rails from a 24V supply. The MAX8719 (U10), MAX1659 (U11), and MAX1735 (U12) provide post-regulated +15V, +5V, and -3V rails. The MAX14850 (U6) digital data isolators provide data isolation. The combined power and data isolation achieved is 600VRMS.

The MAX15062 (U9) step-down DC-DC converter converts the +5V supply from the USB to +3.3V and powers the STM32 (U7) microcontroller and FTDI (U8) USB-UART bridge.

The MAXREFDES61# uses the on-board STM32F4 microcontroller to communicate with the ADC and save the samples in the on-chip SRAM. User reads the sampled data through a terminal program, allowing analysis on any 3rd party software. The simple process flow is shown in Figure 2. The firmware is written in C using the Keil µVision5 tool.

Figure 2. The MAXREFDES61# firmware flowchart.

The firmware accepts commands, writes status, and is capable of downloading blocks of sampled data to a standard terminal program via a virtual COM port. The complete source code is provided to speed up customer development. Code documentation can be found in the corresponding firmware platform files.

Required equipment:

- Windows® PC with a USB port

- MAXREFDES61# board

- 24V power supply

- 5V DC voltage source

The reference design is fully assembled and tested. Follow the steps below to verify board operation:

- Turn off or keep off the 24V power supply.

- The MAXREFDES61# utilizes the FTDI USB-UART bridge IC. If Windows cannot automatically install the driver for the FTDI USB-UART bridge IC, the driver is available for download from www.ftdichip.com/Drivers/VCP.htm.

- Connect the negative terminal of the 24V power supply to the PGND connector on the MAXREFDES61# board. Connect the positive terminal of the 24V power supply to the +24V connector on the MAXREFDES61# board.

- Turn on the 24V power supply.

- Connect the USB cable from the PC to the MAXREFDES61# board.

- Open Hyperterminal or similar terminal program on the PC. Find the appropriate COM port, usually a higher number port, such as COM4, or COM6, and configure the connection for 921600, n, 8, 1, none (flow control).

- The MAXREFDES61# software will display a menu (Figure 3)

- For immediate signal testing, connect the negative terminal of the 5V DC voltage source to the GND terminal of the J3 terminal block. Connect the positive terminal of the 5V voltage source to the V1 terminal of the J3 terminal block. The inputs are labeled on the bottom side of the board.

- Press 0 in the terminal program to start the continuous sampling.

- Press 2 to select channel 2.

- Verify the ADC output code is around 46100.

Figure 3. Terminal program main menu.

Equipment used:

- Audio Precision® SYS-2722 signal source or equivalent

- Voltage calibrator DVC-8500

- Windows PC, a USB port

- MAXREFDES61# board

- +24V power supply

Special care must be taken and the proper equipment must be used when testing the MAXREFDES61# design. The key to testing any high-accuracy design is to use sources and measurement equipment that are of higher accuracy than the design under test. A low-distortion signal source is absolutely required to duplicate the presented results. The input signal was generated using the Audio Precision SYS-2722. The FFTs were created using the FFT control in SignalLab from Mitov Software. Figure 4, Figure 5, Figure 6, Figure 7 show the FFT and histogram test results.

Figure 4. AC FFT, on channel V2, using on-board isolated power, a -12V to +12V 5kHz sine wave voltage input signal, 17kΩ input impedance, a 50ksps sample rate, at room temperature, and a Blackman-Harris window.

Figure 5. AC FFT, on channel 3 (AIN3), using on-board isolated power, a -2.5V to +2.5V 5kHz sine wave voltage input signal, 17kΩ input impedance, a 50ksps sample rate, at room temperature, and a Blackman-Harris window.

Figure 6. DC histogram, on channel I2, using on-board isolated power; a 0V input signal; a 50ksps sample rate; 65,536 samples; at room temperature; a code spread of 7 LSBs with 98.7% of the codes falling within the three center LSBs; and a standard deviation of 0.677.

Figure 7. DC histogram, on channel I2, using on-board isolated power; a 10mA input signal; a 50ksps sample rate; 65,536 samples; at room temperature; a code spread of 8 LSBs with 96.5% of the codes falling within the four center LSBs; and a standard deviation of 0.968.

Reference

1 The new generation of manufacturing production is called Industry 4.0 in Germany and Smart Manufacturing System elsewhere. See, Securing the future of German manufacturing industry, Recommendations for implementing the strategic initiative INDUSTRIE 4.0, Final report of the Industrie 4.0 Working Group, Industry 4.0 Working Group, Acatech National Academy of Science and Engineering, April 2013, https://www.acatech.de/wp-content/uploads/2018/03/Final_report__Industrie_4.0_accessible.pdf. Henceforth cited as Industrie 4.0. Although the Industrie 4.0 report is focused on Germany, the implications of the German research and findings are recognized for industry in other countries. See also Ferber, Stefan, “Industry 4.0 – Germany takes the first steps toward the next industrial revolution,” Bosch Software Group, Blogging the Internet of Things, October 16, 2013, https://blog.bosch-si.com/industry-4-0-germany-takes-first-steps-toward-the-next-industrial-revolution/.

There are many sources for Smart Manufacturing Leadership. An interesting summary report of issues and topics can be found at the Smart Manufacturing Leadership Coalition Committee Working Meeting, Minneapolis, MN, U.S., Thursday, October 20, 2011, https://smart-process-manufacturing.ucla.edu/workshops/2011-workshop/presentations/SMLC%2010-20-11v3.pdf. Also see, Implementing 21st Century Smart Manufacturing, Workshop Summary Report, Smart Manufacturing Leadership Coalition, June 24, 2011, https://smart-process-manufacturing.ucla.edu/about/news/Smart%20Manufacturing%206_24_11.pdf. A simple web search on the topic will reveal considerably more references.

Audio Precision is a registered trademark of Audio Precision, Inc.

Windows is a registered trademark and registered service mark of Microsoft Corporation.

文件和资源

-

MAXREFDES61 Design Files2021/2/18ZIP10 M

支持与培训

搜索我们的知识库,获取技术问题答案。我们专门的应用工程师团队也会随时为您解答技术问题。