Thought Leadership

Accelerating the Transition to Industry 4.0 with Industrial Ethernet Connectivity

The fourth industrial revolution is changing the way we create products thanks to the digitization of our manufacturing and process facilities. We have seen the benefits of automation over many decades and are now fueling these systems with enhanced data, machine learning, and artificial intelligence. Today, autonomous systems are becoming more interconnected and are communicating, analyzing, and interpreting data to enable auxiliary intelligent decisions and actions in other areas of the factory. Smart factory initiatives are creating new business value by increasing output, asset utilization, and overall productivity. They are leveraging new data streams to enable flexibility and refine quality, all while reducing energy consumption and residual waste. Increasingly, edge-to-cloud connected intelligent systems are enabling manufacturing environments to become more efficient by adapting in support of mass customization.

The benefits of Industry 4.0 are predicated on leveraging increased data for better decision making. Timely access to the data and the delivery of that data throughout the automation system hinges on the connectivity network. Networking technology must evolve to handle the increased data volume, as must the manufacturers’ processes and methodologies. An intelligent, interconnected automation environment requires digitally connected systems, machines, robots, etc., creating and sharing information. The means by which these machines communicate and the factory communications network they use is at the heart of the enterprise and the enabler for our Industry 4.0 ambition.

The need for seamless connectivity from every sensor and actuator across the factory floor, even those in remote locations, is not possible with existing infrastructure. If the future is data and its combination at an enterprise level to provide actionable insights, the challenge becomes finding a way to enable these unprecedented volumes of data to flow without crippling the communication network designed to transmit it. This raises the question of how to architect, build, and deploy an industrial communications network that will meet the needs of today’s automation environments and tomorrow’s virtual factory floors.

Why Industrial Ethernet?

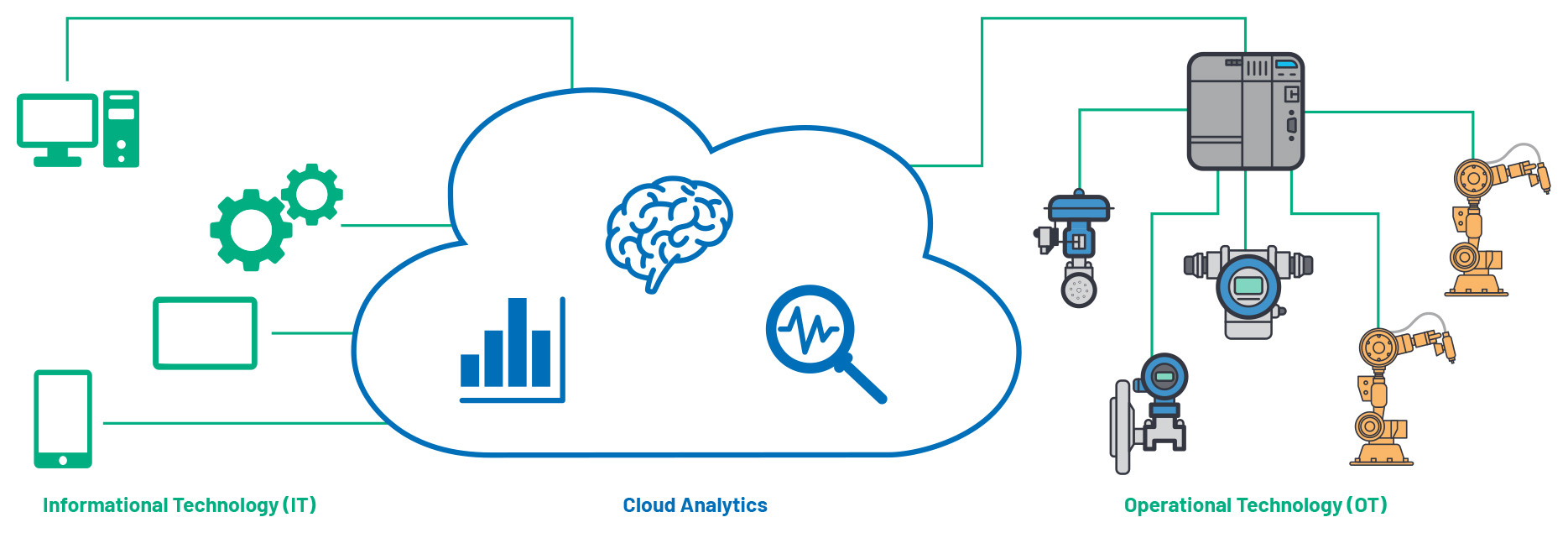

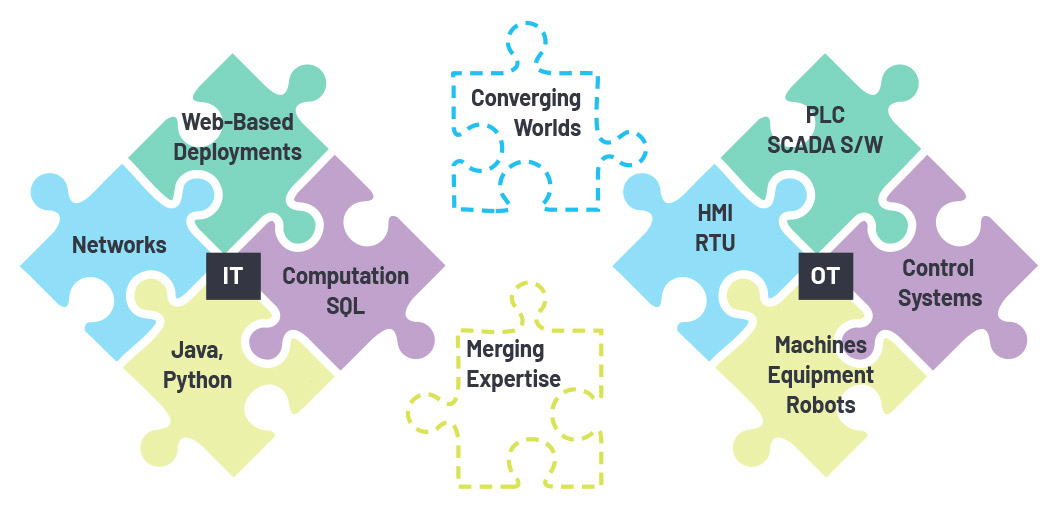

With connectivity being central to the Industry 4.0 vision, three things must become a reality to deliver a truly connected enterprise. Firstly, the higher level information technology (IT) or enterprise infrastructure must converge with the plant floor control network. Secondly, the various networks or manufacturing cells currently in existence on factory floors must all coexist and interoperate. Thirdly, we need seamless, secure connectivity across our process environments, from the edge of the process to the enterprise cloud.

To address these challenges, we need to adopt a foundational networking technology that can support the goal of interoperability, expandability, and reach. Ethernet emerges as the ideal solution, being a well understood technology with extensive deployments. Offering high bandwidth and enabling fast commissioning, it is also deployed extensively in the IT infrastructure of all manufacturing environments.

However, standard Ethernet is not a viable solution for industrial control infrastructure given the need for real-time operation. Operational technology (OT) control networks need to ensure that the message being communicated is delivered to where it is needed on time. This ensures the correct operation of the task or process at hand. The TCP/IP protocol for routing traffic does not inherently guarantee this level of deterministic performance. In the same way that standard Ethernet enables file sharing or access to network devices such as printers, Industrial Ethernet allows controllers to access data and send instruction commands from PLCs to sensors, actuators, and robots dispersed across the factory floor. The key difference is the impact of delayed or undelivered messages. In non-real-time applications, if the webpage is slow to update, the impact is minimal, while in a manufacturing environment, the impact can be high, from wasted materials to accidental human harm. For control systems to work, the message must get to its destination reliably, on time, every time.

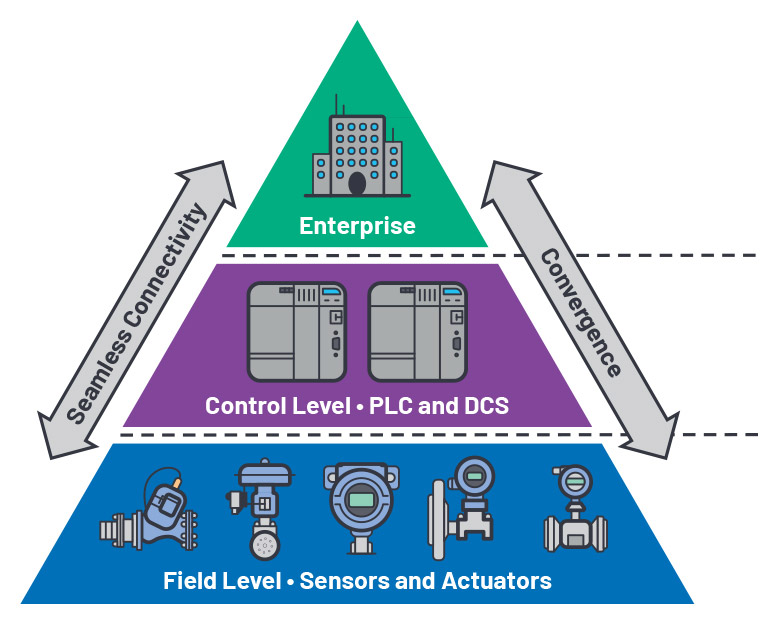

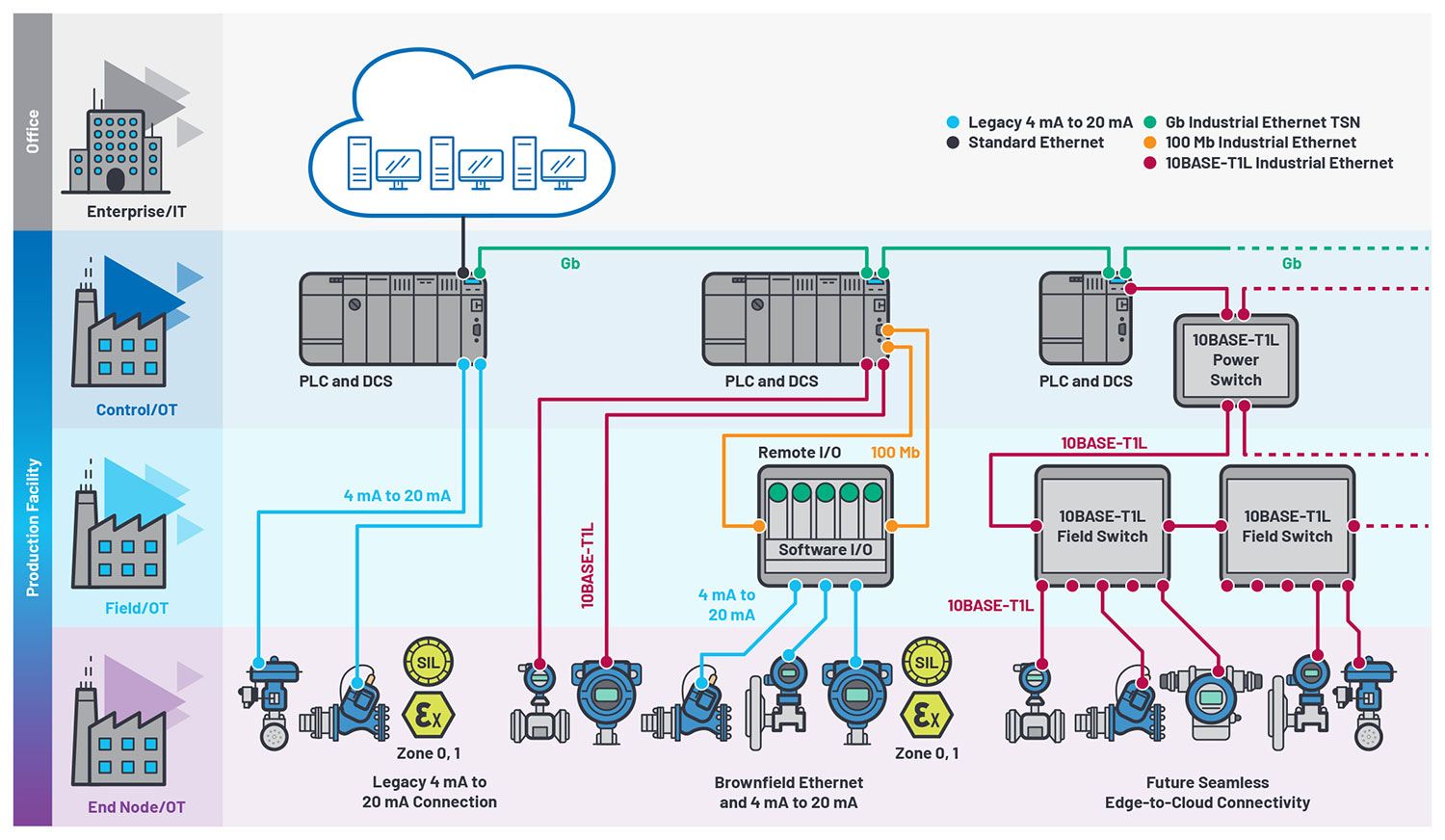

As a result, Industrial Ethernet has emerged as the technology of choice at the control level of the operating technology. The goal is to enable seamless connectivity not just between the IT and high level OT networks, but right down through the various layers of the factory’s OT network to the end node sensor, as illustrated in Figure 3. Today, complex, power hungry gateways are required to enable connectivity from the lower levels of the OT network, to Ethernet at higher layers, where a converged IT/OT network is required. Having a plant-wide, interoperable automation network based on Ethernet would eliminate the need for these gateways, thereby simplifying the network itself. In fact, protocol gateways used to translate and enable connection to the upper layer of the OT network are not directly addressable and have resulted in isolation in the network. This data isolation limits the ability to share information across the factory floor. This is contrary to the vision of Industry 4.0 outlined earlier, where manufacturers want to collect telemetry data from the OT side to drive analytics and business processes on the IT side.

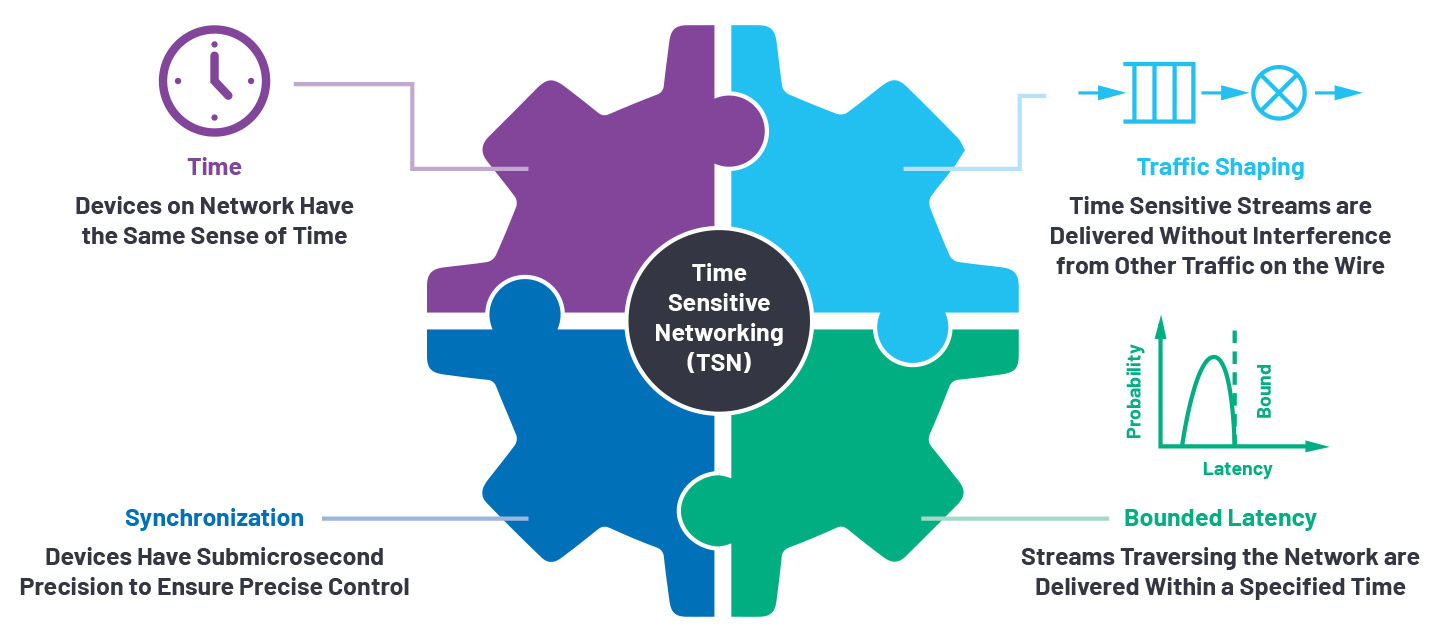

With determinism in packet delivery and timing guarantees a mandatory requirement for control applications, many vendors undertook efforts to provide real-time protocols suitable for OT networks. This resulted in solutions that, while deterministic, were specific to each vendors’ protocol. This, in turn, lead to a host of incompatible solutions, with different types of communication protocols running in different manufacturing cells, each of which could not interoperate. This perpetuates the data isolation, or data islands. A solution is needed that enables different manufacturing cells running different protocols to coexist and share the network in a way that will guarantee their control traffic is not compromised. The answer lies in time sensitive networking (TSN), a vendor-neutral, real-time Ethernet standard based on the IEEE 802.1 specification. As the name implies, TSN is focused on time. This standard transforms standard Ethernet communication into one that provides timing guarantees for mission critical applications. It is designed to ensure information can move from one point to another in a fixed and predictable amount of time. In this way, TSN provides guarantees of timely delivery. For the communication to be predictable, devices on the network must have a shared concept of time. The standard defines a means to transmit certain TSN Ethernet frames on a schedule, while allowing non-TSN frames to be transmitted on a best effort basis (see Figure 4). In this way, TSN enables the coexistence of real-time and non-real-time traffic on the same network. Because all devices share the same time, important data can be transmitted with low latency and jitter at up to gigabit speeds.

The goal is a converged network, where protocols can each share the wire in a deterministic and reliable method. TSN is the toolbox of standards that provides the required determinism. It represents the transition to a reliable and standardized connectivity architecture, removing the isolation of data through proprietary fieldbuses. This convergence of networks will in turn drive the generation of more data through the increased scalability of the network itself, across bandwidths ranging from 10 Mbps to 1 Gbps and beyond.

The likely scenario is that TSN will be adopted throughout new installations, but incrementally in cells or segments within existing facilities. For the manufacturers of field devices, this means that the classic Industrial Ethernet solutions, as well as TSN, will have to be supported for the foreseeable future.

Extending to the Process Edge

Our final and perhaps most impactful change is the ability to enable seamless connectivity from the edge node to the enterprise cloud in process control applications, as shown in Figure 5. To date, connectivity to the edge has been limited by the existing 4 mA to 20 mA or fieldbus technologies available. These are hardwired point-to-point connections in many implementations, restricting the flexibility of the network to evolve and grow overtime. These non-Ethernet-based communications to the field encounter several challenges. Firstly, very limited bandwidth (for example, 1.2 kbps for HART® on 4 mA to 20 mA) that limits the amount and speed of the information flow. Secondly, limited power delivery to the instrument itself, which restricts the functionality of the instrument. Finally, the gateways that exist at the control and IT level are an unsustainable overhead. There is also the challenge of operating in an intrinsically safe environment of Zone 0 and trying to leverage the existing cabling network to support faster, cheaper commissioning.

These challenges have necessitated the development of the IEEE 802.3cg-2019™ standard for 10BASE-T1L, full duplex communication. This standard has recently been approved and specifies 10 Mbps full duplex communication with power over a single twisted-pair cable up to 1 km in length. Data will now start out life in the sensor as an Ethernet packet and traverses the OT and IT infrastructure as an Ethernet packet. There is no need for translation (which creates delays, consumes power, and creates a cost overhead). Existing network architectures will change, as shown in Figure 5, with remote I/O units transitioning to Ethernet field switches. An Ethernet instruction can now be communicated from the controller through 10BASE-T1L multiport field switches, to and from the field instruments. Insight generated at the field node can now be communicated via Ethernet packets (with higher bandwidth) through the field switch network to the PLC/DCS controller and ultimately to the cloud.

There are several distinct advantages that will help drive the transition from legacy fieldbus to Industrial Ethernet. Firstly, the potential to reuse the existing cabling infrastructure (up to 1 km in length) simplifies deployment and reduces retrofitting costs. Secondly, the amount of available power being delivered over the cable to the instrument itself, which was previously confined to 36 mW (best case, with 4 mA to 20 mA deployments), is now up to 60 W (cable dependent) or 500 mW in Zone 0, intrinsically safe applications. The extra available power will now enable higher functionality instruments with end node intelligence. This, married with the 10 Mbit uplink speed now available, will provide the anticipated increased insights to capitalize on the efficiencies promised by Industry 4.0.

What’s Available Today?

New robust, low latency, low power physical layer technology combined with scalable switch fabrics are required to support the evolution of our automation networks. Being at the forefront of Industrial Ethernet, ADI has leveraged its rich automation domain expertise and advanced technologies to develop a deep portfolio of solutions, designed to ensure time critical data, is reliably delivered throughout industrial applications, assuring seamless connectivity and operational efficiency. The ADI Chronous™ portfolio of scalable Ethernet solutions includes physical layer devices (PHYs), embedded switches, and complete platform solutions with multiprotocol software. These are fully tested and verified for fast time to market.

Notable solutions within this portfolio include:

- The ADIN1200, industry-leading 10 Mbps/100 Mbps Industrial Ethernet PHY with enhanced features set and verified robustness.

- The ADIN1300, industry’s lowest latency, lowest power gigabit PHY, offering verified robustness for harsh environments.

- The fido5200/fido5100, a real-time, embedded, two-port multiprotocol switch supporting many of the available TSN features. New TSN features can be implemented via firmware updates as they become available. Multiprotocol software updates are also supported and available through the ADI Chronous developer portal.

For verified robust, scalable, and complete Ethernet solutions that simplify system design and reduce development time, the ADI Chronous solutions are designed specifically with our customers in mind. It’s scalable Ethernet, timed to perfection.

To support the transition and provide a network bridge to legacy field devices, ADI has developed a new technology called software configurable I/O (AD74413R). This will enable the development of field configurable remote I/O units that bridge the gap between legacy instruments and the higher level Ethernet network.

What About Security?

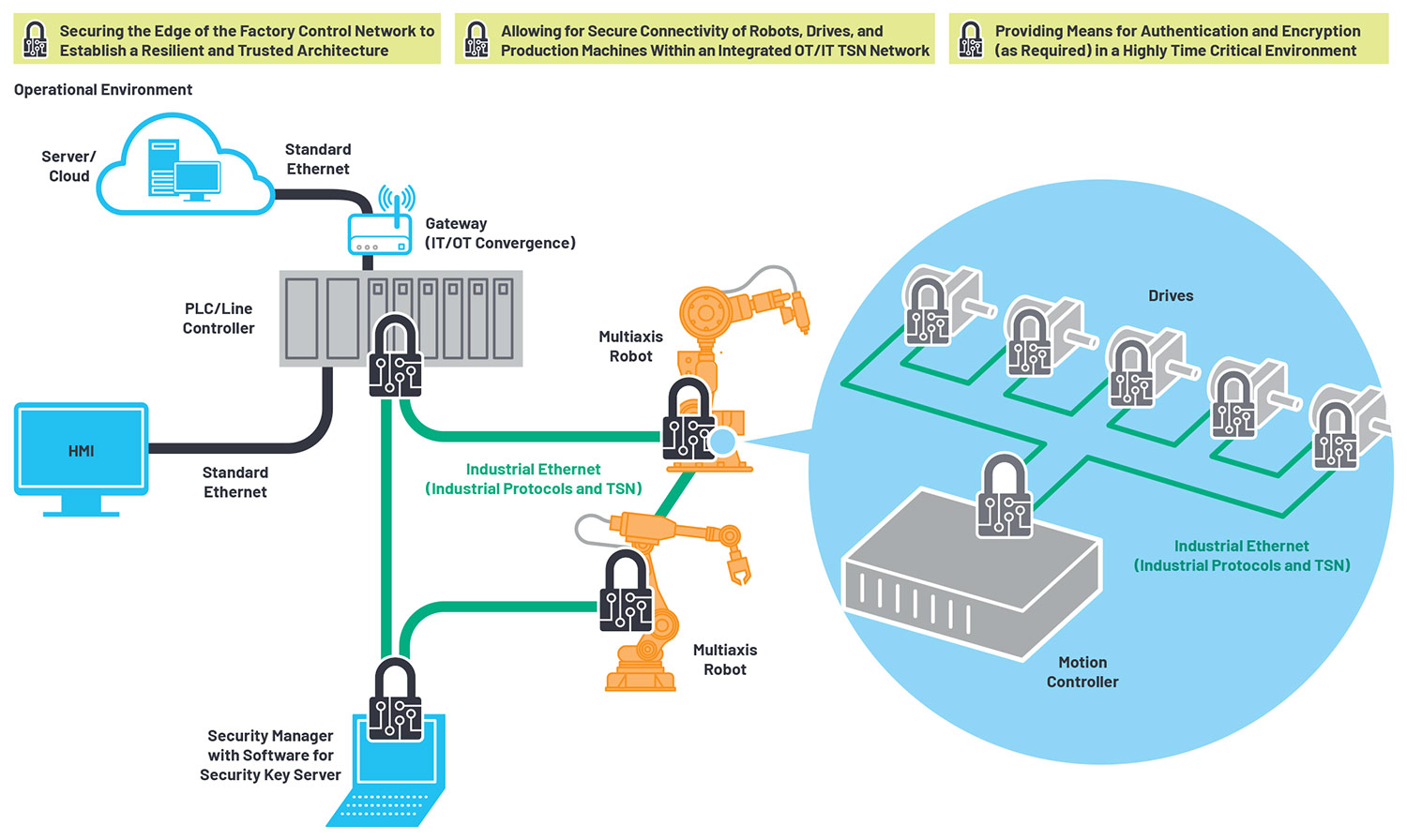

Ethernet has vulnerabilities, and security is one of the most critical concerns impacting the adoption rate of Industry 4.0. By creating an open flow of information throughout the enterprise between OT and IT and from the edge to the cloud, the potential impact of a security breach can be devastating.

Security should be a fundamental risk management consideration in planning your Industry 4.0 strategy. Building security into today’s increasingly complex networks is far from easy; it requires a multilayer approach to make it inherent throughout the system—within edge devices, controllers, gateways, and further up the stack. ADI’s Chronous portfolio offers security at each node point within the system, while minimizing trade-offs in power, performance, and latency.

The Roadmap to Deployment

While Industrial Ethernet has seen considerable growth in recent years, fieldbuses and other legacy networking technologies are still being deployed. We all agree on the advantages brought by a converged network based on Industrial Ethernet. These include a simplified network architecture, cost reduction through the removal of gateways, the elimination of hardwired connections, improved system optimization, increased up-time, etc. The advent of new standards and their imminent ratification is the catalyst needed to accelerate this awaited transition. This is a transition firmly driven by the need for higher performance connectivity networks with increased integration between OT and IT systems. TSN is the vehicle to deliver a converged network and, when married with 10BASE-T1L, will realize seamless edge-to-cloud connectivity. The migration will not happen overnight, but the potential benefits are so compelling that it is likely adoption will outpace standard industrial norms.

At the heart of the Industry 4.0 vision is the ability to automate processes using connected devices with the capacity to collect, send, and receive information. ADI Chronous is unlocking the data and insights previously unobtainable from many edge node devices, thereby awakening new realms of possibilities for data analysis and operation insight. Industrial Ethernet connectivity will awaken this reality through the seamless transfer of current and future data streams across the automation network to the cloud.

There are data islands of information and insight we cannot access today, but as Industrial Ethernet deployment becomes the norm, the challenge for Industry 4.0 will move to security and what to do with all this data to maximize our business value. The smart choice is to partner with a trusted ally that has serviced the industrial market for many decades. Analog Devices has the deep domain expertise, technology, and solutions needed to accelerate the transition to the smart factory of tomorrow.

Close Details

Close Details