Versatile Buck-Boost Converter Offers High Efficiency in a Wide Variety of Applications

Versatile Buck-Boost Converter Offers High Efficiency in a Wide Variety of Applications

2005-05-01

Introduction

Miniature hard disk drives are a popular storage medium for MP3 music files, digital photographs and other data stowed in the latest portable electronics. Likewise lithium-ion batteries are popular for these same devices, which presents a minor problem in that mini disk drives typically require a 3.3V supply, which is right in the middle of the lithium-ion battery’s operating range (3.0V-to-4.2V). This requires a converter that can both step down a fully-charged Li-Ion battery and step up the same battery as it discharges to sub-3.3V levels.

The LTC3442 is a 1.2A buck-boost converter that is ideal for mini disk drive applications, and certainly for other buck-boost applications as well. The LTC3442 extends battery life with 95% efficiency and fits into tight spaces with its 3mm × 4mm DFN package. It builds upon previous LTC buck-boost offerings by adding programmable automatic Burst Mode® operation, switching frequency and average input current limiting.

Features

The LTC3442 buck-boost converter uses the same fixed frequency, four-switch architecture as the LTC3440 and LTC3441, allowing it to use a single inductor to regulate the output voltage with input voltages than can be greater or less than the output. This provides an excellent solution for Li-Ion to 3.3V applications, with higher efficiency, smaller size and lower cost than SEPIC designs. Programmable automatic Burst Mode operation enables the converter to change operating modes without external intervention, for the best efficiency in portable applications. The transition point from fixed frequency PWM mode to Burst Mode operation is easily programmed with a single resistor. In addition, programmable average input current limit allows the user to limit the current drawn from the power source. This feature is useful in USB applications, where the allowable current draw is limited to 500mA maximum. The four internal 100mΩ MOSFET switches provide high efficiency, even at peak currents up to 3A. Programmable switching frequency and soft-start provide flexibility for many different applications. Output disconnect, which prevents any unwanted current flow between VIN and VOUT during normal operation or shutdown, is an inherent feature of the 4-switch architecture.

4W, Li-Ion to 3.3V Converter with Automatic Burst Mode Operation is Ideal for Dynamic Load Applications

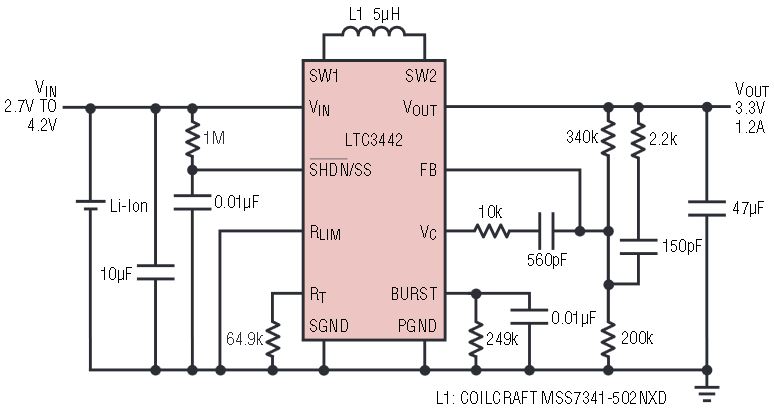

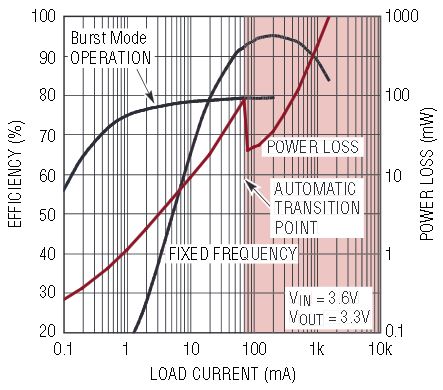

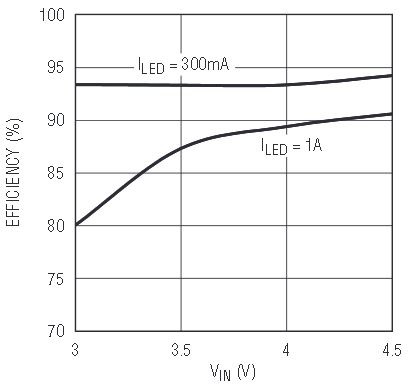

A typical Li-ion to 3.3V application circuit is shown in Figure 1. It provides efficient, well-regulated 3.3V output power at currents up to 1.2A with very low ripple, even as the battery voltage varies from 4.2V down to less than 3V. The automatic Burst Mode feature enables it to maintain high efficiency, even as the load becomes very light. This is ideal for applications such as miniature disk drives in portable devices, which require currents up to an amp during spin-up, a few hundred milliamps during read and write cycles, but much less current during idle times, or when the device goes to sleep. Figure 2 shows the converter efficiency, peaking at 95%. Maintaining regulation when the input voltage drops below 3.3V allows all the energy in the battery to be used. It also allows the converter to maintain regulation during load transients, when the battery ESR may cause the input voltage to drop below 3.3V momentarily. In contrast, step-down designs lose output regulation when the battery voltage approaches or dips below 3.3V.

Figure 1. Li-Ion to 3.3V converter delivers 1.2A with automatic Burst Mode operation.

Figure 2. Efficiency vs load for the converter in Figure 1.

Automatic Burst Mode operation allows the converter to change operating modes as the load current varies, maintaining high efficiency, without any commands required from a host. By mirroring a small fraction of the output current and averaging it on the BURST pin, a voltage is produced that is proportional to the average load current. When this voltage exceeds an internal threshold of 1.12V, the converter operates in fixed frequency mode. When the BURST voltage drops below a threshold of 0.88V, the converter transitions to Burst mode operation. Therefore, raising the value of the resistor on the Burst pin lowers the load current at which Burst mode is entered (values above 250K are not recommended). (Note that the operating mode can be manually controlled by the host at any time by driving the Burst pin above or below these thresholds.)

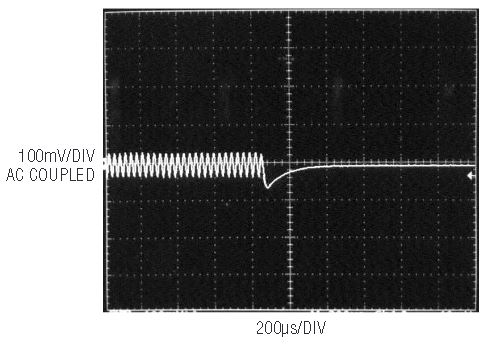

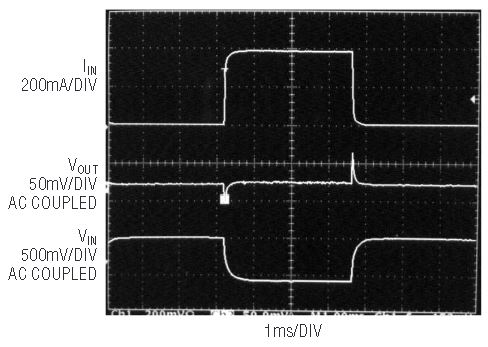

Another feature of the LTC3442 is an adaptive hold circuit that keeps the VC pin and the compensation network charged to the correct voltage during Burst Mode operation, for a smooth transition back to fixed frequency operation. Figure 3 shows the output voltage as the converter switches automatically from Burst Mode operation to fixed frequency mode, in response to an increase in load. If desired, the operating mode can be forced by driving the Burst pin high (for fixed frequency operation) or low (for Burst Mode operation).

Figure 3. Output voltage during the automatic transition between Burst Mode operation and Fixed Frequency operation.

1MHz USB to 5V Converter with Average Input Current Limit

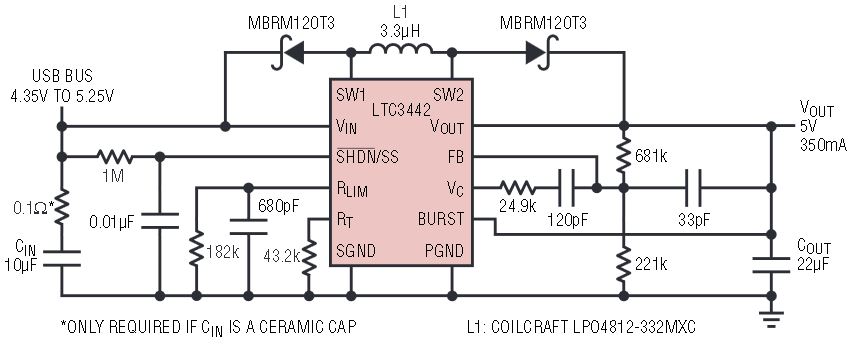

An increasing number of portable electronic devices and computer peripherals are operated with USB power. Although this is convenient for the user, it brings with it some challenges for the designer of the USB powered device. The voltage regulator tolerance of the host, combined with voltage drops in bus-powered hubs and USB cables, cause the 5V available at the end of the USB cable to be poorly regulated, varying from 4.35V to 5.25V (with transients down to 4.0V). Figure 4 shows a low profile (1.2mm), USB to 5V converter using the LTC3442 for high-power bus-powered functions. It accepts the poorly regulated USB input, and delivers 5V with 2% regulation and less than 20mVP–P ripple. Figure 5 illustrates the circuit’s ability to maintain tight regulation during line and load transients. In this example, a step load has caused the USB–supplied current to increase by 400mA, resulting in a 600mV drop in the USB input voltage, while VOUT exhibits only a 60mV disturbance.

Figure 4. A 5V converter with average input current limit for USB applications.

Figure 5. Step load regulation of the USB converter in Figure 4.

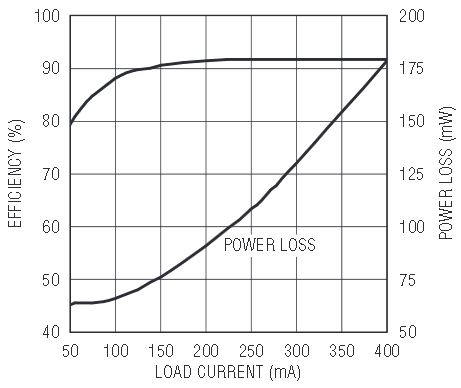

The converter efficiency is as high as 92% at 1MHz, as shown in Figure 6. Note that in this example, the Burst pin is pulled high for fixed frequency operation.

Figure 6. Efficiency vs load for the 5V USB converter in Figure 4.

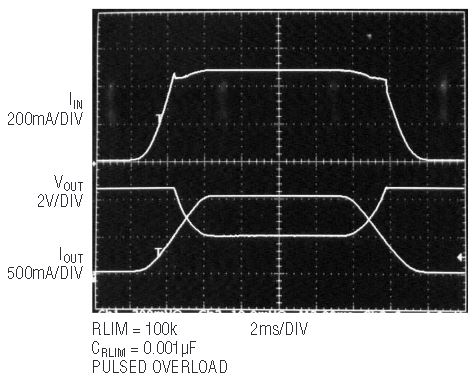

One of the restrictions placed on users of the USB bus is a maximum allowed current draw of 500mA. To guarantee that this limit is not exceeded, USB powered solutions often employ additional current limiting circuitry, increasing size and cost. The LTC3442 solves this problem by including a programmable average input current limit, which works by mirroring a small fraction of the input current and averaging it on the RLIM pin, using an external RC network. The RLIM voltage is also connected to an internal amplifier with a 1V reference. When the RLIM voltage reaches 1V, the amplifier clamps the VC pin, lowering the output voltage as needed to prevent the input current from increasing any further. In the example of Figure 4, the input current is limited to less than 500mA in the event of an overload. The current limit response time is set by the filter capacitor on the RLIM pin. Figure 7 illustrates the circuit’s response to an overload, with VOUT dropping as IOUT increases and the USB input current is clamped to 0.5A.

Figure 7. Input current limit overload response of USB converter.

In this application, Schottky diodes are required to limit the peak voltage on the switch nodes and also provide a small efficiency improvement. Note that since the diodes are back-to-back, the output disconnect feature of the LTC3442 is maintained. The resistor in series with the input filter capacitor damps any oscillation or overshoot resulting from the input capacitor resonating with the USB cable inductance when the cable is first attached. This damping resistor is only required if a ceramic input capacitor is used. When using a tantalum capacitor, the ESR of the capacitor provides damping, eliminating the need for an external resistor.

High Efficiency, Constant Current White LED Driver

High current white LEDs are being used in many new applications, including flashes for cell phone cameras. These applications demand a small, high efficiency solution, capable of supplying a regulated LED current, which may need to be set anywhere from a few hundred milliamps to over 1A, while being powered from a Li-ion battery. With typical white LED voltages ranging from 3V to 4V, a buck-boost converter is necessary to maximize Li-ion battery life.

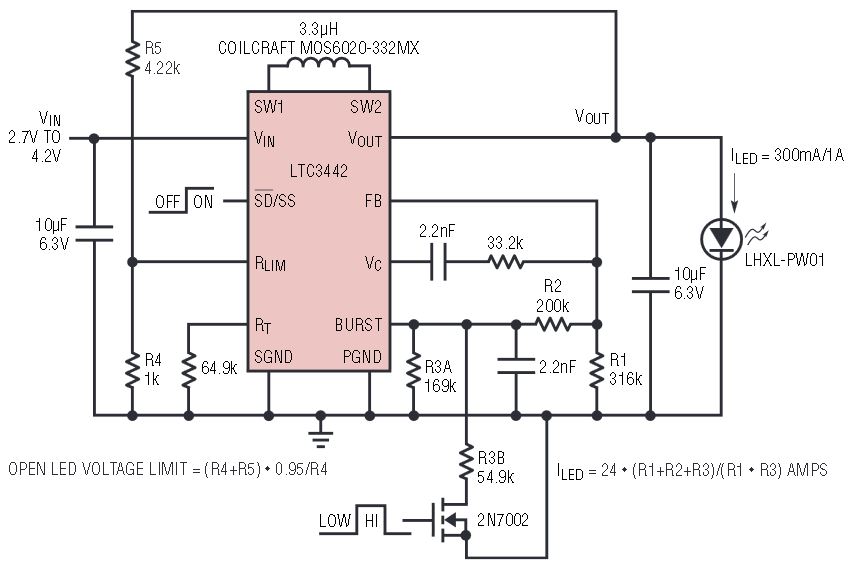

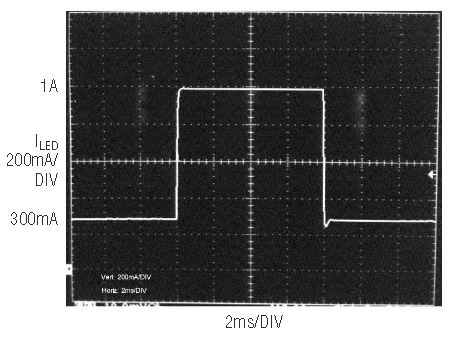

Most LED drivers must use a current sensing resistor to regulate the LED current. This approach lowers efficiency and requires added board real estate, since the resistor must be sized to handle the high peak current in the LED. A unique solution for this application is shown in Figure 8, where the LTC3442 is configured as a fixed frequency constant current source. By utilizing the output current mirror at the BURST pin, normally used for automatic Burst Mode operation, no current sense resistor is required. In this application, the feedback loop is closed on the sensed average output current, rather than the output voltage. With essentially lossless current sensing, 94% efficiency is achieved, as shown in Figure 9. The LED current can be easily programmed or changed quickly, as in a pulsed flash, by changing the resistance on the BURST pin. It can also be turned on and off by means of the shutdown input. Figure 10 illustrates the response to a pulse input for a flash application. The entire solution is only 2mm high.

Figure 8. Constant current white LED driver for Li-Ion-powered applications.

Figure 9. Efficiency vs load for the high current LED driver in Figure 8.

Figure 10. Step response of the LED constant current driver in Figure 8 for flash applications.

This circuit also features overvoltage protection, preventing excessive output voltage in the event that the current path to the LED becomes open-circuited. By connecting the RLIM pin to a resistive divider on VOUT, the RLIM input acts as an overvoltage comparator with a 1.0V reference. Raising RLIM above 1.0V pulls down on the VC pin, limiting the output voltage. By making the value of the divider resistors relatively small, the current sourced by the input current mirror to RLIM has a negligible effect on the overvoltage threshold.

Conclusion

Linear Technology’s LTC3442 synchronous buck-boost converter, with automatic Burst Mode operation and programmable input current limit, simplifies the system power design in a wide variety of applications. The buck-boost architecture and 100mΩ internal switches provide a robust, high efficiency solution with high current capability, while the automatic Burst Mode feature maximizes runtime in portable Li-Ion powered devices with widely varying load requirements. Programmable soft-start and switching frequency, as well as external compensation, make the LTC3442 a very flexible solution. The high level of integration in a 3mm × 4mm DFN package, and the ability to operate efficiently at over 1MHz using low profile inductors and all ceramic capacitors, helps the designer save precious board real estate and meet the stringent height requirements of today’s miniature, portable applications.