Design Note 457: Monolithic Synchronous Step-Down Regulator Delivers up to 12A from a Wide Input Voltage Range

Introduction

The LTC3610 is a high power monolithic synchronous step-down DC/DC regulator that can deliver up to 12A of continuous output current from a 4V to 24V (28V maximum) input supply. It is a member of a high current monolithic regulator family (see Table 1) that features integrated low RDS(ON) N-channel top and bottom MOSFETs. This results in a high efficiency and high power density solution with few external components. This regulator family uses a constant on-time valley current mode architecture that is capable of operating at very low duty cycles at high frequency and with very fast transient response. All are available in low profile (0.9mm max) QFN packages.

| LTC3608 | LTC3609 | LTC3610 | LTC3611 | |

| Input Voltage Range (V) | 4 to 20 | 4.5 to 32 | 4 to 24 | 4.5 to 32 |

| Max Load Current (A) | 8 | 6 | 12 | 10 |

| QFN Package Size (mm) | 7 × 8 × 0.9 | 7 × 8 × 0.9 | 9 × 9 × 0.9 | 9 × 9 × 0.9 |

Typical Application Example

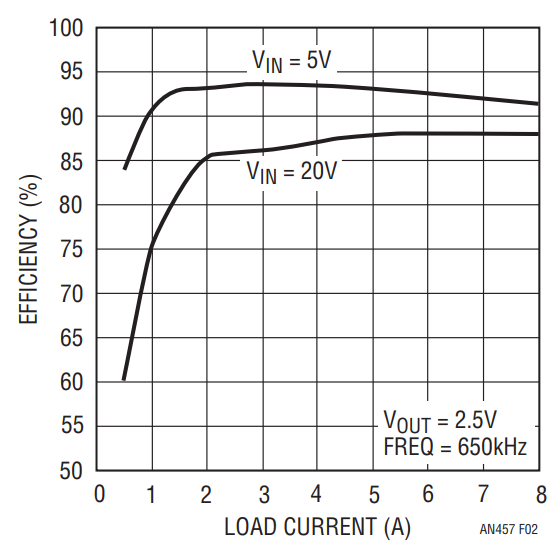

Figure 1 shows a typical application schematic of the LTC3608. This 7mm × 8mm regulator supplies 2.5V at 8A maximum load current from a 4.5V to 20V input source. This application switches at a nominal 650kHz, which allows the use of low profile inductor and capacitors while maintaining high efficiency. The switching frequency can be easily adjusted by a resistor (RON in Figure 1, connected to the ION pin). Figure 2 shows the operating efficiency.

Figure 1. 4.5V to 20V Input to 2.5V/8A High Density Step-Down Converter.

Figure 2. Efficiency vs Load Current of Figure 1.

The FCB pin is connected to ground to force continuous mode operation at light load for both low noise and small output ripple. The FCB pin can also be tied to INTVCC to enable discontinuous mode for higher efficiency at light load. Soft-start is programmable with a capacitor from the RUN/SS pin to ground. Forcing the RUN/SS pin below 0.8V shuts down the device.

The LTC36XX family are valley current mode regulators so they inherently limit the cycle-by-cycle inductor current. The inductor current is sensed using the RDS(ON) of the bottom MOSFET —no additional current sense resistor is required. The current limit is also adjustable with the voltage at the VRNG pin. When the VRNG pin is tied to ground, in the Figure 1 example, the current limit is set to about 16A.

An open-drain logic power good output voltage monitor (PGOOD) is pulled low when the output voltage is outside ±10% of the regulation point. In the case of overvoltage, the internal top MOSFET is turned off and the bottom MOSFET is turned on until the overvoltage condition clears. The LTC36XX also includes a foldback current limiting feature to further limit current in the event of a short circuit. If the output drops more than 25%, the maximum sense voltage is lowered to about one sixth of its original value.

Paralleling Regulators for >12A

These parts can be easily paralleled for high output current applications. Figure 3 shows a 1.2V/24A application using two parallel LTC3610s. Because of the valley current mode control architecture, the paralleled regulators can operate at very low duty cycles with fast transient response and excellent load balance.

Figure 3. Two LTC3610s in Parallel Can Provide 24A Output Current.

The current sharing is simple. Connect the ITH pins together, since the ITH pin voltage determines the cycle-by-cycle valley inductor current. The feedback pins of paralleled LTC3610s share a single voltage divider. The RUN/SS pins are connected so that the LTC3610s start up with same slew rate. The paralleled LTC3610s have excellent thermal balance due to good current sharing.

Conclusion

With broad input and output ranges, high current capability and high efficiency, these monolithic regulators provide small size, low external component count power solutions for many applications from communications infrastructure to industrial distributed power systems.