Smart Battery Charger for Battery Backup

Introduction

The most common power source used for backup power is a battery. In a backup power system it is important to know if the battery is ready and reliable at all times by constantly monitoring its health and state of charge. Smart Batteries are currently the best available industry standard system that can satisfy these requirements.

Two important features of Smart Battery Systems (SBS) are that they are battery chemistry independent and provide a built-in gas gauge. Because the charging system no longer carries the burden of charge monitoring and applying chemistry-specific charge algorithms, the charger itself can be truly generic, accepting any Smart Battery, regardless of type or capacity. A host system needs to do nothing other than provide a Smart Battery charger to guarantee that a healthy battery is kept at full charge and a bad battery is detected.

This certainly simplifies charger design. The same charger can be used without modification in a variety of products. It also simplifies field and factory upgrades to different chemistries or higher capacities.

The LTC4100 Smart Battery charger is primarily targeted at big battery configurations in power hungry portable products, such as notebook computers. Many new products do not require the high voltage capability of the LTC4100, but still need all the advantages of a SBS system. The LTC4101 is a special version of the LTC4100 Smart Battery charger that is optimized to work with battery voltages below 5.5V, while retaining the space saving advantages of the LTC4100.

The LTC4101 Smart Battery Charger

The LTC4101 is a compact Smart Battery charger optimized for battery voltages below 5.5V. It shrinks overall circuit size by reducing the size of external components. For instance, it takes advantage of the compact ceramic capacitors’ space saving features while avoiding any audible noise. It also operates at a high 300kHz switching frequency, which allows the use of a very small, low cost inductor. Inductor values can be as low as 4µH at 4A with 7.5V of input.

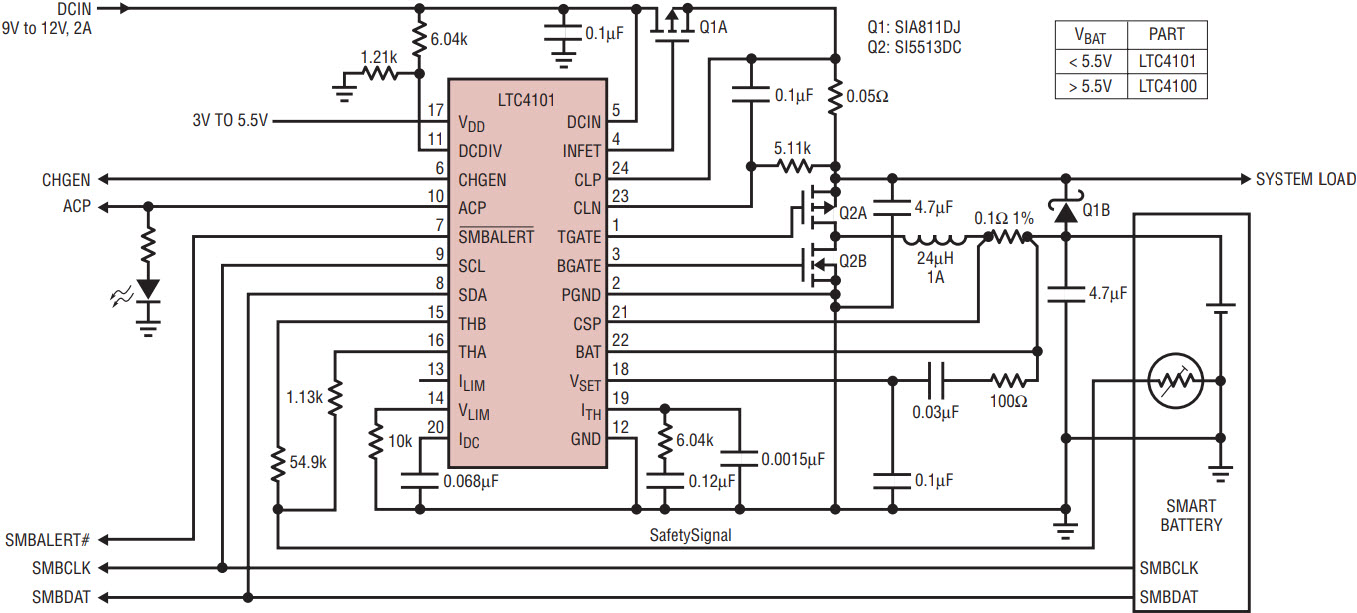

Figure 1. Charger with 2A input current limiting and 1A of charge power.

The LTC4101 is a Level 2 (slave) Smart Battery charger that is compliant with both Smart Battery charger V1.1 and SMBus V1.1 standards. Input voltage range is 6V to 28V while the output charge voltage range is from 3V to 5.5V. A 10-bit current DAC and an 11-bit voltage DAC, with current accuracy of 5% and voltage accuracy of 0.8%, respectively, provide precision charge capabilities. A topside P-channel MOSFET allows 98% maximum duty cycle, dramatically reducing total part count and IC pin count while maintaining efficiency greater than 95% (see Figure 2).

Figure 2. Efficiency at single-cell Li-ion voltages.

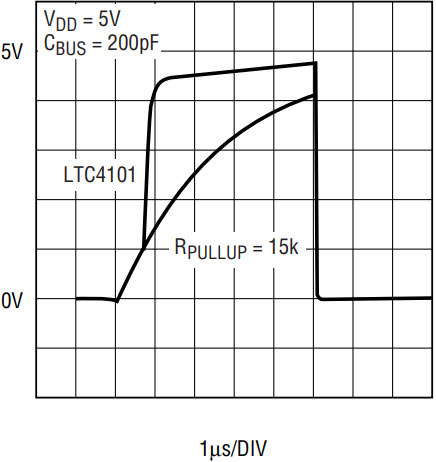

The LTC4101 also offers many unique features, including a current limit and voltage limit system that prevents SMBus data corruption errors from generating harmful charge values. A patented SMBus accelerator1 increases data rates in high capacitance traces while preventing bus noise from corrupting data (see Figure 3).

Figure 3. Built-in SMBus accelerator improves rise time performance and noise margin.

Figure 1 shows a typical compact single battery charger. This circuit can charge batteries with up to 1A and switch continuously down to zero load current. The LTC4101 is capable of charging currents up to 4A. Other features include:

- an AC present signal with precision 3%-accurate user adjustable trip points

- a safety signal circuit that rejects false thermistor tripping due to ground bounce caused by the sudden presence of high charge currents

- a DC input FET diode circuit that prevents battery current from flowing backwards into the wall adapter or DC power source

- an ultrafast overvoltage comparator circuit that prevents voltage overshoot when the battery is suddenly removed or disconnects itself during charge.

- VLIM and ILIM settings that are used to protect the battery from excessive voltage or current conditions that could occur if there are data corruption errors in SMBus communication.

- an input current limit sensing circuit2 that is used to limit charge current to prevent wall adapter overload as the system power increases.

Ceramic Capacitors Reduce Size and Improve Reliability

One of the biggest space saving changes that has occurred in recent years is the use of high capacitance and voltage (high C/V) ceramic capacitors. In switching regulator applications, the low ESR of ceramics allows them to handle a relatively large ripple current per microfarad while remaining relatively inexpensive. Battery chargers can reap the same benefits provided their feedback loops are stable with ceramic capacitors.

Ceramics come with their own unique challenges such as piezoelectric properties that can result in audible noise if there are AC currents with audible frequencies present. Such frequencies can occur in battery chargers at two load extremes: low dropout and light load.

Battery chargers run up against wall adapter voltages that are often just a few volts above the peak battery voltage. Depending on the design, as the charger approaches 100% duty cycle, the switching frequency passes though the audible range on the way to DC. Alternatively, conditions where the charge current falls below the PWM controller’s ability to maintain regulation can create discontinuous switching cycles or cycle-skipping. Cycle-skipping switching periods can occur in the audible range. This typically happens when batteries momentarily disconnect themselves during the charge process for termination condition evaluation, thus forcing the charge current to zero. Ceramic capacitors translate cycle skipping or low dropout switching activity into audible noise. The LTC4101 avoids this problem by switching continuously under all loads, even 0A.

High Switching Frequencies Keep Inductors Small

Charger system designers are often driven to reduce inductance values to take advantage of smaller form factor components. The problem is that less inductance for a given switching frequency results in more inductor ripple current, which increases the output capacitor size. However, if one increases the switching frequency proportional to the reduction in inductance, the output capacitance can remain the same. The LTC4101 operates at a switching frequency of 300kHz, allowing tiny, low profile inductors to be used.

Conclusion

The LTC4101 Smart Battery retains all the same compact form factor advantages of the LTC4100 while being optimized for low voltage battery packs that can be found in compact products that require battery backup.

Notes:

1 U.S. patent number 6650174

2 U.S. patent number 5723970

About the Authors

Related to this Article

Products

Smart Battery Charger Controller

Smart Battery Charger Controller