Overview

Design Resources

Design & Integration File

• Schematic• Bill of Materials

• Gerber Files

• Layout Files

• Assembly Drawing Download Design Files 450.91 K

Evaluation Hardware

Part Numbers with "Z" indicate RoHS Compliance. Boards checked are needed to evaluate this circuit.

- EVAL-SDP-CB1Z ($134.00) System Demonstration Platform

Device Drivers

Software such as C code and/or FPGA code, used to communicate with component's digital interface.

AD7124 IIO Sigma-Delta ADC GitHub Linux Driver Source Code

Features & Benefits

- 0.1 Degree Accurate Thermistor Measurement System

- Highly Integrated Solution

- Up to 4 Thermistors (AD7124-4) or 8 Thermistors(AD7124-8)

Documentation & Resources

-

CN0545 User Guide12/17/2020WIKI

Circuit Function & Benefits

Temperature measurements often play an important role in any type of end applications such as instrumentation, industrial automation, transit, manufacturing processes, and medical applications. There are several types of temperature sensors such as thermocouples, platinum resistance temperature detectors (RTDs), electronic band gap sensors, and thermistors that can be used in temperature measurement systems.

The temperature sensor along with the design that the customer can use depends on the temperature range being measured and the accuracy required. For temperatures in the −50°C to +150°C range, thermistors provide an excellent combination of sensitivity, accuracy, cost, and simplicity. However, thermistors are highly nonlinear. Therefore, circuit linearization techniques are required to ensure accurate temperature values.

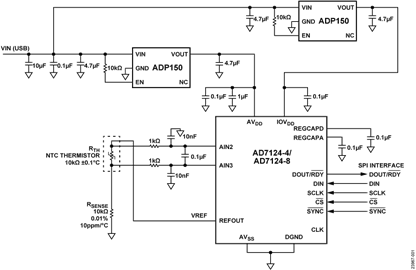

The circuit shown in Figure 1 is an integrated 0.1°C thermistor measurement system based on a low power, low noise, integrated, 24-bit, Σ-Δ analog-to-digital converter (ADC). The system can achieve high resolution, low nonlinearity, and low noise performance, as well as high 50 Hz and 60 Hz rejection. The typical noise free code resolution of the system is approximately 14 bits, which is roughly 0.01°C.

The system integrates several important system building blocks to support thermistor measurement, including a constant current source, a programmable gain amplifier (PGA), an internal reference, and analog and reference input buffers ideal for resistance measurement. This integration allows direct interface with the sensor, greatly simplifying the design while reducing the printed circuit board (PCB) size, cost, and power consumption.

Several options of the on-chip digital filtering, integrated diagnostics, and three power modes provide application flexibility. The current consumed in low power mode is only 255 μA and 930 μA in full power mode. In power-down mode, the complete ADC along with its auxiliary functions are powered down so that the device consumes 1 μA typical. The power options make the device suitable for battery-powered applications, loop powered applications, and nonpower critical applications.

Circuit Description

Thermistor Introduction

Thermistors are inexpensive, nonlinear resistors, whose resistance is a strong function of temperature. Precision applications most often employ thermistors with a negative temperature coefficient (NTC). Positive temperature coefficient (PTC) thermistors are also available but are typically used in safety applications or as resettable fuses. The PTC thermistor exhibits only a slight change in resistance with respect to temperature until its Curie point (or switching point) is reached, above which an increase in resistance of several orders of magnitude occurs over a few tens of °C. The switching point for a PTC thermistor is typically between 60°C and 120°C. In contrast, NTC thermistors are usable over a much larger temperature range, typically −50°C to +150°C, suitable for a wide range of applications, including industrial automation, instrumentation, and medical.

Thermistors operate in a similar manner to RTDs but are ceramic, polymer, or semiconductor (typically metal oxides), and can have much greater responsiveness and temperature coefficients than RTDs. The high sensitivity of the thermistor is a distinct advantage over RTDs because there is no need to compensate for lead resistances. These sensors are categorized by their nominal resistance at 25°C, which ranges from 1 kΩ to 10 MΩ.

Figure 2 shows the temperature response of a typical 10 kΩ NTC thermistor. Note the high nonlinearity characteristics shown in Figure 2, meaning that the measured resistance requires linearization to ensure accurate temperature values.

There are several industry standards that define the tolerance and accuracy limits of a thermistor sensor. For the circuit in Figure 1, a 10 kΩ, Type 44031 NTC thermistor sensor was used, which is specified to measure from −50°C (441.117 kΩ) to +150°C (237.16 Ω). The resistance is 10 kΩ at +25°C with an accuracy of ±0.1°C between 0°C to +70°C and a ±1°C temperature range over the wider temperature range.

Thermistor Transfer Function

The resistance of NTC thermistors decreases as temperature increases. The Steinhart-Hart equation is an empirical expression that was determined to be the best mathematical expression to use to correct the nonlinear response (resistance vs. temperature characteristics) of typical NTC thermistors.

The Steinhart-Hart equation for temperature as a function of resistance follows:

where:

T is the temperature in degrees Kelvin.

A, B, and C are the constants derived from the three temperature test points.

RTH is the resistance in ohms of the thermistor.

The values of A, B, and C are dependent on the specific thermistor model, which can be found in the selected thermistor data sheet. If the data sheet gives A, B, and C, this equation can be used directly to calculate the temperature as a function of the measured resistance.

For this circuit note, thermistor Model Number 44031 (10 kΩ) was used, and the Steinhart-Hart constants for this model are A = 1.032 × 10−3, B = 2.387 × 10−4, and C = 1.580 × 10−7.

Some NTC thermistor manufacturers do not provide the values for the A, B, and C constants. Instead, the thermistor is specified with a single beta (β) constant representing a change in resistance, calculated using the resistance value at two specified temperatures. When a NTC thermistor data sheet provides only a β value, use the following equation to determine the temperature:

R is the resistance in ohms of the thermistor.

R0 is the resistance at temperature T0 (25°C = 298.15°K).

T is the temperatures in Kelvins.

T0 = (25°C = 298.15 K).

Note that Equation 2 is essentially the Steinhart–Hart equation with A = (1/T0) – (1/β)(lnR0), B = 1/β, and C = 0.

When designing a thermistor application, it is important to optimize the system operating temperature range by using the thermistors expected resistance at the minimum and the maximum temperatures. To determine the thermistor resistance at a specific temperature point, use the inverse of the Steinhart-Hart equation that follows:

where:

RTH is the resistance in ohms of the thermistor.

Thermistor Measurements

Thermistors have a greater resistance change per °C compared to other temperature sensor types. For example, a 10 kΩ thermistor has a resistance of 10 kΩ at 25°C. At −50°C, the NTC thermistor resistance is 441.117 kΩ. Therefore, signal levels are larger when compared to other resistance temperature sensors, such as RTDs. Exciting the thermistor with even the smallest possible excitation current available on the AD7124-4/AD7124-8 is not appropriate because the thermistor tends to generate a high output voltage at lower temperatures. For example, an excitation current of 50 μA generates a voltage of 441.117 kΩ × 50 μA = 22 V when measuring a temperature of −50°C. This voltage level is outside the specified range of the AD7124-4/AD7124-8.

A simple approach of measuring RTH is to connect the thermistor in series with a 0.01% sense resistor (RSENSE) as part of a potential divider circuit (see Figure 1). A constant excitation voltage is used to generate a voltage across RTH, and this voltage is then converted to a precision digital representation using the 24-bit, Σ-Δ ADC. This measured voltage is used to calculate the current flowing through RSENSE, which is the same current that flows through RTH. Therefore, determining the value of RTH.

The RSENSE value is equal to the magnitude of RTH at the base temperature of 25°C so that the output voltage is at the midpoint at nominal temperature. When the temperature changes, RTH also changes and the fraction of the excitation voltage across the thermistor also changes, producing an output voltage that is proportional to RTH.

By using the selected reference voltage to supply the thermistor and/or RSENSE and by using this same reference as the ADC reference for the measurement, errors in the excitation voltage source can be cancelled, thereby resulting in a ratiometric measurement result.

The general expression to calculate the voltage across the thermistor (VTH), where the ADC is operating in unipolar mode, is given by the following:

where:

CODE is the ADC code.

VREF is the reference voltage.

G is the selected gain.

N is the resolution of the ADC (24, in this case).

The general expression to calculate VTH, where the ADC is operating in bipolar mode, is given by

The general expression to calculate RTH is given by

Thermistor Design Considerations

The following sections describe how the AD7124-4/AD7124-8 provide the key functions and features needed for an accurate thermistor measurement, and how to connect and to configure the measurement.

ADC

Along with the thermistor sensor specification, the accuracy of the system depends on the performance of the ADC. The AD7124-4/AD7124-8 provide an integrated solution for thermistor measurement. These devices can achieve high resolution, low nonlinearity, and low noise performance as well as high 50 Hz and 60 Hz rejection. The AD7124-4/AD7124-8 consist of an on-chip internal reference, reference buffers, and a low noise PGA, thus allowing direct interface with the sensor and minimizing the required external circuitry.

Power Supplies

The AD7124-4/AD7124-8 have separate analog and digital power supplies. The digital power supply, IOVDD, is independent of the analog power supply, AVDD, and can be from 1.65 V to 3.6 V referenced to DGND. AVDD is referred to AVSS and has a range of 2.7 V to 3.6 V for the low and mid power modes and 2.9 V to 3.6 V for the full power mode. The circuit shown in Figure 1 operates from a single supply. Therefore, AVSS and DGND are connected together, and only one ground plane is used. The AVDD and IOVDD voltages are generated separately using the ADP150 voltage regulators. When using these regulators, the AVDD voltage is set to 3.3 V, and the IOVDD voltage is set to 1.8 V. Using separate regulators ensures the lowest noise.

The power mode selection depends on the current budget allotment for the end application. If the application requires a much higher output data rate and better noise performance, the AD7124-4/AD7124-8 can be configured for full power mode. For any portable application, low power components must be used, and for some industrial applications, the complete system is powered from the 4 mA to 20 mA loop so that the current budget of a 4 mA maximum is allowed. For this type of application, the AD7124-4/AD7124-8 can be programmed in mid or low power mode.

Analog Inputs, Buffers, and Gain Selection

The resistance changes per °C generate a voltage across the thermistor from tens of millivolts to volts over the specified temperature range using a 2.5 V excitation voltage.

The maximum voltage generated across the 10 kΩ NTC thermistor is approximately 2.44 V. Therefore, the PGA gain is programmed to a gain of 1 to ensure that the entire sensor output range is within the allowable input range of the AD7124-4/AD7124-8. When a gain of 1 is used, the PGA is powered down, reducing the current consumption.

The AD7124-4/AD7124-8 incorporate a high impedance analog input stage buffer amplifier. Therefore, the input can tolerate significant source impedances and is tailored for direct connection to external resistive type sensors such as thermistors. The inputs are automatically buffered when the PGA gain is greater than 1. However, the buffer can be disabled when the gain is equal to 1 as long as the source impedance is low.

In the CN-0545, the analog input is driven by the thermistor with a high resistance value (up to 441.11 kΩ), which can cause significant gain and offset errors. Enabling the input buffers allow a wide range of resistor values and electromagnetic capability (EMC) filtering without adding any error. The buffers require at least 0.1 V headroom above and below the supply rails. All of the circuits in this circuit note are designed such that the analog inputs are always within the headroom requirements.

Reference Voltage and Excitation Voltage

The AD7124-4/AD7124-8 have an internal 2.5 V reference. The reference is low noise and low drift with a 15 ppm/°C maximum drift for the AD7124-4/AD7124-8 in the LFCSP and with a 10 ppm/°C drift maximum drift for the AD7124-4 TSSOP and B grade models. Including the reference on the ADC reduces the number of external components required, leading to a reduced PCB size and system cost.

For the circuit shown in Figure 1, the internal reference is selected as the reference voltage for the thermistor measurement. This 2.5 V reference, when enabled, is available at the REFOUT pin and is also used as an excitation voltage to generate the voltage across the thermistor, resulting in a ratiometric configuration.

Therefore, any variations seen in the excitation voltage or internal reference voltage are removed.

This method also ensures that the voltage across the thermistor is always lower than the reference voltage, regardless of its larger resistance value at lower temperatures, which greatly simplifies the direct input connection for measuring the entire temperature range.

Digital and Analog Filtering

Differential (~800 Hz cutoff) and common-mode (~16 kHz cutoff) filters are implemented at the analog inputs as well as at the reference inputs. This filtering is required to reject any interference at the modulator frequency and modulator harmonic frequencies.

To get a high precision measurement from the sensor, it is also important that the sensor noise and accuracy dominate the overall system error. Noise can impact the system accuracy because it limits the smallest possible change in the signal level of the sensor that the ADC can recognize and, therefore, directly impacts the resolution of the system. Noise can also have an impact on the performed calibration because some calibrations reduce error to the order of the noise so less noise leads to more accurate and repeatable measurement results. Therefore, it is important that the ADC resolution and noise performance is several factors better than the sensor noise and resolution.

The AD7124-4/AD7124-8 offer a great deal of on-chip digital filtering flexibility. Several filter options are available. The filter option selected has an effect on the output data rate, the settling time, and the 50 Hz and 60 Hz rejection. For this circuit note, the sinc4 filter and the post filter are implemented. The sinc4 filter is used because this filter has excellent noise performance across the range of output data rates, as well as excellent 50 Hz and 60 Hz rejection. The post filter is used to provide simultaneous 50 Hz and 60 Hz rejection with a 40 ms settling time.

| Filter Type | Input Condition | RMS Noise (μV) | Noise Free Resolution (oC) |

| Sinc4 Filter, Full Power Mode, 50 SPS | Thermistor connected | 44.2 | 0.01 (14 bits) |

| Input shorted | 0.45 | 0.0002 (20 bits) | |

| Post Filter, Low Power Mode, 25 SPS | Thermistor connected | 72.9 | 0.02 (13.4 bits) |

| Input shorted | 1.7 | 0.005 (18.7) |

Table 1 lists the system rms noise values. Table 1 also shows the noise performance when the ADC analog inputs are shorted for the same filter, gain, and output data rate settings. The noise measured is higher when the thermistor is connected because the thermistor itself has some noise.

Calibration

The AD7124-4/AD7124-8 provide different calibration modes that can be used to eliminate offset and gain errors. For this circuit note, internal zero-scale calibration as well as internal full-scale calibration were used. Note that these calibrations remove the ADC gain and offset errors only and not the gain and offset errors created by the external circuitry.

Diagnostics

The AD7124-4/AD7124-8 have on-chip diagnostics that can check that the voltage level on the analog pins are within the specified operating range. The positive analog input voltage (AINP) and negative analog input voltage (AINM) can be separately checked for overvoltages, undervoltages, and ADC saturation. An overvoltage is flagged when the voltage on the analog input exceeds AVDD, while an undervoltage is flagged when the voltage on the analog input goes below AVSS. The extensive diagnostic functionality of the system also includes a cyclic redundancy check (CRC) on the serial peripheral interface (SPI) bus and signal chain checks, which lead to a more robust solution. These diagnostics reduce the need for external components to implement diagnostics, resulting in a smaller solution size, reduced design cycle times, and cost savings. The failure modes, effects, and diagnostic analysis (FMEDA) of a typical application has shown a safe failure fraction (SFF) greater than 90% according to IEC 61508.

Thermistor Wiring Configuration

The AD7124-4 can be configured for four differential or seven pseudo differential channels, and the AD7124-8 can be configured for eight differential or 15 pseudo differential channels. Both use flexible multiplexing. Therefore, any of the analog input pins can be selected as a positive input or a negative input. This feature allows the user to perform diagnostics such as checking that pins are connected. This feature also simplifies the PCB design to accommodate a single thermistor or multiple NTC thermistors.

Figure 3 shows the configuration of the NTC thermistor interfacing with the AD7124-4/AD7124-8. The two leads of the NTC thermistor are connected to the AIN2 and AIN3 pins, respectively. REFOUT is also connected to AIN2 and the NTC thermistor to provide a constant excitation voltage to the thermistor. RSENSE is connected in series with the NTC thermistor and referenced to ground to have a potential divider circuit. Then, this measured voltage, that is, the voltage across the thermistor, is used to calculate the current passing through RSENSE, which is the same current that passes through RTH. Therefore, the RTH value can also be determined.

The AD7124-4/AD7124-8 configuration for the single thermistor measurement is as follows:

- Differential input: AINP = AIN2 and AINM = AIN3

- Voltage bias: REFOUT

- Internal reference: 2.5 V

- Digital filtering: sinc4 50 SPS and post filter 25 SPS

- PGA gain = 1

- Precision RSENSE = 10 kΩ

- Analog buffers enabled

Thermistor Results

For the thermistor circuit shown in Figure 3, data was gathered for different digital filter and power mode configurations of the AD7124-4/AD7124-8, namely the sinc4 filter operating in full power mode and the post filter operating in low power mode as discussed in Digital and Analog Filtering section.

The typical noise free code resolution of the thermistor system is 14 bits for full power mode and the sinc4 filter selected and 13.4 bits for low power mode and post filter, which is equivalent to approximately 0.01°C and 0.02°C error variation on each temperature measurement. Figure 4 and Figure 5 show the noise distribution when a thermistor is connected.

Figure 6 and Figure 7 show the resulting error (set temperature minus measured temperature). For each thermistor temperature setting, the AD7124-4/AD7124-8 are kept at 25°C. As shown in Figure 6 and Figure 7, the error is within the thermistor specification. These plots also show the deviation of the thermistor error across the different AD7124-4/AD7124-8 temperature settings. For each AD7124-4/AD7124-8 temperature setting, an internal zero-scale and full-scale calibration is carried out. As shown in Figure 6 and Figure 7, the overall error is again within the envelope of the thermistor.

Figure 8 and Figure 9 show the error in the measured thermistor temperature, internal zero-scale and full-scale calibration carried out at 25°C. The plots show that carrying out calibration at 25°C or calibrating at each individual temperature of these devices gives similar performance.

Multiple Thermistor Wiring Configuration

The AD7124-4/AD7124-8 can be used as a measurement system for multiple thermistors. When multiple channels are enabled on the ADC, the ADC automatically sequences through the enabled channels, performing one conversion on each channel. When the channel is changed, the complete settling time of the filter is required to generate the conversion, thus affecting the overall throughput rate. Therefore, it is also important to consider the latency of the digital filter when multiplexing between multiple sensors.

The AD7124-4 can connect four NTC thermistors, whereas the AD7124-8 can connect up to eight NTC thermistors. When multiple thermistors are used, each thermistor must have its own precision RSENSE, but the thermistors can share a single excitation voltage (internal VREF). As a minimum, each NTC thermistor requires two analog input pins of the AD7124-4/AD7124-8.

To measure the thermistor voltage, take the following steps:

- Enable the internal reference available on REFOUT.

- Enable all analog input channels that have a thermistor connected across the input.

- REFOUT is then directed to RTH in series with RSENSE. The voltage across RTH is measured on Channel 0 (AIN0 and AIN1). The ADC then continues to sequence through all enabled channels automatically. Note that the EVAL-AD7124-4SDZ or the EVAL-AD7124-8SDZ has an on-board thermistor across AIN4 and AIN5. Make sure to remove this thermistor (R28) when using AIN4 and AIN5.

As an example, four NTC thermistors were connected to the AD7124-4 (see Figure 10), and the AD7124-8 can have eight NTC thermistors connected (see Figure 11). One NTC thermistor is connected across the AIN0 and AIN1 analog input pins (Channel 0 configuration), where the excitation voltage comes from REFOUT, and a second NTC thermistor is also shown connected across the AIN2 and AIN3 analog input pins (Channel 1 configuration), where REFOUT is also used for the bias voltage and so on. Table 2 and Table 3 detail the channel configuration for multiple NTC thermistors using the AD7124-4 and the AD7124-8, respectively.

| Sensor | Channel | VREF | AINP | AINM |

| RTH 1 | 0 | REFOUT | AIN0 | AIN1 |

| RTH 2 | 1 | REFOUT | AIN2 | AIN3 |

| RTH 3 | 2 | REFOUT | AIN4 | AIN5 |

| RTH 4 | 3 | REFOUT | AIN6 | AIN7 |

| Sensor | Channel | VREF | AINP | AINM |

| RTH 1 | 0 | REFOUT | AIN0 | AIN1 |

| RTH 2 | 1 | REFOUT | AIN2 | AIN3 |

| RTH 3 | 2 | REFOUT | AIN4 | AIN5 |

| RTH 4 | 3 | REFOUT | AIN6 | AIN7 |

| RTH 5 | 4 | REFOUT | AIN8 | AIN9 |

| RTH 6 | 5 | REFOUT | AIN10 | AIN11 |

| RTH 7 | 6 | REFOUT | AIN12 | AIN13 |

| RTH 8 | 7 | REFOUT | AIN14 | AIN15 |

Common Variations

To increase the performance and measurement accuracy when using NTC thermistors, it is best to connect the thermistor as close as possible to the ADC as shorter track lengths between the ADC and the sensor gives more accuracy to the measurement.

The multiple thermistor configuration using the AD7124-4/AD7124-8 can also be configured using a 4 × 1/8 × 1 external mux with low on resistance, which allows sharing of a single precision sense resistor (RSENSE). When using this configuration, each thermistor requires some settling time in the measurement. The corresponding settling times are discussed in the Digital and Analog Filtering section and within the AD7124-4 and the AD7124-8 data sheets.

The external components along with their temperature coefficients or temperature drift specifications are usually the main error contributors across the system when operating at the full temperature range. Therefore, it is important to select the sense resistor or resistive sensor, for example, with a lower temperature coefficient to minimize any possible temperature drift errors.

Circuit Evaluation & Test

The following sections outline the general hardware and software steps needed to get the CN-0545 system operational. For exact setup details and more information, see the CN0545 User Guide.

Equipment Needed

The following equipment is required for the thermistor measurement system:

- The EVAL-AD7124-4SDZ or the EVAL-AD7124-8SDZ evaluation board

- The EVAL-SDP-CK1Z or the EVAL-SDP-CB1Z System Demonstration Platform (SDP)

- The AD7124_Eval+ Software

- A power supply

- A 10 kΩ (Type 44031) NTC thermistor sensor

- A 10 kΩ precision sense resistor

- A PC running Windows® with a USB 2.0 port

Setup and Test

Figure 12 shows a functional block diagram of the test setup for the NTC thermistor configuration.

To configure the hardware, take the following steps:

- Set all links on the EVAL–AD7124-4SDZ or the EVAL-AD7124-8SDZ to the default board positions as outlined in the CN0545 User Guide.

- Connect the 10 kΩ (Type 44031) NTC thermistor sensor to the J6 connector on the EVAL–AD7124-4SDZ or the EVAL-AD7124-8SDZ.

- Connect the 10 kΩ precision resistor for RSENSE to the J6 connector on the EVAL–AD7124-4SDZ or the EVAL-AD7124-8SDZ.

- Connect the EVAL–AD7124-4SDZ or the EVAL-AD7124-8SDZ to the EVAL-SDP-CB1Z via the 120-pin header.

- Apply power to the EVAL–AD7124-4SDZ or the EVAL-AD7124-8SDZ.

- Connect the thermistor and precision reference resistor as shown in demonstration mode (see Figure 3).

- Connect the SDP to the PC via the USB cable.

Run the AD7124_EVAL+ Software. The evaluation software supports both the AD7124-4 and the AD7124-8 devices. Upon running this software, the user selects the evaluation board that is connected to the PC. For the AD7124-8, select EVAL-AD7124-8SDZ (AD7124-8 Evaluation Board) from the dropdown menu (see Figure 13).

After selecting the EVAL–AD7124-4SDZ or EVAL-AD7124-8SDZ, the window shown in Figure 14 appears.

To configure the AD7124-4/AD7124-8 for single thermistor measurements, click Thermistor under the Demo Modes section (see Figure 14).

Clicking Thermistor under the Demo Modes section configures the ADC software for the thermistor configuration. One additional step is required before the AD7124-4/AD7124-8 are configured for each thermistor measurement: an internal full-scale and zero-scale calibration of the AD7124-4/AD7124-8. This calibration can be performed via the Registers tab (see Figure 15).

For more details on the ADC register map settings calibration and measurements procedure, see the CN-0545 Hardware and Software User Guide.