How to Fuel Gauge Lithium-Ion Batteries Without Battery Characterization with ModelGauge m5 EZ

How to Fuel Gauge Lithium-Ion Batteries Without Battery Characterization with ModelGauge m5 EZ

Abstract

This application note discusses how to use ModelGauge m5 EZ with an associated EV kit to enhance and increase fuel gauging, thus eliminating battery characterization. Simply connect the battery and start reading the fuel-gauge registers with minimal or no configuration.

Introduction

The ModelGauge™ m5 EZ makes fuel gauging easier than ever before. Simply connect the battery and start reading the fuel-gauge registers with minimal or no configuration.

For conventional fuel gauges, battery characterization is a mandatory requirement to get acceptable performance because of the large distribution of the electrical properties presented by a wide array of Lithium-ion chemistries available in the market. Even for batteries with the same chemistry such as the popular lithium cobalt oxide (LiCoO2), different form factors change the impedance in the batteries that traditionally makes battery characterization a necessary step. For some projects with schedule pressures, the two-three weeks of characterization/data analysis time can be unacceptably long.

The ModelGauge m5 EZ configuration eliminates the need for battery characterization, saving resources and time. It can deliver excellent fuel gauge performance across many different battery chemistries, capacities, and charge voltages. This has been tested on hundreds of batteries in Maxim’s characterization database.

ModelGauge m5 EZ Performance

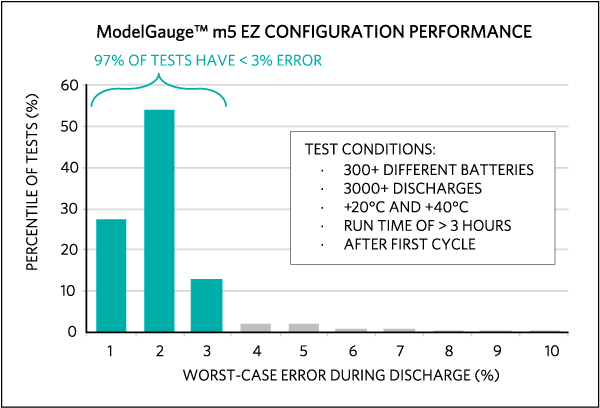

Figure 1 shows an accuracy table of ModelGauge m5 EZ on 300+ batteries tested at +20°C and +40°C with a run time greater than 3 hours.

Figure 1. Accuracy table of ModelGauge m5 EZ configuration performance.

| Description | After First Cycle* (%) | After Second Cycle* (%) |

| Tests with error less than 3% | 97 | 97.6 |

| Tests with error less than 5% | 99 | 99.5 |

| Tests with error less than 10% | 100 | 100 |

| *Test Conditions: +20°C and +40°C, run time of > 3 hours. | ||

Note: Certain special chemistries such as LiFePO4, LiMnO2, LiNiO2, Li2TiO3, and NCA batteries were excluded in the test results because of their significant differences in electrical properties compared to LiCoO2. These and other chemistries can be supported with an alternate ModelGauge m5 EZ model or with custom models.

How ModelGauge m5 EZ Provides Excellent Accuracy Without Battery Characterization

The ModelGauge m5 EZ robust algorithm provides tolerance against battery diversity by incorporating several learning and adaptive mechanisms including the ones explained below.

The ModelGauge m5 algorithm combines the short-term accuracy and linearity of a coulomb-counter with the long-term stability of a voltage-based fuel gauge, along with temperature compensation to provide excellent fuel gauge accuracy. Refer to the OCV Estimation and Coulomb Count Mixing and Fuel Gauge Learning sections in the MAX17055 ModelGauge m5 EZ User Guide MAX17055 User Guide for more information.

The IC automatically compensates for aging, temperature, and discharge rate, and provides accurate state-of-charge (SOC) in percentage (%) or milliampere-hours (mAh) over a wide range of operating conditions. Refer to the Empty Compensation section the MAX17055 ModelGauge m5 EZ User Guide for more information.

ModelGauge m5 EZ provides better fuel-gauge performance after the first cycle as the actual full capacity of the battery is progressively learned. Refer to the Fuel Gauge Learning section in the MAX17055 ModelGauge m5 EZ User Guide for more information.

If cold temperature discharges are included, the SOC accuracy is the following:

| Performance including 0°C, first cycle, run time > 3 hours, error judged as the worst case across each discharge | |

| Description | Percentile Cases (%) |

| Tests with error less than 5% | 92 |

| Tests with error less than 10% | 97 |

Furthermore, ModelGauge m5 EZ improves the error as the battery approaches empty. Refer to the Converge-to-Empty section in the MAX17055 ModelGauge m5 EZ User Guide for more information. When the error is judged at 10%, the error improves as the table below shows:

| Performance including 0°C, first cycle, run time > 3 hours, error judged when the battery is near empty (10%) | |

| Description | Percentile Cases (%) |

| Tests with error less than 5% | 94 |

| Tests with error less than 10% | 98 |

How to Configure ModelGauge m5 EZ

ModelGauge m5 EZ is designed to be used without any initial setup. Simply connect a relaxed battery to the EV kit or custom PCB and begin reading the registers of interest.

However, accuracy can be improved with minimal configuration using the Configuration Wizard (MAX17201/MAX17205/MAX17211/MAX17215) or Configure > Battery (MAX17055) in the EV kit software. The EV kit software can be used without the hardware present to generate the appropriate configuration values. The following parameters should be adjusted in the Configuration Wizard:

- Cell size (mAh)

- Empty voltage (V)

- Charge voltage above/below 4.275V

In the MAX17201/MAX17205/MAX17211/MAX17215 ICs, the Configuration Wizard also configures the cell count and thermistor options of the IC. These parameters are saved to the nonvolatile memory at the last page of the Configuration Wizard, or can be written by any I2C master using the memory map displayed on the last page of the Configuration Wizard.

Refer to the following videos for more details:

EZ Setup of MAX17055 ModelGauge m5 Low IQ Stand-Alone Fuel Gauge

EZ Setup of MAX17201/MAX17211 ModelGauge m5 Stand-Alone Fuel Gauges

| Part | Interface | Series Cells | Cell Balancing | EV Kit |

| MAX17055 | I2C | 1 | MAX17055XEVKIT# (WLP) MAX17055GEVKIT# (TDFN) |

|

| MAX17201 | I2C, SMBus | 1 | MAX17201XEVKIT# (WLP) MAX17201GEVKIT# (TDFN) |

|

| MAX17205 | I2C, SMBus | Multiple | 2S, 3S Configurations | MAX17205XEVKIT# (WLP) MAX17205GEVKIT# (TDFN) |

| MAX17211 | 1-Wire® | 1 | MAX17211XEVKIT# (WLP) MAX17211GEVKIT# (TDFN) |

|

| MAX17215 | 1-Wire | Multiple | 2S, 3S Configurations | MAX17215XEVKIT# (WLP) MAX17215GEVKIT# (TDFN) |

#Denotes RoHS compliant.

Conclusion

ModelGauge m5 EZ simplifies fuel gauge integration into the system by eliminating the need for battery characterization.