Lithium Ion Battery Charger Allows Choice of Termination Method and Includes 100mA Adjustable Low Dropout Regulator

Lithium Ion Battery Charger Allows Choice of Termination Method and Includes 100mA Adjustable Low Dropout Regulator

by

Fran Hoffart

Dec 1 2005

Introduction

Lithium ion batteries, including lithium ion polymer, come relatively close to being the perfect battery: high energy density, lightweight, low self-discharge, high voltage (compared to other cells), no memory problem, low maintenance, and best of all, they are simple to charge. Of course, there are some disadvantages too, but let us leave that for later in this article.

Since many hand held products can operate from a single Li-Ion cell, many single cell chargers use a linear, rather than a switching topology. Linear chargers are simpler than switchers and comparably efficient at the low input-to-output voltage differential typical of portable devices.

This article presents a simple standalone 1A battery charger that combines many desirable charger features and an LDO regulator in a tiny 3mm × 3mm low profile DFN package. Also, a brief discussion on lithium ion battery pros and cons, and charging methods are discussed.

Lithium Ion Batteries Are Simple to Charge

There are several recommended methods for charging Li-Ion cells. One method is to apply a current limited constant voltage to the battery for three hours, then stop. Using this method, the battery will be 100% charged after 3 hours, provided the charge current is set between approximately C1 and C/2.

A second, similar method is to apply a current limited constant voltage to the battery while monitoring the charge current. During the first portion of the charge cycle, the charger is in constant current mode, with the battery voltage slowly rising as the battery accepts charge. As the battery voltage approaches the programmed constant (float) voltage, the charge current begins to drop exponentially. When the charge current drops to a sufficiently low value, the charger stops charging. Depending on the minimum charge current selected, the battery is between 95% and 100% charged. Since Li-Ion batteries are unable to absorb an overcharge, all charge current must stop when the battery becomes fully charged.

A Charger and an LDO Regulator in One Small DFN Package

The LTC4063 is a complete single cell Li-Ion battery charger that provides the user a choice of charge termination methods and includes an adjustable low dropout 100mA linear regulator. In addition to the usual constant-current/constant-voltage charge algorithm, other desirable features include power limiting that reduces the charge current under high ambient temperature and/or high power dissipation conditions. This allows the charger to provide higher charge currents under normal conditions and still provide safe charging under abnormal conditions such as high ambient temperature, high input voltage or low battery voltage.

The LTC4063 contains many common features of other Li-Ion chargers including trickle charge for low battery, auto recharge, charge current monitor, charge status output, capable of charging from USB power, low battery drain current when VIN is removed and precision (±0.35%) battery float voltage accuracy.

What sets this linear charger apart from other single cell chargers is the selectable charge termination and the onboard voltage regulator. Termination can be based on either total time, which is programmable, or minimum charge current which is also programmable, or the charge cycle can be stopped by the user via the charge enable pin.

The low dropout regulator, which is powered from the battery, is adjustable from 1V to almost 4.2V and can provide up to 100mA to a load. A low 15µA operating quiescent current and 2.5µA shutdown current extend battery life.

Charge Termination Methods: Which One to Use

The first portion of a charge cycle consists of forcing a constant current (typically 1C) into the battery until the cell voltage approaches the programmed float voltage (typically 4.2V ±1% or better) at which time the charge current begins to drop. For a depleted battery this occurs after approximately 30 minutes with the battery state of charge at approximately 55% of full capacity. Since the charge current drops rather quickly in the constant voltage portion of the charge cycle, the battery requires another 2 hours to bring the battery up to a 100% charge level. Unfortunately, there is not much that can be done to speed up this portion of the charge cycle without exceeding the recommended charge voltage.

Some chargers utilize a Negative Temperature Coefficient (NTC) thermistor that is located near or inside the battery pack to measure battery temperature. This protects the battery by not allowing a charge cycle to begin if the battery temperature is less than 0°C or greater than 50°C. During a normal charge cycle, there is very little temperature rise for Li-Ion batteries.

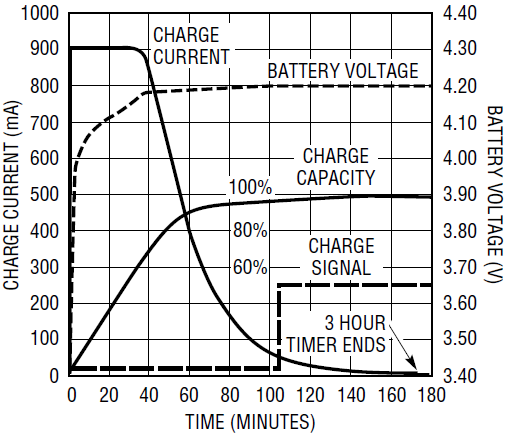

Figure 1 shows a LTC4063 charge cycle for a 900mAHr Li-Ion polymer battery charging at a 1C rate. The curves show the relationship between the charge current, battery voltage, charge capacity and the CHRG output signal. Since the timer termination method was selected, the charge cycle ended after approximately 172 minutes with the battery at 100% charge level. (Note: the charge current near the end of the charge cycle is a very low 6mA). Also shown in Figure 1 is the CHRG open drain output signal, which was programmed to go high when the charge current dropped below 50mA (IDETECT threshold) or approximately C/20.

Figure 1. Charge cycle of a 900mAHr Li-Ion cell charged at 1C using timer termination.

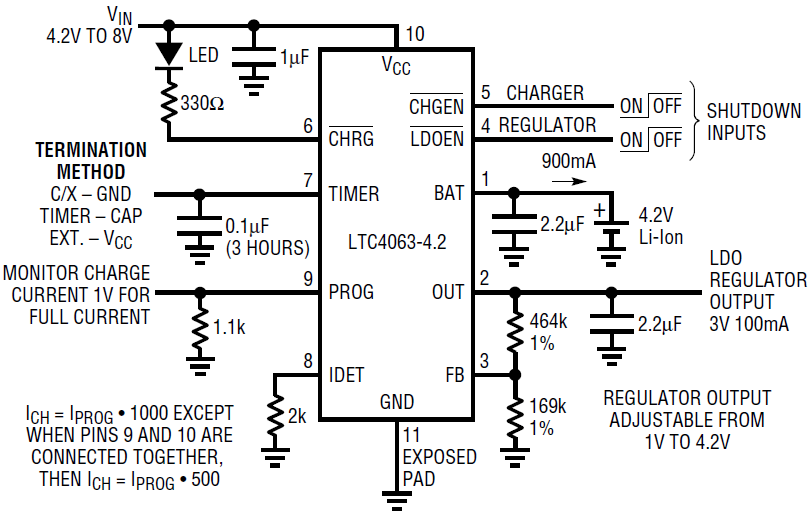

Figure 2. Complete single cell Li-Ion charger with timer termination, 50mA minimum charge current detection and 3V 100mA LDO voltage regulator.

Had the minimum charge current termination method been selected rather than the timer method, the charge cycle would have ended when the CHRG signal went high (after 105 minutes). At that point the battery is approximately 97% charged, and it would take another hour of charging for the last 3%. The programmable IDETECT current threshold level of the LTC4063 has excellent accuracy, even at current levels as low as 5mA. Programming a low IDETECT current and selecting minimum current termination would result in the charge cycle ending at approximately the same time as timer termination.

Which termination is better? From the previous paragraph, it appears that it may not make much difference because by selecting a low IDETECT current level, the two methods can be made virtually identical. Minimum charge current termination can have an advantage in a situation where different charge current levels may need to be selected during a charge cycle, or when charging a battery that still has a partial charge, the charge cycle can be very short. But timer termination may be better if a load that is greater than the programmed IDETECT current level is permanently connected to the battery. In that situation, the charge cycle may never terminate. Also, in timer termination, if the battery does not reach the recharge threshold of 4.1V when the timer ends, the timer is reset and a new charge cycle begins.

About Battery Capacity and Charge Current

The correct charge current is always related to a battery’s capacity, or simply “C”. The letter “C” is a term used to indicate the manufacturers stated battery discharge capacity, which is measured in mAHr. For example, a 900mAHr rated battery can supply a 900mA load for one hour before the cell is depleted. In the same example, charging the battery at a C/3 rate would mean charging at 300mA.

A Quick Primer on Rechargeable Li-Ion Batteries

Within the lithium ion family of batteries there are several formulations: mainly lithium cobalt oxide or lithium manganese oxide as the positive electrode, and either coke or graphite as the negative electrode. The electrolyte is a liquid in cylindrical cells or a solid or a gel in Li-Ion polymer cells. Since no liquid is used in the polymer cells, the cell package can consist of an inexpensive lightweight foil pouch which can be made in various shapes including very thin cells, ideal for cell phones and other small handheld devices. Although the discharge characteristics and performance of the different types of Li-Ion cells vary, the charging characteristics are essentially the same.

Rechargeable lithium battery technology is relatively new, and because of that, many improvements in future battery performance are almost guaranteed. Different materials, chemicals and construction will undoubtedly produce a battery that is ever closer to that perfect battery.

The recommended charge voltage is a compromise between cell capacity, cell life and cell safety. Higher charge voltages increase the mAhr cell capacity, but shorten the cell lifetime. There are also upper limits that must be adhered to for safety reasons. The most common charge voltage is 4.2V±1% although future battery designs may have a slightly higher voltage. In applications that favor cycle life over cell capacity, a lower charge voltage greatly increases cycle life. Shallow rather than deep discharge cycles increase cycle life as well. The end of life for a Li-Ion battery is typically when its capacity drops to 80% of its rating.

One lesser known fact about Li-Ion batteries is their aging characteristics. Li-Ion batteries have a limited lifetime whether they are stored or in daily use. The permanent capacity loss, especially for lithium manganese chemistries, increases with charge level and temperature. For example, storing a battery at a 40% charge level at 25°C for a year could result in a permanent capacity loss of 4%, whereas if stored at a 100% charge level, the permanent capacity loss would be close to 20%. Stored at 100% charge level at 40°C could produce a permanent capacity loss up to 35% after one year. Of course, further improvements in Li-Ion battery technology will surely minimize aging.

Li-Ion batteries cannot absorb overcharge. Charge current must be completely stopped when the battery reaches full charge. Overcharge can cause internal lithium metal plating, which is a safety concern. Also, Li-Ion batteries should not be discharged below 2.5V to 3V, depending on battery chemistry, as internal copper plating can form causing a short circuit.

Battery Pack Protection: What Is It?

Most manufacturers of Li-Ion batteries will not sell batteries unless they include built in battery pack protection circuitry for safety and to prolong battery life. The circuitry includes a FET switch in series with the battery that turns off in the event of an over voltage, under voltage, over current and over temperature condition when either charging or discharging the battery. A prolonged over voltage when charging can result in the battery overheating, bursting or even exploding. When discharging, the pack protection disconnects the battery if the battery voltage drops below a predetermined threshold level or if the battery current exceeds a preset limit. Without pack protection, Li-Ion batteries can easily be damaged or worse, can cause damage to other circuitry or bodily injury.

Conclusion

The LTC4063 Li-Ion battery charger provides the user with an excellent combination of packaging (3mm × 3mm DFN), high charge current (1A), tight float voltage (0.35%), low IDETECT current capability (5mA), choice of termination and an integrated 100mA LDO regulator. Two other chargers share similar charging characteristics but differ on features. The LTC4061 has no regulator but includes a NTC temperature qualification input, a USB current select input and an additional status output. The LTC4062 replaces the LDO regulator with a programmable comparator and reference and also includes a USB current select input.