100V Micropower No-Opto Isolated Flyback Converter in 5-Lead TSOT-23

100V Micropower No-Opto Isolated Flyback Converter in 5-Lead TSOT-23

by

Min Chen

Oct 1 2012

The non-synchronous flyback topology is widely used in isolated power supplies ranging from sub-watt power levels to tens of watts. Linear’s no-opto isolated flyback family dramatically simplifies isolated power supply design with proprietary primary-side sensing, which requires no opto-coupler or transformer third winding for output regulation. The new LT8300, the first micropower part in this family, significantly improves light load efficiency and reduces no-load input standby current to about 200µA.

The LT8300 operates from an input voltage range of 6V to 100V and delivers up to 2W of isolated output power. The 150V integrated DMOS power switch eliminates the need for a snubber in most applications. By sampling the isolated output voltage directly from the primary-side flyback waveform, the LT8300 requires no opto-coupler or transformer third winding for regulation. The output voltage is set with a single external resistor.

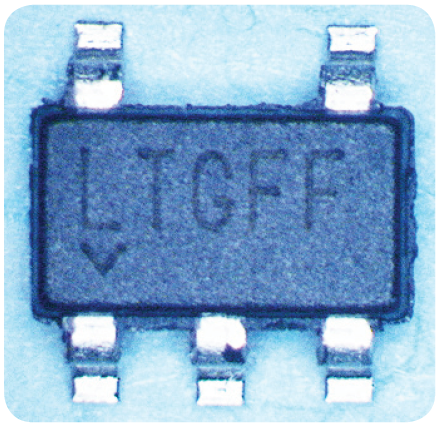

Internal loop compensation and soft start further reduce external component count. Boundary mode operation at heavy load enables the use of small magnetics and produces excellent load regulation. Low ripple Burst Mode operation maintains high efficiency at light load while minimizing output voltage ripple. All these features are packed in a 5-lead TSOT-23 package (Figure 1) with high voltage pin spacing conforming to IPC-2221 requirement.

Figure 1. The LT8300 is available in a 5-lead TSOT-23 package with high voltage pin spacing between pins 4 and 5.

Performance and Simplicity

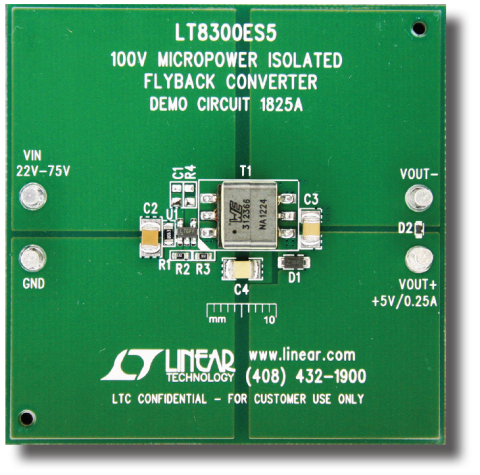

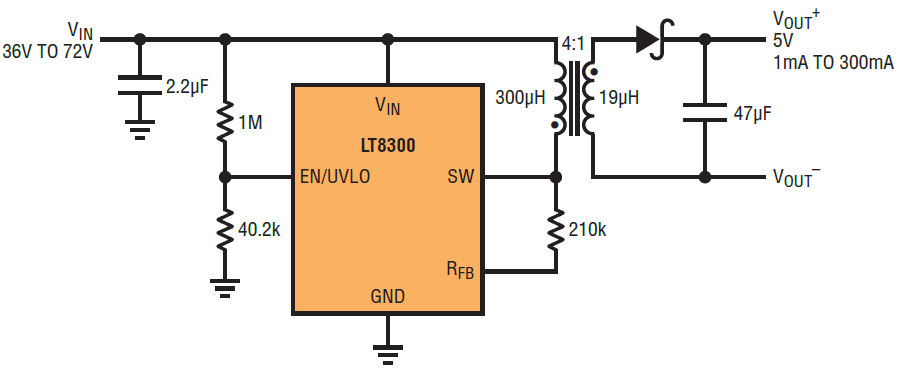

A complete isolated flyback solution fits into an area less than 1 by ½ inch, as shown in Figure 2. Figure 3 shows a typical LT8300 application, generating a 5V isolated output from a 36V-to-72V input. The solution only requires five external components (input capacitor, output capacitor, transformer, feedback resistor and output diode) and two optional undervoltage lockout resistors.

Figure 2. The LT8300 isolated flyback converter solution size is less than 1 inch by ½ inch in a standard demo board DC1825A.

Figure 3. A 5V/300mA micropower isolated flyback converter from a 36V-to-72V input.

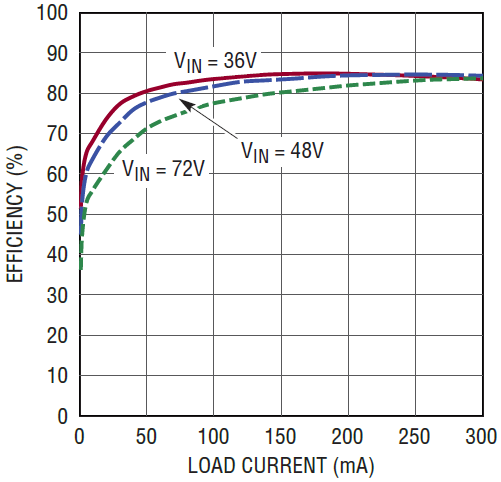

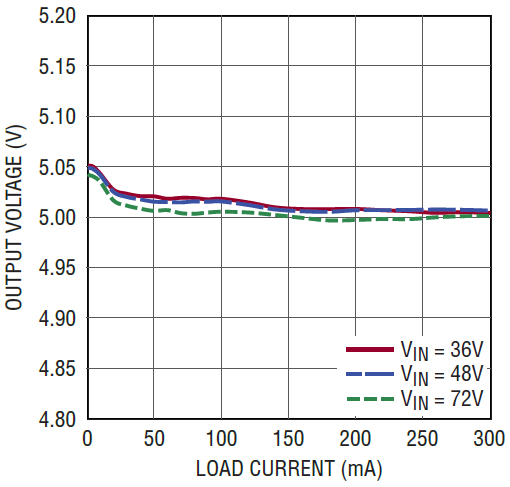

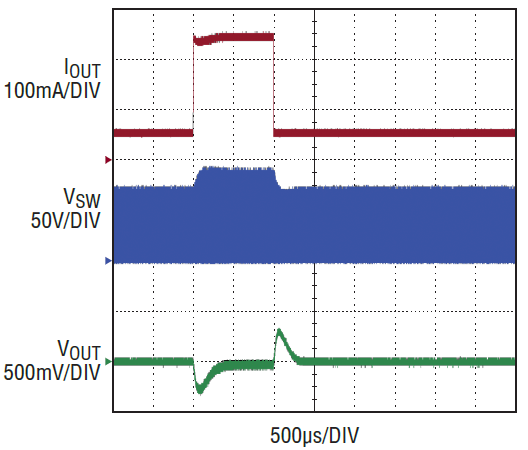

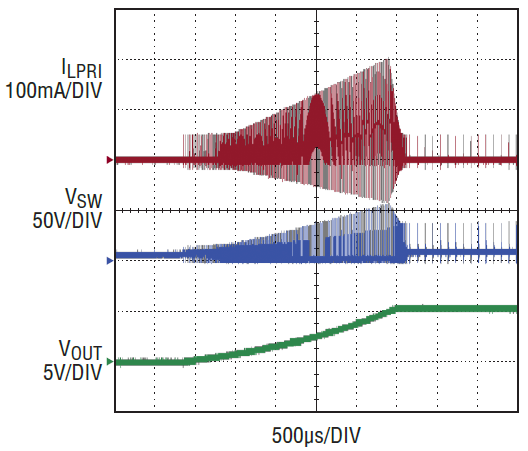

Although the LT8300 simplifies isolated flyback converter design, it delivers superior performance. Figure 4 shows the power efficiency (85% peak) of the 5V application in Figure 3. Figure 5 shows the load and line regulation (±0.5%) of the 5V application in Figure 3. Figures 6 and 7 show its 50mA-to-250mA load step transient and 1mA resistive load start-up waveforms, respectively.

Figure 4. Power efficiency of the 5V application in Figure 3.

Figure 5. Output load and line regulation of the 5V application in Figure 3.

Figure 6. 50mA-to-250mA load step transient waveforms of the 5V application in Figure 3.

Figure 7. 1mA resistive load start-up waveforms of the 5V application in Figure 3.

Post Regulator Eliminates Output Temperature Variation

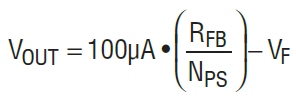

The output voltage in a typical LT8300 application can be expressed as

The first term in the VOUT equation does not have temperature dependence, but the output diode forward voltage VF has a significant negative temperature coefficient (–1mV/°C to –2mV/°C). Such a negative temperature coefficient produces approximately 200mV to 300mV voltage variation on the output across temperature.

For relatively high voltage outputs, say 12V and 24V, the output diode temperature coefficient has a negligible effect on the output voltage regulation. But for lower voltage outputs, such as 3.3V and 5V, the output diode temperature coefficient contributes an additional 2% to 5% output voltage regulation.

For designs requiring tight output voltage regulation across temperature, a micropower low dropout linear regulator can be added to post-regulate the LT8300 output. The LT8300 should be programmed slightly higher than the sum of the regulation voltage and the LDO’s dropout voltage.

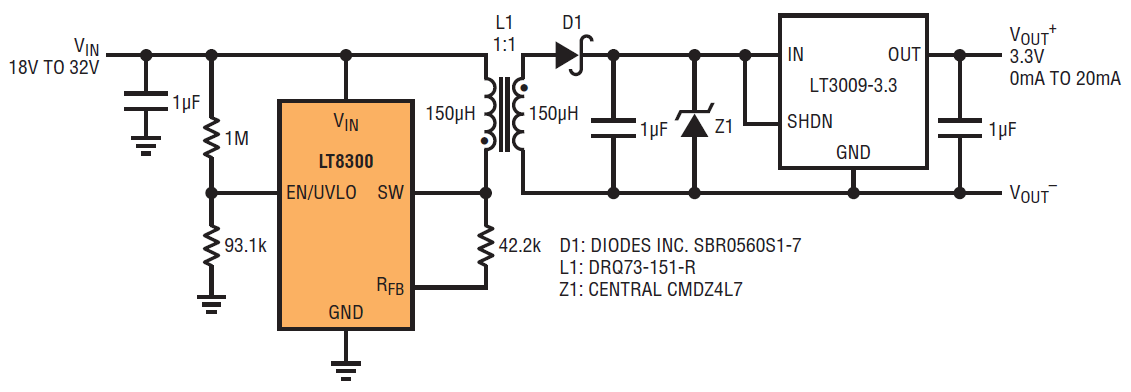

Figure 8 shows the LT8300 combined with a LT3009-3.3 post-regulator to generate a 3.3V/20mA isolated output from an 18V-to-32V input. The no-load input standby current is less than 250µA as shown in Figure 9, which conforms to DEF-STAN61-5.

Figure 8. A 3.3V/20mA micropower isolated converter from an 18V-to-32V input conforming to DEF-STAN61-5.

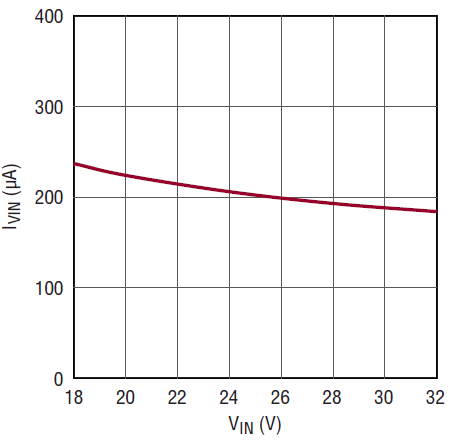

Figure 9. No-load input standby current of the 3.3V application in Figure 8.

Various Input-Referred Power Supplies

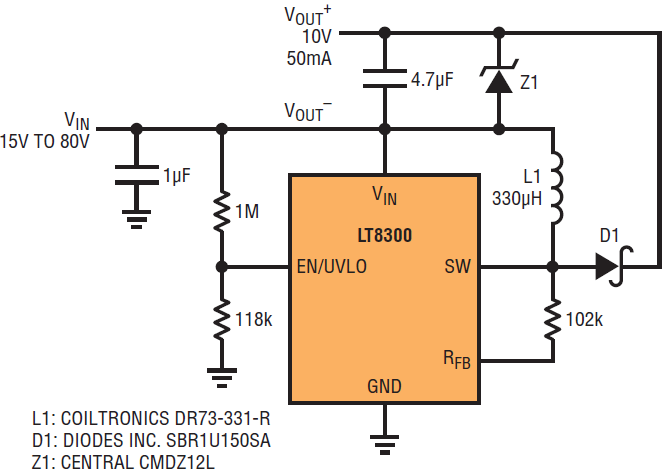

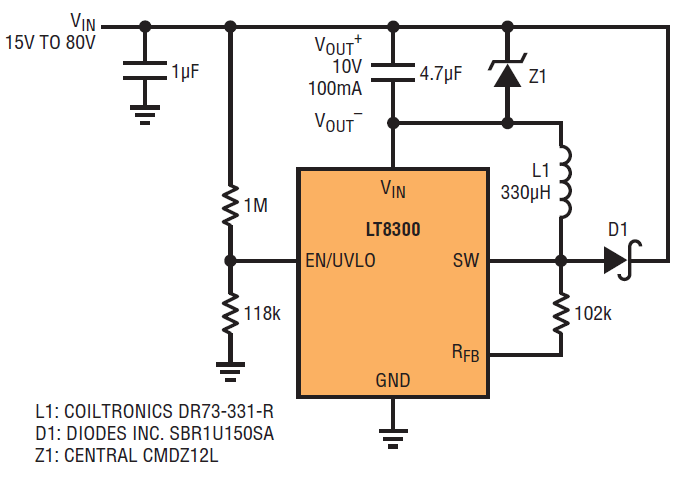

In addition to isolated power supplies, the LT8300 can be used in various non-isolated applications. Two interesting applications are input-referred positive and negative power supplies often used for special gate drivers. Figure 10 shows a simple VIN to (VIN +10V) micropower converter, and Figure 11 shows a simple VIN to (VIN – 10V) micropower converter. In both of these converters, the LT8300’s unique feedback sensing scheme is used to easily develop an output voltage that tracks VIN.

Figure 10. A VIN to (VIN + 10V) micropower converter.

Figure 11. A VIN to (VIN – 10V) micropower converter.

Conclusion

The LT8300 greatly simplifies the design of isolated flyback converters, improves light load efficiency and reduces no-load input standby current when compared to traditional schemes. The high level of integration and the use of boundary and low ripple burst modes results in a simple to use, low component count, and high efficiency solution for isolated power supplies, as well as various special non-isolated power supplies.