The Next Generation of Line Sensors: Power Harvested, Connected, and Lower Maintenance

思想领导力

The Next Generation of Line Sensors: Power Harvested, Connected, and Lower Maintenance

In today’s ever changing energy landscape, power outages continue to cost businesses millions of dollars by interrupting critical operations such as manufacturing. In addition, some power grid equipment in operation throughout the world has reached old age and, in some regions, major storms are becoming more common. Faced with these serious challenges, utility companies can cope with the risk of future service outages in a variety of ways including modernizing distribution networks, managing foliage growth, and hiring more line repair crews. All of these options can be complex to evaluate because they have varying degrees of cost, technical risk, and societal benefits.

A recent focus for utility companies has been locating, hiring, and training more line repair personnel to improve outage responses and achieve better results for customers. But in many parts of the world, the aging workforce effect is well-known, as it is increasingly difficult to find skilled labor and fill vacant line crew positions. Faced with the prospect of prolonged service outages, unhappy customers, and the possibility of government intervention, utility companies need better solutions. What if it were possible to improve the line crew’s work activity so that they allocate more time to actual repair and high priority maintenance and spend less time searching for broken wires?

Capturing Data at Power Grid Nodes Is Key

In the last few years, many countries have experienced prolonged power outages simply because the source of the problem was difficult to locate. But how do utility companies improve the distribution network architecture to achieve better outage response? The answer lies in taking advantage of better line sensor technology that enables lower system cost and deploys to more nodes within the power infrastructure. This technology features more integration, helps achieve better measurement accuracy, consumes less power, and needs less maintenance.

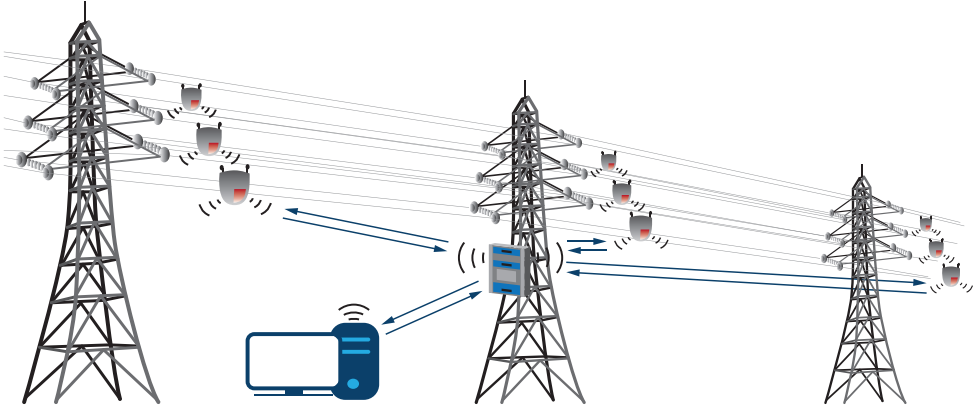

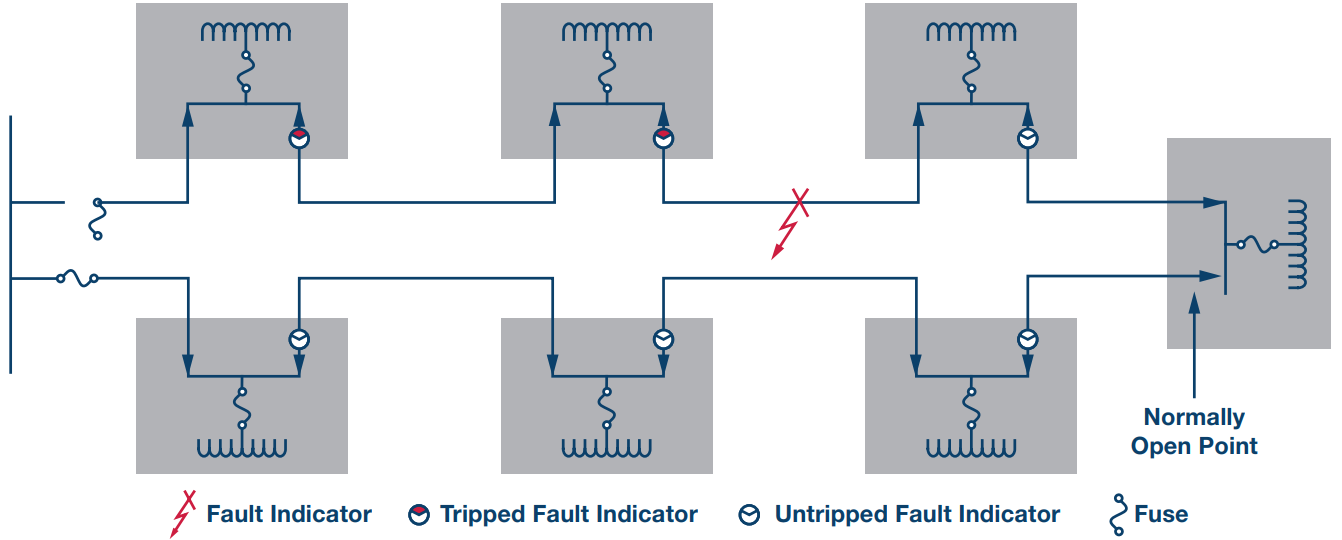

One of the most common use cases for new line sensors is a node monitoring system known as a fault indicator that detects and sends an alert when problems occur so that line crews can service faulted equipment with minimal delay. The diagram in Figure 1 shows fault indicators in use on power distribution lines. There are many names used across different geographies and different suppliers to describe this same system including line monitor, fault monitor, and fault circuit indicator. Throughout this article, this author will use the general term fault indicator for the system and line sensor for the underlying technology used for detecting the physical state of power lines.

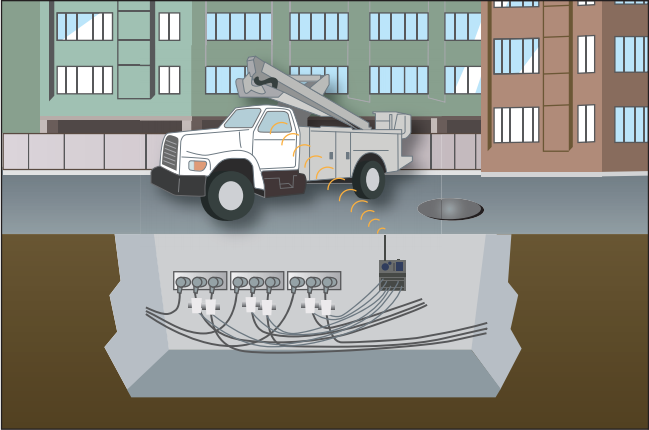

In underground applications, a fault indicator is placed at cable terminations along each primary cable. The indicators upstream of the fault will trip, and the indicators downstream of the fault will remain in the nontripped position. As a result, the service team can easily identify the faulted section of cable or equipment without going through a time consuming isolation process. Underground applications can include transformers, switchgear, cabinets, junction boxes, and splices.

In overhead applications, the easy to spot displays on fault indicators lead the line crew to the problem section of line. Overhead applications can include unfused taps, long feeders with midline reclosers, sectioning switchgear, transitions, and feeders.

Two of the biggest challenges associated with existing fault indicators are 1) they can be expensive to purchase in volume and 2) they require recurring maintenance in order to keep functioning properly. Cumulative purchase cost and recurring maintenance are two primary reasons why utility companies with limited budgets and resources are unable to deploy more fault indicators within their vast power infrastructure.

Improving Fault Indicators Through More Advanced Power Management

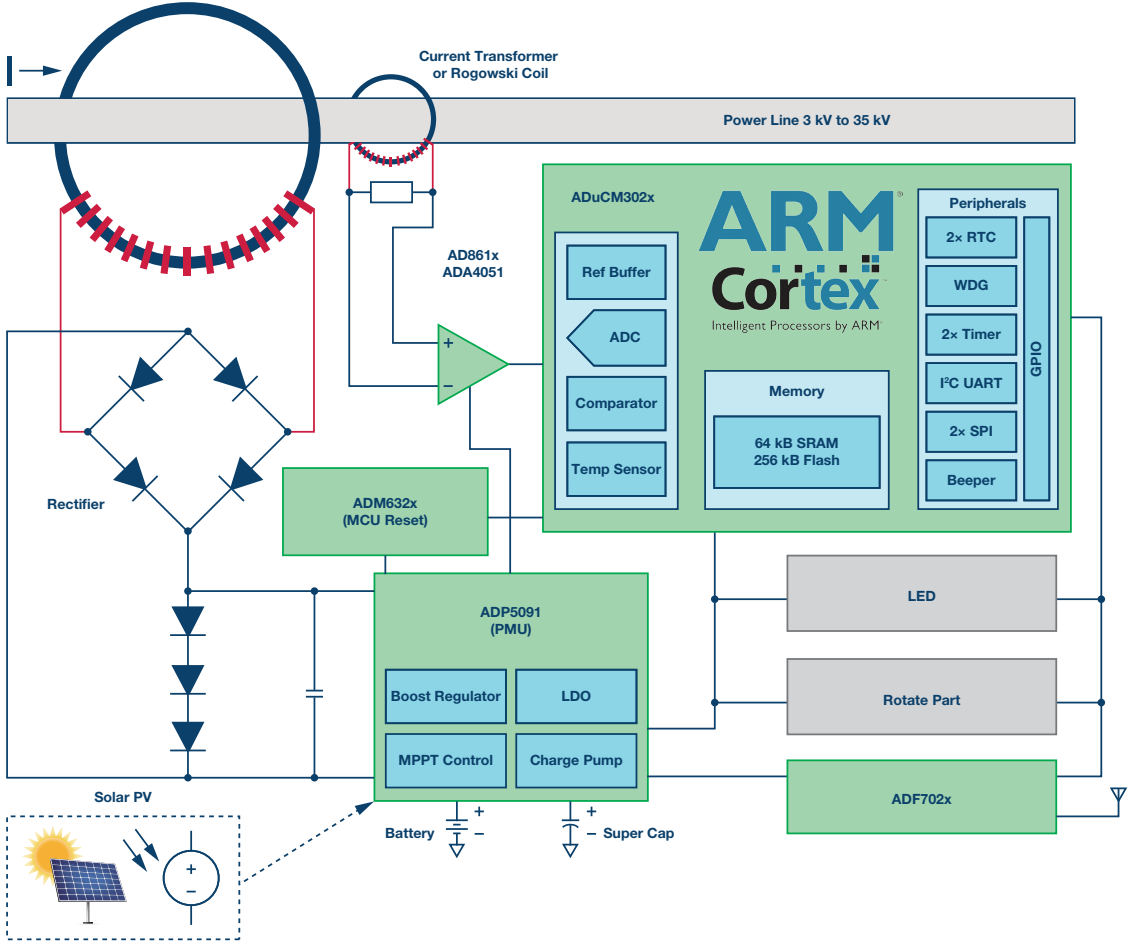

To address these challenges, Analog Devices developed a new line sensor architecture for fault indicators that harvests power at high efficiency and requires less maintenance (Figure 3).

采集电能的故障指示器基本功能看起来简单,但设计相当复杂,尤其是电源架构。其中不仅存在三个独立电源(电力线路传感器、充电电池和超级电容),而且必须有一个控制算法,用来平衡变化的供电条件和变化的负载条件——所有这些设计的目的是保证始终联网工作。关键创新是一种新型多电源路径设计技术,它支持系统更快启动、功耗更低和运行更平稳。通过采用更好的电源管理,电池更换的频率会降低,线路工作人员执行系统检查的次数会减少,因而故障指示器所需的维护会减少。

新型故障指示器设计还能利用更复杂的数据收集技术和更鲁棒的无线通信来提升性能。通过高速精密转换器以远高于电力线路频率的数据速率收集电力线路信息,它们能捕获更高精度的数据。集成短波无线电和GSM协议等无线通信,也能扩大这些设备的覆盖范围。故障指示器可以传输数据和报告其状态,这样线路工作人员搜索故障所花的时间会减少,因而有更多时间来排除故障。

Opportunities for Big Data Analytics that Drive Better Energy Intelligence

Fault indicators that take advantage of advanced line sensor technology present an opportunity to transform the way in which utility companies operate. By collecting data at the node that is more granular, better connected, and less expensive to maintain, utilities can identify and respond to outages faster and with higher confidence. But there are other possibilities to consider. For example, an entire population of fault indicators can provide historical data and alerts so that utilities can apply machine learning algorithms and analytics to drive more efficient line crew activity, lower operating expenses, and achieve better business outcomes.

Conclusion

Utility customers continue to experience prolonged power outages because problems are difficult to locate. One way to overcome this scenario is broader adoption of fault indicators. But two of the biggest drawbacks associated with today’s fault indicators are their high price tag for volume purchases and their periodic maintenance needs.

There is a new line sensor technology for fault indicators that overcomes these challenges by harvesting power at high efficiency and requiring less maintenance. In the future, utility companies can take advantage of next-generation fault indicators and benefit from shorter outages, lower operating expenses, and more satisfied customers.

关闭详情

关闭详情