PD Interface for PoE+ Includes 25.5W Classification and Protection Features in a Low Profile 4mm × 3mm DFN

PD Interface for PoE+ Includes 25.5W Classification and Protection Features in a Low Profile 4mm × 3mm DFN

by

Kirk Su

2009-01-01

Introduction

The third generation Power over Ethernet standard increases the power available to PDs to 25.5W, up from the earlier standard’s 12.95W (see sidebar). In the new standard, a Type-2 (high power) PD must communicate via handshake with Type-2 power sourcing equipment (PSE) to determine that the PSE is capable of providing high power. Type-2 PSEs are backwards compatible to the old standard.

The LTC4265 is a PoE PD interface that can identify 2-event classification (see sidebar) protocol and present an active signal as required for operation in an IEEE 802.3at-compliant PD. In addition, the LTC4265 may be configured for a variety of auxiliary power options with the aid of the shutdown and signature corrupt features.

The LTC4265 is highly integrated and easy to apply, requiring only one classification programming resistor. No additional external components are required to program the LTC4265 since all features (signature resistance, UVLO, OVLO, inrush current, and thermal protection) are built in and programmed into the LTC4265 to guarantee a smooth power-up transition and PD operation with any Power Sourcing Equipment (PSE). This eliminates additional component costs and cumbersome calculations that are required in other power interface products to set thresholds, signature resistance, and current limits. The LTC4265 comes in a low profile, thermally enhanced, 4mm × 3mm DFN package.

Overview of the Third Generation

Power over Ethernet System (PoE+)

The Power over Ethernet (PoE) standard specifies how DC power can be distributed alongside high speed data through a single RJ45 connector. The second generation standard (IEEE 802.3af) allows Powered Devices (PDs) to draw 12.95W from Power Sourcing Equipment (PSEs). The popularity of the standard has PD equipment vendors running up against the 12.95W power limit. To answer the call for more power, the newer IEEE 802.3at standard (also called PoE+) establishes a high power allocation while maintaining compatibility with the existing IEEE 802.3af systems.

In the new standard, PSEs and PDs are distinguished as Type-1 if they comply with the IEEE 802.3af power levels, or Type-2 if they comply with the IEEE 802.3at power levels. The maximum available power to a Type-2 PD is 25.5W.

The IEEE 802.3at standard also establishes a new method for Type-2 equipment to mutually identify each other while maintaining compatibility with the existing PoE systems. A Type-2 PSE has the option of declaring the presence of high power by performing 2-event classification (Layer 1) or by communicating with the PD over the data line (Layer 2). In turn, a Type-2 PD must recognize both layers of communications and identify a Type-2 PSE before beginning 25.5W operations.

What is 2-Event Classification?

The IEEE 802.3at establishes two ways to communicate the presence of a Type-2 PSE. The Layer 1 approach requires a PSE to perform 2-event classification, where classification probing is performed twice. The Layer 2 approach requires the PSE to communicate over the high speed data line. A Type-2 PD is required to recognize a Type-2 PSE using either layer of communication. Layer 1 communication using 2-event classification is included in the IEEE 802.3at standard for the benefit of PSEs/power injectors which do not have access to the high speed data line.

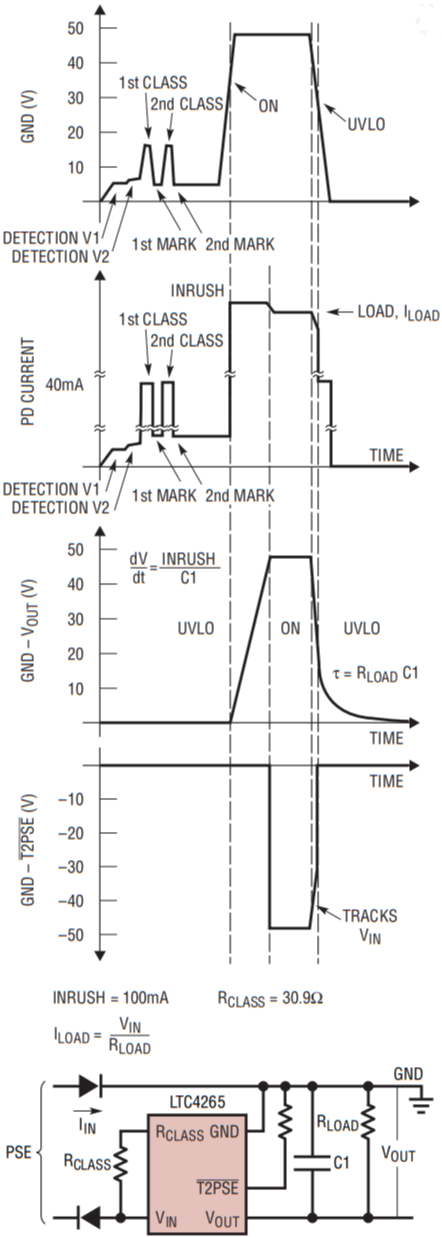

Since Layer 2 communications takes place directly between the PSE and the LTC4265 load, the LTC4265 concerns itself only with recognizing 2-event classification. Figure 1 shows an example of a 2-event classification. The 1st classification event occurs when the PSE presents an input voltage between 14.5V to 20.5V and the LTC4265 presents a class 4 load current. A Type-2 PSE then drops the input voltage into the Mark voltage range of 6.9V to 10V, signaling the 1st Mark event. The PD in the Mark voltage range presents a load current between 0.25mA to 4mA. A Type-2 PSE repeats this sequence, signaling the 2nd Classification and 2nd Mark event occurrence.

Figure 1. Example of 2-event classification waveform.

The Type-2 PSE then applies power to the PD and the LTC4265 charges up the reservoir capacitor C1 with a controlled inrush current. When C1 is fully charged, and the LTC4265 declares power good, the T2PSE output presents an active low signal, or low impedance output with respect to VIN, which alerts the PD load that a Type-2 PSE is present and 25.5W applications may operate.

In essence, a Type-2 PSE recognizes a Type-2 PD when the PSE classifies the PD and sees a class 4 load current. A Type-2 PD recognizes a Type-2 PSE when the PSE classifies twice.

Interfacing to the LTC4265

The LTC4265 has three output signals that interface to other blocks within a PD. The Type-2 PSE indicator bit (T2PSE) alerts the PD load that it may consume the full 25.5W available in the new IEEE 802.3at specification. Two complementary power good pins (PWRGD and PWRGD) are typically used to enable a DC/DC converter after the PD is fully powered.

When a Type-2 PSE completes the 2-Event classification sequence, the LTC4265 recognizes this sequence, and provides an indicator bit, declaring the presence of a Type-2 PSE. The open drain output provides the capability to use this signal to communicate to the PD load.

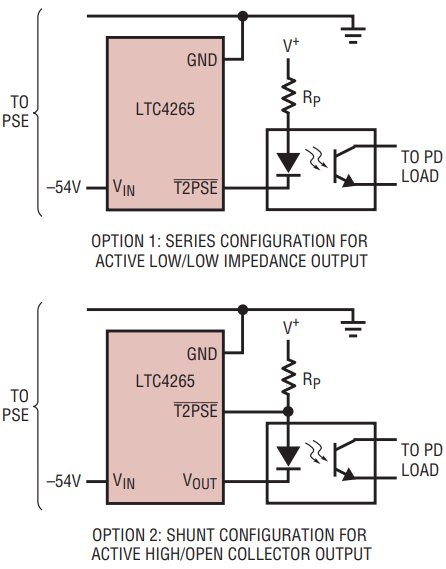

Figure 2 shows two interface options using the T2PSE pin and an optoisolator. The T2PSE pin is active low and connects to the optoisolator to communicate across the isolation barrier. The pull up resistor RP is sized according to the requirements of the optoisolator operating current, the pull-down capability of the T2PSE pin, and the choice of V+. V+ can come from the PoE supply rail (which the LTC4265 GND is tied to), or from the voltage source that supplies power to the DC/DC converter. The former has the advantage of not drawing power unless T2PSE is declared active.

Figure 2. Interfacing with the Type-2 PSE via the T2PSE pin.

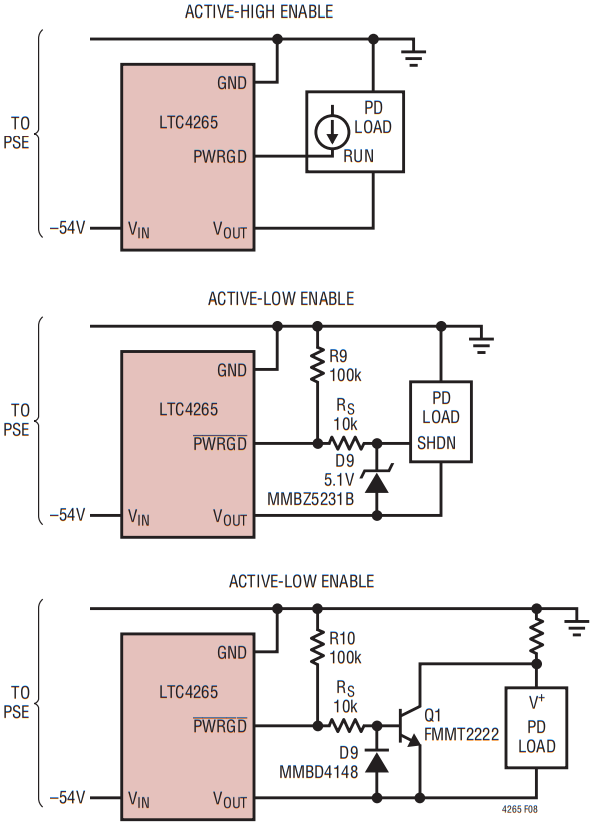

Figure 3 shows options for interfacing the LTC4265 power good pin to the PD load, usually via the run/enable/shutdown pins of a DC/DC converter.

Figure 3. Examples of enabling/disabling the PD load via the complementary power good pins.

The active high PWRGD pin features an open collector output referenced to VOUT, which can interface directly with the run/enable pin of a DC/DC converter. When the PD is powered up by the PSE, the PWRGD pin is high impedance with respect to VOUT. An internal 14V clamp protects the DC/DC converter from excessive voltage. The PWRGD pin is also designed to become high impedance when the SHDN pin is invoked in an auxiliary power application. This prevents the PWRGD pin from interfering with the converter operation when auxiliary power is present.

The active low PWRGD pin connects to an internal, open drain MOSFET referenced to VIN and can interface directly to the shutdown pin of a DC/DC converter. When the PD is powered up by the PSE, the PWRGD pin is low impedance with respect to VIN.

Configuring a PD for Auxiliary Power

In many applications, the PD can run from the PoE port and/or from an auxiliary power source such as a wall adapter. Auxiliary power can be injected into an LTC4265-based PD at the input of the LTC4265, the output of the LTC4265, or even the output of the DC/DC converter. Some PD applications may also prioritize the auxiliary supply or the PoE supply, and/or require a seamless transition between PoE and auxiliary power.

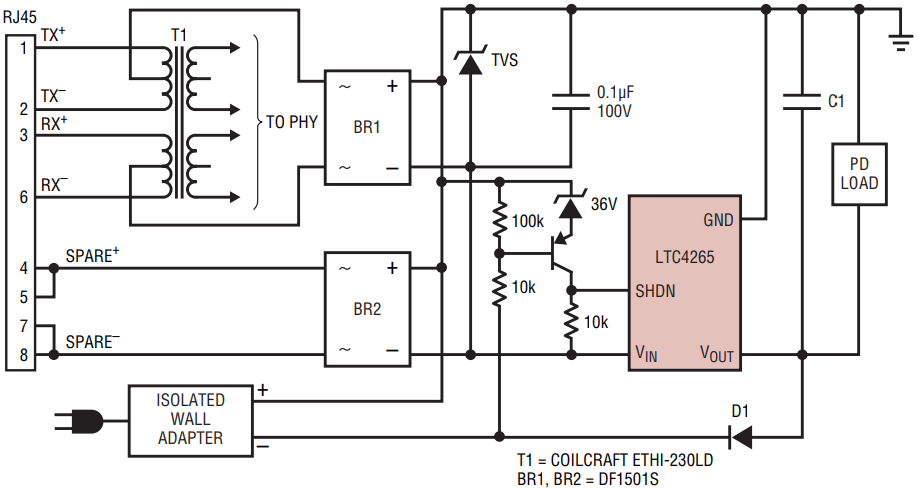

Figure 4 shows the most common auxiliary power method where auxiliary power is injected between the PD interface and the DC/DC converter. In this example, the auxiliary port injects 48V onto the line via diode D1. The components surrounding the SHDN pin are selected so that the LTC4265 disconnects power to the output when the auxiliary supply reaches 36V.

Figure 4. Auxiliary power supply. Auxiliary power takes precedence over PoE power (using the SHDN pin).

This configuration is an auxiliary-dominant configuration. That is, the auxiliary power source supplies the power even if PoE power is already present. When the auxiliary power is applied, the PoE channel stops drawing power. The PSE at this point recognizes that the PD does not draw any current and may cease power delivery to the PD.

This configuration also provides a seamless transition from PoE to auxiliary power when auxiliary power is applied. That is, the DC/DC converter continues to operate through the power transition. But the transition from auxiliary power to PoE power (when the auxiliary is removed) is not seamless since a PSE must redetect the PD before applying power.

Guidelines for Pairing the LTC4265 with a DC/DC Converter

The LTC4265 can be paired with just about any DC/DC converter, but two are particularly well suited to Type-2 Power over Ethernet Applications: the LT3825 flyback controller and LT1952 forward controller. Forward and flyback converters satisfy the electronic isolation requirement in the IEEE 802.3af and IEEE 802.3at specifications. In addition to the topology requirements, the LT3825 and LT1952 controllers are selected based on their ability to tolerate the wide PoE line voltage range, which varies from 36V to 57V.

As PoE power levels increase, the Schottky diode typically placed at the output of the secondary winding becomes an efficiency drain as it dissipates more power with increased output current. In addition, the output diode requires a considerably large heat sink and board area to displace the heat.

For these reasons, many power-hungry PDs are better served by synchronous DC/DC topologies, where the output diode is replaced with an active switch synchronized to the operation of the controller. Both the LT3825 and LT1952 include built-in synchronous drivers, enabling the use of an active switch.

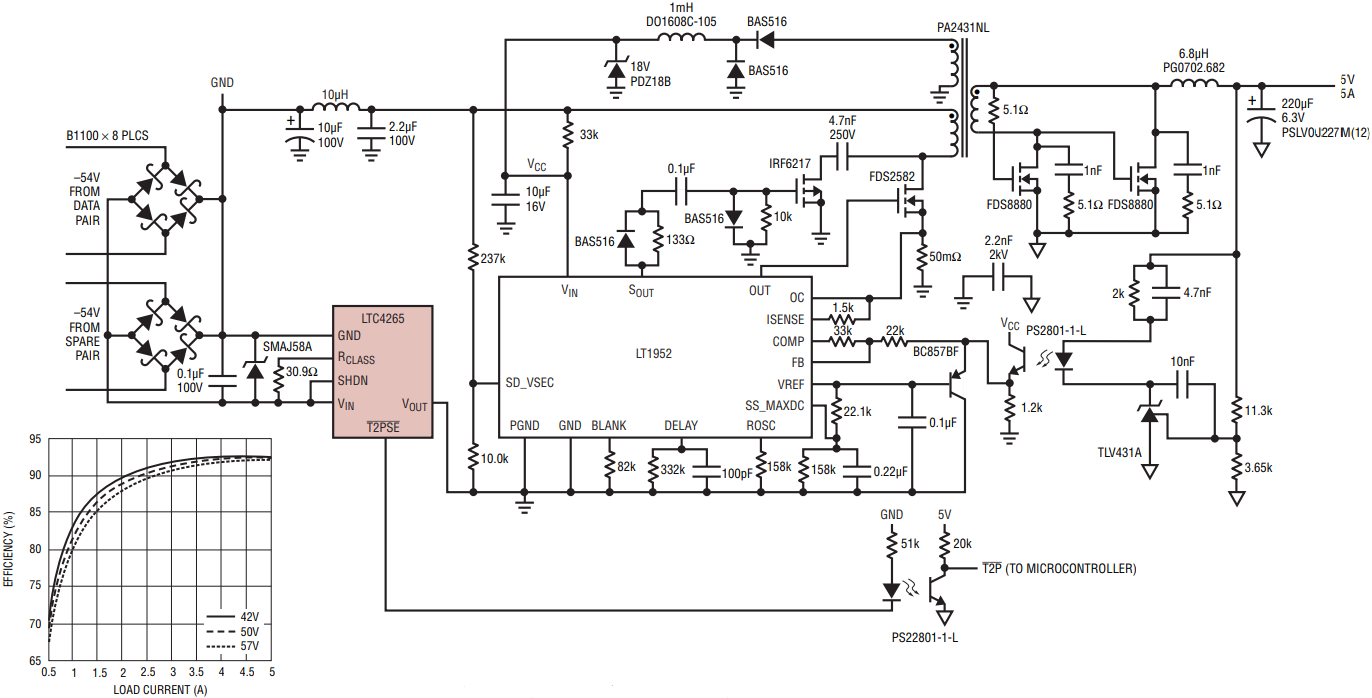

Figure 5 shows the LTC4265 paired with an LT1952 in a self-driven synchronous forward power supply configuration. Figure 6 shows the LTC4265 paired with a LT3825. This is a synchronous flyback power supply configuration with no optoisolator feedback. The LT3825 may also be configured for a forward topology.

Figure 5. PoE-based self-driven synchronous forward power supply.

Figure 6. High efficiency 12V isolated power supply.

These are not the only DC/DC converter solutions that work well with the LTC4265. The LTC4265 can be easily applied in applications that already have a DC/DC converter.

Conclusion

The LTC4265 PD interface provides the features required in a PD interface to operate under the IEEE 802.3at standard with minimum component count. Since all of the features (signature resistance, UVLO, OVLO, inrush current, and thermal protection) are built in, little is needed around its low profile 4mm × 3mm DFN package to create a complete PoE Type-2 interface. Simply pair it with a PoE-ready DC/DC converter by hooking up the Type-2 and power good indicator pins, and a high power PD is ready to go. Add to this the ability to handle auxiliary power, and the LTC4265 proves a versatile PoE+ tool.