面向工业资产健康监测的新型边缘传感解决方案

摘要

本文深入探讨了一款先进的智能振动传感器,重点介绍它基于微机电系统(MEMS)技术的设计、功能和应用。这款传感器的核心目标是在各种工业和研究环境中提供高精度、高可靠性和实时监测能力,展现ADI公司不同MEMS传感技术的实际应用价值。

引言

在现代工业环境中,对机械健康状态进行精确、可靠且实时的监测变得空前重要。状态监控(CbM)系统已成为预测性维护策略的基石,旨在尽可能地减少停机时间、提高生产率并降低维护成本。采用微机电系统(MEMS)技术的先进传感器,结合复杂的诊断算法,正在拓宽能够评估的各类机械的范围。MEMS加速度计的性能近年来取得了进步,已具备与压电振动传感器分庭抗礼的实力。这类MEMS振动传感器不仅拥有低功耗、小尺寸、高集成度、宽带宽等关键优势,噪声水平更低于 100 μg/√Hz ,为维护和设备工程师开辟了全新的CbM范式,助力检测、诊断、预测和规避机器故障。得益于MEMS加速度计的超低功耗特性,有线系统逐步被无线解决方案替代,单轴压电传感器也升级为小巧轻便的三轴模拟器件,更广泛的机械设备得以通过经济高效的方式实现持续监测。本文将探讨基于MEMS技术的振动传感器最新成果,尤其是先进的AVS 1001HF(高频)与AVS 1003LF(低频)加速度计。

状态监控

面向机器人及涡轮机、风扇、泵、电机等旋转机械的状态监控传感器(CMS),可实时记录与机械健康状态及运行性能相关的数据,从而实现针对性的预测性维护和优化控制。在机械生命周期的早期阶段,开展针对性的预测性维护可降低生产停机风险,进而提高可靠性并显著节省成本,让工厂车间的生产效率更上一层楼。据统计,对于遭遇过意外停机的企业而言,平均每次停机持续4小时,每次造成200万美元损失,且这类企业平均每年会发生2次停机事件。1,2

CbM的重要性

CbM的主要功能是提供实时数据,为机械的维护计划提供依据。这种数据驱动的方式确保仅在必要时才进行维护,从而预防意外故障并延长设备的使用寿命。通过减少意外停机,CbM系统有助于维持连续的生产流程并优化资源分配。

具体的解决方案是什么?

这些加速度计代表了工业资产健康监测领域的重大进步。这款传感器的核心目标是在各种工业和研究环境中提供高精度、高可靠性和实时监测能力,展现ADI公司不同MEMS传感技术的实际应用价值。

通过整合高频与低频振动测量能力,结合实时数据处理与传输功能,这些传感器为预测性维护提供了全方位解决方案。它们易于集成、用途广泛且精度出众,成为工业环境中提升生产效率、减少停机时间、优化维护策略的得力助手。

AVS传感器系列重新定义了状态监控,不仅提高了机械设备的运行效率,更为工业资产健康管理树立了新标杆。随着各行各业不断采用智能技术,像AVS系列这样的先进传感器将在推动下一代工业自动化与维护发展方面发挥更加关键的作用。

此解决方案有何优势?

全新AVS传感器系列的一大核心优势在于重新定义了状态监控。传统的状态监控(CbM)需要传感器、大量布线以及专用的数据采集/处理单元。而借助智能AVS传感器,所有这些功能如今都可在传感器内部完成。分析结果能直接发送至可编程逻辑控制器(PLC)或监测与数据采集(SCADA)系统。通过使用数字RS-485接口,仅需一根线缆就能连接多个传感器。

另一重要优势是AVS传感器应用的灵活性:器件正常运行时,仅需发送计算得出的参数;若需要更深入的分析,则可发送原始振动信号并进行解析。

AVS 1001HF和AVS 1003LF传感器

AVS 1001HF传感器

AVS 1001HF是一款单轴数字式高频加速度计,除了可测量振动外,还具备温度检测功能。这款传感器可对振动加速度信号进行处理,通过工业标准的RS-485数字接口及Modbus协议输出数据。它能提供两类数据:振动原始数据流或经计算得出的振动信号参数(见图1)。

AVS 1003LF传感器

AVS 1003LF是一款三轴数字式低频加速度计。与AVS 1001HF类似,它可同时测量振动与温度,并通过RS-485接口及Modbus协议传输数据,旨在实现三个轴向的全方位监测(见图2)。

这两款传感器的详细技术指标参见表1。

| 技术规格 | AVS 1001HF | AVS 1003LF |

| 测量范围 | ±50 g, 峰值 | ±40 g, 峰值 |

| 频率范围 | 0 to 11 kHz | 0 to 1 kHz |

| 采样频率 | 32 kHz | 4 kHz |

| 噪声密度 | 25 µg/√Hz | 80 µg/√Hz |

| 工作电压 | 24 V DC | 24 V DC |

| 电流消耗 | 13 mA | |

| 工作温度 | -40°C to 至85°C | |

| 保护 | IP67 | |

| 抗冲击性 | 10,000 g, 峰值 | 5,000 g, 峰值 |

应用:

- 保护

- 机器监测

- 状态评估

- 动态状态测量

新型AVS传感器系列的优势

直接访问数字数据

集成了数字数据直接访问功能后,无需大量布线,也无需专用的数据采集/处理单元,所有功能均在传感器内部完成,不仅显著简化了安装流程,还降低了整体成本。

应用的多功能性

AVS传感器具备出色的多功能性。正常运行时,仅发送计算得出的参数,可节省带宽和处理能力;如需更深入的分析,可传输并解析原始振动信号,从而更透彻地掌握机械的状态。

可靠的数据传输

通过使用数字RS-485接口,单根线缆即可连接多个传感器,确保在1公里范围内实现可靠的数据传输,从而尽可能地减少了工业噪声干扰,同时为传感器网络的扩展提供了便利。

高精度与低噪声

两款传感器均具有高灵敏度和低噪声特性,提升了振动数据的准确性。AVS 1001HF的灵敏度高达100 mV/g,噪声密度为4 µg/√Hz;AVS 1003LF的噪声密度为80 µg/√Hz ,即便在复杂的工业环境中,也能保证测量的精准性。

MEMS技术

此类传感器的核心优势源于MEMS技术,能够将微型尺寸与高性能有效结合。MEMS传感器具备坚固耐用的特性,对于高要求的工业应用而言至关重要。

高带宽和三轴传感的重要性

高带宽:用于捕捉故障

ADXL1002单轴加速度计拥有11 kHz、3 dB的带宽,对捕捉高频轴承及齿轮故障而言不可或缺,因为低带宽传感器极易遗漏此类故障。凭借高带宽能力,可对关键部件进行精细化分析,确保及早发现并预防潜在故障(见图 3)。

三轴传感:实现全方位监测

三轴传感解决方案(如AVS 1003LF所提供的方案)对于预测单轴传感器可能遗漏的故障至关重要。通过捕捉三个轴向的数据,这些传感器能够更全面地呈现机械的运行状态,从而优化故障预测与维护计划的制定。

案例研究

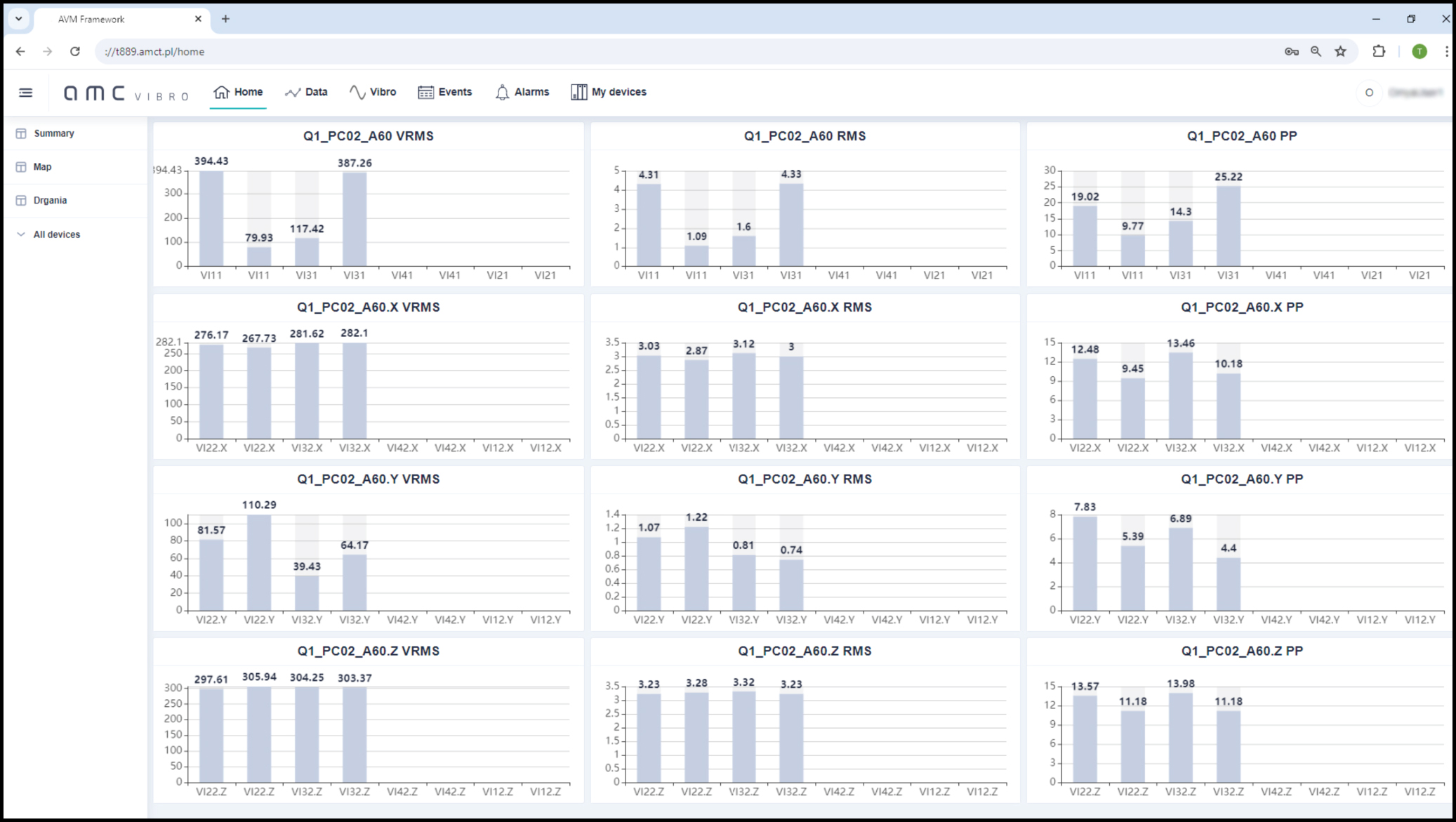

AVS 1001HF与AVS 1003LF加速度计已整合至AMC云端状态监控系统中。传感器采集的原始信号传输至边缘处理单元,计算出诊断特征后,再将数据发送至云服务器。客户可快速便捷地获取有关机械健康状态的信息。系统提供的图表包括:设备分布图、自定义模拟图(含柱状图等多种组件)、报警信息、趋势图、波形图、频谱图等。图4展示了系统提供的部分图表。

可配置的柱状图方便操作人员快速评估。若出现超限情况,柱形会改变颜色:黄色表示警告,红色表示报警。还可添加图片及其他组件,使信息更通俗易懂且直观易用。

另一种一级图表是事件/警报视图(图5)。操作人员可查看当前活跃的阈值超限情况,也可查阅历史变化记录。当然,系统提供了多种筛选选项,能让操作人员大幅节省时间。

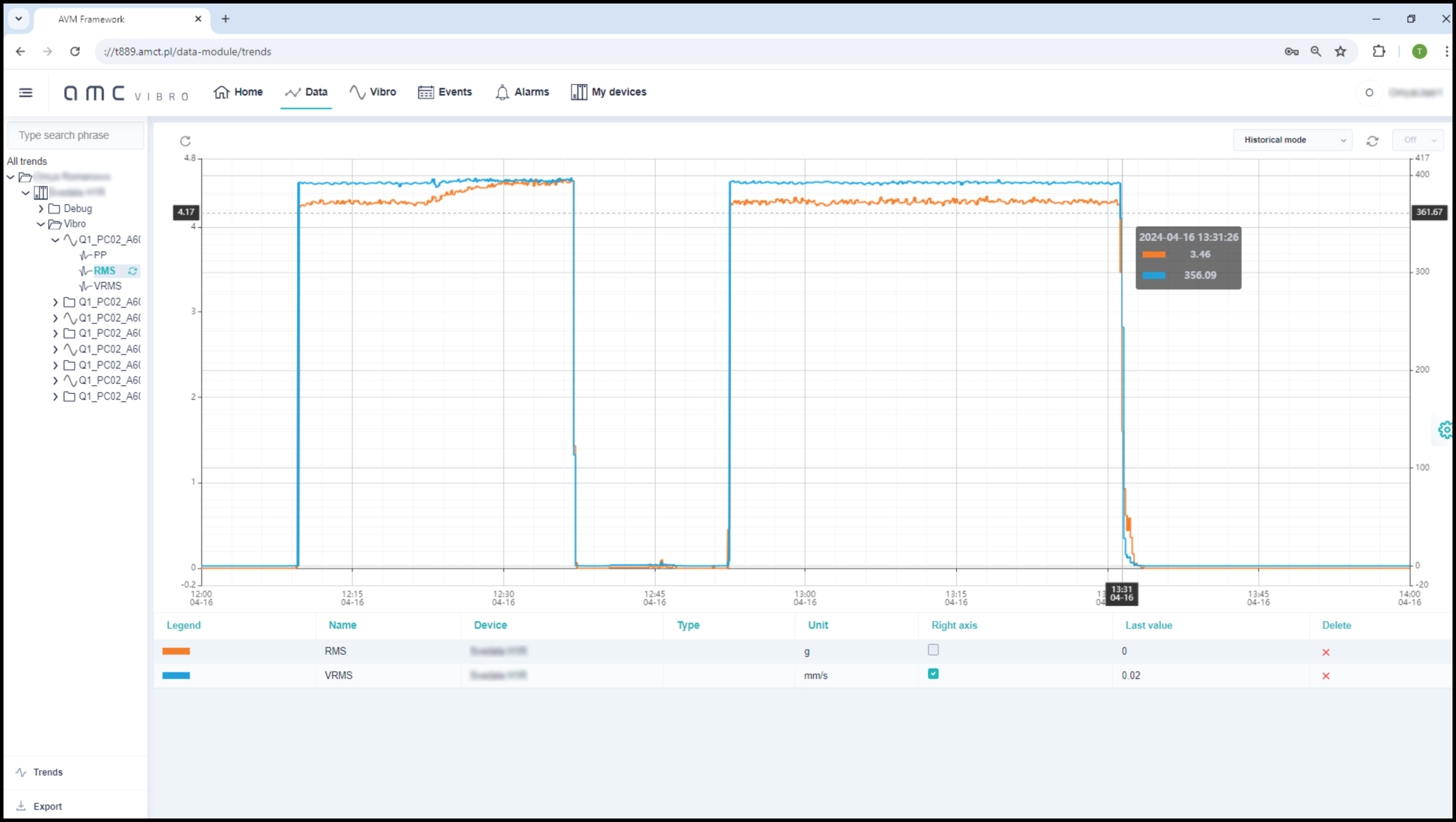

趋势图展示了所选振动参数(均方根值和速度均方根值)的历史变化(图6)。用户可快速掌握这些参数随时间的变化特征,例如波动性、上升趋势,或与其他测量值的相关性。

有时,我们需要更深入的分析。多数情况下,需找出振动水平升高的原因,而对原始振动信号的分析正是探究根源的关键所在。振动专家可通过波形图和频谱图对这些信号进行分析。

此外,通过数字协议(如Modbus、OPC UA和MQTT),可轻松实现与其他系统的数据交互。另一实用功能是能够将关注的数据导出至文件,以便进行深入透彻的分析(见图7)。

这些数据来自一台筛分机,其上总共使用了8个传感器(4个高频传感器和4个低频传感器)。图8展示了其中一个安装在轴承上的传感器。

安装结果表明,这些传感器不仅功能完备,且具备在恶劣环境中持续监测资产状态的能力。

结语

AVS 1001HF和AVS 1003LF加速度计代表了工业资产健康监测领域的重大进步。通过整合高频与低频振动测量能力,结合实时数据处理与传输功能,这些传感器为预测性维护提供了全方位解决方案。它们易于集成、用途广泛且精度出众,成为工业环境中提升生产效率、减少停机时间、优化维护策略的得力助手。

AVS传感器系列重新定义了状态监控,不仅提高了机械设备的运行效率,更为工业资产健康管理树立了新标杆。随着各行各业不断采用智能技术,像AVS系列这样的先进传感器将在推动下一代工业自动化与维护发展方面发挥更加关键的作用。

参考文献

1 Graham Immerman,“The Actual Cost of Downtime in the Manufacturing Industry”,IIoT World,2018年11月。

2 “What Downtime Really Costs—and Why Maintenance Contracts Make Sense”,Sumitomo Drive Technologies,2025年4月