摘要

As consumer devices continue to shrink in size, power considerations and appropriate thermal design become increasingly important for circuit designers and board layout engineers. This tutorial helps designers to ensure that a board is both electrically sound and thermally balanced for proper operation and optimum efficiency.

A similar version of this article appeared in the October 31, 2011 issue of EDN.

A Quick Thermal Tutorial

In general, thermal equations for semiconductor devices can be modeled after electrical equations, such that the well known and beloved Ohm's Law (V = I × R) becomes ΔT = P × θ, where ΔT is the thermal differential in °C, P is the power in watts, and θ is the thermal impedance (°C/W). For semiconductor devices, ΔT is the temperature differential from the junction of the device (e.g., the hottest point in the die) and another point (e.g., the case, ambient air, or board), and the thermal impedance, θ, is the thermal resistance from one point to another. Thermal impedance is often measured from the junction of an IC to another point (the ambient air, package, case, or board) and is described as junction-to-ambient resistance, θJA, junction-to-case resistance, θJC, or junction-to-board resistance, θJB, in data sheets (Figure 1).

Figure 1. Semiconductor IC thermal impedances can be modeled in much the same way as electrical circuits, as described by Ohm's Law.

Good thermal design is required to keep a device operating within safe temperature limits. The junction temperature, TJ, for an IC can be calculated as TJ = TA + (P × θJA) and it should never exceed the limit listed in the manufacturer's data sheet (generally ranging from +125°C to +175°C). Thermal impedance values also should be obtained from the original manufacturer, as they are both highly package and device dependent.

It is important to note that, while thermal equations can be modeled as electrical equations, the expected accuracy when working with electricity does not hold true for thermal operation. Often, actual thermal characteristics can vary as much as 30% from the calculated value.

Power Considerations for the Board

Board layout should be considered from the very beginning of a design. The most important rule for high power circuit boards is to know your power path. The location and amount of power flowing through a circuit is a major factor when deciding the IC position and type and amount of heat dissipation required on the printed circuit board (PCB).

Many factors affect the amount of layout for a given design. These factors include:

- The amount of power flowing through the circuit

- The ambient temperature around the device and the board

- The amount of airflow around the device and the board

- The board material

- IC density on the board

Component Placement

Analog circuits and mixed-signal circuit boards generally include high-power analog blocks and sensitive digital or low-power analog blocks. Begin the layout by designing and placing power blocks. Keep connections in individual power blocks short and wide and ensure against unnecessary ground loops and noise generation. Multiple tutorials and application notes have been written about layout techniques and recommendations for high power circuits.1,2,3 In general, remember to:

- Identify and reduce current loops, especially high current paths.

- Limit resistive voltage drops and other parasitics between components.

- Locate high-power circuitry away from sensitive circuitry.

- Use good grounding techniques.

Furthermore, avoid collecting multiple power components together on a PCB. Placing these heat-generating components evenly over the board maximizes the thermal balance of the board and protects the PCB from warping. Efficiently reducing heat on the board also protects other sensitive circuitry and signals during operation.

IC and Component Mounting

As power flows through a circuit, both passive and active components generate heat. Heat generated in passive components and ICs alike must be dissipated to the cooler ambient air around the device. This heat is generally dissipated through the package or through the lead frame of the device.

In the past few years, IC package manufacturers have built increasingly thermo-friendly packages. However, even with these packaging advances, heat dissipation becomes increasingly difficult as IC continue to shrink in size.

Many IC packages and board designs do not leave much room for an external heat sink, requiring another method to extract heat—enter the exposed pad (EP). A die inside a package with an EP is directly connected to the EP for optimum thermal performance. Correctly mounting these ICs on the PCB optimizes heat transfer from the package to the board. Discussions on thermal considerations and mounting techniques for individual ICs have been well documented by a number of reliable sources and are out of the scope of this paper. For more information on mounting techniques for individual packages, see application note 862, "Thermal Considerations of QFN and Other Exposed-Paddle Packages."

Heat Sinks

Components in the power path can generate large amounts of heat. These components need to dissipate the heat quickly and efficiently to the ambient environment. One commonly used method of heat dissipation is the addition of an external heat sink to the board. The purpose of a heat sink is to remove heat from a device and distribute it to the ambient air. Generally made from highly thermal conductive materials like aluminum or copper, external heat sinks provide a larger area to dissipate heat and should be placed in the path of airflow, if possible, for maximum dissipation. IC positioning becomes increasingly important when using external heat sinks and the board must be designed so that a heat sink can be affixed in the proper location. To optimize heat transfer from the IC to the heat sink, you can also use a thermal epoxy to ease the heat transfer between the devices.

Heat sinks generally require a great deal of room on a board and may not be appropriate for small or compact applications. When space is at a premium, design the PCB to optimize heat transfer through the board itself.

Board Layout

Special care should be taken to properly route high-power paths between ICs and components. Resistance in copper traces can account for significant power loss and heat generation on a board if not used appropriately. Keep traces between power components short and wide, and use thicker copper traces for high current paths. The recommended minimum trace width per amp for a 10°C rise in temperature ranges from 10mil to 30mil for 1oz copper and is based on the design chart in the IPC-2221 standard for PCB design.4 (See the Trace Thickness section in this tutorial for more information.) Using traces that are too small for a given current may result in degraded overall performance or even fuse open in extreme cases. As far as power traces are concerned, larger is better.

Board designers can also use large copper planes and vias in the board to remove heat from devices. Large planes increase the available area on a PCB for heat dissipation from a device. Ideally these planes are connected on the top or bottom layers of the boards to maximize the transfer to the ambient environment, however even internal planes can be used to draw out some of the power dissipated from devices on the PCB.

Vias are used to transfer power from one layer on a board to another. They direct heat from the package-board connections to another plane or layer. Multiple vias reduce the thermal resistance from the IC to the dissipating plane.

A Quick Example

Maxim's battery simulation circuit5 is a relatively simple and straightforward example of a high-power circuit for layout purposes. This circuit does not contain any switching devices or sensitive control circuitry, eliminating the need for multiple ground planes or protective measures.

The major power path of the simulator circuit begins at the BATT+ node and flows through the 100mΩ series input resistance and the TIP35 transistor to return at the BATT- node (Figure 2).

Figure 2. Maxim's battery simulator circuit.

Assuming a 3A charge current, the input sense resistor must be capable of handling at least 900mW. To minimize changes in the resistance during operation, a sense resistor capable of handling more than 1W should be used to ensure a constant input series resistance. A single 5W resistor or multiple 1W resistors in parallel work well (Figure 3).

The TIP35 transistor in the circuit must handle the bulk of the power in the circuit. Under the worst-case conditions, power across the TIP35 transistor can be calculated as follows:

PTIP35 = 4.2V × 3A = 12.6W

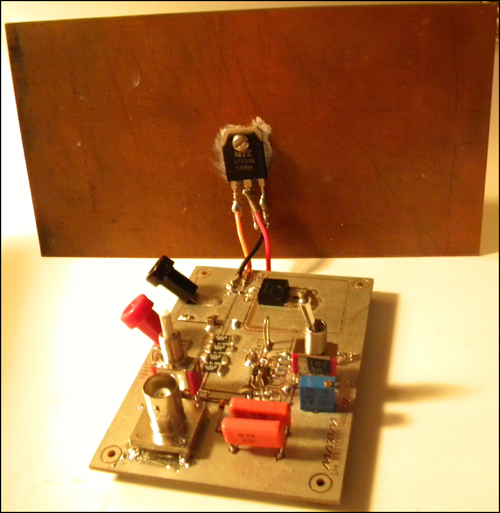

A heat sink capable of handling 15W or more should be used to incorporate a reasonable safety margin. In testing this circuit, we used a 0.1cm × 10cm × 18.5cm piece of copper to heat sink the TIP35.

Figure 3 shows the 2-layer board for this circuit. Multiple 400mΩ 1W resistors are used in parallel for the 100mΩ input sense resistance. Although not easily seen in the figure, multiple vias have been used to connect the BATT- pad on the top layer to the bottom layer, increasing the area of the BATT- plane. Thermal paste has been used to enhance the heat transfer from the transistor to the heat sink.

Figure 3. The battery simulator board with external heat sink for the TIPC32 transistor.

Trace Thickness

An important aspect of design for a high-power board is the thickness of the connections between components. Like wires, PCB copper traces have a resistance, and trace thickness can be a very important factor in the way a high-power circuit board performs. Many of today's high-power electronic circuits require PCBs with copper thickness ratings of 2oz or greater before the boards can deliver the full output power and dissipate the excess heat generated when delivering the power to the load. Designers often expect the PCB fabrication house to build the PCB with the correct copper thickness. However, if the PCB fabrication process is not well controlled, the PCB can end up with copper thickness that is lower than specified. When the circuit doesn't perform as expected, it can take many long and frustrating hours to track down a problem that stems from thinner-than-desired copper wiring.

Maxim engineers have developed a quick and easy method for verifying PCB copper thickness prior to assembly. This helps lower costs by reducing troubleshooting time, preventing unnecessary waste, and avoiding any down-time on the production line.

Copper thickness is often measured in "oz per square foot" (sq. ft), hence the term "copper weight." To determine the PCB copper weight, a test strip of predetermined length and width can be added in a convenient location on the PCB. Next, measure the resistance of this test strip. Since the resistance of the test strip is too small to be detected with a common ohmmeter, pass a small constant current through the test strip and measure the voltage across the test strip. This voltage is proportional to the resistance across the test strip. Finally, convert the measured voltage across the test strip to copper weight.

Just a low-cost constant current source, voltmeter, and a 5W resistor are needed to take the measurements. This test setup can be easily replicated for sample testing, low-volume production testing on multiple production lines, or at incoming inspection to sort out the PCBs with thinner-than-desired copper layers. It will minimize the chance of using an out-of-spec board.

Let's look at how it works: Include a test strip that is 50 mils wide and contains two vias (one at each end of the test strip), spaced 2000 mils apart (center to center), to the PCB as part of the PCB manufacturing process. Pass a 50mA current through the test strip. This can be done by connecting a ~5V DC power source, an ammeter, and a 100Ω (5W) resistor all in series across the test strip (Figure 4). Adjust the ~5V DC power source until the ammeter reads exactly 50mA. Measure the voltage across the test strip (in millivolts). Since the voltage across the test strip is very small, make sure all the connections are making good contact.

Figure 4. 2000 mil × 50 mil copper weight test strip setup and connections.

Convert the voltage across the test strip to copper weight using the following equation:

where VSTRIP is the voltage across the test strip measured in millivolts, and CuWt is the copper weight of the test strip measured in [oz/sqft]

For example, measuring a 2000mil × 50mil test strip carrying 50mA of current, we measure a voltage of 0.489mV across the stip. Using the CuWt equation, it is clear that this strip has a copper weight of 2oz.