High Power 2-Phase Synchronous Boost Replaces Hot Diodes with Cool FETs—No Heat Sinks Required

High Power 2-Phase Synchronous Boost Replaces Hot Diodes with Cool FETs—No Heat Sinks Required

2009-01-01

Introduction

For low power designs, non-synchronous boost converters offer a simple solution. However, as power levels increase, the heat dissipated in the boost diode becomes a significant design problem. In such cases, a synchronous boost converter, with the diode replaced with a lower forward voltage drop switch, significantly improves efficiency and relieves many issues with thermal layout. Although the topology is more complicated, Analog Devices offers controller ICs that simplify the design of high power synchronous boost applications. The LT3782A boost controller, for instance, includes predrive outputs for external synchronous switch drivers. It also integrates strong bottom switch drivers for high gate charge high voltage MOSFETs and uses a constant frequency, peak current mode architecture to produce high output voltages from 6V to 40V inputs. Its 2-phase architecture keeps external components small and low profile.

Synchronous Operation

At high current levels, a boost diode dissipates a significant amount of power, while a synchronous switch can burn far less. It all comes down to the forward voltage drop. The power dissipated in the boost diode is IIN • VD, while the power dissipated by the synchronous switch is I2IN • RDS(ON). (or IIN • VDS(ON)). A typical sub-10mΩ MOSFET running 10A dissipates 1W, while the 0.5V drop of a typical Schottky diode burns a whopping 5W. Because the forward drop of a synchronous MOSFET is proportional to the current flowing through it, FETs can be paralleled to share current and drastically reduce power dissipation. On the other hand, paralleling boost diodes does little to reduce power dissipation as the forward drop through the diodes holds fairly constant. The non-synchronous boost diode topology is more than just inefficient relative to a synchronous solution—the extra heat generated in a boost diode must go somewhere, necessitating a larger package footprint and heat sinking. At high power levels, a non-synchronous boost application becomes larger in size and higher in cost over a synchronous solution.

Multiphase Operation Reduces Application Size

There are a number of good reasons to choose a multiphase/multi-channel DC/DC converter over an equivalent single-phase solution, including reduced EMI and improved thermal performance, but the biggest advantage can be a significant reduction in application size. Although a 2-phase solution requires more components, two inductors and two MOSFETs instead of one, it offers a net reduction in space and cost. This is because the inductors and MOSFETs are more than proportionally smaller than those required in the single-phase solution. Moreover, because the switching signals are mutually anti-phase, their output ripples tend to cancel each other out, thus reducing the total output ripple by 50%, which in turn reduces output capacitance requirements. The input current ripple is also halved, which reduces the required input capacitance and reduces EMI. Finally, the power dissipated as heat is spread out over two phases, reducing the size of heat sinks or eliminating them altogether.

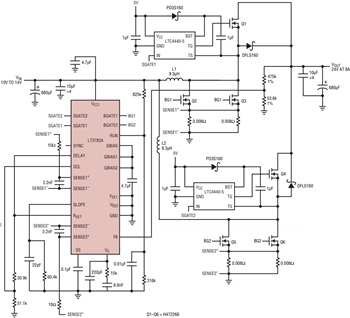

24V at 8A from a 10V–15V Input

Figure 1 shows a high power boost application that efficiently produces a 24V/8A output from a 10V–15V input. The LTC4440 high side driver is used to level shift the SGATE signals and drive the synchronous MOSFETs. The 250kHz switching frequency optimizes efficiency and component size/board area. Figure 2 shows the layout. Proper routing and filtering of the sense pins, placement of the power components and isolation using ground and supply planes ensure an almost jitter free operation, even at 50% duty cycle.

Figure 1. Compact high power boost application efficiently produces a 24V/8A output from a 10V–15V input.

Figure 2. Layout of the circuit in Figure 1. Note that no heat sinks are needed, even at the high power levels produced by this relatively compact circuit.

Figure 3 shows the efficiency of the circuit in Figure 1 with synchronous MOSFETs (measured to 8A) and the efficiency of an equivalent non-synchronous circuit using boost diodes (measured to 6A). The 1% improvement in peak efficiency may not seem significant, but take a look at the difference in heat dissipation shown in Figure 4, which shows thermal images of both circuits under equivalent operating conditions. The thermal advantages of using synchronous switches are clear.

Figure 3. Efficiency and power loss of the circuit in Figure 1 compared to the efficiency of the circuit when the synchronous FETs are replaced with non-synchronous boost diodes.

a. Thermal image of the board in Figure 2 built up with synchronous FETs.

b. Thermal image of the board in Figure 2 built up with boost diodes.

Figure 4. The board in Figure 2 runs fairly cool (a), but when the synchronous FETs are replaced with boost diodes, the entire board heats up considerably with the diodes running significantly hotter than the FETs (b). (VIN = 12V, ILOAD = 6A, two minutes after power up.)

Conclusion

The 2-phase synchronous boost topology possible with the LT3782A offers several advantages over a non-synchronous or a single-phase boost topology. Its combination of high efficiency, small footprint, heat sink-free thermal characteristics and low input/output capacitance requirements make it an easy fit in automotive and industrial applications.