900mA Li-Ion Charger in 2mm × 2mm DFN is Thermally Regulated for Faster Charge Time

900mA Li-Ion Charger in 2mm × 2mm DFN is Thermally Regulated for Faster Charge Time

by

David Kim

2005-06-01

Introduction

It can be tough to design a high performance linear Li-Ion battery charger for cell phones, MP3 players and other portable devices. The overriding design problem is how to squeeze the charger onto ever-shrinking boards, while managing the heat inherently generated by the charge process. The typical solution is to lower the maximum charge current to a sub-optimal value to avoid overheating, thus increasing charge time.

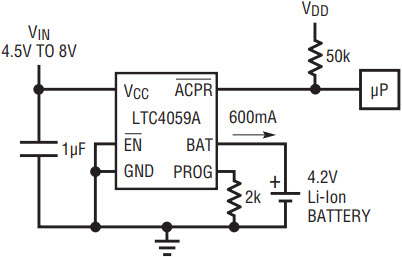

The LTC4059 is designed to shorten charge time even while squeezing the charger into the smallest spaces. The LTC4059 is a 2mm × 2mm DFN package constant-current/constant voltage Li-Ion linear charger with a built-in 900mA MOSFET, accurate charge current monitor output and thermal regulation control. Thermal regulation in this device is different, and much better, than the thermal shutdown found in most chargers. Thermal feedback control allows a designer to maximize the charge current, and thus decrease charge time without the risk of damaging the LTC4059 or any other components. Figure 1 shows a typical application.

Figure 1. Simple and tiny Li-Ion battery charger offers thermal regulation for improved charge time.

Figure 2 shows a complete 2.5mm × 2.7mm charging circuit that includes the LTC4059 and two passive components. The internal MOSFET architecture requires no blocking diode or external sense resistor.

Figure 2. Chargers do not get smaller than this (2.5mm × 2.7mm).

In addition to its miniscule size, the LTC4059 includes other important features for the latest cellular phones, wireless headsets, digital cameras, wireless PDAs and MP3 players. Supply current in shutdown mode is very low—10µA from the input supply, and under 1µA from the battery when the input supply is removed. It also has the capability of charging single cell Li-Ion batteries directly from a USB port.

Constant Current/Constant Voltage/Constant Temperature

The LTC4059 uses a unique architecture to charge a battery in a constant-current, constant-voltage or constant temperature fashion. In a typical operation, to charge a single cell Li-Ion battery, the user must apply an input voltage of at least 4.5V to the VCC pin along with a 1% resistor connected from PROG to GND (using the formula RPROG = 1000 • 1.21V/ICHG) and EN pin under 0.92V. When all three conditions are met, the charge cycle begins in constant-current mode with the current delivered to the battery equal to 1210V/RPROG.

If the power dissipation of the LTC4059 and/or high ambient temperature results in the device junction temperature rising to near 115°C, the part enters constant temperature mode and the thermal feedback loop of the LTC4059 decreases the charge current to regulate the die temperature to approximately 115 °C. This feature allows the user to program a charge current based on typical operating conditions and eliminates the need for the complicated thermal over-design necessary in other linear chargers. Typically, the thermal feedback loop conditions are temporary as the battery voltage rises with its charge (resulting in lower power dissipation across the MOSFET) but it is the worst case situation that one must account for when determining the maximum allowable values for charge current and IC temperature.

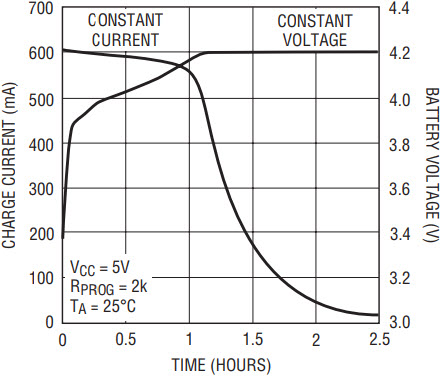

Once the die temperature drops below 115 °C, the LTC4059 returns to constant-current mode straight from constant temperature mode. As the battery voltage approaches the 4.2V float voltage, the part enters constant-voltage mode. In constant-voltage mode LTC4059 begins to decrease the charge current to maintain a constant voltage at the BAT pin rather than a constant current out of the BAT pin (Figure 3).

Figure 3. Complete charge cycle (800mAh Battery).

Regardless of the mode, the voltage at the PROG pin is proportional to the current delivered to the battery. During the constant current mode, the PROG pin voltage is always 1.21V indicating that the programmed charge current is flowing out of the BAT pin. In constant temperature mode or constant voltage mode, the BAT pin current is reduced. The charge current at any given charge cycle can be determined by measuring the PROG pin voltage using the formula ICHRG = 1000 • (1.21V/RPROG).

Using the battery voltage and the PROG pin voltage information, the user can determine the proper charge termination current level (typically 10% of the full-scale programmed charge current). Once the desired charge current level is reached, the user can terminate the charge cycle simply by pulling up the EN pin above 1.2V.

Board Layout

Properly soldering the exposed metal on the backside of the LTC4059 package is critical for minimizing the thermal resistance. Properly soldered LTC4059 on a 2500mm2 double sided 1oz copper board should have a thermal resistance of approximately 60°C/W. When the LTC4059 is not properly soldered (or does not have enough copper), the thermal resistance rises, causing the LTC4059 to enter constant-temperature mode more often, thus resulting in longer charge time. As an example, a correctly soldered LTC4059 can deliver over 900mA to a battery from a 5V supply at room temperature. Without a backside thermal connection, this number could drop to less than 500mA.

Li|CC, ACPR

Two versions of the part are available, depending on the needs of the battery chemistry. The LTC4059 has a Li|CC pin, which disables constant-voltage operation when it is pulled up above 0.92V. In this mode, the LTC4059 turns into a precision current source capable of charging Nickel chemistry batteries. In the LTC4059A, the Li|CC pin is replaced by an ACPR pin, which monitors the status of the input voltage with an open-drain output. When VCC is greater than 3V and 150mV above the BAT pin voltage, the ACPR pin will pull to ground; other wise the pin is forced to a high impedance state.

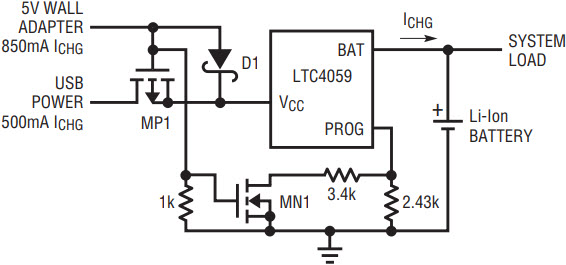

Combining Wall Adapter and USB Power

Figure 4 shows an example of combining wall adapter and USB power inputs. In this circuit, MP1 is used to prevent back conduction into the USB port when a wall adapter is present and D1 is used to prevent USB power loss through the 1K pull-down resistor. The 2.43k resistor sets the charge current to 500mA when the USB port is used as input and the MN1 and 3.4k resistor is used to increase the charge current to 850mA when the wall adapter is present.

Figure 4. Charger that combines both wall adapter and USB power inputs.

Conclusion

The LTC4059 is industry’s smallest single cell Li-Ion battery charger capable of up to 900mA charge current. The thermal regulation feature of LTC4059 allows the designer to maximize the charge current and shorten the charge time without the risk of damaging the circuit. The small circuit size, thermal protection, low supply current and low external component count make LTC4059 an ideal solution for small portable and USB devices.

关于作者

Dave Kim is a Director for Automotive Systems Engineering for Power Products and Power electronics applications and systems design for more than 25yrs. He has joined Linear Technology (now part of Analog Devices) in 1997. ...