Simple Converter Drives Luxeon White LEDs from Batteries

Introduction

The high output 1W white LEDs from Luxeon and Nichia provide illumination levels close to 12W incandescent levels while dissipating only 1W and lasting for 50,000 hours or more. These devices promise enormous power savings and reduced maintenance cost for many lamp applications. However, these LEDs must be driven with a constant current to maintain proper brightness. The forward voltage drop varies between 2.8V and 4.0V over process and temperature extremes. The circuit used to drive the LED must compensate for this forward voltage variation while maintaining constant current drive. Existing boost circuits generally use voltage feedback switching converters with extra circuitry to sense output current rather than voltage. This results in complex circuits with poor efficiency.

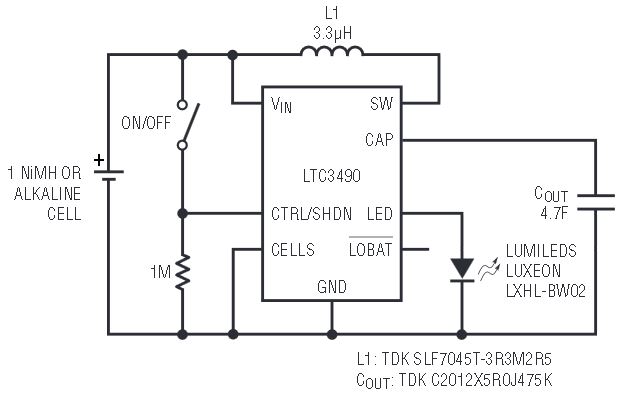

The LTC3490 provides a simple solution for boosting a single or dual cell battery voltage to the necessary LED forward voltage and regulating the current through the LED load. The high frequency (1.3MHz) operation allows small inductor and capacitor values. The current sensing resistor and loop compensation components are internal, reducing the component count. The LTC3490 is a synchronous converter eliminating the rectifier diode and its associated efficiency loss. The only required components are the boost inductor and an output filter capacitor. The shutdown and dimming functions add a few resistors, and an input capacitor is recommended in certain conditions.

Circuit Description

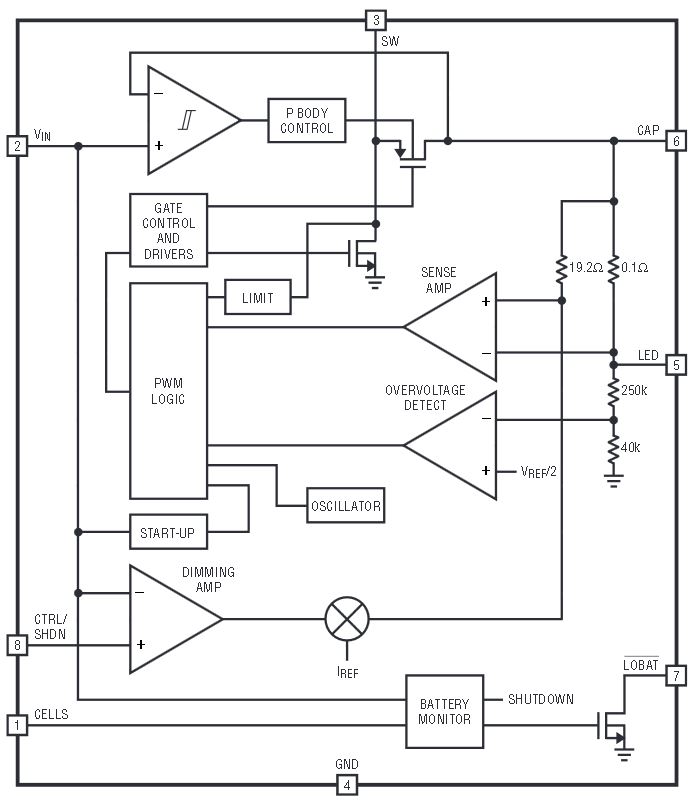

The LTC3490 is a synchronous boost converter. Its block diagram is shown in Figure 1. It will start up with input voltage as low as 0.9V using a low voltage startup circuit. When the output voltage exceeds 2.3V, the boost circuits turn on and the startup circuit shuts off. The boost converter is a fixed frequency, current mode architecture.

Figure 1. LTC3490 block diagram.

The LED current is sensed with an internal 0.1Ω resistor on the high side, which allows the LED cathode to be grounded. A sense amplifier compares this voltage to a reference current flowing through a ratiometrically matched 19.2Ω resistor. The sensed voltage difference is integrated and used to set the PWM controller. The LED current is therefore constant regardless of the LED forward voltage.

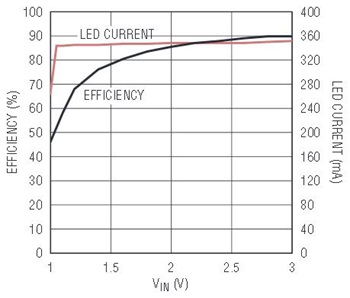

The LTC3490 is up to 90% efficient in dual cell applications and over 70% in single cell applications (Figure 2). The dual cell and single cell circuits are shown in Figures 3 and 4, respectively.

Figure 2. LTC3490 efficiency.

Figure 3. Minimum component 2-cell circuit.

Figure 4. Minimum component 1-cell circuit.

Overvoltage Protection

Output overvoltage protection is required because the current sensing controller can drive the output voltage to damaging levels if there is no load. This occurs if the LED is removed from the circuit or has failed. As long as the output current is below 350mA, the output voltage continues to climb and would damage the LTC3490 without overvoltage protection. The overvoltage detector forces the LTC3490 into shutdown when the output voltage is greater than 4.5V. The overvoltage detector remains on and will restore normal operation when the output drops below 4.5V.

Dimming Function

The LTC3490 allows the LED current to be gradually reduced using the CTRL/SHDN pin. The CTRL/SHDN input has three functions: shutdown, dimming control and constant current output. The pin is ratiometric to VIN, which allows simple resistor dividers for setting current values. When CTRL/SHDN is below 0.2 • VIN, the part is in shutdown and draws minimal current. When CTRL/SHDN is greater than 0.9 • VIN, the part is in constant 350mA mode. When CTRL/SHDN is between 0.2 • VIN and 0.9 • VIN, the LED current varies linearly between 0mA and 350mA.

Low Battery Detection

The LTC3490 provides two levels of low battery detection. These levels are set by the CELLS pin, indicating the number of battery cells. The low battery detection is set at 1.0V when the CELLS pin is low, and at 2.0V when the CELLS pin is tied to VIN. This corresponds to single cell and dual cell operation, respectively. When the battery voltage drops below the detection level, an open drain output on the LOBAT pin is pulled low. This output can be used to drive an indicator or can be fed back to the CTRL/SHDN pin to lower the LED current to extend remaining battery time.

There is also an undervoltage lockout, which shuts down the LTC3490 when the battery voltage drops below 0.8V/cell. This prevents excessive battery current (single cell) and cell reversal in unevenly discharged NiMH cells (dual cell).

Battery Reality Check

Batteries have a phenomenon called discharge recovery. When a load is removed from a nearly discharged battery, the terminal voltage recovers to surprisingly high voltages. Thus when a nearly discharged battery trips the LTC3490 dead battery shutdown, the reduction in current draw allows the battery to recover. This turns the LTC3490 back on, putting the load back on the battery. The battery voltage drops, triggering shutdown again. This phenomenon causes LTC3490 to turn the LED current on and off rapidly. The observed effect is that the average LED current slowly drops as the battery nears the end of its charge.

Conclusion

The LTC3490 provides a simple solution to driving the high output white LEDs from alkaline or NiMH batteries. It offers high efficiency with a low parts count.