Integrated High Voltage Switching Charger/PowerPath Controller Minimizes Power Dissipation and Fits into 2cm2

Integrated High Voltage Switching Charger/PowerPath Controller Minimizes Power Dissipation and Fits into 2cm2

2006年09月01日

Introduction

GPS navigators, PDAs, MP3 players and other handheld devices draw on an increasing array of power sources for recharging their batteries. These sources include USB (4.5V), low voltage AC adaptors (4.5V–5V), high voltage AC adaptors (12V–24V), Firewire and automotive batteries. USB has the advantage of convenience while the high voltage sources offer faster charging at home and in the car. One issue with high voltage sources is that the voltage difference between the high voltage source and the battery is large enough that a linear charger cannot handle the power dissipation, thus dictating the need for a switching regulator.

The LTC4089 and LTC4089-5 integrate a high voltage, wide input range (6V–36V) monolithic 1.2A buck switching regulator, a USB input, a PowerPath controller and a linear charger into a compact thermally enhanced 3mm × 6mm DFN package. The LTC4089’s buck regulator output voltage follows the battery voltage, thus minimizing the overall power dissipation, while the LTC4089-5 has a fixed 5V output.

The USB is current limited power, so the LTC4089’s PowerPath controller distributes the available power, with the load taking precedence and any remaining current used to charge the Li-ion battery.

If the load current exceeds available current from USB, the additional current needed is drawn from the battery. If a high voltage source is connected to the input of the buck regulator (HVIN), the current is drawn from this source instead of the USB.

Figure 1 shows a complete solution that fits into less than 2cm2 with all components on one side of the PCB (Figure 2).

Figure 1. Typical application of the LTC4089.

Figure 2. A complete LTC4089/LTC4089-5 USB/high voltage/Li-ion charger application fits into 2cm2.

Operation

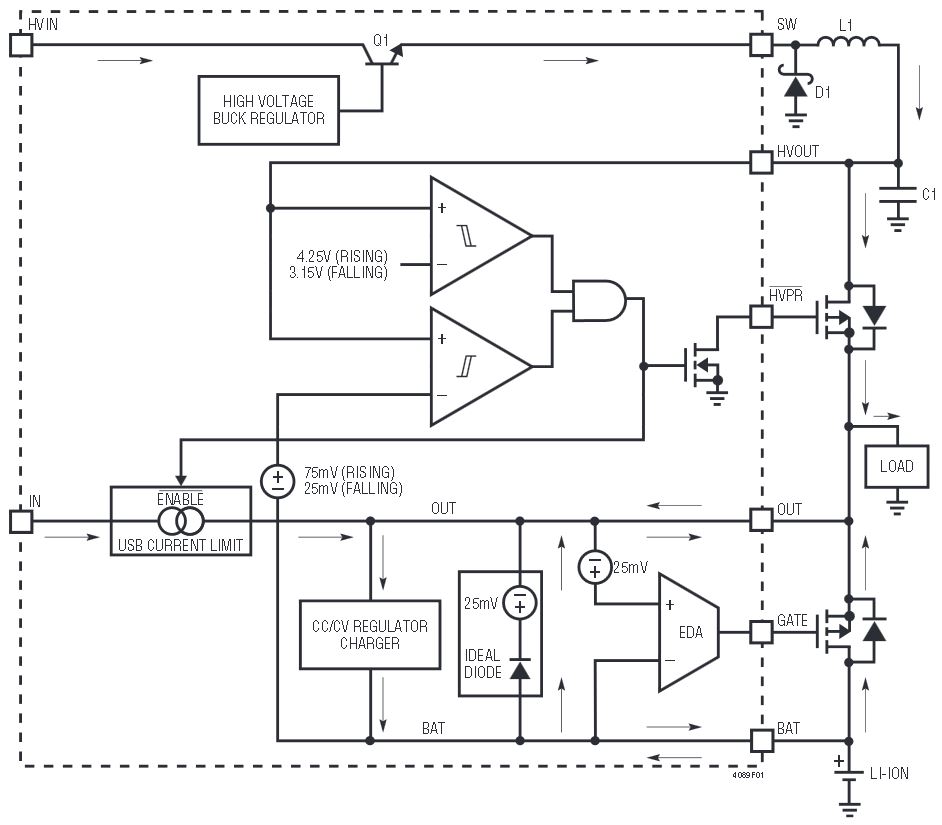

As shown in the simplified block diagram (Figure 3), both the LTC4089 and LTC4089-5 consist of an integrated high voltage monolithic buck regulator, a PowerPath controller and a Li-ion battery charger. They are designed to manage power from a high voltage source (e.g., FireWire/IEEE1394, 12V–24V automotive batteries, 12V–20V wall adaptors, etc.), a low voltage source (e.g., USB or 5V wall adaptor) and a single-cell Li-ion battery. When an external power source is connected to the supply pins, it delivers power to the OUT pin and charges a battery connected to the BAT pin.

Figure 3. A block diagram of the LTC4089 and LTC4089-5 shows the PowerPath controller, wide-input-range buck regulator and battery charging features.

When high voltage is present at the HVIN pin, the monolithic high voltage switching regulator regulates the HVOUT voltage. An external PFET between HVOUT (connected to the drain) and OUT (connected to the source) is controlled by the HVPR pin, allowing OUT to supply the power to the load and charge the battery. The LTC4089 maintains about 300mV between the OUT pin and the BAT pin, while the LTC4089-5 provides a fixed 5V OUT voltage. The HVIN input takes priority over the IN input (i.e., if both HVIN and IN are connected to power sources, load current and charge current are provided by the HVIN input).

Power supplies with limited current capability (such as USB) are connected to the IN pin, which has a programmable current limit via a resistor connected at CLPROG pin. Battery charge current is adjusted to ensure the sum of the load current (which takes priority) and the charge current does not exceed the programmed input current.

The high voltage buck regulator operates at 750kHz in constant frequency current mode, allowing the use of a small 10μH–33μH inductor while providing 1.2A nominal output current and minimizing the number of the external compensation components.

Features

High Voltage Switching Converter Saves an Adaptor

The LTC4089 and LTC4089-5’s input voltage range is 6V to 36V, well within the range of automotive batteries, Firewire, and other high voltage sources—no extra conversion to a lower voltage is needed.

Adaptive Buck Output Voltage Minimizes Total Power Loss

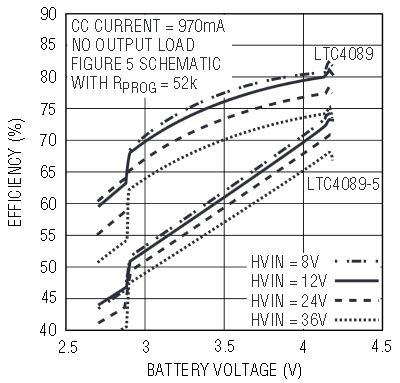

The LTC4089’s buck converter output voltage, VOUT, regulates to 0.3V above the battery voltage so that the battery can be charged efficiently with the linear charger. Figure 4 shows the overall efficiency at various input voltages. The minimum VOUT is 3.6V to ensure the system can operate even if the battery is excessively discharged.

Figure 4. The efficiency of LTC4089/LTC4089-5 when charging from HVIN.

USB PowerPath Controller/Charger Maximizes Power Available to the System and Solves Other Problems

In a traditional battery powered device, the input charges the battery and the system’s power is directly taken from the battery. This simple topology presents some significant problems:

- Case 1. The load current is restricted to the trickle charge current. If the battery is excessively drained, the charger enters trickle charge mode, thus reducing the available system current to the 50mA to 100mA trickle charge. This may not be enough to start up the system, forcing the user to wait until the charger is in constant-current mode

- Case 2. The system will not work without a battery. If a battery is not present, some systems will not turn on because this is considered a fault, or the charger output oscillates.

- Case 3. Available power reduces with battery voltage. Because the available system load power depends on the battery voltage, when USB input is used, the available system power is restricted to 1.6W (3.2V battery voltage).

- Case 4. The battery cannot be fully charged. In this scenario, the battery slowly charges because the system draws the bulk of the available power, leaving little current for the charger. The problem arises because the safety timer runs out before the battery can be fully charged.

The LT4089/LTC4089-5’s PowerPath controller/charger solves the above problems (see Table 1) and provides other benefits (see “Additional Features” below).

| Case | Scenario | Traditional Dual Input Charger | LT Power Manager/Charger |

| 1 | Battery voltage below trickle charging voltage | Available current to system is only trickle charge current (50mA–100mA), which may not enough to start the system | Full adaptor/USB power available to system |

| 2 | Battery is not present | Most chargers consider this as a fault. System can’t start | Full adaptor/USB power available to system |

| 3 | VBATT = 3.2V or USB input | Available power to system is limited to 1.6W. | Worst case 2.2W available to system. |

| 4 | System consuming close to input power | Can’t distinguish the available charging current. Charger timer runs out before battery is fully charged | Charger timer increases charging time with decreasing available charging current. Battery always fully charged. |

For instance, in Case 1, the system gets the current it needs—anything left over is available to trickle-charge the battery. The removal of the battery (Case 2) doesn’t affect the system’s available power, which is over 99% from a wall adaptor and 98% from the USB (0.1V drop on the 0.2Ω FET). This means that the available power to the system is at least 2.2W (assuming a 4.5V USB) versus 1.6W when battery is at low 3.2V (Case 3). The LTC4085 has a smart, adaptive safety timer, whose time extends inversely to the charging current in constant-current charging mode. This solves the problem in Case 4.

Additional Features

The LT4089/LTC4089-5 offers other advantages over a basic charger in line with a battery:

- Seamless transition between the three power sources: AC adaptor, USB input, and Li-ion battery.

- 200mΩ monolithic ideal diode from battery to system load. An external FET gate signal is provided if user wants to use an external switch between the battery and the load to reduce RDS(ON) losses.

- Charging current is system load dependent, guaranteeing the compliance to USB current limits

- Constant-current/constant-voltage battery charge operation

- Thermal foldback to maximize charging rate without risk of overheating

- Accurate monitoring of USB current: 5% for 500mA and 10% for 100mA

- Preset 4.2V charge voltage with 0.8% accuracy

- NTC thermistor input for temperature qualified charging

- C/10 charge current detection output (CHRG)

- High voltage present indication (HVPR)

Applications

Figure 5 shows a typical LTC4089/LTC4089-5 circuit schematic. Designing a complete USB, high voltage, battery charger circuit is relatively easy—only a few external components are needed to set the operating parameters:

- IN pin (USB) current limit is set by resistor connected to CLPROG pin (2.1kΩ for 475mA USB current limit with maximum of 500mA considering component tolerances)

- Charge current is set by a resistor connected to PROG pin (71.5kΩ for 700mA charge current)

- Charge safety timer is a function of RPROG (R4) and capacitor C4 connected to TIMER pin. A typical value is 0.15μF for a 3-hour charging time for the constant charging current of 700mA. The time for the constant current charge portion increases with decreasing available charging current to ensure the battery is always fully charged. The increase in charge time is reflected on the frequency of the triangular waveform on C4.

Figure 5. The typical application circuit schematic diagram.

Application Caveats

High Voltage Buck Input Surge Protection

The small size and low impedance of ceramic capacitors make them an attractive option for the input bypass capacitor at LTC4089/LTC4089-5’s buck HVIN pin. However, these capacitors can cause problems if the circuit is plugged into a live supply (see Linear Technology Application Note AN88 for a complete discussion). The low loss ceramic capacitor combined with parasitic inductance in series with the source forms an under-damped LC tank circuit and the voltage at the HVIN pin can ring as much as twice the nominal input voltage, possibly exceeding the maximum voltage rating and damaging the part. If the input supply is poorly regulated or the user can hot plug the LTC4089/LTC4089-5 into an energized supply, an input network should be designed to prevent the overshoot.

Figure 6a shows the waveforms that result when an LTC4089 circuit is connected to a 24V supply through six feet of 24-gauge twisted wire. The first plot is the response with a 2.2μF ceramic capacitor at the input. The input voltage HVIN rings as high as 35V and the input current peaks at 20A. One method of damping the tank circuit is to add another capacitor with a series resistor to the circuit. In Figure 6b an aluminum electrolytic capacitor has been added. This capacitor’s high equivalent series resistance dampens the circuit and eliminates the voltage overshoot. The extra capacitor improves low frequency ripple filtering and can slightly improve the efficiency of the circuit, though it is likely to be the largest component in the circuit. An alternative solution is shown in Figure 6c. A 1Ω resistor is added in series with the input to eliminate the voltage overshoot (it also reduces the peak input current). A 0.1μF capacitor improves high frequency filtering. This solution is smaller and less expensive than the electrolytic capacitor. For high input voltages its impact on efficiency is minor, reducing efficiency less than one half percent for a 5V output at full load operating from 24V.

Figure 6. A well chosen input network prevents input voltage overshoot and ensures reliable operation when the LTC4089/LTC4089-5 is connected to a live supply.

High Voltage Buck Output Capacitor Selection

All the ceramic capacitors used in the circuit are recommended to be X5R or better (X7R). However, be cautious about the claimed initial capacitance value (e.g., some 0805 size 22μF/6.3V X5R caps measure only 11μF at no bias) and derating with bias and temperature (some X5R caps derate to less than 20% of their initial values with full 6.3V voltage bias). It is critical to use a 22μF/16V X5R or better cap at the output of the LTC4089 buck regulator (connected to HVOUT), as low capacitance causes duty-jitter in certain conditions. The LTC4089-5 can operate with a 22μF/6.3V ceramic cap at the output.

High Voltage Buck Current Limit

As shown in Figure 7, the buck output current capability is a function of inductance and the input voltage. For most of the input range, the output current limit is 1A for a 10μH inductor and 1.1A for a 33μH inductor. When powered from the high voltage source, if the sum of the system load current at the OUT terminal and charge current (set by RPROG) exceeds the buck output current limit, the buck output voltage collapses to the battery voltage.

Figure 7. The high voltage switching regulator’s maximum output current for two different value inductors.

Accept USB and 5V Adaptor with Different Current Limits

Like all other LTC PowerPath controllers, the LTC4089/LTC4089-5 can be configured to accept 5V adaptor/USB input in the same USB connector or different connectors with different current limits by changing the resistance connected to CLPROG pin. Figure 8 shows the schematic diagrams.

Figure 8. IN pin accepting USB and 5V Adaptor with different current limits.

Conclusion

The LTC4089 and LTC4089-5 combine a monolithic high voltage switching buck regulator, a full featured Li-ion battery charger, and a PowerPath controller in a tiny 3mm × 6mm DFN package. They solve many battery charging and power path problems and easily fits into handheld applications, such as portable GPS navigators and MP3 players, where a high voltage source and small PCB space are required.