Ideal Diode Betters a Schottky by a Factor of Four in Power and Space Consumption

Ideal Diode Betters a Schottky by a Factor of Four in Power and Space Consumption

著者

Meilissa Lum

2008年06月01日

Introduction

High availability systems often use parallel power supplies or battery feeds to achieve redundancy and enhance system reliability. Traditionally, Schottky ORing diodes are used to connect these supplies at the point of load and prevent backfeeding into a faulty power supply. Unfortunately, the forward voltage drop of these diodes reduces the available supply voltage and dissipates significant power at high currents—costly heat sinks and elaborate layouts are needed to keep the diodes cool.

When power dissipation is a concern, the Schottky diode can be replaced with a MOSFET-based ideal diode. This reduces the voltage drop and power dissipation, thereby reducing the complexity, size and cost of the thermal layout and increasing system efficiency. The LTC4355, LTC4357 and LTC4358 enable MOSFET-based ideal diode solutions for various applications—the choice depends on the current and operating voltage of the application. Table 1 compares these devices.

| Part Number | Description | Operating Voltage | Configuration | Package |

| LTC4355 | Positive Voltage Diode-OR Controller and Monitor | 9V–80V, 100V Abs Max | Dual, External MOSFETs | DFN14 (4mm × 3mm), SO16 |

| LTC4357 | Single Positive Voltage Ideal Diode Controller | 9V–80V, 100V Abs Max | Single, External MOSFET | DFN6 (2mm × 3mm), MSOP8 |

| LTC4358 | Ideal Diode | 9V–26.5V, 28V Abs Max | 5A Internal MOSFET | DFN14 (4mm × 3mm), TSSOP16 |

Ideal Diode Easier to Use Than a Schottky

Of particular interest is the LTC4358, which includes an internal 20mΩ MOSFET as the pass element. No external components are required. The IN pins are the source of the MOSFET and act like the anode of a diode, while the drain behaves as the cathode, as shown for a 12V/5A application in Figure 1. When power is first applied, the load current initially flows through the MOSFET’s body diode. The MOSFET’s gate is enhanced and turned on to maintain a 25mV forward voltage drop. If the load current causes more than 25mV of voltage drop, the MOSFET is driven fully on, and the forward drop equals RDS(ON) • ILOAD. If the load current reverses, as may occur during an input short, the LTC4358 responds by turning off the internal MOSFET in less than 0.5μs.

Figure 1. No external components are needed for a 12V/5A ideal diode.

Power Saved Versus Schottky Diode

Compared to a B530C Schottky diode in the SMC package, not only is the LTC4358’s DE14 (4mm × 3mm) package one-fourth the size, the voltage drop and power dissipation are also considerably less as shown in Figure 2. The reduced voltage drop of the ideal diode also increases the voltage at the load, which reduces the capacitance required to hold up the output during supply disruptions. The power dissipated at 5A in the Schottky is 2W versus 0.5W for the LTC4358. With one-fourth the power dissipated, system efficiency is increased and PCB layout is simplified—no need for costly and bulky heat sinks.

Figure 2. The LTC4358 ideal diode takes on a 5A B530C Schottky diode. The LTC4358 easily wins in voltage drop, power loss and package size.

PCB Layout

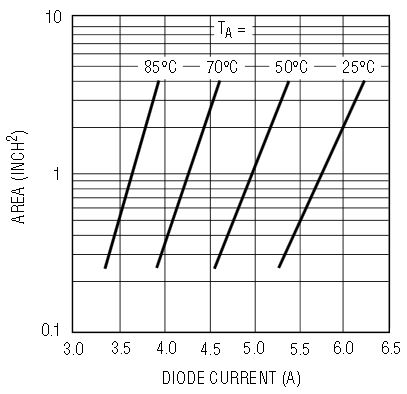

As described above, with only one-fourth as much power dissipation as a Schottky, thermal layout with the LTC4358 is much easier. Most of the heat escapes the part through the DRAIN/exposed pad, while some exits through the IN pins. Maximizing the copper of these connections increases the allowable maximum current. Figure 3 shows an optimal layout for a 1" × 1" single sided PCB with the DFN package. Copper connected to the exposed pad above and below the LTC4358 helps remove heat from the package. If you are using a two-sided PCB, use vias under the LTC4358 to transfer heat to copper on the bottom of the PCB, thus increasing the maximum current by 10%. Use Figure 4 to determine the amount of copper area needed for a specified current and ambient temperature.

Figure 3. DFN layout considerations for 1" × 1" single sided PCB.

Figure 4. Maximum diode current vs PCB area.

Conclusion

The LTC4358 is a MOSFET-based ideal diode that can directly replace a 5A Schottky diode in 9V to 26.5V applications. The LTC4358 betters a Schottky by a factor of four on voltage drop, power loss and package size, thus significantly shrinking the thermal layout and improving overall performance. Also, simple optimization the PCB layout increases the maximum current—no heat sinks required.

著者について

Meilissa Lum has been an analog IC design engineer for Linear Technology (now part of Analog Devices, Inc.) formerly since 2005. She designs ideal diode products for the hot swap group. Meilissa earned a Bachelor’s degree ...