High Power Desktop CCFL Controller Enables Wide Dimming Ratios while Maximizing Lamp Lifetime

High Power Desktop CCFL Controller Enables Wide Dimming Ratios while Maximizing Lamp Lifetime

2001年05月01日

Introduction

Liquid crystal displays (LCDs), long standard in laptop computers and handheld instruments, are gaining in popularity as desktop computer displays. In the larger sizes required for desktop monitor applications, providing uniform backlighting for LCDs requires multiple, high power lamps. In addition, the lamps must have a dimming range and life expectancy comparable to those of previous generations of desktop displays. Cold cathode fluorescent lamps (CCFLs) provide the highest available efficiency for backlighting LCD displays. The CCFL requires a high voltage supply for operation. Typically, over 1000 volts is required to initiate CCFL operation, with sustaining voltages from 200V to 800V. A CCFL can operate from DC, but migration effects damage the CCFL and shorten its lifetime. To achieve maximum life, CCFL drive should be sinusoidal, contain zero DC component and not exceed the CCFL manufacturer’s minimum and maximum operating current ratings. Low crest-factor sinusoidal CCFL drive also maximizes current-to-light conversion efficiency, reduces display flicker and minimizes EMI and RFI emissions. The LT1768 high power CCFL controller, with its unique Multimode Dimming™ feature, provides the necessary lamp drive to enable a wide dimming range, while maintaining lamp lifetime, in multiple-lamp CCFL applications.

LT1768 Dual CCFL Backlight Inverter

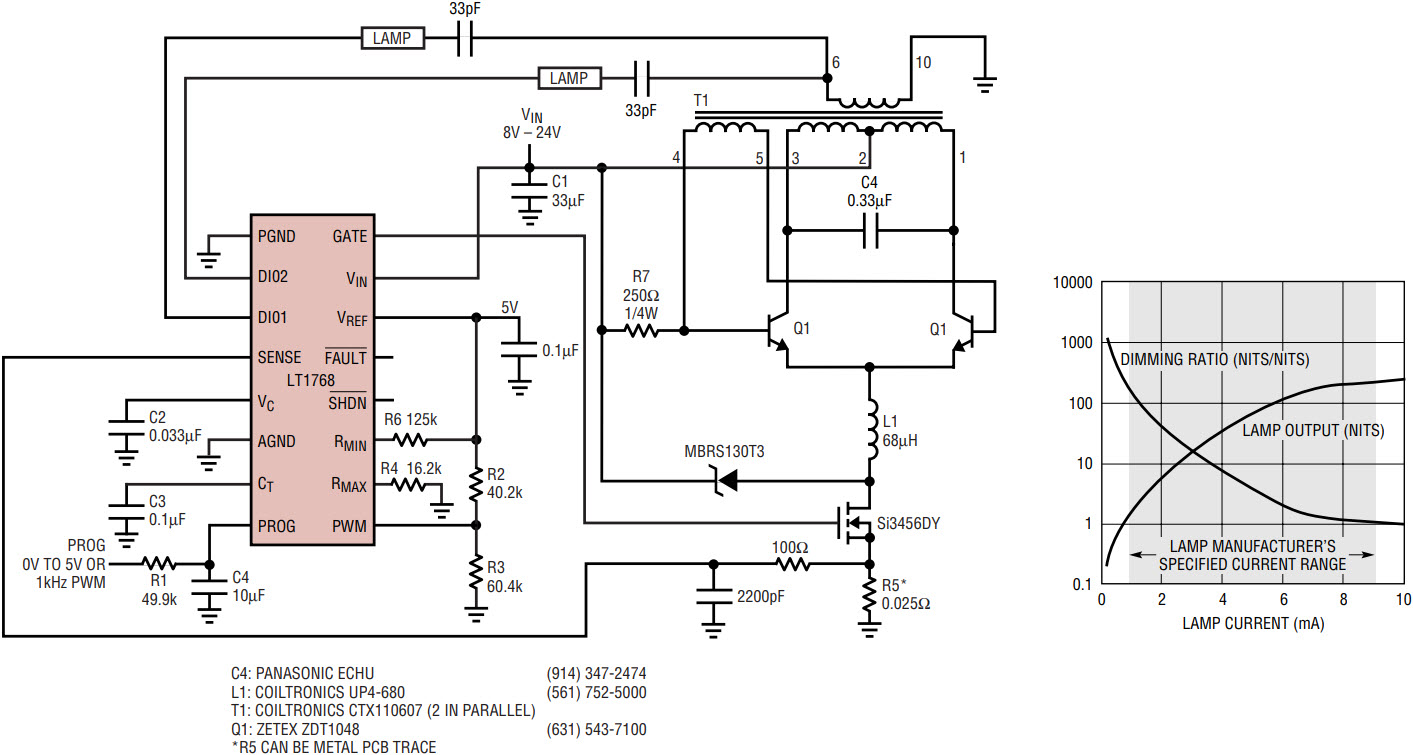

The circuit in Figure 1 is a dual, grounded-lamp backlight inverter that operates from an input of 9V to 24V, delivers a maximum current of 9mA per CCFL and has a dimming ratio greater than 100:1. The LT1768 in the circuit is a 350kHz fixed frequency, current mode, pulse width modulator that provides the lamp-current control function for the inverter.

Figure 1. 14W CCFL supply produces a 100:1 dimming ratio while maintaining minimum and maximum lamp-current specifications.

The CCFL current in Figure 1 is controlled by a DC voltage on the PROG pin of the LT1768. This voltage feeds the LT1768’s Multimode Dimming block, which converts it to a proportional current and feeds it to the VC pin. As the VC pin voltage rises, the LT1768’s GATE pin is pulse width modulated at 350kHz. The GATE pulse width is determined on a cycle-by-cycle basis by the voltage on the sense pin (L1’s current multiplied by sense resistor R6) exceeding a predetermined voltage set by the VC pin. The current mode pulse width modulation produces an average current in inductor L1 proportional to the voltage on the VC pin. Inductor L1 then acts as a switched mode current source that feeds a current-driven Royer-class converter1 with efficiencies as high as 90%. T1, C4 and Q1 comprise the Royer-class converter, which provides the CCFLs with a zero DC component, 60kHz sinusoidal waveform whose amplitude is based on the average current in L1. Sinusoidal currents from both CCFLs are then returned to the LT1768 through the DIO1/DIO2 pins. A fraction of the CCFL current from the negative half of its sine wave pulls against the internal current source at the VC pin, closing the loop. A single capacitor on the VC pin provides loop compensation and CCFL current averaging, which results in constant CCFL current. Varying the value of the internal current source via the Multimode Dimming block varies the CCFL current and resultant CCFL light intensity.

Multimode Dimming

Previous backlighting solutions used intensity control schemes that were limited to linear or PWM control. Linear intensity control schemes provide the highest efficiency in backlight circuits, but either limit the dimming range or violate lamp minimum or maximum CCFL specifications to achieve wide dimming ratios. PWM control schemes offer wide dimming range but produce high crest-factor waveforms detrimental to CCFL life and waste power at higher CCFL currents. The LT1768’s patented Multimode Dimming combines the best of both control schemes to extend CCFL life while providing the widest possible dimming range.

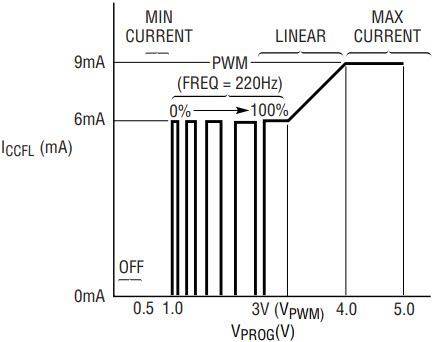

Referring to Figure 2, CCFL current has five distinct modes of operation. Which mode is in use is determined by the voltages on the PROG and PWM pins and by the currents that flow out of the RMAX and RMIN pins.

Figure 2. Lamp current vs PROG voltage for Figure 1’s circuit.

Off mode (VPROG < 0.5V) sets the CCFL current to zero and inhibits the GATE pin from switching.

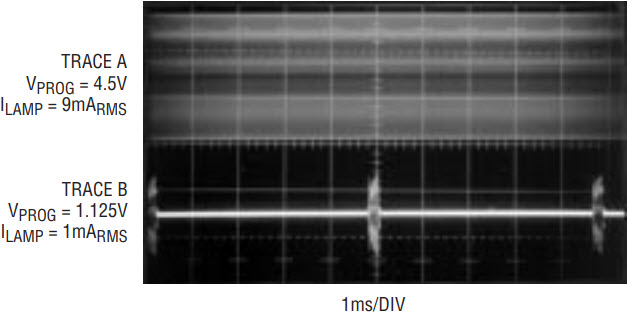

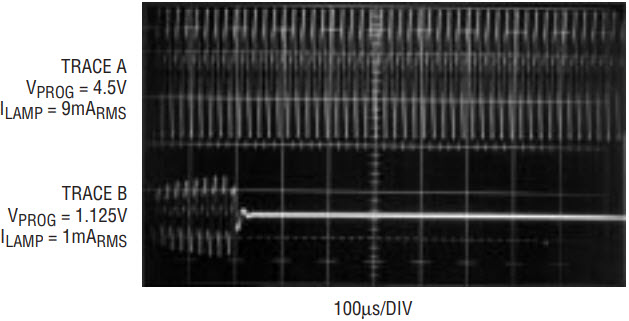

Minimum current mode (0.5V < VPROG < 1.0V) sets the average CCFL current (ICCFLMIN) to ten times the current out of the 1.26V-referenced RMIN pin. The exact ratio of RMIN current to RMS CCFL current must be empirically determined due to the offset between the average and true RMS values of the sinusoidal waveform. The minimum CCFL current determines the dimming range of the display. Setting RMIN to produce the minimum specified CCFL current guarantees the maximum CCFL lifetime for all PROG voltages but limits the dimming range. Setting RMIN to produce currents less than the minimum specified CCFL current increases the dimming range but places restrictions on the PROG voltage for normal operation in order to maximize lifetime. To achieve the maximum dimming ratio possible, ICCFLMIN should be set to zero by connecting the RMIN pin to the VREF pin. For example, setting R6 in Figure 1 to 10k and connecting it to ground sets the minimum CCFL current to 1mA but limits the dimming ratio to 6:1. Alternatively, setting R6 in Figure 1 to 125k and connecting it to the REF pin produces a dimming ratio of 100:1 at 1mA of lamp current, but sets the minimum CCFL current to zero. In this case, the PROG voltage must be kept above 1.125V (1mA CCFL current) during normal operation to meet the CCFL specifications and maximize lifetime. Taking the PROG voltage in Figure 1 to 1V (0mA CCFL current) enables dimming ratios greater than 500:1 but violates minimum CCFL specifications and is not recommended. Trace B in Figure 3 shows Figure 1’s CCFL current waveform operating at 1mA in PWM mode.

Figure 3a. CCFL current for Figure 1’s circuit.

Figure 3b. CCFL current for Figure 1’s circuit (expanded time scale).

Maximum current mode (VPROG > 4.0V) sets the CCFL current (ICCFLMAX) to roughly one hundred times the current out of the 1.25V referenced RMAX pin. As with minimum CCFL current, the exact ratio must be empirically determined. Setting the CCFL current in this mode to the manufacturer’s maximum rating ensures no degradation in the specified lamp lifetime. In the example of Figure 1, maximum CCFL current is set to 9mA by setting R4 to 16.2k. Trace A in Figure 3 shows Figure 1’s CCFL current waveform operating at 9mA in maximum current mode.

In linear mode (VPWM < VPROG < 4.0V), CCFL current is controlled linearly with the voltage on the PROG pin. The equation for the CCFL current in linear mode is:

ICCFL = ((ICCFLMAX – ICCFLMIN)/3) • ((VPROG/1V) – 1) + ICCFLMIN

For the best current-to-light conversion and highest efficiency, the LT1768 should normally operate in the linear mode. In the example of Figure 1, linear mode runs from VPROG = 3.0V to VPROG = 4.0V with lamp current equal to 3mA • ((VPROG/1V) – 1).

In PWM mode (1.0V < VPROG < VPWM), the CCFL current is modulated between ICCFLMIN and the value for ICCFL in linear mode with VPROG = VPWM. The PWM frequency is set by a single capacitor on the CT pin. The PWM frequency is equal to 22 • 10–6Hz/CT. The PWM duty cycle is set by the voltage on the PROG pin with 1V equal to 0%, and 100% (linear mode) equal to VPWM. The LT1768’s PWM mode enables wide dimming ratios while reducing the high crest factor found in PWM-only dimming solutions. The PWM voltage should be set so that the LT1768 runs in linear mode over the most widely used operating range. In the example in Figure 1, PWM mode runs from VPROG = 1V to VPROG = 3.0V with CCFL current modulated between 0mA and 6mA. The PWM modulation frequency is set to 220Hz by capacitor C3.

When combined, these five modes of operation allow the creation of a DC-controlled CCFL current profile that can be tailored to each particular display. With linear mode, CCFL current control over the most widely used current range and with PWM mode at the low end, the LT1768 enables wide dimming ratios while maximizing CCFL lifetimes.

LT1768 Fault Modes

The LT1768 also has fault detection to ensure that lamp current and Royer transformer ratings are not exceeded under fault conditions. If the current in either CCFL is less than 125µA for a minimum of one PWM clock cycle, the FAULT pin will be activated and ICCFLMAX will be halved. This function ensures that the maximum CCFL current set by RMAX will not be exceeded even under fault conditions. If current in both CCFLs is less than 125µA, and the voltage on the VC pin reaches its clamp value (indicating an open-load condition) for a minimum of one PWM cycle, the gate drive will be latched off. The latch can be cleared by setting VPROG to 0V or placing the LT1768 in shutdown mode.

Additional Features

The LT1768 also contains a temperature-compensated 5V reference, an undervoltage lockout feature for VIN < 8V, thermal shutdown and a logic-compatible shutdown pin that reduces supply current to 50µA when activated. The LT1768 is available in a GN16 package.

Conclusion

The LT1768 high power CCFL controller, with its unique patented dimming control scheme, accurate minimum and maximum lamp currents and lamp fault protection enables wide dimming ratios and maximizes CCFL lifetime in single- or multiple-lamp LCD displays.