Guidelines for Transient Immunity Testing of MAX22190/MAX22192 Industrial Digital Input Serializers

要約

The MAX22190 and MAX22192 are IEC 61131-2 compliant industrial digital input devices. Their transient immunity performance is verified on the MAX22190EVKIT and the MAX22192EVKIT with external components. The test methodology and test setup are based on IEC 61000-4-x standards. Detailed test equipment, test setup and test results are described.

Introduction

Industrial products must undergo extensive EMC testing and pass certification according to IEC standards. As an IC manufacturer, Maxim Integrated performs board-level tests on our components to demonstrate their performance levels and provide guidelines so engineers can optimize their performance. This application note looks at the three specific tests for Transient Immunity Standards, commonly called IEC 61000-4-x, which cover tests for ESD (-2), Electrical Fast Transient (EFT)/Burst (-4), and Surge (-5). Board-level design recommendations are discussed, and test results are presented using Maxim's MAX22190EVKITand MAX22192EVKIT.

The MAX22190/MAX22192 are IEC 61131-2-compliant industrial digital input devices. They translate eight current-sinking industrial inputs to a serialized SPI-compatible output. The MAX22192 differs from the MAX22190 in that it integrates the digital isolation function (equivalent to the MAX14483) which is a separate IC on the MAX22190EVKIT.

The MAX22190 and MAX22192 are designed to operate in harsh industrial environments. The devices can withstand a ±1kV line-to-ground surge with a minimum 1kO series resistor, and ±8kV Contact ESD and ±15kV Air-Gap ESD with a minimum 1kO series resistor.

The MAX22190's transient immunity performance is verified on the MAX22190EVKIT with external components. The MAX22192's transient immunity performance is verified on the MAX22192EVKIT with external components. The test methodology and test setup are based on IEC 61000-4 standards. Detailed test equipment, test setup, and test results are described in the sections below. This report should not be used as compliant certification.

IEC 61000-4 Test Standards

Industrial products are tested for Transient Immunity Standards, as specified in IEC 61000-4. Three main tests are verified for ESD (-2), EFT/Burst (-4), and Surge (-5).

Performance Criteria for Immunity Tests

The results of an immunity test are typically classified into four categories, as listed in Table 1. The end-application requirements and its ability to tolerate transient noise determine whether the system sees the specific performance criteria as a failure or not.

| Criteria | Description |

| Performance Criteria A | Normal operation with no performance degradation |

| Performance Criteria B | Temporary performance degradation which is self-recoverable (data loss/data error) |

| Performance Criteria C | Temporary performance degradation which requires intervention (device reset or power cycle) |

| Performance Criteria D | Loss of function which is not recoverable (device damage) |

Maxim's industrial ICs are typically designed to survive transient immunity events using a combination of integrated functionality and external (board-level) components, such as series pulse-tolerant resistors, transient voltage suppressors (TVSs), and safety-certified Y-capacitors. A simplified schematic of the external protection devices typically used for industrial interface applications is shown in Figure 1.

Figure 1. Simplified schematic for optional external protection components.

IEC 61000-4-2 ESD Testing

The electrostatic discharge (ESD) immunity test emulates the discharges of tens of nanoseconds duration directly on the electronic components. Two discharge methods are used: Contact Discharge and Air-Gap Discharge. An ESD test generator is used with a “sharp point” to make direct connection to the EUT (pin) for Contact ESD testing (Figure 2). A “round tip” is added to the generator and is brought close to the EUT (pin) to trigger a spark for Air-Gap ESD testing.

| Level | Contact Discharge (kV) |

Air-Gap Discharge (kV) |

| 1 | ±2 | ±2 |

| 2 | ±4 | ±4 |

| 3 | ±6 | ±8 |

| 4 | ±8 | ±15 |

Figure 2. ESD Contact Discharge waveform.

IEC 61000-4-4 EFT

The electrical fast transient/burst immunity test indicates the capability of the device or equipment to maintain data integrity during repetitive electrical fast transients and bursts, which often occur from arcing contacts in switches and relays. The EFT Test levels are listed in Table 3.

An EFT/surge generator with an output voltage range up to ±4kV with a 50O output impedance is used to generate the voltage waveforms defined by the IEC specification. Two waveforms are usually tested (shown in Figure 3): a 5kHz repetition frequency with 15ms burst duration and 300ms burst period, and a 100kHz repetition frequency with 0.75ms burst duration and 300ms burst period.

A capacitive-coupling clamp (CCC) provides the ability to couple the fast transients (burst) from the EFT generator to the input pins of the MAX22190/MAX22192 without any galvanic connection. The equipment under test (EUT) is tested with the inputs tied low (0V), high (24V), or floating, as shown in Figure 4. After each EFT test, the evaluation kit (EV kit) GUI reads the status of the EUT (through the SPI interface) to see if the EFT transient caused any damage, changed any register contents, or caused a device reset.

| Level | Power, Eerth Voltage Peak (kV) |

Signal and Control Voltage Peak (kV) |

| 1 | ±0.5 | ±0.25 |

| 2 | ±1 | ±0.5 |

| 3 | ±2 | ±1 |

| 4 | ±4 | ±2 |

Figure 3. EFT/Burst waveform.

Figure 4. EFT test setup.

IEC 61000-4-5 Surge

The surge immunity test indicates the capability of the device or equipment to survive surges caused by events such as lightning strikes or industrial power surges caused by switching heavy loads or short-circuit fault conditions. The surge test levels are listed in Table 4.

The standard specifies different surge pulse profiles, specifically six classes of test levels which depend on the end-equipment installation conditions. The class determines the protection with corresponding voltage levels. In addition, this defines the coupling mode (line-to-line or line-to-ground) and the source impedance (Zs) required. The test class applicable to industrial digital inputs are Class 3 for asymmetrical operated circuits/lines with suggested test levels of ±2kV for line-to-line and ±1kV for line-to-ground. Refer to the IEC 61000-4-5 standard for further details.

The 1.2µs/50µs surge pulse is shown in Figure 5. The surge tests intended for power lines and for I/O ports have different source impedances and, therefore, need different CDNs. The MAX22190 and MAX22192 are tested according to I/O port requirements, and their input surge performance is tested with a 40O + 0.5µF CDN, up to ±1kV line-to-ground and ±2kV line-to-line.

| Level | Test Voltage (kV) |

| 1 | ±0.5 |

| 2 | ±1 |

| 3 | ±2 |

| 4 | ±4 |

Figure 5. 1.2µs/50µs surge voltage waveform.

The standard specifies a source impedance of 42O and, since the external generator has an internal impedance of 2O, an external 40O resistor is used in series with the generator, as shown in the simplified schematic in Figure 6.

Figure 6. Surge test setup.

MAX22190EVKIT and MAX22192EVKIT Description

The MAX22190EVKIT (and MAX22192EVKIT) provides the hardware and software necessary to evaluate the MAX22190 (and MAX22192) features and performance.

The MAX22190EVKIT has two MAX22190 devices on the EV kit, one (U1) is configured for Type 1/3 digital inputs, and the other (U2) is configured for Type 2 inputs. Galvanic isolation between the 'logic' and 'field' domains use the MAX14483and MAX12931 digital isolators.

The MAX22192EVKIT has a MAX22192 and a MAX22190 on the EV kit: the MAX22192 (U1) is configured for Type 1/3 digital inputs, and the MAX22190 (U2) is configured for Type 2 inputs. Galvanic isolation between the logic and field domains uses the isolated SPI interface that is integrated in the MAX22192.

The MAX22190 EV kit GUI is used to configure the MAX22190 registers and read back the digital input and fault status during the test. The MAX22190EVKIT works with the USB2PMB2 adapter board to communicate between the PC and the MAX22190 device through the USB port. Similarly, the MAX22192 EV kit GUI is used with the MAX22192EVKIT.

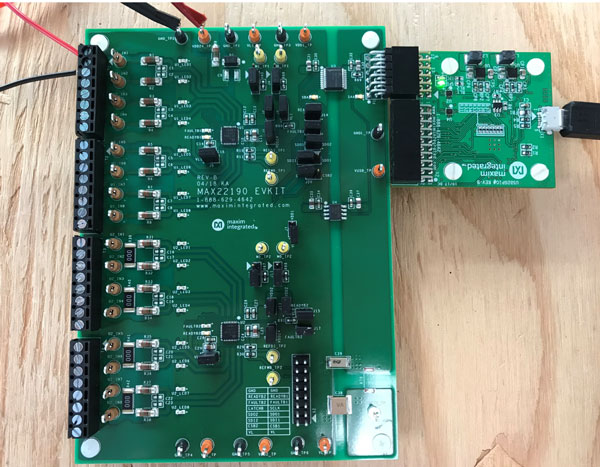

To verify the MAX22190/MAX22192 transient immunity performance, the necessary external protection components are included on the EV kits (Figures 7a and 7b). Details of the differences between the two EV kits are listed in Table 5 with pictures in Figure 8. These items and their impact on performance are discussed in the following sections.

Figure 7a. MAX22190EVKIT block diagram.

Figure 7b. MAX22192EVKIT block diagram.

| EV KIT | ICs | Isolation | Input Resistor | Y Capacitor | TVS | Terminal Block |

| MAX22190 EVKIT | U1 = MAX22190 (Type 1, 3) U2 = MAX22190 (Type 2) |

MAX14483, MAX12931 | CMB0207 MELF | 3300pF GNDF-PE, 1000pF GNDF-GNDL | SMAJ33A | Phoenix Contact, 1.7mm clearance |

| MAX22192 EVKIT | U1 = MAX22192

(Type 1, 3) U2 = MAX22190 (Type 2) |

Integrated in MAX22192, MAX12931 | CRCW2512-HP | 3300pF GNDF-PE, 1000pF GNDF-GNDL | SMAJ33A | Wago, 2.5mm clearance |

Figure 8. MAX22190EVKIT and MAX22192EVKIT.

Input Resistor

A minimum 1kO series resistor is required between the field input and the MAX22190/MAX22192 input pin to limit the surge current going into the device. This also sets the high-to-low and low-to-high input voltage thresholds. For Type 1 and Type 3 inputs, a 1.5kO resistor is recommended. For Type 2 inputs, a 1kO resistor is recommended with two input channels in parallel.

The input resistor must be a pulse-withstanding type to survive the surge pulses. Two resistor components are tested and verified with the MAX22190 and MAX22192.

- CMB0207 MELF resistor on the MAX22190EVKIT

This resistor is used on the MAX22190EVKIT. It can withstand ±1kV line-to-ground surge and ±8kV Contact ESD. However, arcing was observed across the two resistor pads when ±15kV Air-Gap ESD was applied to the input. This is due to the fact that the clearance between the two resistor pads on the PCB was too small to prevent the arcing. During the ±15kV Air-Gap ESD test, we removed the resistor from the pads, installed the CMB0207 perpendicular to the PCB using the pad connected to the MAX22190 input, and applied the ESD directly to the resistor. With this modification, this board passed ±15kV Air-Gap ESD.

Care should be taken to maintain large enough clearance between resistor pads on the PCB when designing pulse-withstanding resistors to prevent arcing. - CRCW2512-HP thick film resistor on the MAX22192EVKIT The MAX22192EVKIT uses CRCW2512-HP thick film resistors at the inputs. They have a larger package than the CMB0207 type, allowing this board to pass ±1kV line-to-ground surge, ±8kV Contact ESD, and ±15kV Air-Gap ESD.

Safety-Rated Y-Capacitor

Earth connection is provided on the EV kits to verify the line-to-earth transient immunity performance. It is required to install a safety-rated Y-capacitor between the field ground (GNDF) and earth (PE) to reach the best ESD and EFT performance. The Y-capacitor value can be adjusted based on the application. By default, a 3300pF capacitor is installed on the MAX22190EVKIT and MAX22192 EVKIT.

The MAX22190EVKIT has onboard galvanic isolation between the field ground and logic ground (GNDL). The MAX14483 and MAX12931 digital isolators have a basic insulation rating. A safety-rated Y-capacitor is required between the field ground and logic ground if ESD or EFT is applied between field ground and logic ground. The Y-capacitor value can be adjusted based on the application. By default, a 1000pF capacitor is installed on these EV kits.

The MAX22192EVKIT has integrated galvanic isolation (with a basic insulation rating) between the field ground and logic ground. A safety-rated Y-capacitor is required between the field ground and logic ground if ESD or EFT is applied between field ground and logic ground. The - capacitor value can be adjusted based on the application. By default, a 1000pF capacitor is installed on these EV kits.

TVS Diode on the VDD24

The MAX22190/MAX22192 VDD24 pin does not have integrated surge protection, so a TVS diode is required to protect the VDD24 pin from ESD, EFT, and surge. Since the VDD24 pin has an Abs Max of +70V, a smaller TVS diode can be selected based on different surge series resistance. With 42O surge impedance, SMAJ33A is recommended, and with 2O surge impedance, SM30T39AY is recommended.

A small series resistor can also be implemented on the VDD24 pin to further limit the surge current into the VDD24 pin. A 150O pulse-withstanding series resistor is included on the EV kits. The value can be adjusted based on the application. Care should be taken when selecting the resistor value that the voltage drop across the resistor does not trigger VDD24 into UVLO. This resistor must be a pulse-withstanding type to survive the surge pulses.

Input Terminal Block

There are 3.5mm pitch terminal blocks used as field inputs on the MAX22190EVKIT. Arcing was observed between the field input pin and the adjacent field ground pin during ±15kV Air-Gap ESD Maxim Integrated Page 12 of 17 testing. This was due to not enough clearance (1.7mm) between two adjacent pins (input and field-ground) on this terminal block. In the MAX22192EVKIT, this issue is fixed by using larger pitch terminal blocks and the clearance was increased to 2.5mm.

Test Methodology and Results

The equipment used for testing the MAX22190EVKIT and MAX22192EVKIT are listed in Table 6, and a picture of the test bench setup is shown in Figure 9.

| Equipment | Description | Test(S) |

| MAX22190EVKIT or MAX22192EVKIT | EUT | All |

| ESD Test Generator | Teseq® NSG438 with Air-Gap Discharge Tip 403-826 | Contact ESD and Air-Gap ESD |

| EFT/Surge Generator | Haefely® Technology ECOMPACT4 and Teseq NSG 3040A | EFT and Surge |

| Signal and Data Line Coupling Network | Teseq CDN 117 | Surge |

| Coupler with 0.5µF Capacitor | INA 174A | Surge |

| Capacitive Coupling Clamp | Teseq CDN 3425 | EFT |

Figure 9. MAX22190EVKIT and MAX22192EVKIT transient immunity testing bench setup.

Test Setup and Results

The MAX22190EVKIT is powered by an external 24V source through the VDD24 test point. C38 is populated with a 3300pF Y-capacitor. C39 is populated with a 1000pF Y-capacitor.

The USB2PMB2 (or USB2GPIO) is attached to connector X1, and the logic side is powered by 3.3V generated from the USB2PMB2 (or USB2GPIO), which is powered by the 5V supply on the USB port on the PC. The MAX22190 EV kit GUI (or MAX22192 EV kit GUI) is used to configure the devices and read and write all their registers.

Both U1 and U2 are configured in SPI Mode 0, which is independent slave mode. All jumpers are in their default position as shown in the MAX22910EVKIT and MAX22912EVKIT data sheets. The bit for power-on-reset (POR) is cleared before each test. Register content and basic device functionalities are verified after each test.

In Figures 10 to 12, images of the MAX22190EVKIT under test are shown. The same tests were done using the MAX22192EVKIT. See the ESD test results in Table 7.

Figure 10. MAX22190EVKIT under test.

IEC 61000-4-2

- Test level: ±8kV Contact Discharge, ±15kV Air-Gap Discharge.

- Input condition: input floating, input low (0V), input high (24V).

- ESD pulses of 1Hz are applied 10 times at both positive polarity and negative polarity. Maxim Integrated Page 14 of 17

- MAX22190EVKIT series resistor is mounted in vertical position to prevent the arcing MAX22190EVKIT series resistor is mounted in vertical position to prevent the arcing across the two resistor pads on the PCB.

Figure 11. Contact Discharge ESD test.

Figure 12. Air-Gap Discharge ESD test.

| ESD Test | Test Condition | Configuration | Levels | Observation |

| Contact Discharge | Line-to-Field Ground | RIN = 1kO or 1.5kO | ±8kV | Operates normally after disturbance is removed; no device reset or register content change |

| Line-to-Logic Ground | RIN = 1kO or 1.5kO, 1000pF Y-capacitor between GNDF and GNDL | ±8kV | Operates normally after disturbance is removed; no device reset or register content change | |

| Line-to-Earth | RIN = 1kO or 1.5kO, 3300pF Y-capacitor between GNDF and Earth | ±8kV | Operates normally after disturbance is removed; no device reset or register content change | |

| VDD24-to-Field Ground | With TVS and 150O series resistor | ±8kV | Operates normally after disturbance is removed; no device reset or register content change | |

| VDD24-to-Logic Ground | With TVS and 150O series resistor, 1000pF Y-capacitor between GNDF and GNDL | ±8kV | Operates normally after disturbance is removed; no device reset or register content change | |

| Air-Gap Discharge | Line-to-Field Ground | RIN = 1kO or 1.5kO | ±15kV | Operates normally after disturbance is removed; no device reset or register content change |

| Line-to-Logic Ground | RIN = 1kO or 1.5kO, 1000pF Y-capacitor between GNDF and GNDL | ±15kV | Operates normally after disturbance is removed; no device reset or register content change | |

| Line-to-Earth | RIN = 1kO or 1.5kO, 3300pF Y-capacitor between GNDF and Earth | ±15kV | Operates normally after disturbance is removed; no device reset or register content change | |

| VDD24-to-Field Ground | With TVS and 150O series resistor | ±15kV | Operates normally after disturbance is removed; no device reset or register content change | |

| VDD24-to-Logic Ground | With TVS and 150O series resistor, 1000pF Y-capacitor between GNDF and GNDL | ±15kV | Operates normally after disturbance is removed; no device reset or register content change |

In summary, both the MAX22190 and MAX22192 meet Performance Criteria B for ESD tests.

IEC 61000-4-4

- Test level: Up to ±4kV.

- Input condition: Input floating, input low (0V), input high (24V).

- Two EFT frequencies: 5kHz with 15ms burst time, 100kHz with 0.75ms burst time.

- EFT/Burst was applied for one minute while monitoring the input data register continuously, both positive polarity and negative polarity.

- Both field input and field ground are coupled inside the capacitive clamps and then connected to the input terminal block.

In summary, both the MAX22190 and MAX22192 meet Performance Criteria A for EFT tests as listed in Table 8.

| Test Condition | Configuration | Levels | Observation |

| Input Line | RIN = 1kO or 1.5kO, 3300pF Y-capacitor between GNDF and earth | ±4kV | Operates normally without disturbance |

| VDD24 Line | With TVS and 150O series resistor, 3300pF Y-capacitor between GNDF and earth | ±4kV | Operates normally without disturbance |

IEC 61000-4-5

- Test level: up to ±1kV line-to-ground, up to ± 2kV line-to-line (both inputs floating only).

- Input condition: input floating, input low (0V), input high (24V). Maxim Integrated Page 17 of 17

- Surge pulses are applied 10 times, at 10s intervals, both positive polarity and negative polarity.

- CDN: 40O + 0.5µF

In summary, both the MAX22190 and MAX22192 meet Performance Criteria B for surge on the input pins and Performance Criteria C for surge on the VDD24 supply as listed in Table 9.

| Test Condition | Configuration | Levels | Observation |

| Line-to-Line | RIN = 1kO or 1.5kO | ±2kV | Operates normally after disturbance is removed; no device reset or register content change |

| Line-to-Field Ground | RIN = 1kO or 1.5kO | ±1kV | Operates normally after disturbance is removed; no device reset or register content change |

| Line-to-Logic Ground | RIN = 1kO or 1.5kO, 1000pF Y-capacitor between GNDF and GNDL | ±1kV | Operates normally after disturbance is removed; no device reset or register content change |

| Line-to-Earth | RIN = 1kO or 1.5kO, 3300pF Y-capacitor between GNDF and earth | ±1kV | Operates normally after disturbance is removed; no device reset or register content change |

| VDD24-to-Field Ground | With TVS diode and 150O series resistor | ±1kV | Device reset after the surge; POR is triggered by surge |

| VDD24-to-Logic Ground | With TVS diode and 150O series resistor, 1000pF Y-capacitor between GNDF and GNDL | ±1kV | Operates normally after disturbance is removed; no device reset or register content change |

Summary

The MAX22190 and MAX22192 were tested in Maxim's lab according to IEC 61000-4 for ESD (-2), EFT/Burst (-4), and Surge (-5) using the MAX22190EVKIT and MAX22192EVKIT. By following the recommended external components and PCB layout guidelines for these EV kits, the devices will pass ESD Level 4 (±8kV Contact and ±15kV Air-Gap) to Performance Criteria B, EFT Level 4 (±4kV I/O to ground) to Performance Criteria A, and Surge Class 2 (±1kV line-to-ground with 42O coupling) to Performance Criteria B. This provides engineers with a guideline for designing their equipment to pass compliant certifications.