DC/DC Converter, Capacitor Charger Takes Inputs from 4.75V to 400V

Introduction

High voltage power supplies and capacitor chargers are readily found in a number of applications, including professional photoflashes, security control systems, pulsed radar systems, satellite communication systems, and explosive detonators. The LT3751 makes it possible for a designer to meet the demanding requirements of these applications, including high reliability, relatively low cost, safe operation, minimal board space and high performance.

The LT3751 is a general purpose flyback controller that can be used as either a voltage regulator or as a capacitor charger. The LT3751 operates in boundary-mode, between continuous conduction mode and discontinuous conduction mode. Boundary-mode operation allows for a relatively small transformer and an overall reduced PCB footprint. Boundary-mode also reduces large signal stability issues that could arise from using voltage-mode or PWM techniques. Regulation is achieved with a new dual, overlapping modulation technique using both peak primary current modulation and duty-cycle modulation, drastically reducing audible transformer noise.

The LT3751 features many safety and reliability functions, including two sets of undervoltage lockouts (UVLO), two sets of overvoltage lockouts (OVLO), no-load operation, over temperature lockout (OTLO), internal Zener clamps on all high voltage pins, and a selectable 5.6V or 10.5V internal gate driver voltage clamp (no external components needed). The LT3751 also adds a start-up/short-circuit protection circuit to protect against transformer or external FET damage. When used as a regulator, the LT3751’s feedback loop is internally compensated to ensure stability. The LT3751 is available in two packages, either a 20-pin exposed pad QFN or a 20-lead exposed pad TSSOP.

New Gate Driver with Internal Clamp Requires No External Components

There are four main concerns when using a gate driver: output current drive capability, peak output voltage, power consumption and propagation delay. The LT3751 is equipped with a 1.5A push-pull main driver, enough to drive +80nC gates. An auxiliary 0.5A PMOS pull-up only driver is also integrated into the LT3751 and is used in parallel with the main driver for VCC voltages of 8V and below. This PMOS driver allows for rail-to-rail operation. Above 8V, the PMOS driver must be deactivated by tying its drain to VCC.

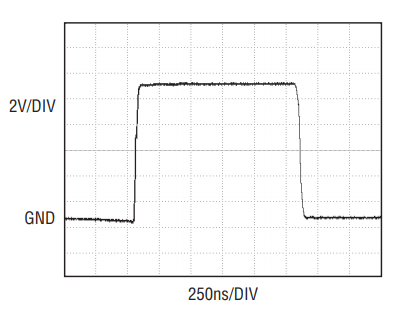

Most discrete FETs have a VGS limit of 20V. Driving the FET higher than 20V could cause a short in the internal gate oxide, causing permanent damage. To alleviate this issue, the LT3751 has an internal, selectable 5.6V or 10.5V gate driver clamp. No external components are needed, not even a capacitor. Simply tie the CLAMP pin to ground for 10.5V operation or tie to VCC for 5.6V operation. Figure 1 shows the gate driver clamping at 10.5V with a VCC voltage of 24V.

Figure 1. Gate driver waveform in a typical application.

Not only does the internal clamp protect the FET from damage, it also reduces the amount of energy injected into the gate. This increases overall efficiency and reduces power consumption in the gate driver circuit. The gate driver overshoot is very minimal, as seen in Figure 1. Placing the external FET closer to the LT3751 HVGATE pin reduces overshoot.

High Voltage, Isolated Capacitor Charger from 10V to 24V Input

The LT3751 can be configured as a fully isolated stand-alone capacitor charger using a new differential discontinuous-conduction-mode (DCM) comparator—used to sense the boundary-mode condition—and a new differential output voltage (VOUT) comparator. The differential operation of the DCM comparator and VOUT comparator allow the LT3751 to accurately operate from high voltage input supplies of greater than 400V. Likewise, the LT3751’s DCM comparator and VOUT comparator can work with input supplies down to 4.75V. This accommodates an unmatched range of power sources.

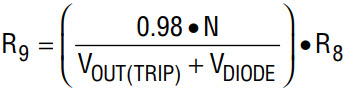

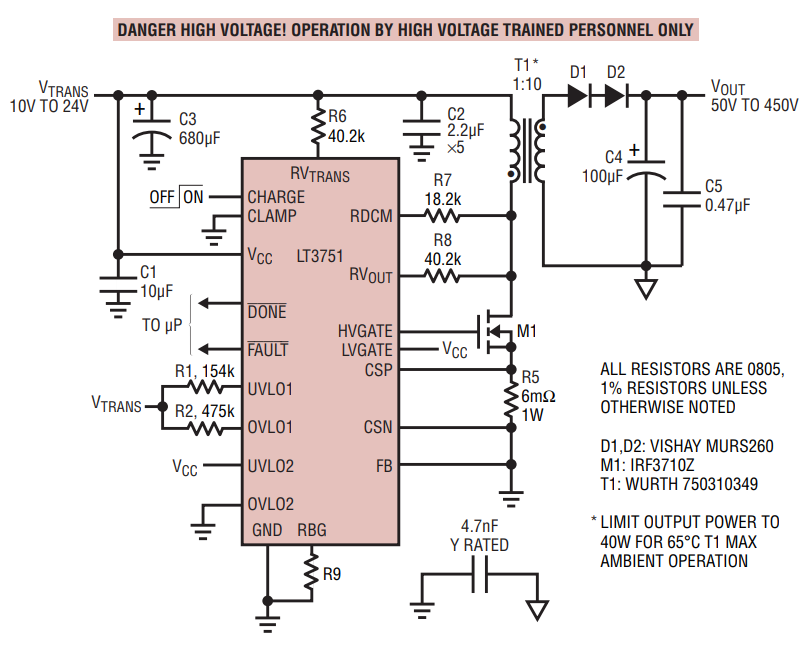

Figure 2 shows a high voltage capacitor charger driven from an input supply ranging from 10V to 24V. Only five resistors are needed to operate the LT3751 as a capacitor charger. The output voltage trip point can be continuously adjusted from 50V to 450V by adjusting R9 given by:

Figure 2. Isolated high voltage capacitor charger from 10V to 24V input.

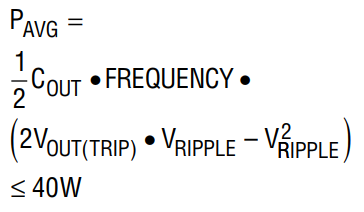

The LT3751 stops charging the output capacitor once the programmed output voltage trip point (VOUT(TRIP)) is reached. The charge cycle is repeated by toggling the CHARGE pin. The maximum charge/discharge rate in the output capacitor is limited by the temperature rise in the transformer. Limiting the transformer surface temperature in Figure 2 to 65°C with no air flow requires the average output power to be ≤40W given by:

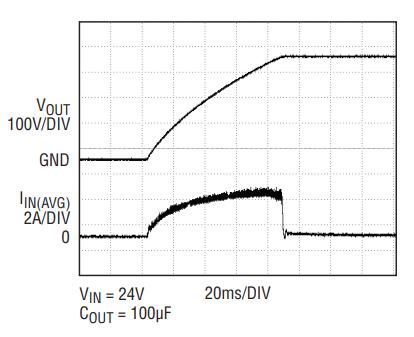

where VOUT(TRIP) is the output trip voltage, VRIPPLE is the ripple voltage on the output node, and frequency is the charge/discharge frequency. Two techniques are used to increase the available output power: increase the airflow across the transformer, or increase the size of the transformer itself. Figure 3 shows the charging waveform and average input current for a 100µF output capacitor charged to 400V in less than 100ms (R9 = 976Ω).

Figure 3. Isolated high voltage capacitor charger charging waveform.

For output voltages higher than 450V, the transformer in Figure 2 must be replaced with one having higher primary inductance and a higher turns ratio. Consult the LT3751 data sheet for proper transformer design procedures.

High Voltage Regulated Power Supply from 10V to 24V Input

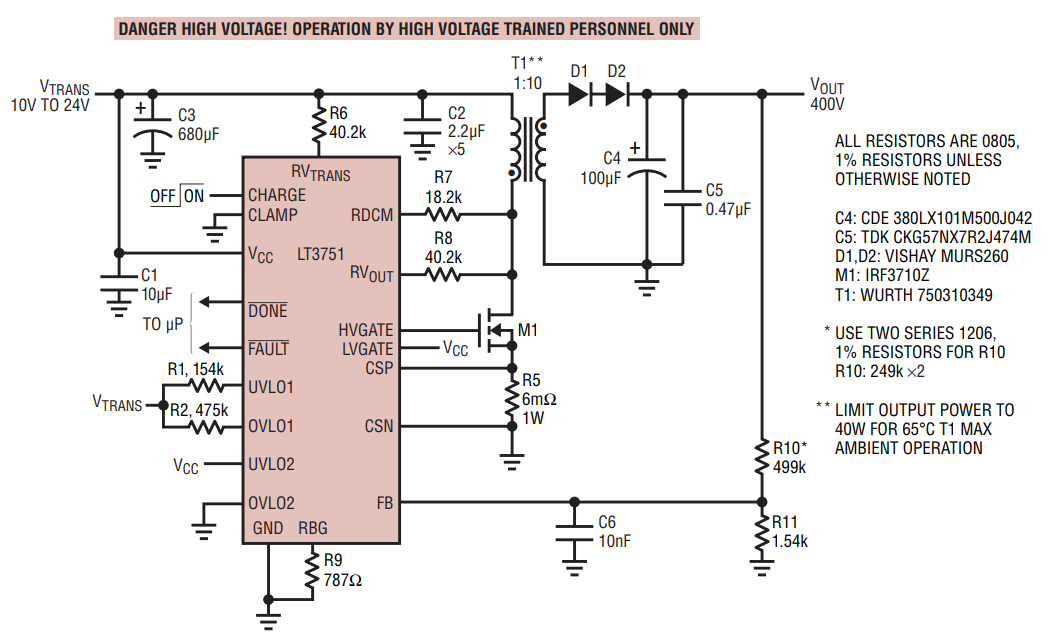

The LT3751 can also be used to convert a low voltage supply to a much higher voltage. Placing a resistor divider from the output node to the FB pin and ground causes the LT3751 to operate as a voltage regulator. Figure 4 shows a 400V regulated power supply operating from an input supply range of 10V to 24V.

Figure 4. A 10V to 24V input, 400V regulated power supply.

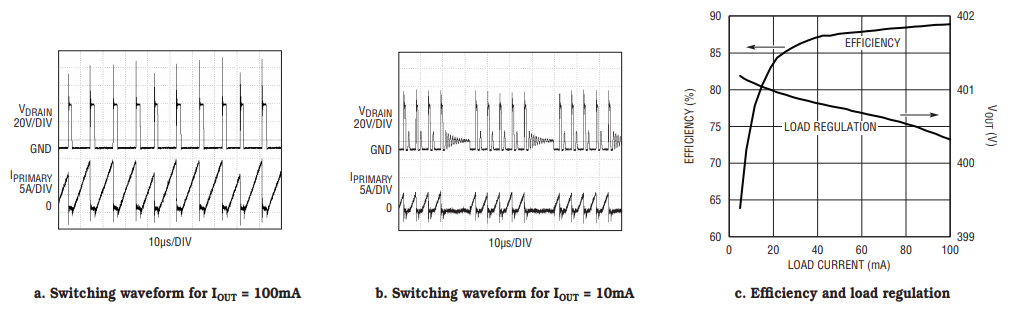

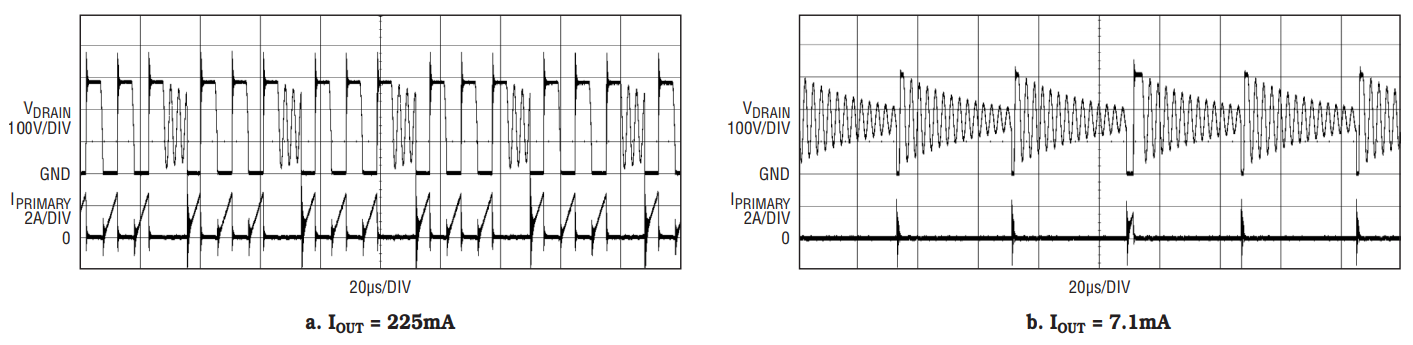

The LT3751 uses a regulation control scheme that drastically reduces audible noise in the transformer and the input and output ceramic bulk capacitors. This is achieved by using an internal 26kHz clock to synchronize the primary winding switch cycles. Within the clock period, the LT3751 modulates both the peak primary current and the number of switching cycles. Figures 5a and 5b show heavy-load and light-load waveforms, respectively, while Figure 5c shows efficiency over most of the operating range for the application in Figure 4.

Figure 5. High voltage regulator performance.

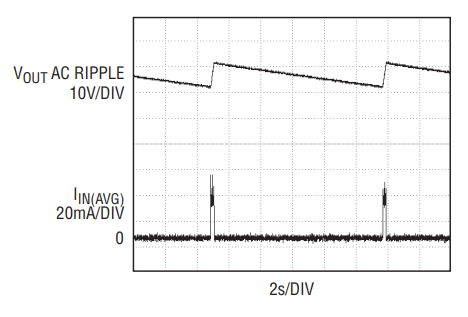

The clock forces at least one switch cycle every period which would overcharge the output capacitor during a no-load condition. The LT3751 handles no-load conditions and protects against over-charging the output node. Figure 6 shows the LT3751 protecting during a no-load condition.

Figure 6. The LT3751 protecting the output during a no-load condition.

Resistors can be added to RVOUT and RBG to add a second layer of protection, or they can be omitted to reduce component count by tying RVOUT and RBG to ground. The trip level for the VOUT comparator is typically set 20% higher than the nominal regulation voltage. If the resistor divider were to fail, the VOUT comparator would disable switching when the output climbed to 20% above nominal.

Note that the FB pin of the LT3751 can also be used for a capacitor charger. The LT3751 operates as a capacitor charger until the FB pin reaches 1.225V, after which the LT3751 operates as a voltage regulator. This keeps the capacitor topped-off until the application needs to use its energy. The output resistor divider forms a leakage path from the output capacitor to ground. When the output voltage droops, the LT3751 feedback circuit will keep the capacitor topped-off with small, low current bursts of charge as shown in Figure 6.

High Input Supply Voltage, Isolated Capacitor Charger

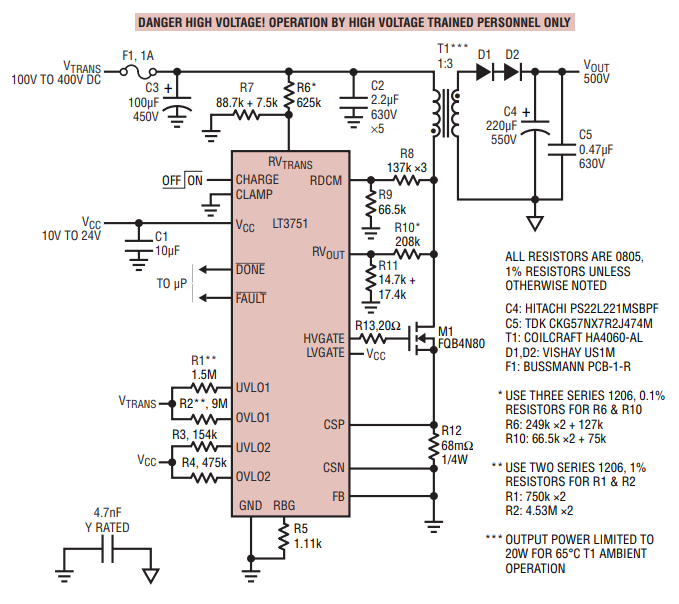

As mentioned above, the LT3751 differential DCM and VOUT comparators allow the part to accurately work from very high input supply voltages. An offline capacitor charger, shown in Figure 7, can operate with DC input voltages from 100V to 400V. The transformer provides galvanic isolation from the input supply to output node—no additional magnetics required.

Figure 7. A 100V to 400V input, 500V output, isolated capacitor charger.

Input voltages greater than 80V require the use of resistor dividers on the DCM and VOUT comparators (charger mode only). The accuracy of the VOUT trip threshold is heightened by increasing current IQ through R10 and R11; however, the ratio of R6/R7 should closely match R10/R11 with tolerances approaching 0.1%. A trick is to use resistor arrays to yield the desired ratio. Achieving 0.1% ratio accuracy is not difficult and can reduce the overall cost compared to using individual 0.1% surface mount resistors. Note that the absolute value of the individual resistors is not critical, only the ratio of R6/R7 and R10/R11. The DCM comparator is less critical and can tolerate resistance variations greater than 1%.

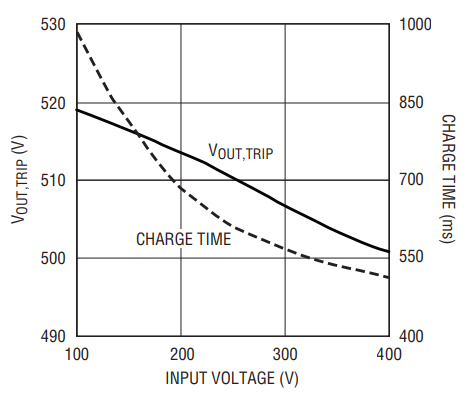

The 100V to 400VDC input capacitor charger has an overall VOUT(TRIP) accuracy of better than 6% over the entire operating range using 0.1% resistor dividers. Figure 8 shows a typical performance for VOUT(TRIP) and charge time for the circuit in Figure 7.

Figure 8. Isolated capacitor charger VOUT(TRIP) and charge time with respect to input voltage.

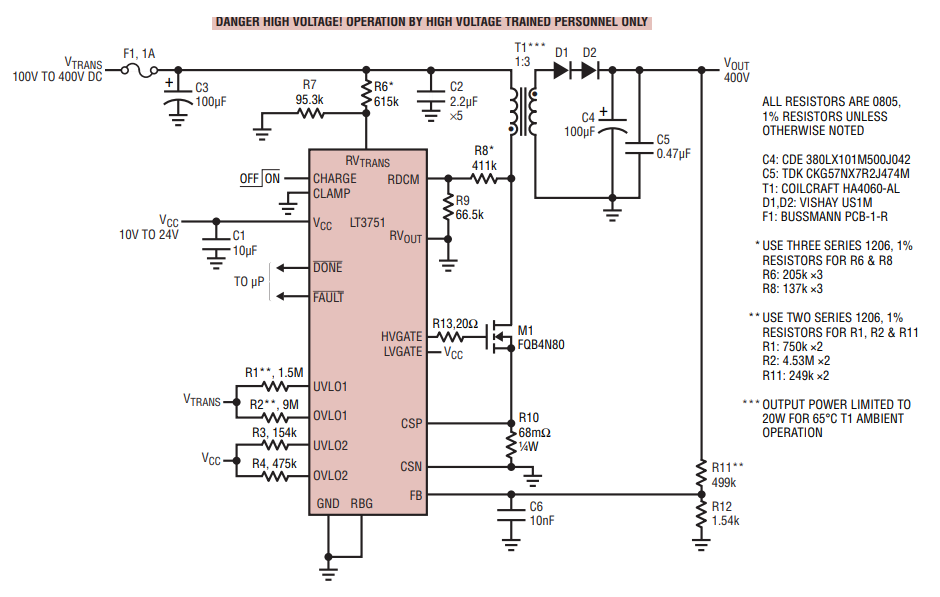

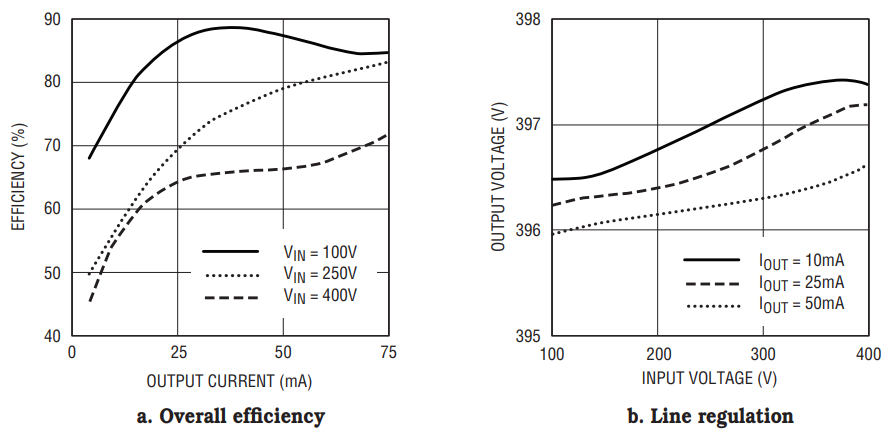

High Input Supply Voltage, Non-Isolated Capacitor Charger/Regulator

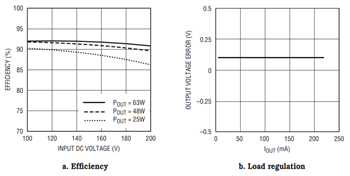

The FB pin of the LT3751 can also be configured for charging a capacitor from a high input supply voltage. Simply tie a resistor divider from the output node to the FB pin. The resistor dividers on the RVTRANS and RDCM pins can tolerate 5% resistors, and all the RV(OUT) and RBG pin resistors are removed. This lowers the number and the tolerance of required components, reducing board real estate and overall design costs. With the output voltage resistor divider, the circuit in Figure 9 is also a fully functional, high-efficiency voltage regulator with load and line regulation better than 1%. Efficiency and line regulation for the circuit in Figure 9 are shown in Figure 10a and Figure 10b, respectively.

Figure 9. A 100V to 400V input, 400V output, capacitor charger and voltage regulator.

Figure 10. High voltage input and output regulator performance.

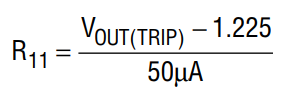

Alternatively, a resistor can be tied from VOUT to the OVLO1 pin or OVLO2 pin. This mimics the VOUT comparator, stopping charging once the target voltage is reached. The FB pin is tied to ground. The CHARGE pin must be toggled to initiate another charge sequence, thus the LT3751 operates as a capacitor charger only. Resistor R12 is omitted from Figure 9 and resistor R11 is tied from VOUT directly to OVLO1 or OVLO2. R11 is calculated using the following equation:

Note that OVLO1 or OVLO2 will cause the FAULT pin to indicate a fault when the target outpaut voltage, VOUT(TRIP) , is reached.

High Voltage Input/Output Regulator with Isolation

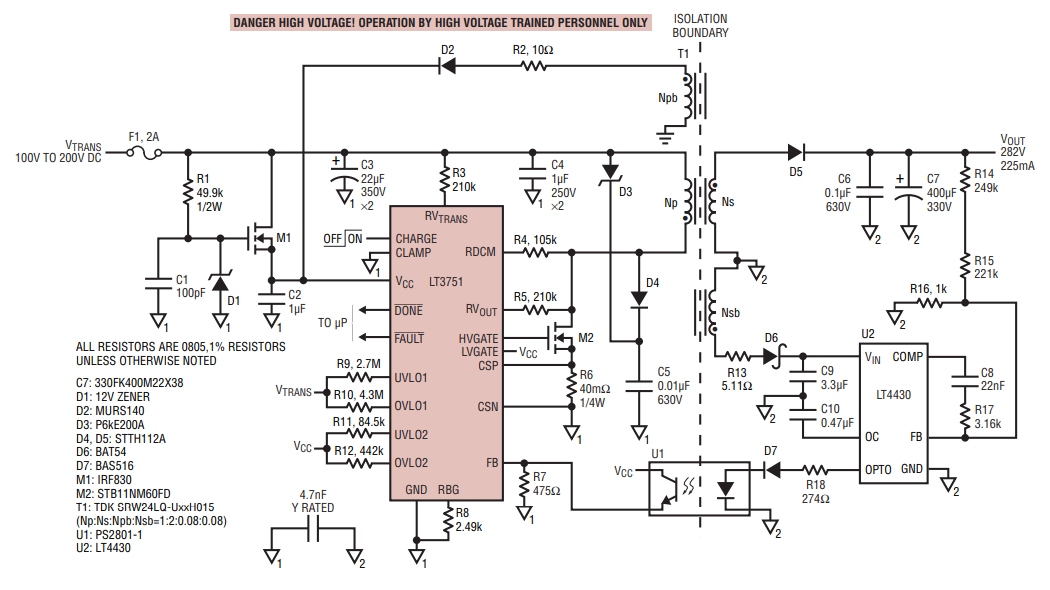

Using a resistor divider from the output node to the FB pin allows regulation but does not provide galvanic isolation. Two auxiliary windings are added to the transformer in circuit shown in Figure 11 to drive the FB pin, the LT3751 controller, and the optocoupler on the feedback resistor divider. The auxiliary windings provide the desired galvanic isolation boundary while maintaining an isolated feedback path from the output node to the LT3751 FB pin. Figures 12 and 13 show the regulator’s performance.

Figure 11. Fully isolated, high output voltage regulator.

The fully isolated, high voltage input/output regulator yields over 90% efficiency. Load regulation is excellent as shown in Figure 13b, due mainly to the added gain of the optocoupler circuit.

Figure 12. Switching waveforms.

Figure 13. Fully isolated, high voltage regulator performance.

Conclusion

The ability to run from any input supply voltage ranging from 4.75V to greater than 400V and the abundance of safety features make the LT3751 an excellent choice for high voltage capacitor chargers or high voltage regulated power supplies. In fact, the LT3751 is, for now, the only boundary-mode capacitor charger controller that can accurately operate from extremely high input voltages. The LT3751 simplifies design by integrating many functions that—due to cost and board real-estate—would otherwise not be realizable. Although several designs are shown here, the LT3751 includes many more features than we can show in one article. We recommended consulting the data sheet or calling the Analog Devices applications engineering department for more in-depth coverage of all available features.