Horiba Speeds Up Safety, Sustainability, and Productivity With Real-time, Infrared Gas Analysis

SIGNALS+ NEWSLETTER SUBSCRIPTION

Stay updated and leverage Signals+ latest insights, information and ideas on Connectivity, Digital Health, Electrification, and Smart Industry.

Thank you for subscribing to ADI Signals+. A confirmation email has been sent to your inbox.

You'll soon receive timely updates on all the breakthrough technologies impacting human lives across the globe. Enjoy!

CloseHORIBA SPEEDS UP SAFETY, SUSTAINABILITY, AND PRODUCTIVITY WITH REAL-TIME, INFRARED GAS ANALYSIS

June 22, 2022

Everyone knows that offensive, rotten-egg smell when you turn on your gas stove or when you’re in your car and you get a whiff of exhaust in the cabin. While these gases may be toxic in large doses, they’re fairly harmless and easily detected.

But in the industrial manufacturing world, not all gases are so easily detected and their effects can have even wider ranging issues, including having major impacts to productivity and the environment.

Real-time, infrared gas analysis is the ideal solution and of the utmost importance in these circumstances. On a broad scale, industries including automotive, energy production, and semiconductor manufacturing could leverage real-time, infrared gas analysis, and sensing technologies to help attain their safety, productivity, and environmental goals.

Enter the HORIBA Group.

AT A GLANCE

COMPANY

The HORIBA Group of worldwide companies provides an extensive array of instruments and systems for applications ranging from automotive R&D, process and environmental monitoring, in vitro medical diagnostics, semiconductor manufacturing, and metrology to a broad range of scientific R&D and QC measurements.

TECHNOLOGIES

HORIBA has developed its proprietary infrared gas measurement method, infrared laser absorption modulation (IRLAM™)*, to address the market’s needs for speed, accuracy, and versatility in measuring a wide range of gases. As part of this solution, HORIBA used Analog Devices’ ultralow noise and high speed signal processing technologies, including ultrahigh speed analog-to-digital converters (ADCs).

CHALLENGE

Detect trace amounts of highly volatile, dangerous gases in differing environments, while contending with various conditions of heat, wind, sound, vibration, etc.

GOAL

Contribute to global environmental conservation, safety, and health, and moreover to improving energy problems.

~5 MIN.

TIME IT TAKES FOR HIGH CONCENTRATIONS OF CARBON MONOXIDE (CO) TO KILL SOMEONE.1

43%

OF OVERALL NATURAL GAS USAGE IS IN INDUSTRIAL SETTINGS.2

“HORIBA is all about staying ahead of the curve. So when we were developing IRLAM real-time gas analysis technology, we knew we needed a partner who could deliver deep technical insight, but who also designed solutions for real-time measurements. ADI met all those parameters. They’re a true solutions provider … much more than a chip manufacturer!”

Dr. Kyoji Shibuya

IRLAM Development Manager

INDUSTRY-APPROVED: REAL-TIME, INFRARED GAS ANALYSIS

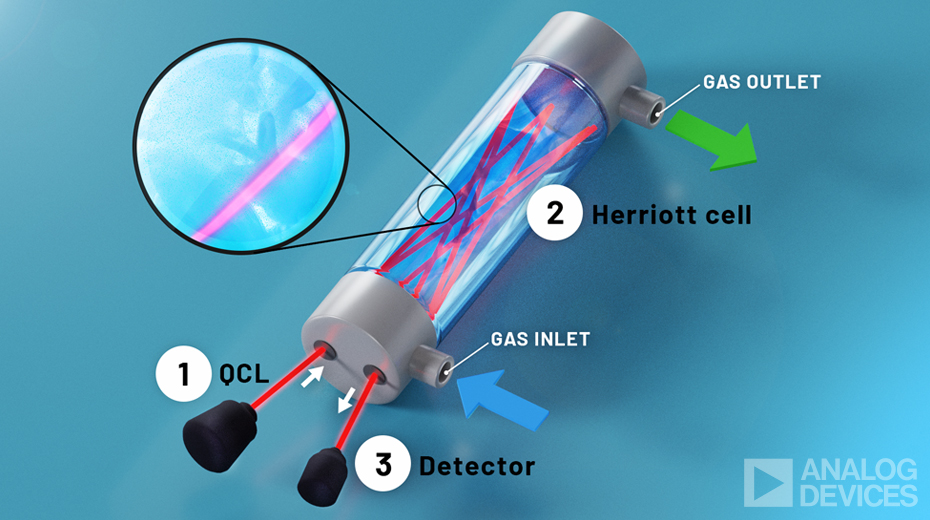

- Infrared light emitted from the QCL is injected into the Herriott cell.

- The gas to be analyzed is introduced into the Herriott cell, and the infrared light is absorbed by the gas in a long optical path while being reflected many times.

- The absorbed infrared signal is acquired by the detector, and the concentration of the gas to be analyzed is calculated.

Productivity cannot be understated in a manufacturing environment. HORIBA understands this and realizes that helping monitor the petrochemical process, including natural gas monitoring, helps improve productivity dramatically. This increased productivity also leads to reduced energy and material consumption—which helps manufacturers in their quest to achieve their sustainability initiatives.

With this in mind, HORIBA stepped to the fore in developing and commercializing a proprietary technology called IRLAM. IRLAM is used to monitor petrochemical process gas, including natural gas, and ultimately improve productivity.

This general-purpose, real-time gas analyzer maximizes the efficiency of the measurement process, and analyzes gas components in various industries including:

AUTOMOTIVE

Speedily monitors and controls environmentally hazardous substances contained in exhaust gas. This important technology enables more environmentally friendly performance in internal combustion engines while the industry transitions to electric vehicles.

95%

of all CO emissions in cities may come from motor vehicle exhaust.3

ENERGY PRODUCTION

Detects impurities in hydrogen energy production. Also, for gasification and reforming processes of hydrogen raw materials, HORIBA delivers gas measurement for hydrogen purity, engineering for plant integration, and analytical technologies for catalyst materials used in hydrogen separation, recovery, and purification processes.

SEMICONDUCTOR MANUFACTURING

IRLAM’s high accuracy, high speed measurement allows inline monitoring of semiconductor process gases. It allows fine control of gas concentration based on real-time measurement data and improves processing accuracy, manufacturing yield, and productivity while reducing material and time loss.

OUT OF A LONG-LASTING PARTNERSHIP, IRLAM EMERGES

Long before IRLAM hit the market with its leading-edge performance, HORIBA required precision signal conditioning that would reliably detect even the most subtle traces of gas. For that technology, HORIBA turned to a tech partner it was quite familiar with—the sensing solution experts at ADI. ADI’s industry-leading signal conditioning technology bridges the physical and digital world, even for tough-to-detect signals in challenging environments, like detecting toxic gases in manufacturing plants.

With a partnership spanning two decades, ADI has been providing critical devices to HORIBA’s key applications, including advanced precision technologies. These technologies have helped support HORIBA’s need for a laser driver circuit for realizing fast and sophisticated control of a light source. Today, HORIBA’s trusted confidence in ADI has grown to a more open and collaborative relationship.

For IRLAM, HORIBA leveraged ADI’s ultralow noise, high speed, and high resolution SAR ADCs for signal processing and was able to create a solution with a unique set of capabilities that is already being deployed in a variety of applications for gas measurement protocols.

When detecting dangerous gases, speed is of the essence. HORIBA’s IRLAM technology achieves both high speed and high accuracy measurement with real-time monitoring, feedback, and control of various systems and processes that previously could only be measured in batches. When you’re operating in a high throughput environment such as manufacturing plants, this capability can be a true lifesaver.

ADI SOLUTION HIGHLIGHTS FOR HORIBA

DESIGN CHALLENGES |

ADI SOLUTIONS |

|||

Laser Generation & Drive |

Novel HORIBA QCL drive modulation required for concentration calculation algorithm | Integrated waveform generator enables flexible modulation scheme. Integrated thermal control minimizes subsystem footprint |

||

Signal Processing |

Ultra-sensitive photo detector requires precision high speed and low noise signal conditioning (–1 dB flatness at 100 MHz) to improve gas detection speed | Only ADI’s precision with speed signal chain technology meets the requirements for low noise, high speed signal processing | ||

Architecture Design |

Supplier collaboration required for unique high speed + precision system design to achieve design specifications | Concurrent development and partnership in signal processing circuit architecture enabled by trusted ADI applications engineering expertise |

ACHIEVING WORTHWHILE GOALS WITH REAL-TIME, INFRARED GAS ANALYSIS

Real-time, infrared gas analysis is an indispensable technology that touches many industries. What’s more, this key technology will play an ever-expanding role in the development of next-generation energy sources, including hydrogen, which is gaining momentum around the world in our march toward carbon neutrality. As manufacturing and automotive industries across the globe strategize for a more sustainable future, how they measure and analyze gas will be paramount in ensuring the safety of their work environments, and the growth of their businesses.

HORIBA and ADI look to be quintessential elements in helping manufacturers achieve these worthwhile goals. Proof of their partnership is their combined technologies, which have resulted in the creation of IRLAM, which some HORIBA managers believe will become the standard gas analyzer in the industry, much like NDIR, which measures the concentration of gases such as carbon oxides in the atmosphere, exhaust gases, etc.

While speed may not always be a determining factor in a manufacturer’s success, in the case of HORIBA’s IRLAM real-time infrared gas detection, it can be transformative.

References

* IRLAM is a registered trademark or trademark of HORIBA, Ltd. in Japan and other countries.

1 Divya Jacob and Shaziya Allarakha. “12 Signs There Is Carbon Monoxide in Your House.” MedicineNet.

2 “Uses in Industry.” NaturalGas.org, September 2013.

3 Linda C. Brinson and Francisco Guzman. “How Much Air Pollution Comes From Cars?” HowStuffWorks, July 2021.