Abstract

With dramatic improvements in opex and operator/user efficiency, smart metering and automatic meter reading continue to be deployed for home utilities. When it comes to water and gas consumption measurement, these smart meter devices, which work remotely and untethered, operate on primary cells and are expected to have a lifetime of 10 years or greater. Wireless transmission remains the most popular connectivity mechanism; as a result, the device consumes nominal power for data collection and monitoring and most of the power for data transmission via RF. The challenge of powering the smart meter RF power amplifier is solved with the help of an efficient boost converter, the MAX8815A, and a supercapacitor.

Introduction

We are in the midst of a smart metering revolution; the global smart meter market is expected to grow tremendously over the next five years. Smart metering has advantages for the utility provider and for the user. For the provider, it eliminates the resources required for an operator to make monthly visits to each meter location. The provider can remotely control the water/gas supply. More importantly, the data collected remotely can be aggregated and analyzed in real time, which can help spot leakages, detect tampering, and provide other useful data analytics to reduce opex. The consumer will also have electronic access to his or her consumption data, leading to better resource management. Smart meters, in particular water and gas meters, use wireless connectivity and are poised to move from wireless M-BUS or proprietary standards to 4G and 5G.

A common characteristic of these devices is remote operation for long periods of time, which is achieved using powerful primary, nonrechargeable batteries. Lithium thionyl chloride batteries are often chosen for their high capacity. These batteries, although packing a charge of tens of Ahr, under ‘old and cold’ conditions, can release it only in trickle amounts, due to their increased impedance. However, during wireless data transmission, the meter’s power amplifier (PA) requires peaks of current an order of magnitude higher than the battery can deliver. In this design solution we discuss the challenge of powering the PA, and provide a solution based on an efficient, low shutdown current and compact boost converter able to deliver the required peak current with the help of a supercapacitor.

Figure 1. Smart gas meter example.

RF Power Amplifier Demand

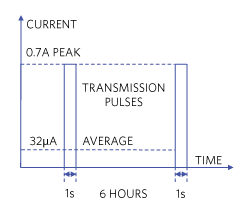

For the purpose of this case study, the PA works off a constant voltage of 4.1V. As seen in Figure 2, the PA requires a current burst of 0.7A for 1s every 6 hours to transmit data. The rest of the time, the PA is shut down. This corresponds to an average current 32µA.

Figure 2. PA transmission current pulse.

Powering the PA

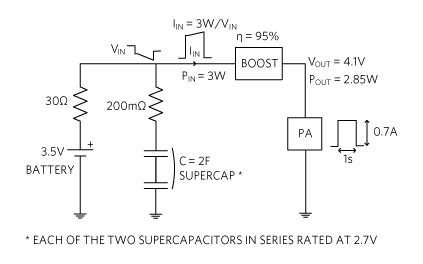

A 3.5V, D-cell lithium thionyl chloride battery can be used to power such a PA. This battery would have a 19Ahr charge, which translates to 217µA on average over a 10-year lifetime. Such a battery may have a worst-case (old and cold) impedance as high as 30Ω. Accordingly, it can deliver at best 117mA. In order to deliver 0.7A, we need the help of another energy source like a supercapacitor which can provide high-density capacitance in a compact volume and ideally suited for burst energy.

A typical 10F supercapacitor has a voltage rating of 2.7V. Since the supercapacitor has to work in parallel with the 3.5V D-cell lithium thionyl chloride, two capacitors in series are used to withstand the battery voltage.

Under an 'old and cold' scenario, these two 10F supercapacitors in series (5F total) may derate down to as low as 2F and 200mΩ. This supercapacitor ensemble (C), charged with 3.5V and a 200mΩ ESR, easily delivers 0.7A. At the first order, the capacitor, loaded with I = 0.7A for a time T = 1s should droop just about 350mV (VDROOP = T × I/C) with an additional voltage drop across the ESR of about 140mV.

The strategy then is to have the supercapacitor deliver current to the PA for 1s (1s × 0.7A = 0.193mAhr). During the subsequent 6 hours of shut down, the supercapacitor is replenished by the battery. While many system designers use a supercapacitor to augment a primary cell battery, currently some battery vendors also provide a battery + supercapacitor combo in industry-standard battery housing like say, D-cell.

PA Voltage Regulator

In Figure 3, during the 6 hours of PA shutdown, the D-cell battery charges the supercapacitor C up to the D-cell voltage, for example 3.5V. At the end of the charging cycle there is no further current exchange between the battery and the supercapacitor, and their voltages coincide. When the rising front of the PA current peak arrives, the supercapacitor provides the bulk of the energy causing its voltage to sag. The boost voltage regulator boosts the sagging input voltage, providing a constant 4.1V and 0.7A to the PA with η = 95%.

The process of charge and discharge of the supercapacitor is outlined in detail with the aid of simulations in the following section.

Figure 3. Boost converter powers the PA under ‘cold and old’ conditions.

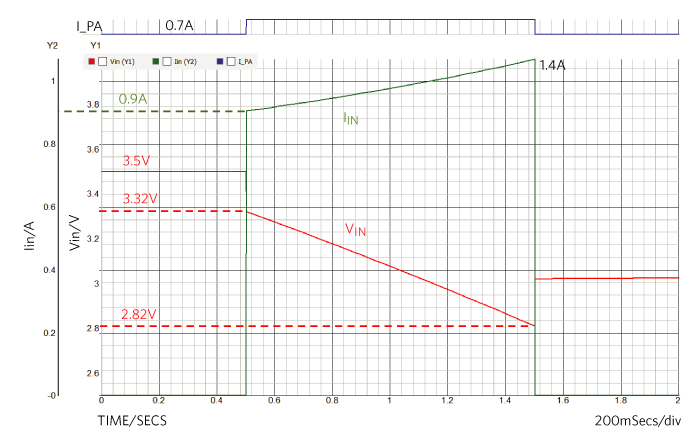

The circuit in Figure 3 is simulated, and the resulting waveforms are shown in Figure 4. The blue waveform is the PA current transmission pulse. The red waveform shows the boost converter input voltage going down from 3.5V primary cell voltage to 2.82V during the 0.7A PA pulse (blue graph). The corresponding input current, in green, starts at 0.9A (PIN/VIN) and rises up to 1.4A as the input voltage decreases, maintaining constant input power so as to supply the 0.7A output current at 4.1V.

Figure 4. Boost converter input and output waveforms.

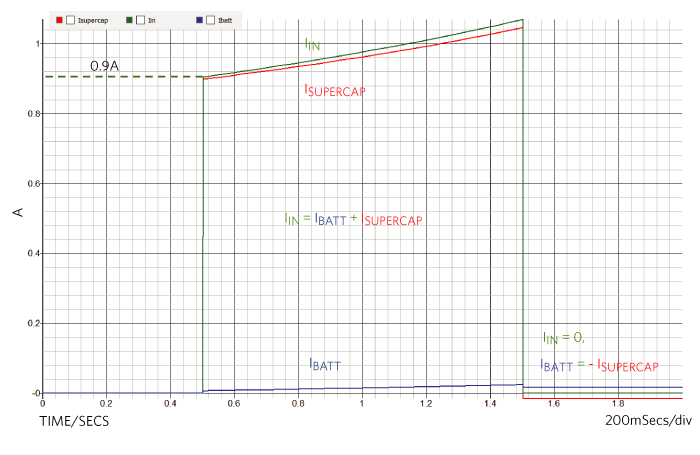

Figure 5 shows how most of the current pulse IIN (green trace) comes from the supercapacitor’s current ISUPERCAP (red), the contribution to the input current from the battery being minimal. During the PA shutdown the input current IIN is null and the battery current +IBATT (blue) recharges the capacitor (-ISUPERCAP).

Figure 5. Input currents during PA transmission and shutdown.

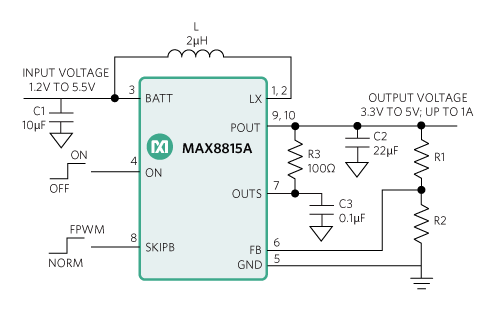

With 10-year lifetime requirement, it is extremely critical that the boost converter used does not drain away the battery with its quiescent current, thereby reducing the life of the battery and hence the life of the smart meter. As an example, the MAX8815A DC-DC step-up converter in Figure 6 is a high-efficiency, low-quiescent-current, synchronous step-up converter. The IC has a unique and proprietary True Shutdown™ mode that enables very low shutdown supply current (0.1µA), which minimally erodes the battery life in the order of 0.09% or only a couple of days of operation over 10 years. The high efficiency of the boost converter IC and its ability to boost from a very low voltage up to the PA voltage further extends the duration of untethered operation.

Figure 6. Application diagram of a high-efficiency, low-quiescent-current boost converter.

The IC output will range from VIN to 5V for a single-cell lithium thionyl chloride battery. It has a preset 2.5A current limit and operates down to 1.2V. Features include soft-start, which limits inrush current during startup, True Shutdown, and internal compensation. The IC is available in a compact 10-pin, 3mm × 3mm TDFN package and supports a -40°C to +85°C extended temperature range.

Conclusion

Smart meters operate for 10 to 20 years of time remotely and untethered, relying on powerful non-rechargeable lithium thionyl chloride batteries. They present a complex power management design problem with energy sources that include batteries and supercapacitors. In this design solution, we discussed the challenges of powering a smart meter wireless RF power amplifier and provided a solution based on an efficient, low shutdown current and compact boost converter, which delivers the required peak current with the help of a supercapacitor.

Glossary

Opex: Operating Expense

Related to this Article

Products

1A, 97% Efficiency, 30µA Quiescent Current, Step-Up Converter with True Shutdown