Multiphase Power Conversion for Portable and Point-of-Load Boost Applications

Multiphase Power Conversion for Portable and Point-of-Load Boost Applications

Sep 1 2003

Introduction

Multiphase power converters offer the advantages of higher efficiency, smaller size and lower capacitor ripple currents over their single phase counterparts. The higher effective switching frequency and phased ripple currents significantly reduce the size and cost of the filter capacitors and lower output ripple, while allowing the use of several small inductors. This has made them popular in many high current buck (step-down) applications, especially where space is a concern. With the LTC3425, the industry’s first multiphase monolithic boost converter, you can achieve the same performance and size benefits in boost (step-up) applications.

This 4-phase synchronous boost converter can deliver over 12W of power in a smaller size, with higher efficiency and lower output ripple than is achievable with a comparable single-phase boost converter. The LTC3425 can startup with as little as 1V, and operate with inputs up to 4.5V, making it suitable for a variety of input voltage applications. The output voltage range is 2.4V to 5.25V, and peak current capability is over 5A.

Multiphase Converters: They’re Not Just for Buck Applications Anymore

The high frequency (up to 8MHz) 4-phase architecture allows the use of small, low cost inductors rather than a single large, bulky inductor, and requires much less output filter capacitance than the equivalent single-phase circuit. This is ideal for space-constrained boards, Point-of-Load regulators, and portable devices that demand the use of low-profile components. For example, in a 2-cell NiCd or NiMH to 3.3V/2A boost application, the peak inductor current required for a single-phase design is nearly 5A.

Figure 1 shows the size difference between a typical single inductor that would be required to handle this current, and the inductors that could be used in a 4-phase design. Figure 1 also compares the output capacitors required to achieve the same output ripple voltage in single-phase and 4-phase applications. Table 1 shows specifications for the inductors pictured in Figure 1—not only are the four small inductors much thinner, but they also have a lower combined DC resistance for improved efficiency.

Figure 1. How does a multiphase boost converter improve on its single phase counterpart? First of all, a multiphase topology saves space and simplifies layout by removing bulky, hard-to-place components and replacing them with easier-to-fit, low profile components. Inductor and output capacitor size comparison of single-phase and 4-phase circuits.

| Inductor | Inductance (µH) | Required Qty | Total Area (mm2) | Height (mm) | Max Total DC Resistance (Ω) | Total Peak Current Rating (A) | |

| 1-Phase | Coilcraft DO3316 | 2.2 | 1 | 122 | 5.21 | 0.012 | 7.0 |

| 4-Phase | TDK RLF5018T | 2.7 | 4 | 29.12 × 4 = 116.5 | 2.05 | 0.033/4 = 0.0083 | 1.8 × 4 = 7.2 |

Easy to Use

Designing a converter using the LTC3425 is no different than designing a traditional single phase boost converter. All the power switches are internal, so the 4-phase operation is transparent. Current limit and switching frequency for all four phases are each programmed by a single resistor, as in single phase designs. Setting the output voltage and compensating the loop are also no different than in other familiar designs.

Circuit Description: Four Independent Power Stages

Each of the four phases has an NMOS and a PMOS power switch, and controls its own inductor current using a peak current mode control loop, consisting of a current comparator with adaptive slope compensation and a reverse current comparator for discontinuous mode operation. In discontinuous mode, an internal resistor is placed across the inductor when the synchronous rectifier turns off, damping any high frequency ringing.

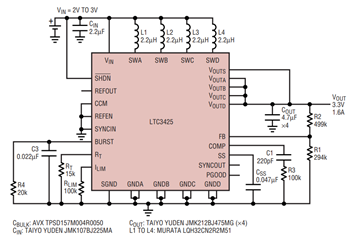

A single error amplifier is used for all four phases, and controls the peak current required to maintain regulation. Referring to Figure 2, the loop compensation components are connected between COMP and GND. Soft-start time is set by the CSS capacitor, which ramps the current limit up to its final value during startup.

Figure 2. 2-cell to 3.3V boost application.

Each VOUT pin should have its own ceramic filter capacitor located as close as possible to the VOUT and GND pins in that phase. These are typically 0805 size parts. The pinout of the LTC3425 lends itself to a tight symmetrical layout of the power components. With the 4-phase architecture, low output voltage ripple is achieved using only the four small ceramic capacitors, even at load currents of 2A or more. An optional bulk capacitor on VOUT can be added to improve transient response with dynamic loads. This can be a ceramic, tantalum, or an OSCON-style capacitor.

The output disconnect feature effectively eliminates the PMOS body diode between the switch node and VOUT during shutdown, allowing VOUT to discharge to zero volts, all while achieving less than 1µA shutdown current. The disconnect feature also blocks unwanted current flow between VIN and VOUT, eliminating the large inrush currents during startup that are inherent to most boost converters.

The internal oscillator, programmed by a resistor from RT to GND, generates four internal clock pulses, each phase shifted by 90°. The switching frequency can be set from 100kHz to as high as 2MHz per phase, for an effective frequency of 8MHz as seen at the output filter cap. Maximum duty cycle for each phase is set to 90%. A sync input and oscillator output are provided for synchronizing the converter to a system clock, or synchronizing two converters together. Note that the sync input and clock output are at four times the switching frequency of each phase.

In Burst Mode® operation, only phase A is active, reducing switching and quiescent losses for maximum efficiency. In this mode, phase A operates with a fixed peak inductor current of 0.6A typical. Drawing just 12µA of quiescent current in Burst Mode operation allows the LTC3425 to operate with high efficiency during very light load conditions.

2-Cell to 3.3V/2.2A Boost Application, with Automatic Burst Mode Operation

Figure 2 shows a typical application circuit using the LTC3425 to boost from two NiCd or NiMH cells to 3.3V. This design can supply over 2A of load current with efficiencies up to 94% while switching at 1MHz per phase (4MHz output ripple frequency). Maximum component height is a slim 2.05mm. High efficiency is maintained over a very wide load range, as shown in Figure 3.

Figure 3. Efficiency vs load of 3.3V boost, using automatic Burst Mode operation.

A key feature of the LTC3425 is the programmable automatic Burst Mode operation, which allows the user to set the load current where the converter enters Burst Mode operation, extending the efficiency at light load. This is ideal for systems where the mode cannot be controlled manually by the host. Since the Burst Mode circuit monitors average output current (rather than peak inductor current), the mode threshold is not affected by input voltage variation. In this example, the Burst Mode threshold is set by R4 to 100mA. When the average load current drops below 100mA, the part enters Burst Mode operation, when the load current increases again, it leaves Burst Mode operation and returns to fixed frequency operation. Capacitor C3 filters the switching ripple at the Burst pin.

Because of the bulk capacitor on VOUT in this example, only a single compensation capacitor is required. The feed-forward network, consisting of RFF and CFF, reduces output ripple in Burst Mode operation and further improves transient response during load steps. It also lowers the high frequency impedance at the FB pin, allowing the use of large value feedback resistors for maximum light load efficiency.

3.3V/Li-Ion to 5V/2.4A Boost Application with Active Clamp

Figure 4 shows the LTC3425 in a 5V boost application. This circuit can deliver 5V at 2.4A from a single Li-Ion cell, or from a 3.3V supply. That’s 12W of output power in a 475mm2 (0.74in2) footprint with a component height of only 2.5mm. As Figure 5 shows, the efficiency peaks at 95%. Output ripple at full load, shown in Figure 6, is less than 20mVP–P.

Figure 4. Li-Ion/3.3V to 5V boost application with active clamp.

Figure 5. Efficiency vs load of 5V boost.

Figure 6. Li-Ion to 5V output voltage ripple at 2.5A load.

In this application, Schottky diodes are used as part of an active clamp to limit the peak voltage seen at the switch nodes during the anti-cross-conduction time between the turn-on and turn-off of the internal NMOS and PMOS switches. The use of the external SOT-23 P-channel MOSFET (Q1) and 0.47µF capacitors (CS) preserves the output disconnect feature of the LTC3425, allowing VOUT to go to 0V in shutdown and limits the inrush current. If output disconnect is not required, Q1 and CS can be eliminated, and the Schottky diodes can be tied directly from SW to VOUT.

This circuit also illustrates the features and flexibility of the LTC3425. There is a 1.22V, short circuit protected reference output that can be turned on or off (for higher efficiency at very light loads), a sync input for synchronizing the internal oscillator to an external clock, and an open-drain Power Good output that monitors the output voltage.

The CCM input allows the user to force continuous conduction mode, which eliminates pulse skipping at light loads for noise sensitive applications. When CCM is pulled high, the synchronous rectifier stays on until a reverse inductor current of about 0.6A is sensed. Note that this lowers the efficiency at light load, and should only be used during fixed frequency mode operation.

In this example, the BURST pin is used to manually command either fixed frequency or Burst Mode operation. This can improve the transient response by bringing the converter out of Burst Mode operation prior to a large load step. A scope photo of the output step response, while operating in fixed frequency mode, is shown in Figure 7.

Figure 7. Step response for a 2A load step.

Low Cost, Very Low Profile 5W Boost Application Using All Ceramic Caps

Many portable applications have strict limitations on component height. This can be a challenge for a power converter, since the inductor and filter capacitors are usually among the tallest components. The LTC3425’s 4-phase architecture is ideal for these applications. An example of a two cell to 3.3V/1.6A boost converter with a component height of only 1.55mm is shown in Figure 8.

Figure 8. Low cost, 1.55mm profile 3.3V boost example.

In this design, the only output filter capacitors needed are the four 0805 size, 4.7µF ceramics, with a height of 1.35mm. Output voltage ripple is under 50mVP–P at full load. The four low-cost inductors are only 1.55mm high, with a 3.2mm by 2.5mm footprint. The entire 5W power converter can fit into a 20mm by 16mm space, as seen in Figure 9.

Figure 9. 3.3V boost demo (circuit shown in Figure 8).

2- or 3-Phase Operation

For cost-sensitive applications or for reduced board area with lower maximum current capability, the LTC3425 can be used as a 2- or 3-phase converter by simply de-populating one or two of the inductors. Figure 10 illustrates the typical efficiency difference between 2-, 3- and 4-phase operation. In Burst Mode, there is no efficiency penalty, since only phase A is used.

Figure 10. Typical efficiency with 2, 3 and 4 phases (fixed frequency mode).

Conclusion: Good Things Do Come in Small Packages

The examples here illustrate the performance, flexibility, small size and ease-of-use of the LTC3425. The synchronous 4-phase architecture achieves high efficiency over a wide range of loads while enabling the use of low-profile components. The four-to-one reduction in output ripple current makes it possible to achieve very low output voltage ripple using small, lower cost ceramic capacitors. Users can choose between automatic or manual Burst Mode operation, pulse skipping mode or forced continuous conduction mode for noise sensitive applications. All these features, along with output disconnect, soft-start, 1µA shutdown current, anti-ringing control, thermal shutdown, a buffered reference output and a Power Good output are packed in a small 5mm by 5mm, thermally enhanced QFN package.

About the Authors

David Salerno was a Design Section Leader for the Power by Linear group of Analog Device (former Linear Technology) for nearly 20 years. His main focus was the DC/DC Converter design on boost applications. David hold an B...