Keep Your Head Up with a High-Dimming Ratio Automotive LED Driver

Abstract

Automotive LED drivers must have a high dimming ratio and increased accuracy to correctly reproduce color and provide low noise to avoid interference with the car radio. The LED drivers must be robust enough to directly interface with the battery. In this design solution, we review the features necessary for LED drivers to safely connect to the battery while providing high performance in a flexible architecture for ease of reuse. Subsequently, we introduce a novel LED driver IC that meets these stringent requirements for automotive LED lighting.

Introduction

An LED driver IC for automotive applications must meet many requirements. It must be flexible, implementing multiple functions like high beam, low beam, fog lights, daytime running lights (DRLs), position and turn-signal lights. It must have a high dimming ratio in applications like head-up displays (HUDs), in order to produce a clear image in bright sunlight and a subdued image that will not obscure a driver’s vision at night. It must also be robust enough to withstand the transient high-voltage dump produced by an automobile battery.

The current intensity must be very accurate, since it controls the LED color. The PWM dimming frequency must be above 100Hz to be undetected as a flicker by the human eye. A high and well-controlled PWM switching frequency above the AM frequency band is required to reduce radio frequency interference (RFI). Spread-spectrum modulation is also necessary to meet electromagnetic interference (EMI) standards. Finally, high efficiency helps reduce heat generation and improves automotive system reliability.

In this design solution, we review the necessary features for automotive LED drivers to safely interface with the car battery while providing high performance in a flexible architecture for ease of reuse in many applications. Subsequently, we will introduce a novel IC that meets these requirements.

Figure 1. Modern car fog lights.

Figure 1. Modern car fog lights.

Powering the LED Driver

Powered from a car battery, the LED driver input voltage is typically 12V but can be as high as 16V on a fully charged battery. Vehicles that employ start/stop technology experience large voltage dips when the engine starts, so the lower limit for the power source can be 6V or lower.

If the car battery is accidentally disconnected from the alternator during a charge, a voltage surge as high as 120V is generated. This voltage surge is clamped by a transient voltage suppressor (TVS) whose clamping range must be above the maximum battery voltage (16V) and below the breakdown voltage of the front-end voltage regulator (for example 36V).

A reverse-polarity protection diode is also required to protect the system against accidental battery polarity reversal when the battery is disconnected and reconnected during maintenance.

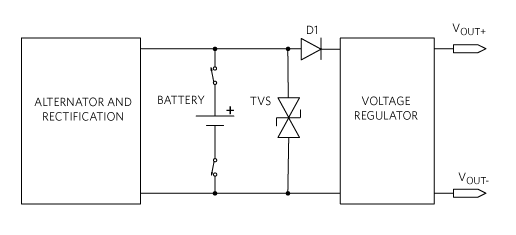

Figure 2 shows the typical front-end protection and regulation electronics as they interface with the battery.

Figure 2. Typical car protection and regulation front-end.

Figure 2. Typical car protection and regulation front-end.

Dimming

Dimming is a ubiquitous function in many automotive lighting applications and an important safety feature for LED headlights. The human eye can barely detect light dimming from 100% to 50%. Dimming must go down to at least 1% or less to be clearly discernable. Head-up displays in particular (Figure 3), need a high dimming ratio to produce a clear image in bright sunlight and a subdued image that will not obscure the driver’s vision at night. With this in mind, it’s not surprising that dimming is specified by a ratio of 5000:1 or higher. Given that the human eye, under proper conditions, can sense a single photon, there is practically no limit to this function.

Figure 3. Car equipped with HUD display.

Figure 3. Car equipped with HUD display.

Since current must be kept constant to preserve color, the best dimming strategy for LEDs is PWM (pulse-width modulation), where the light intensity is modulated by time-slicing the current rather than by changing the amplitude. The PWM frequency must be kept above 100Hz to prevent the LED from flickering.

With PWM dimming, the limit to the minimum LED “on/off” time is the time it takes to ramp up/down the current in the switching regulator inductor. This may add up to tens of microseconds of response time, which is too slow for LED headlight cluster applications that require fast and complex dimming patterns. Dimming in this case can only be performed by individually switching on/off each LED in a string by means of dedicated MOSFET switches. The challenge for the current control loop is to be fast enough to quickly recover from the output voltage transient due to switching in and out of the diodes.

Basic Headlight System

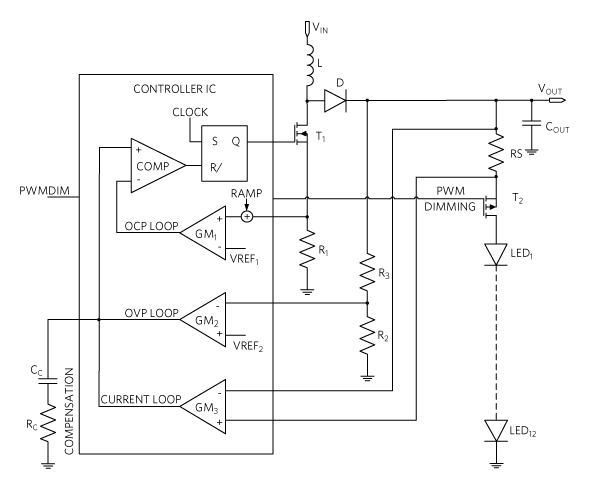

A basic headlight system architecture that can accommodate a series of LEDs uses a boost converter. In the boost controller IC of Figure 4, one of the three feedback loops (CURRENT LOOP) ensures tight control of the output current. The other two feedback loops perform overvoltage protection (OVP LOOP) and overcurrent protection (OCP LOOP) for the string of 12 diodes, which creates 42V across the string (3.5V per LED).

Figure 4. Typical boost LED control system.

Figure 4. Typical boost LED control system.

In addition to current and voltage control, the IC must be equipped with all the features previously described (dimming, spread spectrum, etc.). High-side current sensing (via the resistors RS) is required to protect the LED system in case of shorts from the output to the ground or battery input.

Flexible LED Controller Architecture

Ideally, an LED controller should have a flexible architecture that supports multiple configurations that can implement different features. We have discussed the boost configuration, but we should also consider the buck-boost configuration. A buck-boost mode configuration is necessary if the diode string is short, for example, two or three LEDs (7V or 10.5V) against a battery voltage that can vary from less than 6V (cold crank) up to 16V. If the concern is input-to-output isolation, then a SEPIC (discontinuous output current) or a Chuck (continuous output current) converter may be the right solution. A single controller that supports many architectures has clear advantages of economies of scale and ease of reuse.

High Dimming Ratio Controller

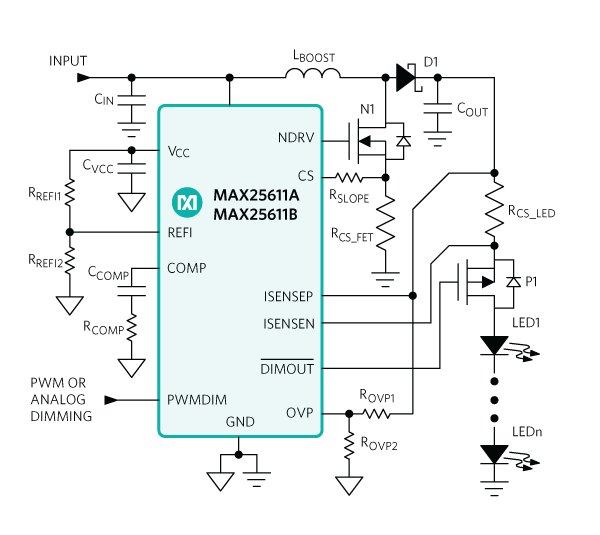

As an example, the single-channel HB LED driver shown in Figure 5 is used for automotive front-light applications such as high beam, low beam, daytime running light (DRL), turn indicator, fog light, and other LED lights. It can take an input voltage from 5V to 36V and drive a string of LEDs with a maximum output voltage of 65V.

This 36V LED driver IC offers the most flexible schemes for driving LEDs, allowing either boost, high-side buck, SEPIC mode, or buck-boost mode configurations. The PWM input provides LED dimming ratios of up to 5000:1, and the REFI input provides additional analog dimming capability. The IC has built-in spread-spectrum modulation for improved electromagnetic compatibility performance. The IC can also be used in zeta and Cuk converter configurations.

Figure 5. Boost LED application diagram.

Figure 5. Boost LED application diagram.

For high-efficiency applications, the switching frequency is internally set at 350kHz with the A version. For applications favoring small passives and small PCB size, the B version’s frequency is set at 2.2MHz. The IC is housed in a small 4mm x 4mm 12-pin SWTQFN-EP package with exposed pad for best heat dissipation.

The TVS in Figure 2 can be implemented with Littlefuse® TPSMF4L20A, having a clamping range between 22.2V and 32.4V.

The diode D1 in Figure 2 can be implemented with the ideal diode controller (MAX16141) and two external MOSFETs for minimum power losses.

Conclusion

An automotive LED driver must be flexible enough to support many different lighting applications. It must have a high dimming ratio and accuracy to correctly reproduce color, provide low noise to avoid interference with the car radio, and be robust enough to directly interface with the battery. In this design solution, we reviewed the features necessary for the LED driver to safely connect to the battery while providing high performance in a flexible architecture for ease of reuse. Subsequently, we introduced a novel LED driver IC that meets these stringent requirements.

Learn More

- Achieve Superior Automotive Exterior Lighting with a High-Power Buck LED Controller

- Flexible LED Controller Simplifies Automotive Exterior Lighting Design

Related to this Article

Products

PRODUCTION

Automotive High-Voltage, HB-LED Controller

PRODUCTION

Automotive High-Voltage, HB-LED Controller