I2C System Monitor Combines Temperature, Voltage and Current Measurements for Single-IC System Monitoring

I2C System Monitor Combines Temperature, Voltage and Current Measurements for Single-IC System Monitoring

Jan 1 2011

The limit on the complexity of large integrated circuits is dominated by how much power they can dissipate. The trend in µprocessors and FPGAs is toward packing more features into smaller ICs, run at ever-lower voltages. The resulting rise in power dissipation makes it increasingly difficult to monitor and control sources of heat. Where it was once suitable to have a single chassis temperature monitor to deduce the health of the system, modern electronic systems produce many high power, point sources of heat that would go undetected with a simple chassis monitor.

Even PC processors feature dedicated secondary fans in order to keep specific die junction temperatures below an acceptable level. One line of defense against overheating is to increase fan speeds, while another is to temporarily disable the heat source. In telecommunication systems and other always-on applications, it is not acceptable to disable the system, so the only line of defense is to increase cooling.

One problem with reactive cooling is that large HVAC systems have lag—they require time to reduce the ambient temperature. Moreover, microprocessors and FPGAs are embedded in chassis with surrounding thermal mass, which take even longer to respond to a request for cooling. Therefore it is important to monitor not only the temperature, but also the rate of temperature change in order to apply the correction before temperatures escalate to dangerous levels. An integrated power and temperature monitoring system can use changes in power consumption to anticipate changes in temperature.

The LTC2990 measures ambient and remote temperature, plus voltage and current, so the measurements are easily combined. Temperature sensors can be diodes or transistor sensors—remote sensor diodes are available as substrate diodes in large microprocessors and FPGAs. The I2C serial interface provides four addresses accommodating up to four LTC2990s on the same bus.

LTC2990 Features

- Measures Voltage, Current and Temperature

- Measures Two Remote Diode Temperatures

- ±1ºC Accuracy, 0.06ºC Resolution

- ±2ºC Internal Temperature

- 15-Bit ADC Measures Voltage and Current

- 3V to 5.5V Supply Operating Voltage

- I2C Serial Interface with Four Selectable Addresses

- Internal 10ppm Voltage Reference

- 10-Lead MSOP Package

Principle of Operation

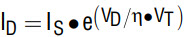

Measuring the absolute temperature of a diode is possible due to the relationship between current, voltage and temperature described by the classic diode equation:

or

where ID is the diode current, VD is the diode voltage, η is the ideality factor (typically close to 1.0) and IS (saturation current) is a process dependent parameter. VT can be broken out to:

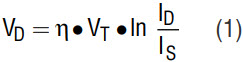

where T is the diode junction temperature in Kelvin, q is the electron charge and k is Boltzmann’s constant. VT is approximately 26mV at room temperature (298K) and scales linearly with Kelvin temperature. It is this linear temperature relationship that makes diodes suitable temperature sensors. The IS term in the equation above is the extrapolated current through a diode junction when the diode has zero volts across the terminals. The IS term varies from process to process, varies with temperature, and by definition must always be less than ID. Combining all of the constants into one term:

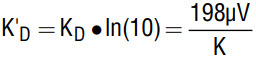

where KD = 8.62−5, and knowing ln(ID/IS) is always positive because ID is always greater than IS, leaves us with the equation that:

where VD appears to increase with temperature. It is common knowledge that a silicon diode biased with a current source has an approximately –2mV/°C temperature relationship (Figure 1), which is at odds with the equation. In fact, the IS term increases with temperature, reducing the ln(ID/IS) absolute value yielding an approximately –2mV/deg composite diode voltage slope.

Figure 1. Diode voltage VD vs temperature T(K) for different bias currents.

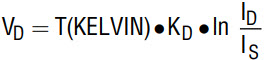

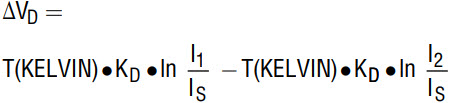

To obtain a linear voltage proportional to temperature we cancel the IS variable in the natural logarithm term to remove the IS dependency from the equation 1. This is accomplished by measuring the diode voltage at two currents I1, and I2, where I1 = 10 • I2), Subtracting we get:

Combining like terms, then simplifying the natural log terms yields:

![]()

and redefining constant

yields

Solving for temperature:

means that is we take the difference in voltage across the diode measured at two currents with a ratio of 10, the resulting voltage is 198µV per Kelvin of the junction with a zero intercept at 0 Kelvin.

Thus, the equation describes a perfectly linear, monotonically increasing temperature result provided that the current ratio is constant, but arbitrary to the absolute value of the currents. The two independent diode voltages measured at I1 and I2 both have negative temperature dependence (~2mV/°C), but the diode voltage at the larger bias current has a slightly smaller negative slope, yielding a positive composite ∆VD term (Figure 1). Another way to think of it is that when the junction is biased at a higher current, it is more probable (by a factor of ln(I1/I2) that a thermally generated carrier will have sufficient energy to exceed the diode junction energy barrier. Using this method, common diodes and transistors can be used as temperature sensors over an operating range of –55ºC to 150°C, typically limited by packaging materials.

One complication with the method described above is the effect of series resistance with the sensor diode. At 193µV/°C slope, it does not take much series resistance to yield artificially high temperature readings due to the additional voltage drop (the temperature would always report falsely high). This series resistance can be in the form of copper traces and junction contact resistances. Moreover, this resistance can have a temperature coefficient (copper is 3930ppm/°C) yielding a temperature dependent additive term. To combat this, multiple ∆VD measurements are made at multiple operating points, so the series resistance can be calculated and compensated. The LTC2990 simplifies all of these complications, compensates for them and converts the diode temperature straight to a digital result, where it can be read over the I2C interface to a host microcontroller or FPGA.

Ideality Factor and Compensation

The LTC2990 can report temperature in units of degrees Celsius or Kelvin. Kelvin temperature is valuable when fine-tuning scaling calibration factors (η) of various manufacturers’ devices. Since absolute temperature is measured by silicon diodes, the gain or slope of a sensor extrapolates to absolute zero, or 0 Kelvin. An ideality factor error of +1%, or 1.01, represents a temperature error of 273.15 • 0.01 ≈ 2.7°C at 0°C. At 100°C (398.15K), a 1% error in ideality factor translates to an error of approximately 4°C. The LTC2990 is factory calibrated for an ideality factor of 1.004, which is typical of the popular MMBT3904 NPN transistor. Transistor sensors are made of ultra-pure materials, inherently hermetic, small and inexpensive, making them very attractive for –55°C to 125°C applications. The linearity of transistor sensors eliminates the need for linearization in contrast to thermocouples, RTDs and thermistors. The semiconductor purity and wafer-level processing limits device-to-device variation, making these devices interchangeable (typically < 0.5°C) for no additional cost. Several manufacturers supply suitable transistors—some recommended sources are listed in Table 1.

Figure 2. Reported uncompensated diode temperature TD(K) vs temperature T(K) with series resistance.

| Manufacturer | Part Number | Package |

| Fairchild Semiconductor | MMBT3904 | SOT-23 |

| Central Semiconductor |

CMPT3904 | SOT-23 |

| CET3904E | SOT883L | |

| Diodes, Inc. | MMBT3904 | SOT-23 |

| On Semiconductor | MMBT3904LT1 | SOT-23 |

| NXP | MMBT3904 | SOT-23 |

| Infineon | MMBT3904 | SOT-23 |

| Rohm | UMT3904 | SC-70 |

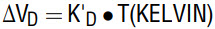

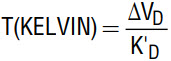

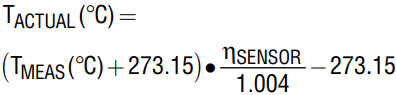

If a target sensor ideality factor differs from 1.004, it can be compensated in the following manner:

where TACT and TMEAS are in Kelvin degrees. To perform the scaling in Celsius degrees:

Temperature Monitoring Applications

Figure 3 illustrates a typical application where the LTC2990 is configured to measure a substrate diode, which monitors the microprocessor temperature and three system power supply voltages (12V, 5V and 3.3V). To extend the measurement range of the voltage inputs, resistive voltage dividers are used for the 5V and 12V voltages. For this application the 0.1% accuracy of the LTC2990 introduces negligible gain error over what is produced by the resistor divider network.

Figure 3. Single LTC2990 accurately monitors three voltage rails and microprocessor temperature (via substrate diode).

The 14-bit resolution also allows the use of larger voltage divider networks while maintaining high resolution. For example, compare the LTC2990 to a device with a 10-bit dynamic range that can measure 12V to 2% accuracy. The LTC2990 can measure a 192V signal with the same LSB weight (11.72 mV) as the 10-bit part and maintain 2% accuracy, again dominated by the 1% precision of the external voltage divider network components.

Figure 4 shows an example of high voltage monitoring. The LTC6102HV is optimized for accurate high-side current sensing. Using a voltage divider for current sensing would result in large gain errors, > 4%, and low resolution for the current sensing function. By attenuating the common-mode voltage with a voltage divider, the differential voltage is attenuated by the same factor. By making the sense resistor larger to increase the gain, the power-loss scales with the square of sense voltage.

Figure 4. High voltage current sensing.

Liquid Level Sensing

Figure 5 illustrates a simple application that uses temperature measurement to indicate liquid level. A heater is pulsed, and the temperature sensor is monitored for a corresponding change in temperature. The measurement indicating the liquid level threshold is actually a combined thermal conductivity and heat capacity measurement, which is proportional to the change in temperature.

Figure 5. Liquid level sensor.

In operation, the remote temperature is measured and stored for reference, after which the heater is switched on, and given a few seconds to heat the surroundings. The temperature is again measured and compared with the first temperature. If the temperature difference is greater than a preset threshold, the sensor is determined to be above the liquid level. If the sensor is submerged in the liquid, the relatively larger heat capacity of the liquid prevents the temperature from rising quickly. The smaller the discernable temperature change, the less heater power is required for detection. For this application, filtering the remote temperature sensor can trade time for power.

Airflow Measurement

Airflow can also be measured by monitoring temperature. Figure 6 illustrates a method using a heater and a temperature sensor similar to the liquid level application. In this application the cooling power of the fan is tested by turning on a small heater and measuring the temperature rise, or the rate of temperature rise with the remote sensor. In the absence of cooling air, both the absolute and the rate of temperature rise increases.

Figure 6. Fan/air filter/temperature alarm.

This method can be used to detect faulty fans, or dust buildup on air filters. Whatever the cause, the circuit can signal inadequate cooling conditions. Thermistors are undesirable in this application because their change in resistance is not consistent over a broad operating temperature range.

Temperature monitoring can signal the alarm for overheating, but simple temperature monitoring cannot predict overheating. By measuring power (voltage and current) and cooling capacity, one can predict a problem prior to a catastrophic failure. This is important, because it takes time to correct an over-temperature condition due to the heat capacity of the system and its immediate environment.

Humidity Measurement

Humidity can also be measured using temperature monitoring as shown in Figure 7. One can implement a humidity sensor in the form of a psychrometer. A psychrometer uses two temperature sensors to detect humidity: one of them is dry and acts as a reference; the other is dampened and exposed to airflow. The cooling effectiveness of the water on the wet sensor is a function of humidity. In a 100% humidity environment, the forced air on the wet sensor yields no evaporation and thus yields no cooling effect. Conversely, in an arid environment, the cooling due to the heat of evaporation can cool the “wet bulb” temperature sensor significantly. The dry temperature sensor reads the same with or without airflow.

Figure 7. Wet bulb psychrometer.

The temperature difference function is non-linear, and commonly implemented with lookup tables in a host microprocessor. Thus the temperature difference between the wet and dry temperature sensor in the presence of air movement is an indirect measurement of humidity.

Current Sensing with Parasitic Resistance

The application circuit in Figure 8 uses the LTC2990 as a current monitor. The sense resistor in this application is the parasitic resistance in a buck switching regulator. At the output of the buck regulator is the switching node, which typically toggles between VCC and ground. The average value of this voltage is the output regulated voltage. The load current runs through the power supply inductor, which has a series parasitic resistance. This parasitic resistance is typically small and is minimized in the power supply design to maximize efficiency.

Figure 8. Current sensing with inductor parasitic resistance.

The RC filter across the inductor into the LTC2990 V1 and V2 pins filters out the transitions seen on the switching node. The quiet node is equivalently filtered to maintain circuit balance due to LTC2990 input common-mode sampling currents. Knowing RPARASITIC and V1 – V2, the load current can be calculated. Moreover, VCC is measured by the LTC2990, so load voltage and load current are known; thus load power can be calculated.

Because RPARASITIC is typically copper, it has a temperature coefficient of resistance (TCR) of ~3930ppm/°C. By measuring the inductor temperature, this relatively large error source can be compensated by introducing a temperature dependent gain coefficient inversely proportional to the resistor TCR. Knowing the load power, the inductor temperature and ambient temperature from the LTC2990 internal temperature sensor, you can predict the rise in temperature of the inductor for various load currents. This can be important to avoid inductor core saturation at high temperatures, which can be a potentially catastrophic event to the buck regulator.

Measurement Accuracy and Noise

The LTC2990 can measure temperatures at a rate of ~20Hz. This allows the designer to trade resolution and noise performance for speed. At 20Hz, the noise is ~1.2°C peak to peak, or ~0.2°C RMS. For most board level monitoring applications this is excellent performance, though there are applications that require lower noise levels, which can be obtained by controlling the measurement bandwidth. The temperature data output is digital, so this requires the band limiting function to be in the form of a digital filter. Example filters and their simulated performance for equal over-sampling ratios are illustrated in Figures 9 through 11.

Figure 9. Example pseudo-code for an FIR filter.

Figure 10. Example pseudo-code for an IIR filter.

Figure 11. Simulated IIR filter response.

The LTC2990 measurement resolution is 14-bit for voltages and 15-bit for currents. The monitor contains an internal reference with 10ppm/°C stability, requiring no external support components. Ground referenced single-ended voltages can be measured in a range of zero volts to VCC + 0.2V, (4.9V max), and differential voltages in a range of ±300mV with a common mode voltage range of zero volts to VCC + 0.2V, which is suitable for current sensing and bridge circuits.

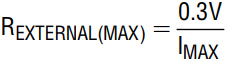

Scaling single-ended, ground referenced voltages is common practice using standard voltage dividers with precision resistors. Sensing current with high accuracy requires more attention to detail. In the case of current measurements, the external sense resistor is typically small, and determined by the full-scale input voltage of the LTC2990. The full-scale differential voltage is 0.3V. The external sense resistance is then a function of the maximum measurable current, or:

The Fine Points of Current Sense Measurement

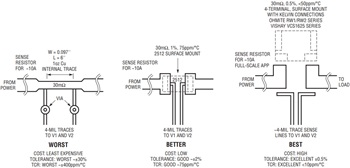

If you wanted to measure a current range of ±10A, the external shunt resistance would equal 0.3V/10A = 30mΩ. This resistance is fairly small, and one may be tempted to implement this resistor using a thin copper trace on the printed circuit board. The dimension of this resistor is determined by the bulk resistance of the PCB copper, the thickness of the copper clad sheet, the length and width of the copper trace. PCB clad material thickness is specified by weight in units of ounces per square foot. Typical copper thicknesses are ½, 1, and 2 oz, corresponding to 0.7, 1.4 and 2.8 mils thickness, respectively. When multi-layer printed circuit boards are manufactured, via holes are electroplated. This electroplating process, also adds copper thickness to the outer copper layers or the PCB. Even if the thickness of the copper clad on the PCB stock material is well controlled, the thickness of the trace will have a manufacturing variable due to plating thickness, when plating the via holes. The copper thickness uncertainty impacts the sense resistor value, and hence the resulting differential volts/amp that the LTC2990 measures.

Figure 12. Temperature compensated current sense resistor.

| Sense Resistor Type | Resistance Tolerance (%) | TCR % for 50°C Rise, (ppm) | Total Error %, (Bits Precision) |

| Copper Trace • R Not calibrated • TCR Not calibrated |

20 | 20, (3970) | 40, (1.3) |

| 2-Terminal Discrete Resistor • R Not calibrated • TCR Not calibrated | 2 | 0.375, (75) | 2.375, (5.4) |

| 4-Terminal Precision Discrete Resistor • R Not calibrated • TCR Not calibrated |

0.5 | 0.05, (10) | 0.55, (7.5) |

| Copper Trace • R Calibrated & Compensated • TCR Calibrated & Compensated |

0.025 | 0.5, (3970 ±100) | 0.525, (7.5) |

| 2-Terminal Discrete Resistor • R Calibrated & Compensated • TCR Compensated |

0.025 | 0.375, (75) | 0.4, (8.0) |

| 4-Terminal Precision Discrete Resistor • R Calibrated & Compensated • TCR Compensated |

0.025 | 0.05, (10) | 0.075, (10.4) |

| 4-Terminal Precision Discrete Resistor • R Calibrated & Compensated • TCR Calibrated & Compensated |

0.025 | 0.005, (x ±1) | 0.075, (11.7) |

Copper has a relatively high temperature coefficient of resistance (TCR), with a value of ~3930ppm/K. The TCR of copper also changes with temperature. Assuming that the current through the sense resistor produces negligible self-heating over a –40°C to 85°C temperature range, the copper resistance changes about 50%. If the sense resistor does heat itself, there is a nonlinear current-to-voltage distortion in the measurement. For this reason, there are special sense resistors manufactured with low TCR values (Figure 13). If the temperature rise in the sense resistor is large due to large currents, even small TCRs can yield large measurement errors. The LTC2990 can be used to track the sense resistor temperature so its TCR can be compensated for, improving measurement accuracy.

Figure 13. Current sense connections.

Figure 14. Temperature compensated copper trace resistor.

Conclusion

The LTC2990 is able to measure electrical power (via voltage and current) and temperature and serve up the results with 14-bit resolution via I2C. Combo power and temperature measurements are commonly used for industrial control and fault monitoring applications, including air and fluid flow, liquid level, over/under temperature, power sharing and limiting, redundancy management, alarm generation, nonvolatile memory write/erase protection, and countless others. The small package size, integrated voltage reference and 1µA shutdown current are ideal for portable electronics applications. Remote diode sensors are available in extremely small packages (Central Semiconductor CET3904E: 1.05mm × 0.65mm) allowing for fast thermal response times, taking advantage of the 50ms temperature measurement capabilities of the LTC2990.