Easy High Density Power: 48A Surface Mount DC/DC Power Supply Uses Four Parallel 12A μModule Regulators

Easy High Density Power: 48A Surface Mount DC/DC Power Supply Uses Four Parallel 12A μModule Regulators

by

Alan Chern

Jan 1 2008

Introduction

Linear Technology’s μModule DC/DC regulators simplify power supply design by offering the black box convenience of traditional power modules in an IC form factor. For example, the LTM4601 μModule regulator is a complete step-down power module in a 15mm × 15mm × 2.8mm LGA package.

The LTM4601 accepts 4.5V to 20V inputs and can produce outputs anywhere from 0.6V to 5V at 12A. The wide input and output ranges and excellent thermal performance of the LTM4601 allow it to be easily dropped into a variety of applications with minimal design effort—just set the output voltage with a single resistor and determine the requisite bulk input and output capacitances.

Another significant advantage of the LTM4601 over power-module- or IC-based systems is its ability to easily scale up as loads increase. If load requirements are greater than one μModule regulator can produce, simply add more modules in parallel. The design of a parallel system involves little more than copying and pasting the layout of each 15mm × 15mm μModule regulator. Electrical layout issues are taken care of within the μModule package—there are no external inductors, switches or other components to worry about. Even heat distribution is improved with parallel regulators, thus enabling surface mount solutions for high power density applications.

To demonstrate the simplicity and performance of a paralleled μModule regulator design, this article discusses electrical guidelines, layout considerations, and thermal specifics for designing a compact 48A, 0.6V–5V VOUT, 4.5V–20V VIN converter using four LTM4601 μModule DC/DC regulators.

DC/DC μModule Regulator: A Complete System in an LGA Package

The LTM4601 μModule DC/DC regulator is a high performance power module shrunk down to an IC form factor. It is a completely integrated solution—including the PWM controller, inductor, input and output capacitors, ultralow RDS(ON) FETs, Schottky diodes and compensation circuitry. Only external bulk input and output capacitors and one resistor are needed to set the output from 0.6V to 5V. The supply can produce 12A (more if paralleled) from a wide input range of 4.5V to 20V, making it extremely versatile. The pin compatible LTM4601HV extends the input range to 28V.

Output features include output voltage tracking and margining. The high switching frequency, typically 850kHz at full load, constant on time, zero latency controller delivers fast transient response to line and load changes while maintaining stability. Should frequency harmonics be a concern, an external clock can control synchronization via an on chip phase lock loop.

48A from Four Parallel μModule Regulators

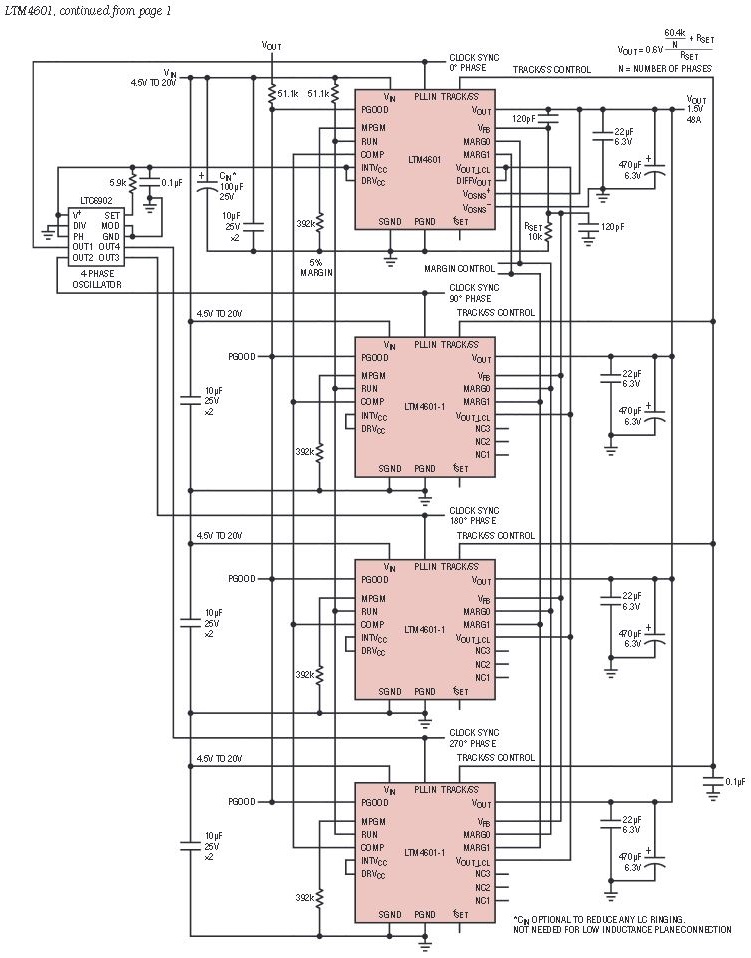

Figure 1 shows a regulator comprising four parallel LTM4601s, which can produce a 48A (4 ×12A) output. The regulators are synchronized but operate 90° out of phase with respect to each other, thereby reducing the amplitude of input and output ripple currents through cancellation. The attenuated ripple in turn decreases the external capacitor RMS current rating and size requirements, further reducing solution cost and board space.

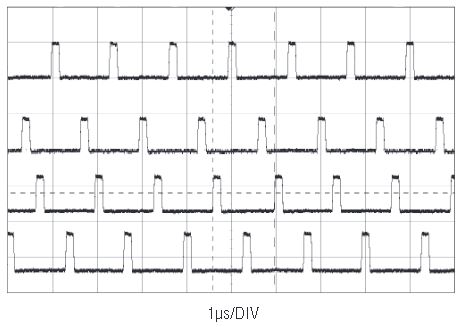

Synchronization and phase shifting is implemented via the LTC6902 oscillator, which provides four clock outputs, each 90° phase shifted (for 2- or 3-phase relationships, the LTC6902 can be adjusted via a resistor.). The clock signals serve as input to the PLLIN (phase lock loop in) pins of the four LTM4601s. The phase-lock loop of the LTM4601 comprises a phase detector and a voltage controlled oscillator, which combine to lock onto the rising edge of an external clock with a frequency range of 850kHz ±30%. The phase lock loop is turned on when a pulse of at least 400ns and 2V amplitude at the PLLIN pin is detected, though it is disabled during start-up. Figure 2 shows the switching waveforms of four LTM4601 μModule regulators in parallel.

Figure 1. Designing a high density power supply for a limited space application could not be easier. Here, four LTM4601 μModule regulators are paralleled in a simple scheme. Board layout is just as easy, since there are so few external components.

Figure 2. Individual LTM4601 switching waveforms for the circuit in Figure 1 shows the 90° out-of-phase relationship.

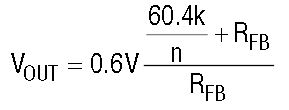

Only one resistor is required to set the output voltage in a parallel setup, but the value of the resistor depends on the number of LTM4601s used. This is because the effective value of the top (internal) feedback resistor changes as you parallel LTM4601s. The LTM4601’s reference voltage is 0.6V and its internal top feedback resistor value is 60.4kΩ, so the relationship between VOUT, the output voltage setting resistor (RFB) and the number of modules (n) placed in parallel is:

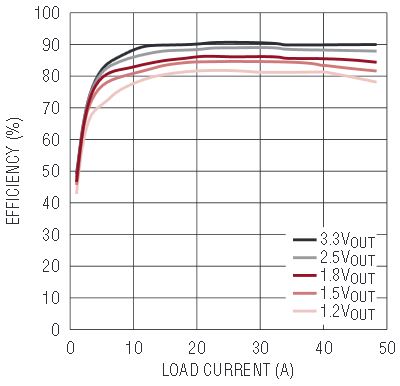

Figure 3 illustrates the system’s high efficiency over the vast output current range up to 48A. The system performs impressively with no dipping in the efficiency curve for a broad range of output voltages.

Figure 3. Efficiency of the four parallel LTM4601s remains high over a wide range of outputs.

Layout

Layout of the parallel μModule regulators is relatively simple, in that there are few electrical design considerations. Nevertheless, if the intent of a design is to minimize the required PCB area, thermal considerations become paramount, so the important parameters are spacing, vias, airflow and planes.

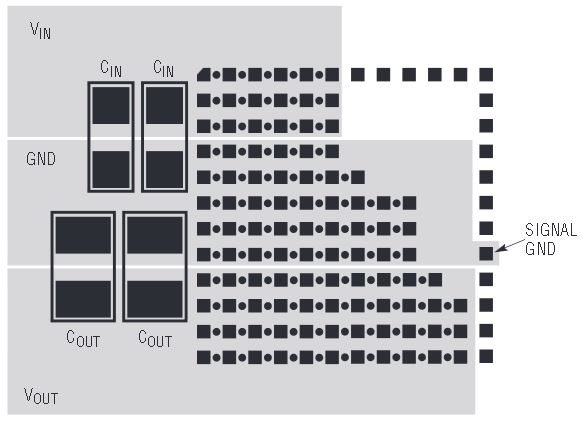

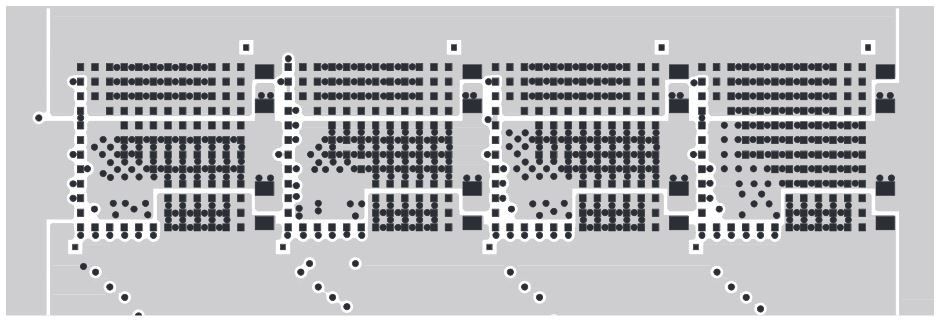

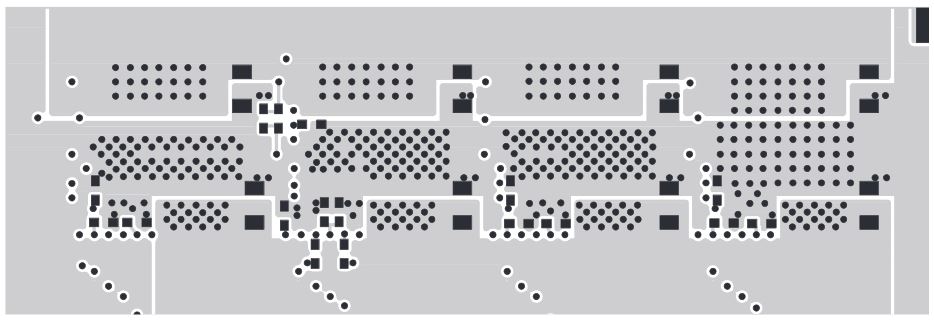

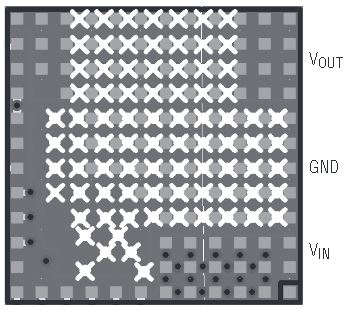

The LTM4601 μModule regulator has a unique LGA package footprint, which allows solid attachment to the PCB while enhancing thermal heat sinking. The footprint itself simplifies layout of the power and ground planes, as shown in Figure 4. Laying out four parallel μModule regulators is just as easy, as shown in Figures 5 and 6.

Figure 4. The LTM4601’s pin layout promotes simple power plane placement and uncomplicated part paralleling.

Figure 5. Top layer planes for 4-parallel μModule system.

Figure 6. Bottom layer planes for 4-parallel μModule system.

If laid out properly, the LGA packaging and the power planes alone can provide enough heat sinking to keep the LTM4601 cool.

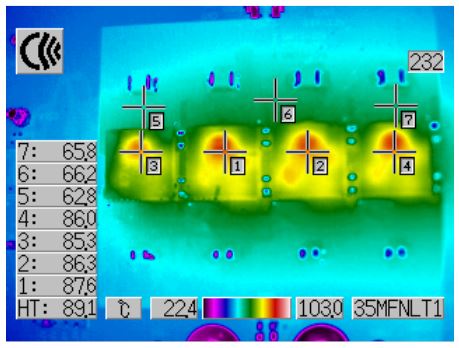

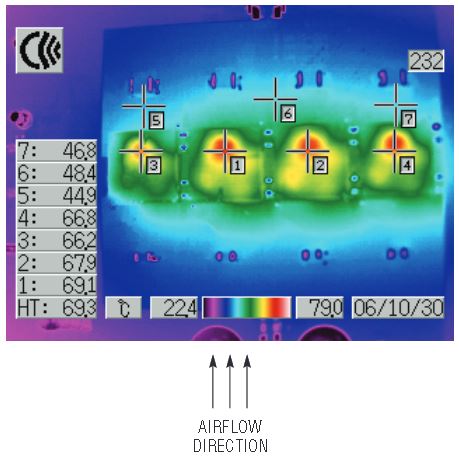

Figure 7 is a thermal image of the DC1043A board with readings of the temperatures at specific locations. Cursors 1 to 4 give a rough estimation of the surface temperature on each module. Cursors 5 to 7 indicate the surface temperature of the PCB. Notice the difference in temperature between the inner two regulators, cursors 1 and 2, and the outside ones, cursors 3 and 4. The LTM4601 μModule regulators placed on the outside have large planes to the left and right promoting heat sinking to cool the part down a few degrees. The inner two only have small top and bottom planes to draw heat away, thus becoming slightly warmer than the outside two.

Figure 7. Thermograph of four parallel LTM4601s without airflow (20V input to 1.5V output at 40A).

Further heat dissipation is possible by adding vias underneath the part. Vias provide a path to the power planes and into the PCB, which helps draw heat away. Vias should not be placed directly under the pads. Figure 8 shows the layout of the vias on the DC1043A demonstration circuit. The cross marks indicate the vias in between the LGA pads.

Figure 8. Via placement (cross marks) under a single μModule regulator.

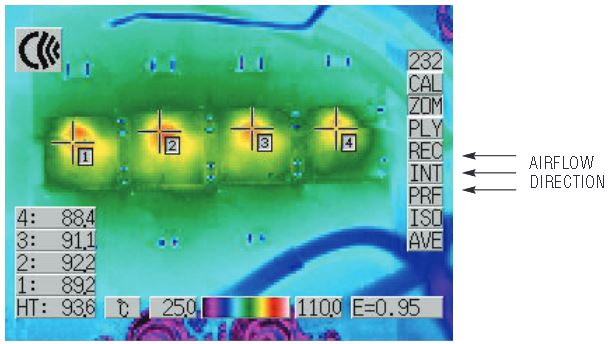

Airflow also has a substantial effect on the thermal balance of the system. Note the difference in temperature between Figure 7 and Figure 9. In Figure 9, a 200LFM airflow travels evenly from the bottom to the top of the demo board, causing a 20°C drop across the board compared to the no air flow case in Figure 7.

Figure 9. Thermograph of four parallel LTM4601s with 200LFM bottom-to-top airflow (20V input to 1.5V output at 40A).

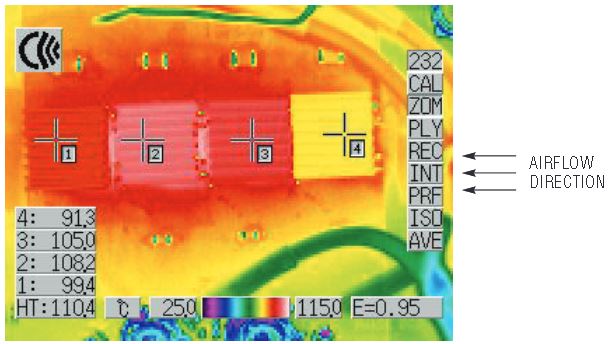

The direction of airflow is also important. In Figure 10 the airflow travels from right to left, pushing the heat from one μModule regulator to the next, creating a stacking effect. The μModule device on the right, the closest to the airflow source, is the coolest. The leftmost μModule regulator has a slightly higher temperature because of spillover heat from the other LTM4601 μModule regulators.

Figure 10. Thermograph of four parallel LTM4601s with 400LFM right-to-left airflow in 50°C ambient chamber (12V input to 1V output at 40A).

Heat transfer to the PCB also changes with airflow. In Figure 7, heat transfers evenly to both left and right sides of the PCB. In Figure 10, most of the heat moves to the left side. Figure 11 shows an extreme case of heat stacking from one μModule device to the next. Each of the four μModule regulators is fitted with a BGA heat sink and entire board is operated in a chamber with an ambient temperature of 75°C.

Figure 11. Thermograph of four parallel LTM4601s with BGA heat sinks and 400LFM right-to-left airflow in a 75°C ambient chamber (12V input to 1V output at 40A).

Start-Up, Soft-Start and Current Sharing

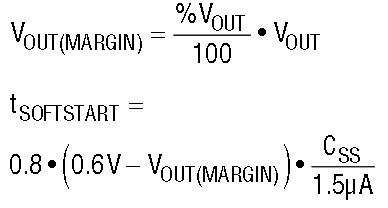

The soft-start feature of the LTM4601 prevents large inrush currents at start-up by slowly ramping the output voltage to its nominal value. The relation of start-up time to VOUT and the soft-start capacitor (CSS) is:

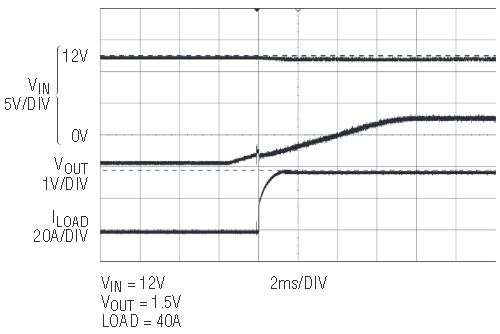

For example, a 0.1μF soft-start capacitor yields a nominal 8ms ramp (see Figure 12) with no margining.

Figure 12. Soft-start ramp for four parallel LTM4601s.

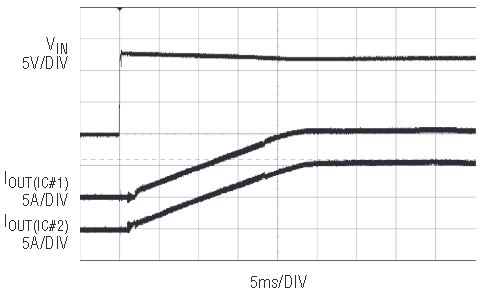

Current sharing among parallel regulators is well balanced through start-up to full load. Figure 13 shows an evenly distributed output current curve for a 2-parallel LTM4601 system, as each rises to a nominal 10A each, 20A total.

Figure 13. Current sharing among parallel regulators is well balanced through start-up to full load. Two parallel LTM4601s, as each rises to a nominal 10A each, 20A total.

Conclusion

The LTM4601 μModule regulator is a self-contained 12A step-down regulator in an IC form factor. It can be easily paralleled to increase load capability to 48A as shown here. Thermal performance is equally impressive at 48A of output current with balanced current sharing and smooth uniform start-up. The ease and simplicity of this design minimizes development time while saving board space.

About the Authors

Alan Chern is a former associate design engineer at Linear Technology (now part of Analog Devices). He was responsible for supporting uModule® Power products in design, testing, demo board production, and product evaluatio...