Dual Controller Provides 2μs Step Response and 92% Efficiency for 1.5V Rails

Dual Controller Provides 2μs Step Response and 92% Efficiency for 1.5V Rails

by

Mike Shriver

Aug 1 2012

Introduction

The LTC3838 is a dual output, dual phase buck controller that employs a controlled constant on-time, valley current mode architecture to provide fast load step response, high switching frequency and low duty cycle capability. The switching frequency range is 200kHz to 2MHz—its phase-locked loop keeps the frequency constant during steady-state operation and can be synchronized to an external clock. The LTC3838 accepts a wide input range, 4.5V to 38V, and can produce 0.6V to 5.5V outputs.

The remotely sensed VOUT1 has a voltage regulation accuracy of 0.67%, from 0°C to 85°C, even with a voltage difference of ±0.5V between local ground and remote ground. The current sense comparators are designed to sense the inductor current with either a sense resistor for high accuracy or with the inductor DCR directly for reduced power losses and circuit size.

1.5V/25A and 1.2V/25A Buck Converter

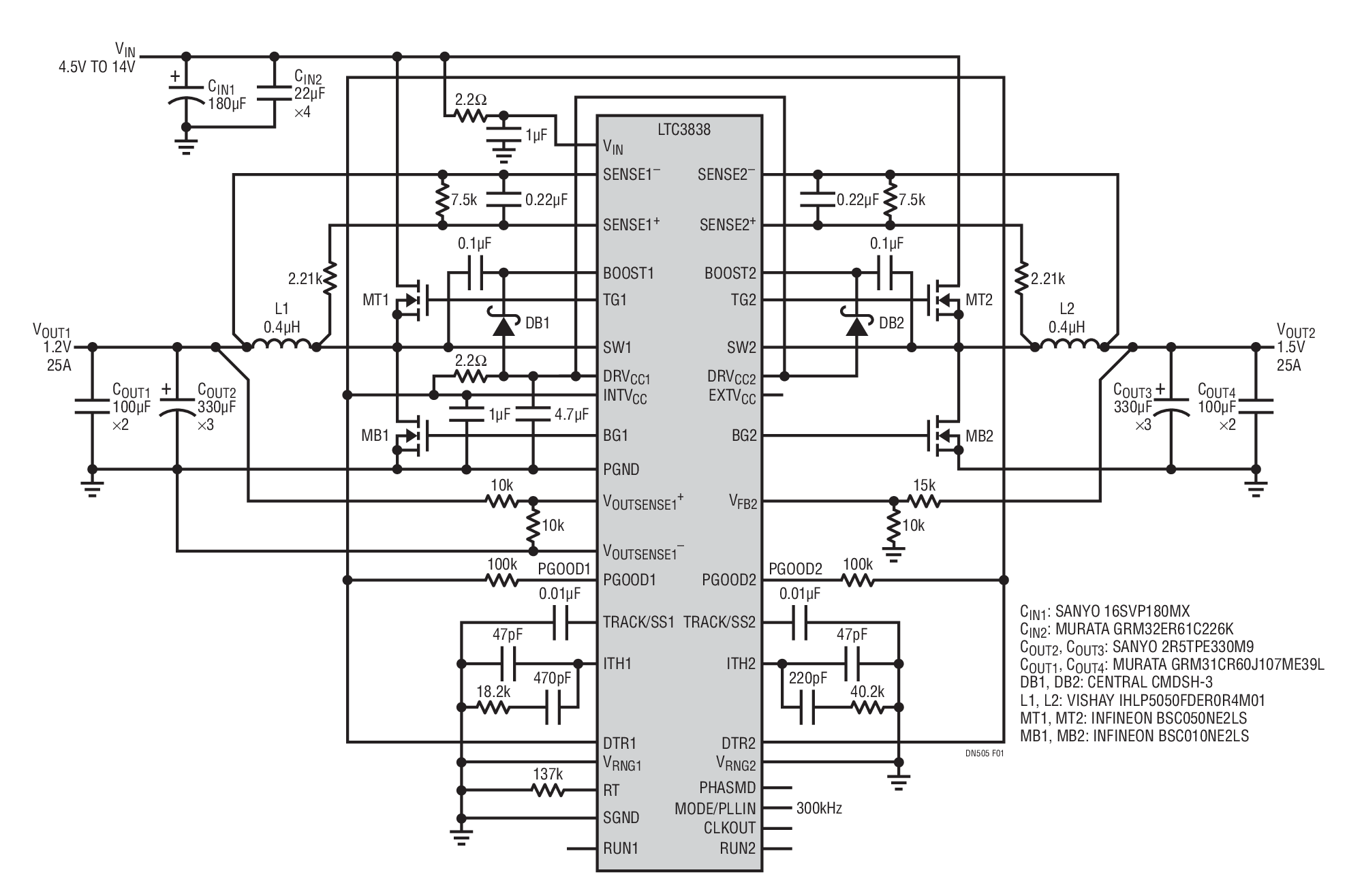

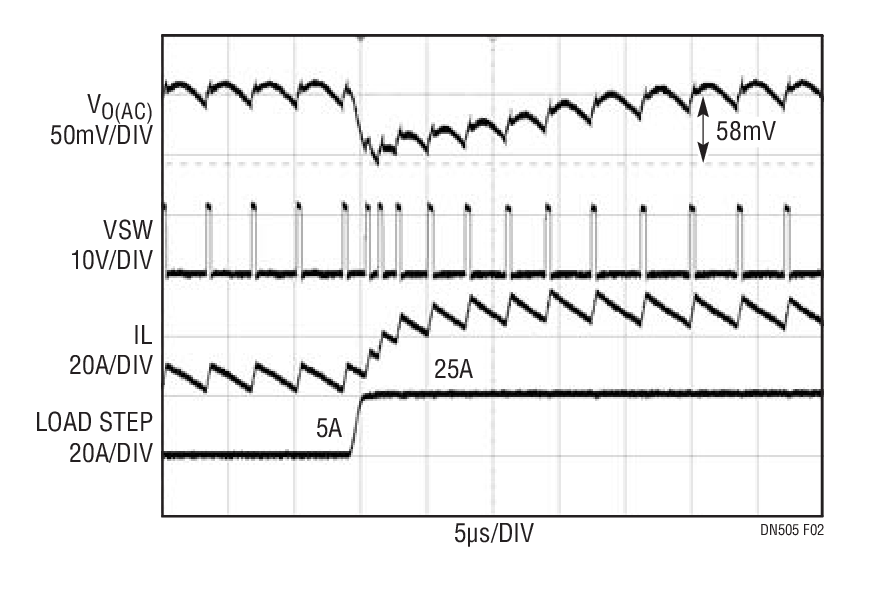

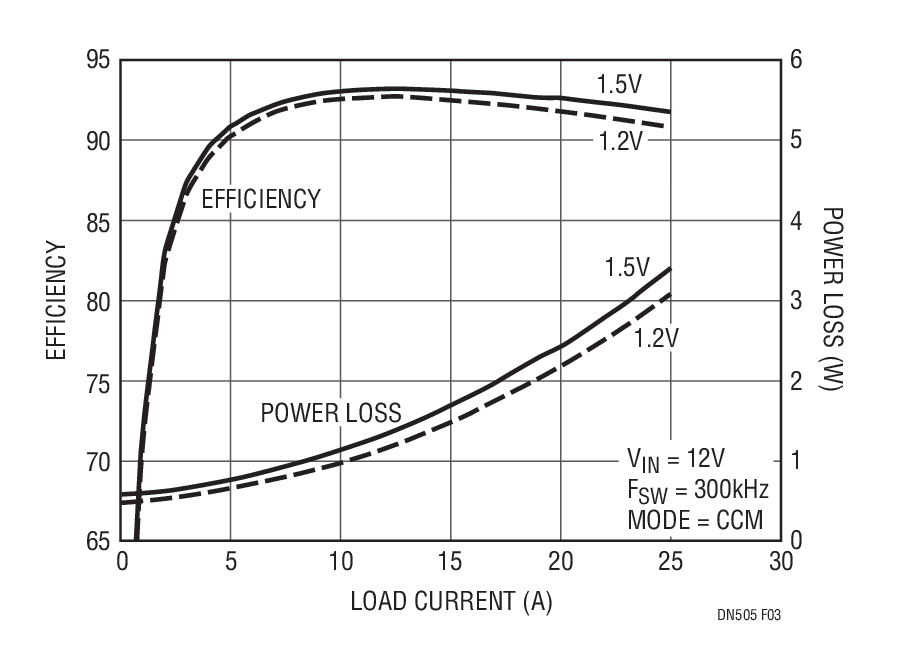

Figure 1 shows a dual 25A output buck converter synchronized to an external 300kHz clock. The controlled constant on-time valley current mode architecture allows the switch node pulses to temporarily compress when a 5A to 25A load step is applied to the 1.2V rail, resulting in a voltage undershoot of only 58mV (see Figure 2). The full load efficiency for the 1.5V and 1.2V rails is 91.8% and 90.8%, respectively, as shown in Figure 3. The high efficiency is realized by the strong gate drivers, optimized dead time and DCR sensing.

Figure 1. Dual Output, 1.5V/25A and 1.2V/25A Buck Converter Operating at FSW = 300kHz

Figure 2. 20% to 100% Step Load Response of the 1.2V Rail at VIN = 12V, FSW = 300kHz, Mode = FCM

Figure 3. Efficiency and Power Loss of the 1.5V/25A and 1.2V/25A Converter

The two channels operate 180° out-of-phase, which permits the use of fewer input capacitors due to input capacitor ripple current cancellation. For higher current applications, two or more phases can be tied together to form a single output, PolyPhase® converter. The benefits include a faster load step response, reduced input and output capacitance and reduced thermal dissipation.

Detect Transient Feature Further Speeds Up Transient Response

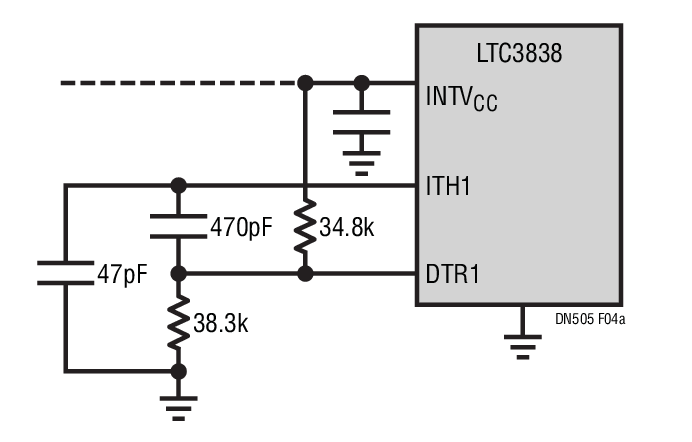

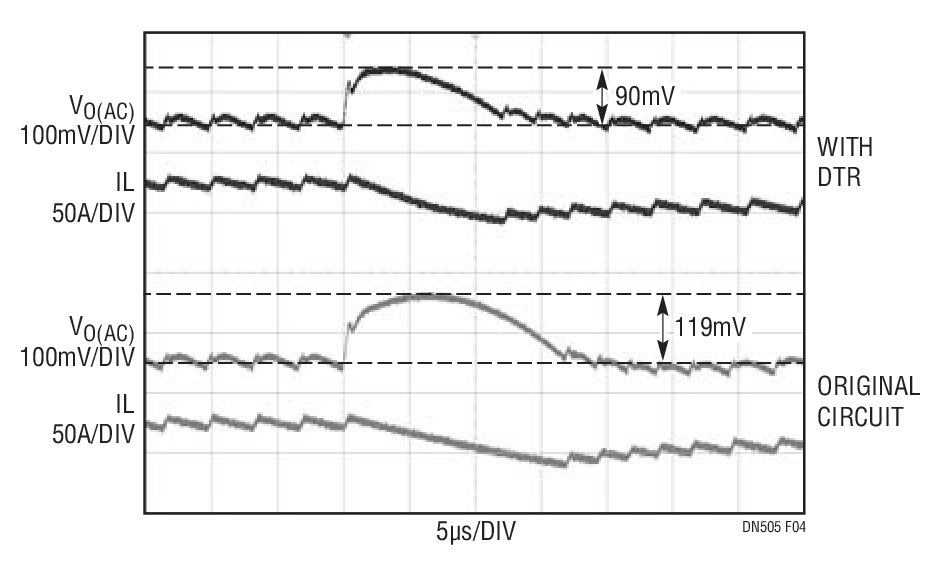

An innovative feature of the LTC3838 is the load release transient detect feature. The DTR pin indirectly monitors the output voltage by looking at the AC-coupled ITH signal. If the inferred overshoot exceeds a user set value, the bottom FET turns off. This allows the inductor current to slew down at a faster rate, which in turn reduces the overshoot. Per Figure 4, a 32% reduction in the overshoot is realized on the 1.2V rail. Greater improvements occur at lower output voltages.

Figure 4a. Implementation of the Detect Transient Feature on the 1.2V Rail

Figure 4b. 100% to 20% Step Load Response of the 1.2V Rail with and without the Detect Transient Feature, VIN = 12V, FSW = 300kHz, Mode = FCM

Conclusion

The LTC3838 is a dual output buck controller ideal for applications that require a fast load step response, high switching frequency, high efficiency and accurate output voltages. Other features include selectable operating modes: forced continuous mode (FCM) for fixed frequency operation or discontinuous mode (DCM) for higher efficiency at light load, programmable current limit thresholds, soft-start, rail tracking and individual PGOOD and RUN pins. The LTC3838 comes in a 5mm × 7mm QFN package or a thermally enhanced 38-lead TSSOP package.

About the Authors

Mike Shriver is a Senior Applications Engineer at Analog Devices. He has over 17 years’ experience at Linear Technology (now ADI), working in power applications. Prior to Linear Technology, he worked for Artesyn Technologi...