Alternating Control and Optimizing the Bandwidth in H-Bridge Buck-Boost Circuits

Alternating Control and Optimizing the Bandwidth in H-Bridge Buck-Boost Circuits

by

Mark Derhake

Sep 25 2025

Abstract

This article will explore the benefits of using alternating buck-boost control and delve into the control limitations that affect the transient response of the buck-boost architecture. It will also provide strategies to optimize the transient performance in each operating region.

Introduction

H-bridge buck-boost ICs are commonly used in applications requiring a constant voltage or current source even when the system battery drops to lower voltages. They are typically used when a single-stage converter is desired, and the output can be above or below the input voltage. They are also used as current sources for LED applications to simplify the design of the typical boost to buck into a single stage. These ICs may see use over other buck-boost topologies such as single-ended primary inductor converters (SEPICs) due to the cost of the coupled inductor.

True to its name, the H-bridge buck-boost architecture is a composite of both a buck circuit and boost circuit combined into a single converter. The circuit requires four switches to operate. These four switches are used to regulate the output by sensing the ratio between the output and input to determine the mode of operation.

The H-bridge buck-boost works by operating in one of several modes. When the input voltage is much higher than the output voltage, the circuit will operate in pure buck mode by toggling switches 1 and 2 (see Figure 1). When the input voltage is much lower than the output, the circuit will operate in pure boost mode by toggling switches 3 and 4 (see Figure 1). When the input voltage is close to the output, the circuit will operate in buck-boost mode. When in this mode, there are several ways that the four switches can be controlled to achieve proper regulation.

Modes of Operation

To determine the mode of operation, the circuit must sense the ratio of the output and input. This ratio is then compared to internally set values to determine the mode of operation. Typically, some hysteresis is given to these values to ensure smooth transitions between modes of operation for rising and falling input voltages.

Buck Region

When the internal comparator for buck mode triggers due to the output being sufficiently lower than the input, the circuit will operate as a pure buck converter. To operate in the buck region, switch 3 must always be closed and switch 4 must always be open. Switches 1 and 2 can then toggle LX1 as they would in a normal forced pulse-width modulation (FPWM) buck converter (Figure 2).

Boost Region

When the internal comparator for boost mode triggers due to the output being sufficiently higher than the input, the circuit will operate as a pure boost converter. To operate in the boost region, switch 1 must always be closed and switch 2 must always be open. Switches 3 and 4 can then toggle LX2 as they would in a normal FPWM boost converter (Figure 3).

Buck-Boost Region

When the output is close to the input (either slightly higher or lower), then the circuit will operate in the buck-boost region.

Alternating Buck-Boost Control

With alternating buck-boost control, the circuit will regulate the output by alternating between the buck and boost sides. This means that initially, the circuit will operate the buck switches, and the duty cycle will be set by the comp voltage. The buck switches will operate for a full switching period before the circuit changes to the boost side. Once the buck side has finished a full period, the boost side will toggle with its duty cycle also being controlled by the voltage on comp. This operation allows for both sides of the H-bridge to adjust each buck and boost pulse as needed to regulate the output. This also means that the operating frequency is effectively halved due to each half of the H-bridge toggling only after the other side has finished (Figure 4).

This control method sees many benefits. The first is efficiency since the switching frequency halves in the buck-boost region fewer switching losses occur. Electromagnetic interference (EMI) sees a similar benefit. Even though the switching frequency is halved, it is always consistent, which simplifies EMI. Finally, this method allows for an improved transient response. This is because the effective boost duty cycle is lower when the output is slightly higher than the input. Meaning that the right half plane zero (RHPZ) in this control scheme is kept at higher frequencies in the buck-boost region.

To see how the circuit regulates in the buck-boost region, consider the case where the input is slightly higher than the output. The buck-boost cycle starts by controlling the buck side by closing switches 1 and 3. This will cause the inductor current to rise to its peak value with a slope of (VIN – VOUT)/L1. Once the buck on-time has finished, the control loop will open switch 1 and will close switch 2 . During the off-time of the buck cycle, the inductor current will slew down to its valley value with a slope of VOUT/L1, defining the inductor peak to peak ripple. Once a full switching period has elapsed on the buck side, the logic circuit will switch over to the boost side. The boost side will start by opening switch 2 and keeping switches 1 and 3 closed. This action represents the off-time for the boost. The inductor current during this time will rise in the same manner as the buck on-time with a current slope of (VIN – VOUT)/L1. Once the boost off-time is finished, the control loop will program the boost on-time by opening switch 3 and closing switch 4. This will cause the inductor current to build back up to the beginning level of the buck on-time with a slope of VIN/L1 (Figure 5).

Next, consider the case where VIN is slightly lower than VOUT. In this case, each switching period remains the same. The main difference between the two cases is that when VIN > VOUT, the inductor current ripple is set by the buck off-time whereas when VIN < VOUT, the inductor current ripple is now set by the boost on-time. The inductor current ripple will also double in the buckboost region. This happens because the frequency of the buck and boost sides of the H-bridge is halved. This is illustrated in Figure 6 as the inductor current completes a full period only after one full buck and boost period have completed.

Efficiency Benefit

In the buck-boost circuit, the overall power stage efficiency will drop when the circuit enters the buck-boost region. When using alternating control, the efficiency of the buck-boost region can be improved. This happens due to the effective frequency drop during the buck-boost region. For example, during buck operation, if operating at 2.1 MHz, switches 1 and 2 will both turn on and off once every 476 ns. When operating in the boost region, the same is true for switches 3 and 4. When operating in the buckboost region, this fact is still the same, except now the switches are alternating between each side. This means that the number of switching events is still the same even in the buck-boost region making the efficiency of this control method better.

Transient Benefit

Consider the scenario where the output is slightly greater than the input. In this case, the circuit is in the buck-boost region. Since the circuit is now boosting more than it is bucking, the boost RHPZ will begin to affect the circuit more. This effect is less pronounced when using alternating buck-boost control since the inductor current can ramp for a longer time in the boost region. This effect also means that changes in the input voltage have less effect on the output since the inductor current can ramp for a longer period to correct for changes in the input quicker.

Transient Optimization of the Buck-Boost

When compensating a buck-boost IC, the selection of the crossover frequency must account for the worst-case load, input voltage, output capacitor value, and inductor value. Since the buck-boost IC can operate in the boost region, this means that the worst-case VIN is likely to also cause the circuit to operate in pure boost mode. When operating in pure boost mode, the circuit encounters an additional limitation in the form of the RHPZ. Since the RHPZ is a function of the time delay between charging the inductor and delivering energy to the output, the loop must be compensated to account for 1/3 to 1/5 of this frequency. Due to this, the transient response of the buck-boost circuit becomes limited even when more bandwidth is available in the buck region where no RHPZ is present. Typically, to compensate the control loop, a resistor-capacitor compensation network is used to provide the proper phase and gain consisting of Rcomp1 and Ccomp. To optimize the transient in both boost and buck regions, an extra resistor (Rcomp2) is added to the RC compensation network. A switch is also placed across Rcomp2 to bring it into and out of the compensation network depending on the region of operation. When the circuit is operating in boost mode, the switch will short across Rcomp2, lowering the crossover frequency. When the circuit enters the buck-boost or buck regions, the switch opens, and Rcomp2 helps increase the gain and phase further. This has the effect of increasing the crossover frequency. This operation allows the circuit to have a sufficiently low crossover for the boost region, while also having a sufficiently high crossover for the buck region (see Figure 7).

Control Loop (Average Current-Mode Control)

There are many ways to implement the control loop for the buckboost circuit. The main one of interest is average current-mode control, which provides several benefits that other control methods lack.

Noise Immunity

In average current-mode control, the inductor current is sensed and compared against the compensation level. This is then fed into an inner loop error amplifier that contains an RC compensation network. This integrator provides high gain for the inner loop. This compensated inner loop is then compared against a sawtooth to generate the duty cycle. This provides higher noise immunity as any spikes in current in the inductor waveform get filtered out since the loop is regulating the average current. Consider the case for peak or valley current-mode control where the sensed inductor current is small relative to the peak or valley value. This results in lower noise immunity since any current spikes present on the sensed current may cause incorrect sampling without some leading-edge blanking or filtering of the sensed current. Even with filtering in place, at low load currents, the slope compensation may become large relative to the sensed signal causing larger deviation in regulation.

Min Ton and Min Toff

Since average current-mode control uses an integrator for the inner current loop with a sawtooth fed to a comparator to generate the duty cycle, the minimum on- and off-times can be much smaller, compared to peak current mode or valley current mode, which will have larger min on- and off-times due to having circuits like leading-edge blanking.

No Slope Compensation

Average current-mode control does not require slope compensation. This simplifies the maximum current limit, since it is no longer a function of the added slope. Since no slope compensation is needed, this also means that average current mode has better performance in discontinuous conduction mode (DCM) as well when compared to peak current mode where the slope compensation can become a large part of the sensed signal.

Parallel Operation

If multiple converters are to be operated in parallel, then average current-mode control provides the best current sharing. This is because the outer loop will program the average current of each converter, whereas peak or valley current mode will have some offset in the current in each converter due to each having slightly different inductances.

Design Example

The goal is to design a circuit with a VIN range of 6 V to 18 V, VOUT = 13 V, load = 2.5 A, and to minimize the output cap. The goal is to achieve a VOUT p-p of ±5%. To minimize the output cap, start by selecting a switching frequency of 2.1 MHz. At 2.1 MHz, 1 µH is typically used for the inductor value. The VOUT limits allow for a 650 mV transient. To estimate the output cap required, first start by considering the worst-case VIN, which will put the circuit in the boost region. In the boost region, the RHPZ can be calculated using Equation 1.

By solving for the RHPZ, and dividing by 5, the crossover frequency in the boost region will be set at 35 kHz. Equation 2 can be used to estimate the output cap.

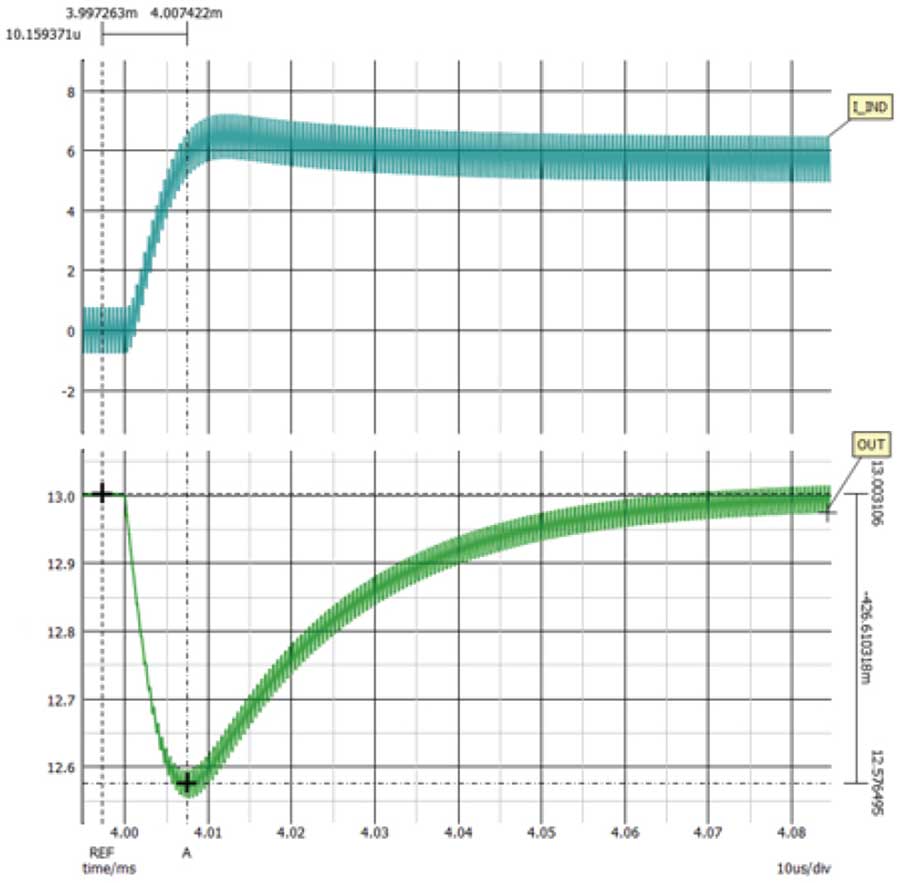

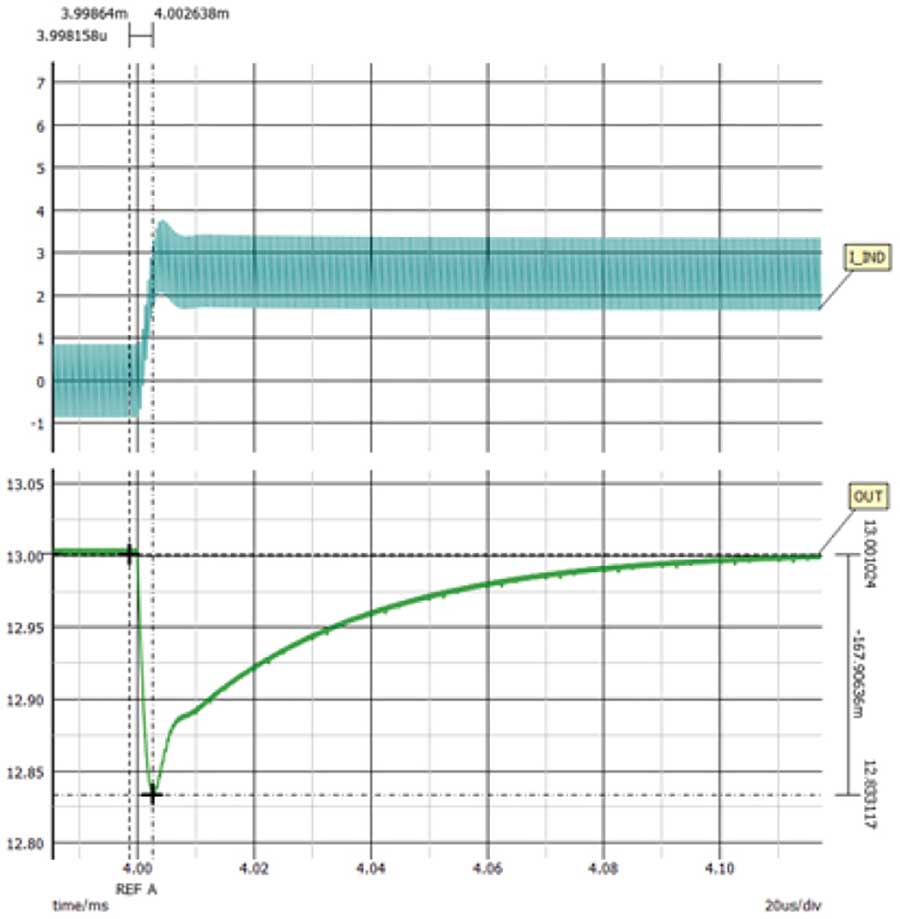

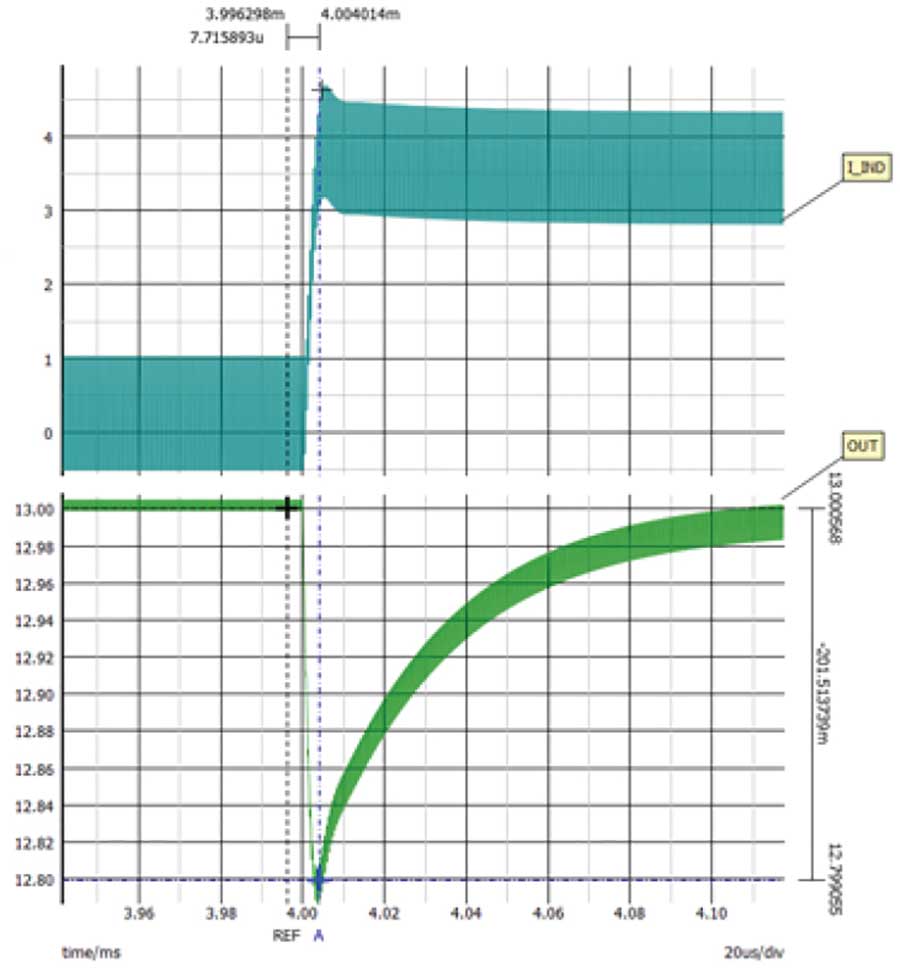

By solving this equation, the output cap is estimated at 17.5 µF. Round this value up to 22 µF. With the components chosen, comp can now be designed starting in the boost region to achieve a 35 kHz crossover. Once Rcomp and Ccomp are selected, the circuit must now be compensated for the buck region at 18 VIN. Since there is no RHPZ, select the crossover to be 100 kHz. Rcomp2 can then be adjusted to achieve this crossover. With everything in place, the transient response in each case is checked. The transient in the buck and buck-boost regions are reduced due to the addition of Rcomp2. See figures 8, 9, and 10.

Conclusion

To optimize the buck-boost circuit, alternating buck-boost control can be used for its many advantages over standard control methods allowing for improved transient response, improved efficiency, simplified design, and improved EMI. The transient response of the buck-boost circuit can be further optimized with the addition of Rcomp2 to help improve the loop bandwidth.

About the Authors

Mark Derhake is an applications engineer with over three years of industry experience. He graduated from Southern Illinois University

Edwardsville with his bachelor’s in electrical and computer engineering in 2020. In 202...