15A μModule Regulator Solves Thermal Problems by Converting 12V to 1V with High Efficiency

15A μModule Regulator Solves Thermal Problems by Converting 12V to 1V with High Efficiency

Oct 1 2011

Advances in silicon process technology continue to reduce transistor geometries down to historical levels in microprocessors, FPGAs and ASICs. The power supply voltage levels necessary to power these large, complex digital devices also continue to shrink, creating unique power supply design challenges.

One major concern is the power regulator’s conversion efficiency at low output voltages. For example a typical high efficiency switching regulator that converts 12V to 3.3V at 15A has a conversion efficiency of ~93%. For practical purposes, such a regulator incurs most of its efficiency loss due to I2R losses. Therefore 93% efficiency for processing 49.5W to the load equates to a 3.72W loss.

Likewise, a low output voltage requirement of 1V at 15A with an efficiency of 76% incurs a power loss of 4.74W. Typical high density power solutions are challenged to achieve high efficiencies at low output voltages due to the size constraints of the power stage. The power stage must have high performance power MOSFETs and inductors to improve low voltage conversion efficiency not just an increase the solution size.

In reality, many feature-laden digital devices have current requirements in the >30A range for the low voltage supply. Thus a 76% efficiency 1V output would incur a 9.48W loss for a 30A load, which would certainly cause thermal challenges. The thermal problems multiply with the number of 30A regulators required on a system board.

Unchecked regulator power losses, when added to other system power losses create serious thermal challenges. One issue is that small-geometry ASIC or FPGA leakage currents rise with system temperature, thus compromising system performance and reliability.

One possible solution is to use a power converter module that can deliver significantly higher output power than necessary for the application, and run it at an output current point that maximizes efficiency. Of course, overly large solutions are not feasible in space-constrained systems and the current limit of this solution is much higher than the required current.

Another solution is to use a discrete power converter that is optimized for low output voltage efficiency. But again space constraints and component sourcing can be challenging. Another challenge with a discrete design is how to effectively cool it and heat sink the various discrete power components, which have different heights.

μModule Solution

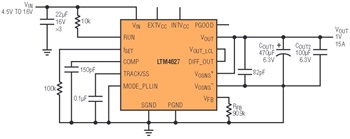

Figure 1 shows a complete 1.0V at 15A converter that uses the LTM4627 μModule regulator housed in a 15mm × 15mm × 4.32mm package. The LTM4627 integrates the high performance power path and control circuitry, thus simplifying the design to a few external bulk capacitors and a few small resistors.

Figure 1. A complete 1V at 15A converter requires only a few components around the LTM4627 μModule regulator, which comes in a thermally enhanced 15mm × 15mm × 4.32mm package.

The LTM4627 features include fully differential remote sensing, output voltage tracking and soft-start, high efficiency at light loads utilizing the Burst Mode operation or pulse-skipping features, voltage monitoring and frequency synchronization. The LTM4627 uses a current mode architecture, which enables multiple μModule regulators to run in parallel (Figure 5), sharing the load for increased output current with accurate current limit control.

The LTM4627 μModule regulator is optimized for high efficiency conversion to low output voltages—with a complete converter packaged in a small, thermally enhanced form factor. The input voltage range is 4.5V to 20V with output voltage programming from 0.8V to 5V. Figure 2 shows efficiencies of 82% to 83% for 1V at 15A from 5V, 8V and 12V inputs. This is an efficiency improvement of 6% to 7% over typical (and larger) solutions, or a power loss improvement of 1.68W in a small form factor.

Figure 2. Efficiency of the regulator in Figure 1.

Figure 3 shows a LTM4627 thermal plot for 12V to 1V at 15A with no airflow or heat sinking. The temperature rise is ~40°C above 25°C ambient at 65°C. The power loss of ~3W multiplied by the data sheet specified θJA thermal resistance of 13°C/W matches the 40°C rise in the thermal plot.

Figure 3. Thermal plot of the LTM4627 converting 12V to 1V at 15A with no forced air or heat sink.

The LTM4627 package has a highly thermal conductive substrate with a layout that is thermally modeled and designed to enhance thermal performance and uniform heat spreading. While the package is small, it presents enough surface area to a PCB (and heat sink) to minimize the overall thermal resistance of the solution.

Figure 4 shows the LTM4627 12V to 1V derating curve. The LTM4627 can operate in higher ambient temperatures with full load capability in a very small form factor.

Figure 4. Derating curves for the LTM4627 converting 12V to 1V.

Figure 5 shows a 2-phase, 30A design utilizing two parallel LTM4627 μModule regulators that are clocked 180° out-of-phase using clock signals from the LTC6908-1.

Figure 5. A 2-phase, 30A design based on two parallel LTM4627 μModule regulators clocked 180° out-of-phase. For higher output currents, simply add more LTM4627s.

Current sharing is well balanced during both steady state DC load and dynamic transients. The accurate remote sense amplifier yields outstanding voltage accuracy at the load point. For even higher output currents, simply add more LTM4627s.

Conclusion

The LTM4627 μModule regulator is a high performance versatile DC/DC converter that can be used in many applications requiring high efficiency over a wide output voltage range. The very small form factor and ease of use make the LTM4627 ideal for space-constrained designs.

About the Authors

Eddie Beville is a power module design manager responsible for the design and development of the μModule® family. Eddie holds a BS in Electronic Engineering Technology from Chapman University, Orange, California. Eddie enj...