Overview

Design Resources

Design & Integration File

- Schematic

- PCB Layout

- Fab Package

- Hardware

- Software

- BOM

Evaluation Hardware

Part Numbers with "Z" indicate RoHS Compliance. Boards checked are needed to evaluate this circuit.

- MAXREFDES175# ($71.74) EV Kit

Description

Today’s cars are equipped with many remote units used for radio and global positioning antennas and remote cameras and microphones. Quite often those remote units are supplied by the head unit through cables that require a regulated and protected power supply source. The MAXREFDES175 reference design shows how to implement eight phantom power supplies and how to take advantage of the numerous diagnostic features offered by the MAX20084 using the BeagleBone® Black platform.

Design files, firmware, and software can be found on the Design Resources tab. The board is also available for purchase.

Features & Benefits

- Eight automotive phantom power supplies

- I2C programmability and diagnostic

- Portable software driver

Details Section

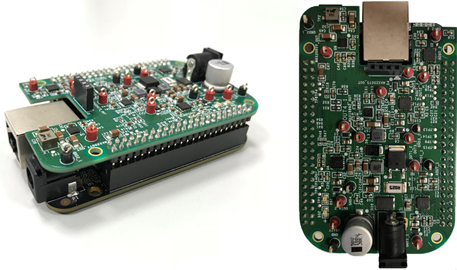

The MAXREFDES175 gives different automotive phantom supply application scenarios implemented on a custom BeagleBone Black (BBB) cape. After describing the cape hardware architecture, the reference design analyzes and tests each individual phantom supply. Finally, a generic software driver for the MAX20084 phantom supply is presented followed by a specific BBB integration example. The following picture shows the cape assembled on the BeagleBone Black.

Figure 1.

System Diagram

Figure 2. System block diagram.

Introduction

The MAX20084 is a dual-antenna power supply with an I2C interface for diagnostics and control. The dual 270mA antenna supplies are linear regulators whose output voltage is set individually through the I2C. Additionally, internal registers are used to set the current limit, open-load threshold, and other parameters. An internal 8-bit ADC allows the channel current to be measured and queried through the I2C. A high voltage enable pin (EN) can be used to shut down the device and reduce power consumption to its minimum. An open drain fault pin (FLT) can be used as an interrupt source for the main processor in the case of a fault.

Thanks to the I2C interface and the MAX20084 extensive programmability, multiple remote phantom supplies can be integrated in the system and reduce the number of tracks to be routed across the board.

The MAXREFDES175 BeagleBone cape embeds eight remote phantom supplies in a 3.4in × 2.1in, 6-layer board, which also integrates two step-down regulators, a high voltage boost, and a CAN transceiver based on the MAX13041.

Cape Hardware Architecture

The MAXREFDES175 implements four dual-channel phantom supplies with different configurations deploying the MAX20084 dual phantom supply LDO/Switch with extensive diagnostic and the I2C interface. The BBB individually configures and monitors each phantom supply through the I2C bus and a few GPIO lines, which are used to enable the MAX20084 (EN pin) and monitor the fault status (FLT pin). Each MAX20084 output can be configured by the BBB to regulate a voltage between 3.3V and 12V (LDO), or, alternatively, any channel can be configured as a switch. Additionally, the output current on all channels can be monitored in real time through the I2C interface.

Figure 3 illustrates the cape hardware architecture.

Figure 3. Cape hardware architecture.

As shown in Figure 3, the first MAX20084 (1) is directly powered by the car battery and provides a switched version of the battery supply on each of its two outputs. The two switched battery outputs are ideal for each remote unit that needs a protected battery supply. Each output is protected against short to ground, short to battery, overcurrent, and battery overvoltage fault conditions.

The second MAX20084 (2) is powered by a 5V regulated rail generated by the MAX20077 high voltage synchronous buck converter with integrated FETs. The MAX20084 (2) outputs a 3.3V regulated voltage on channel 1 (LDO) and a switched 5V rail on channel 2 (Switch). These outputs can be used to power GPS and GNSS satellite positioning remote modules. The 5V output of the MAX20077 is also used to power the BBB and the MAX13042 CAN transceiver.

For some remote applications it is required to sustain the power supply during a battery cold crank event. For this type of application, a front-end boost is required to maintain the input voltage of the MAX20084 high enough during the cold crank event.

One common example is a remote radio antenna power supply where often a well-regulated 8.5V rail is required during a cold crank battery voltage drop. For this reason, the MAX20084 (4) is not connected directly to the battery but to the MAX16992 boost controller. The MAX16992 regulates a stable 10V output when the battery drops during cold crank, assuring 1.5V voltage headroom to the MAX20084 (4) and allowing 8.5V proper regulation on the outputs. During the normal battery condition, the MAX16992 boost does not switch and the MAX20084 (3) is supplied by the battery voltage (minus the boost Schottky diode forward-voltage drop).

Another example is a remote camera application where a 5V rail needs to be supplied during cold crank and the current demand is high (up to 200mA). To reduce the power dissipation on the MAX20084 when the battery voltage is in normal condition (12V to 14V), a switching step-down converter is placed between the MAX16992 boost output and the MAX20084 (3). The MAX20075 synchronous buck converter with integrated FETs is used to regulate a 6.6V rail, which becomes the input supply for the MAX20084 (3). This architecture results in a 1.6V headroom voltage that is enough to properly regulate 5V on the MAX20084 (3) outputs at 200mA and, at the same time, keep the power dissipation on the MAX20084 low (0.32W per channel).

For power supplies that require a regulated voltage, the channels must be configured in LDO mode. Additionally, the voltage headroom between the IN_ pin of the MAX20084 and the OUT_ pin of the specific channel must always be higher than the MAX20084 LDO dropout voltage, as shown in Figure 4.

Figure 4. MAX20084 LDO dropout voltage.

To reduce the external component sizes and lower the EMI, all DC-DC regulators switch at 2.2MHz using spread spectrum modulation.

Figure 5 illustrates the MAX20084 (4) 8.5V output rails and the MAX20084 (3) 5V output rails during a 4V cold crank event. The output voltages are well regulated even when the battery voltage drops to 4V.

Figure 5. Cold crank event.

Cape Software Architecture

A generic C++ driver is used as the main component to implement the software architecture shown in Figure 6. The driver implements a MAX20084 software object which can be instantiated multiple times (one for each physical MAX20084 device).

Figure 6. Cape software architecture.

The MAX20084 software object requires three functions to be linked in order to be properly constructed. These three routines are used to read a register from the MAX20084, write a register to the MAX20084 and read the MAX20084 FLT pin status. Examples of these routine implementations as well as the MAX20084 software object initialization can be found in the src/MAX20084_cape.cpp file included in the MAXREFDES175# software MAXREFDES175_SW.zip in the Design Resources tab.

The MAX20084 software object initialization is as follows:

new MAX20084(user_defined_I2C_register_write_func, user_defined_I2C_register_read_func, user_defined_GPIO_read_func );

Also provided is the MAX20084 software object source code, which can be found in the files src/MAX20084.cpp and include/MAX20084.h, along with the driver documentation (doc/help.chm).

The MAX20084_CAPE object instantiates four entities of the MAX20084 objects. Each MAX20084 object is successively and properly configured in terms of output voltage and enabled:

max20084[1]->set_output_voltage(CHANNEL_1, VOUT_3V3);

max20084[1]->set_output_voltage(CHANNEL_2, SWITCH_MODE);

The MAX20084_CAPE object also exposes a get status function, which reports the status of each individual MAX20084 and outputs the actual output current for each channel.

The main (src/mainapp.cpp) instantiates a MAX20084 CAPE and generates a periodic thread which polls the status of each MAX20084.

To test the cape, a simple run.sh script is included and builds the software using a GNU to make and launch the example software.

Required Equipment:

- BeagleBone Black with Debian® OS

- 12V/1A power supply

- MAXREFDES175 BeagleBone cape

- Plug the BeagleBone cape on top of the BeagleBone Black board.

- Connect a 12V/1A supply between the GND and VBATT test points of the MAXREFDES175#. Alternately, plug a 12V/1A wall power supply into the standard J1 connector of the MAXREFDES175.

- Log in to the BeagleBone Black.

- Unzip the MAXREFDES175_SW.zip file and copy the MAXREFDES175_SW folder into the BeagleBone Black.

- Navigate to the MAXREFDES175_SW folder and type ./run.sh.

Figure 7. Debian BeagleBone.

Documentation & Resources

-

MAXREFDES175 Design Files2/15/2021ZIP14 M

Support & Training

Search our knowledge base for answers to your technical questions. Our dedicated team of Applications Engineers are also available to answer your technical questions.