Synchronous Buck Controller Extends Battery Life and Fits in a Small Footprint

Synchronous Buck Controller Extends Battery Life and Fits in a Small Footprint

by

Peter Guan

2001-02-01

Introduction

Portable electronic devices continue to decrease in size and their supply voltages are also falling, but load current requirements are increasing as a result of higher processing speed and improved features. This trend places more constraints on today’s portable power supplies, but Analog Devices has the solution. The LTC1773 is a synchronous DC/DC controller that packs high output current capability and low operating quiescent current in a small MSOP-10 package. Its input voltage range is from 2.65V to 8.5V; this is ideal for 1- or 2-cell Li-Ion batteries as well as 3- to 6-cell NiCd and NiMH battery packs because it allows the batteries to operate near end of charge. A precise internal undervoltage lockout circuit prevents deep discharge of the battery below 2.5V. Popular features such as OPTI-LOOP™ compensation, soft start and Burst Mode™ operation are also included. Combined with its small MSOP package, the LTC1773’s high operating frequency of 550kHz allows the use of small, surface mount components to provide a compact power supply solution.

Operation

Figure 1 shows a typical application of the LTC1773 in a 5V to 2.5V/3A step-down converter. Figure 2 shows its efficiency vs load current. The LTC1773 uses a constant frequency, current mode architecture to drive an external pair of complementary power MOSFETs. An internal oscillator sets the operating frequency of the device. The P-channel MOSFET turns on with every oscillator cycle and turns off when the internal current comparator trips, indicating that the inductor current has reached a level set by the ITH pin. An internal error amplifier, in turn, drives the ITH pin by monitoring the output voltage through an external resistive divider connected to the VFB pin. While the P-channel MOSFET is off, the synchronous N-channel MOSFET turns on until either the inductor current starts to reverse, as indicated by the SW pin going below ground, or until the beginning of the next cycle.

Figure 1. 5V to 2.5V/3A step-down converter.

Figure 2. Efficiency of Figure 1’s circuit with several input voltages.

Synchronous, Burst Mode and Forced Continuous Operation

Three modes of operation can be selected through the SYNC/FCB pin. Tying it above 0.8V or leaving it floating will enable Burst Mode operation, which increases efficiency during light load conditions. During Burst Mode operation, the peak inductor current limit is clamped to about a third of the maximum value and the ITH pin is monitored to determine whether the device will go into a power-saving Sleep mode. The ITH level is inversely proportional to the output voltage error. When the inductor’s average current is higher than the load requirement, the output voltage rises while the ITH level drops. When ITH dips below 0.22V, the device goes into Sleep mode, turning off the external power MOSFETs and most of the internal circuitry; in this state, the LTC1773 consumes only 80µA of quiescent current. At this point, the load current is being supplied by the output capacitor. As the output droops, ITH will be driven higher. When ITH rises above 0.27V, the device resumes normal operation.

For frequency-sensitive applications, Burst Mode operation can be inhibited by tying the SYNC/FCB pin to below 0.8V to force continuous operation, which will continually drive the external power MOSFETs synchronously regardless of the output load. The inductor current is allowed to reverse in this case.

In addition to being a logic input threshold, the 0.8V threshold of the SYNC/FCB pin can also be used to regulate a secondary winding output by forcing continuous synchronous operation regardless of the primary output load. A logic-level clock signal connected to the SYNC/FCB pin synchronizes the operating frequency to an external source between 585kHz and 750kHz. Burst Mode operation is automatically disabled during synchronization to reduce noise. Instead, cycle skipping occurs under light load conditions because current reversal is not allowed. This boosts the low current efficiency while providing low output ripple.

Run/Soft Start

Upon power up, the RUN/SS pin is pulled high by an internal current source; an external capacitor can be placed at the pin to program its rise time to ensure a soft start at the output by limiting the amount of charge current into the output capacitors. The RUN/SS pin also serves another function: if the pin is tied below 0.65V, the part goes into shutdown and consumes less than 10µA of input current.

Fault Protection

The LTC1773 incorporates protection features such as programmable current limit, input undervoltage lockout, output overvoltage protection and frequency foldback when the output falls out of regulation.

One of the advantages of a current mode switching regulator is that current is regulated during every clock cycle, thus providing current overload protection on a pulse-by-pulse basis. Current limit is programmed through an external high-side sense resistor. The maximum sense voltage across this resistor is 100mV. But taking into account current ripple, input noise and sense resistor tolerance, 70mV should be used in choosing the proper sense resistor (RSENSE = 70mV/IOUT).

To protect a battery power source from deep discharge near its end of charge, an internal undervoltage lockout circuit shuts down the device when VIN drops below 2.5V. This reduces the current consumption to about 2µA. A built-in 150mV hysteresis ensures reliable operation with noisy supplies.

During transient overshoots and other more serious conditions that may cause the output to rise out of regulation (>7.5%), an internal overvoltage comparator will turn off the main MOSFET and turn on the synchronous MOSFET until the overvoltage condition is cleared. During this time, if the main MOSFET is defective or shorted to ground, current will flow directly from VIN to ground, blowing the system fuse and saving the other board components.

In addition, if the output is shorted to ground, the frequency of the oscillator is reduced to about 55kHz, 1/10 of the nominal frequency. This frequency foldback ensures that the inductor current has enough time to decay, thereby preventing runaway. The oscillator’s frequency will gradually increase back to 550kHz when the VFB pin rises above 0.4V.

Dropout Operation

During the discharging of a battery source, when the input supply voltage decreases toward the output voltage, the duty cycle increases toward the maximum on-time. The output voltage will then be determined by VIN minus the I • R voltage drops across the external P-channel MOSFET, the sense resistor and the inductor.

OPTI-LOOP Compensation

To meet stringent transient response requirements, other switching regulators may need to use many large and expensive output capacitors to reduce the output voltage droop during a load step. The LTC1773, with OPTI-LOOP compensation, requires fewer output capacitors and also allows the use of inexpensive ceramic capacitors. The ITH pin of the LTC1773 allows users to choose the proper component values to compensate the loop so that the transient response can be optimized with the minimum number of output capacitors.

Line and Load Regulation

The current mode architecture of the LTC1773 ensures excellent line and load regulation without cumbersome compensation and excessive output capacitance. Figures 3a and 3b show the response of the LTC1773 to a 100mA to 5A load step during Burst Mode and continuous mode operations, respectively.

Figure 3a. Load-step response, Burst Mode operation.

Figure 3b. Load-step response, continuous mode operation.

1.8V/7A Application

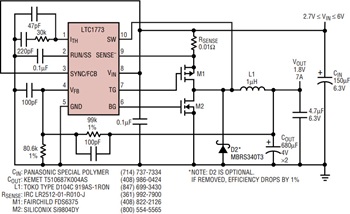

Figure 4 shows a step-down application from 3.3V to 1.8V at 7A. When operating below 5V, care should be taken to choose the proper sublogic-level MOSFETs that have relatively low gate charge. For high current (>3A) applications, single P-channel and N-channel MOSFETs should be used instead of complementary MOSFETs in one package. A good figure of merit for MOSFETs is the RDS(ON) gate-charge product. The lower this value is, the higher the application’s efficiency will be.

Figure 4. 3.3V to 1.8V/7A regulator.

In addition to normal step-down applications, the LTC1773 can also be used in a zeta converter configuration that will do both step-down and step-up conversions, as shown in Figure 5. This application is ideal for battery-powered operation, in which a regulated 3.3V output is maintained during the entire discharge cycle of a Li-Ion battery from 4.7V to 2.5V.

Figure 5. Single Li-Ion cell to 3.3V/1A synchronous zeta converter.

Conclusion

The LTC1773 offers flexibility, high efficiency and many other popular features in a small MSOP-10 package. For low voltage portable systems that require small footprint and high efficiency, the LTC1773 is the ideal solution.