LTC3202 Charge Pump Improves Efficiency for Powering White LEDs

Introduction

White LEDs continue to make significant inroads as backlights for color active-matrix liquid crystal displays in portable equipment. They offer size, reliability and cost advantages over competing solutions such as cold cathode fluorescent lamps (CCFLs). However, they require a higher voltage than can be provided by a sagging lithium-ion battery. Charge pumps provide an economical and compact means of attaining a modest increase in voltage.

Although charge pump solutions are simple, they can have drawbacks. They are typically noisy and have only mediocre efficiency. The noise is generated from the large current changes due to the pumping action and couples galvanically to circuits powered from the same supply. The efficiency loss is due to the extra input current required to charge the flying capacitor prior to delivering output power. The LTC3202 addresses both of these problems. It is a fractional conversion charge pump that can produce a regulated voltage (up to 1.5 × VIN) or current of up to 125mA from a 2.7V to 4.5V input.

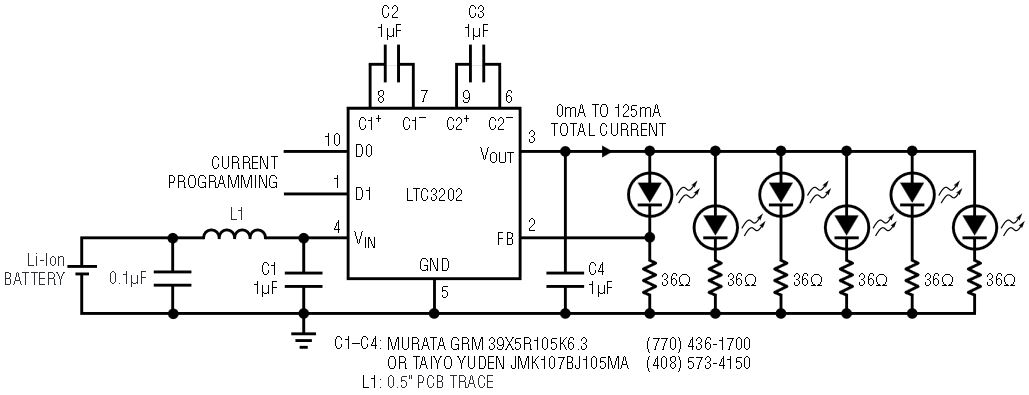

Figure 1 shows the LTC3202 configured to drive white LEDs from a lithium-ion battery. Rather than doubling the battery voltage, it uses a split-capacitor technique to multiply it by only 1.5. With this reduced multiplication factor, the input current is reduced from more than twice the load current to just over 1.5 times the load current. This technique results in approximately 25% less input current than would be required for a voltage doubling charge pump to drive the same load.

Figure 1. LTC3202 configured to drive white LEDs.

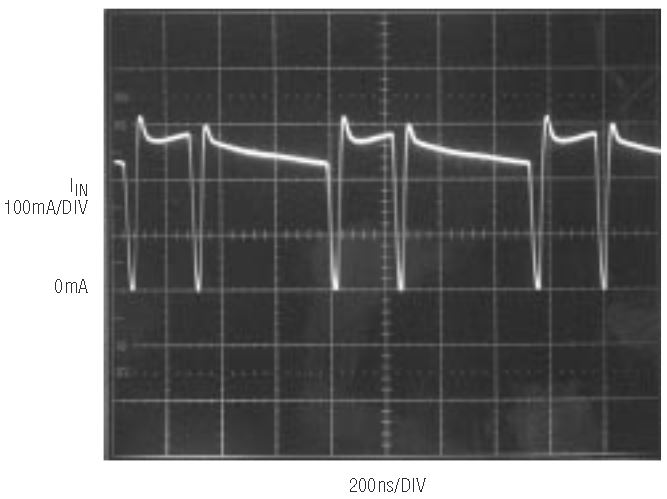

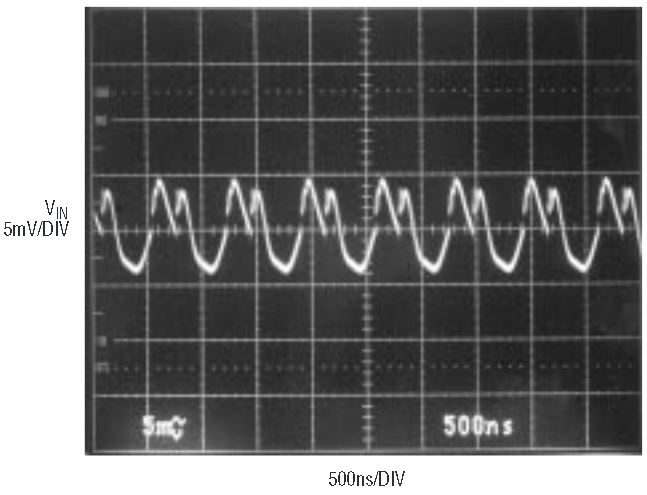

Tackling the noise problem, the LTC3202 uses a linear regulation technique to ensure that the charging and discharging currents for the flying capacitors are just enough to supply the load current and that they remain nearly constant over each clock phase. Figure 2 shows the input current waveform of the LTC3202. The charge pump operates on two phases, where a break-before-make circuit creates the missing notches. The notches are all that the low impedance ceramic input capacitor is required to filter. The result is a very small amount of voltage ripple at the clock frequency and some higher harmonics due to the edges. The higher frequency noise is easily filtered by a second small input capacitor and a tiny parasitic inductor fabricated on the printed circuit board. The resulting battery waveform is shown in Figure 3.

Figure 2. Input current waveform at the input bypass capacitor.

Figure 3. Input waveform of circuit in Figure 1 (VIN = 3.6V, ILOAD = 90mA).

Rather than a fixed output voltage, the LTC3202 has an external feedback pin for maximum flexibility. This feature is ideal for powering white LEDs, since they prefer a current excitation to voltage. By incorporating the first LED in the feedback loop, its current is precisely programmed. The remaining LEDs are controlled by virtue of similarity and the ballast voltage across the resistors. Using the 2-bit onboard digital-to-analog converter, the LED brightness can be set to one of three different levels under software control.

Conclusion

In the 8-pin MSOP package, the LTC3202 fractional charge pump provides a simple and efficient solution for powering white LEDs. Because of its small size, tiny external capacitors, higher efficiency and low noise, constant frequency operation, the LTC3202 is ideally suited for communications and other portable products.