High Efficiency Nickel Charger Operating to 34V is Easily Configured to Deliver a Safe Fast Charge

High Efficiency Nickel Charger Operating to 34V is Easily Configured to Deliver a Safe Fast Charge

2006-03-01

Introduction

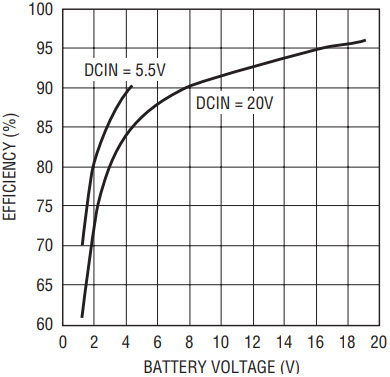

The LTC4011 is a complete standalone nickel chemistry fast charger that operates at high efficiency with an input voltage of up to 34V, even with a battery voltage that is much less than the DC input supply. Typical efficiency with a 5.5V and 20V input supply is shown in Figure 1. An undervoltage lockout of 4.25V ensures stable operation with an input as low as 5V, assuming a 10% tolerance. The IC offers a full range of charge control features that are easy to program with a minimal number of external components. Its multiple levels of safety features provide reliable fault protection that is also simple to configure. The LTC4011 functions without the need for any host Microcontroller Unit (MCU) support and requires no software of firmware.

Figure 1. The LTC4011 charging efficiency with 2A output current.

Accurate, Rock-Solid Fast Charge Termination

The LTC4011 implements a complete fast charge control algorithm, best suited for charge rates of C/2 to 2C for NiMH batteries and C/3 to C, or higher, for NiCd batteries. This means fully discharged batteries can be recharged to 100% capacity in one hour or less. Reliable charge termination at these higher rates is controlled by well-proven voltage and temperature detection techniques tailored to the selected nickel chemistry to ensure minimum charge time without degradation of recharge cycle life. Various internal and external filters, both analog and digital, eliminate spurious noise in the voltage and temperature data channels used to determine both general battery health and appropriate charge termination.

Monitoring Battery Voltage for –ΔV

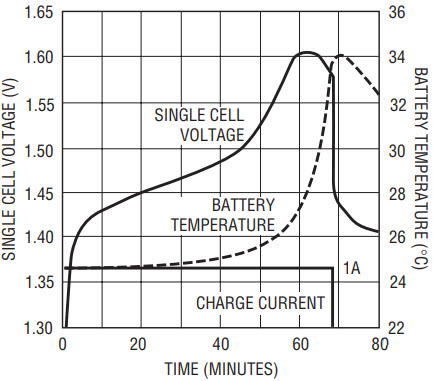

The primary fast charge termination technique employed by the LTC4011 involves detection of peak battery voltage followed by a sufficient drop in that terminal potential (–ΔV detection). The typical NiCd charge cycle shown in Figure 2 is terminated by –ΔV.

Figure 2. A 1C NiCd charge cycle.

To support a wide range of battery pack configurations, the IC senses the average cell voltage of the battery pack. A simple resistive voltage divider between the positive battery terminal and the VCDIV pin, along with some capacitance to eliminate residual PWM switching noise, is all that is required to provide this average cell voltage to the VCELL input pin. This technique, combined with the 5V to 34V input operating range, allows charging of from 1 to 16 in-series nickel cells. A negative delta of only 10mV to 20mV per cell indicates the battery is fully charged. The VCELL voltage is also monitored as a measure of basic battery health and to detect catastrophic fault conditions, as described below.

Monitoring Battery Temperature for ΔT/Δt

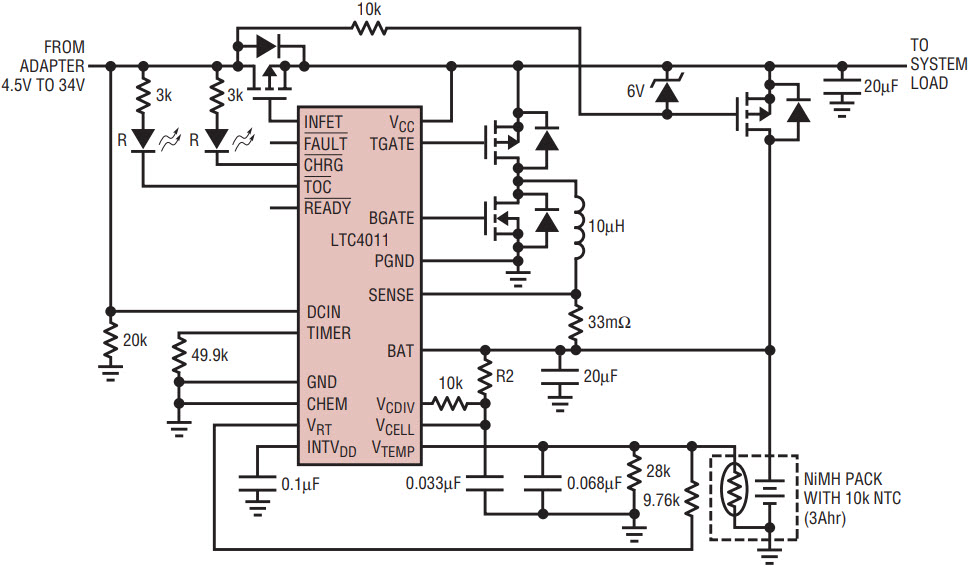

The LTC4011 can also process battery temperature using information provided by a negative temperature coefficient (NTC) thermistor. The thermistor should be in good thermal contact with the cell casings located most near the center of mass of the battery pack. This thermistor is then included in a voltage divider network between the VRT pin and ground, as shown in Figure 3, to provide a linearized input to the VTEMP pin. This configuration is flexible enough to support a very wide range of NTC thermistor types.

Figure 3. A 3A NiMH charger with full PowerPath control.

An external analog single-pole passive filter is recommended to eliminate PWM switching noise. The voltage on the VTEMP pin is then used by the LTC4011 to qualify the charge process according to an acceptable range, roughly 0°C to 45°C. In addition, the internal data acquisition subsystem uses an on-board real-time clock to monitor the rate of temperature increase of the battery (ΔT/Δt) during fast charge. Values between 1°C/min and 2°/min typically indicate a fully charged nickel battery.

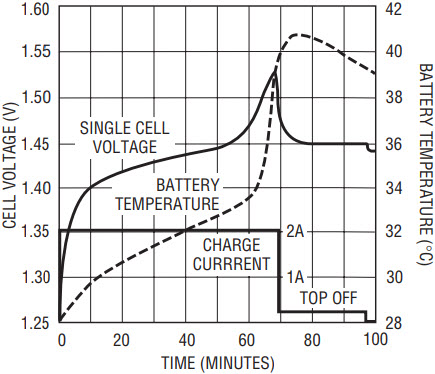

Figure 4 shows a NiMH charge cycle at a 1C rate with the fast charge portion of the charge cycle terminated by ΔT/Δt. Temperature processing is optional on the LTC4011 for all chemistries. Simply tying VTEMP to VRT disables all temperature-based charge qualification and termination.

Figure 4. Typical NiMH charge cycle at 1C.

Chemistry-Specific Battery Profiling

The basic charging algorithm applied by the LTC4011 is modified for the selected battery chemistry. Tying the CHEM pin to ground selects NiMH charging parameters, while leaving the CHEM pin open or tying it to VRT selects NiCd charging parameters. While similar, these chemistries do require slightly different fast charge termination to ensure maximum recharge cycle life. The older NiCd chemistry benefits from slight overcharge. When charging NiCd cells, the LTC4011 uses threshold levels that favor –ΔV termination, resulting in a final charge of slightly more than the rated capacity (100%) of the pack. In this case, ΔT/Δt termination, if enabled, serves as a secondary termination technique for additional safety. This is shown in the example of Figure 2.

Newer NiMH batteries are normally designed to accept higher charge rates than their older NiCd cousins, but manufacturers often warn against any amount of overcharge. So, for NiMH cells, the LTC4011 selects internal thresholds that favor ΔT/Δt termination at a point when the pack is charged to about 95% capacity. In order to avoid false termination on highly discharged cells that have been inactive for a long period of time, the IC can vary the ΔT/Δt limit as the fast charge cycle progresses. The –ΔV limit then serves as secondary termination (safety), and the IC applies a timed top-off charge after fast charge termination to achieve 100% capacity, as shown in Figure 4. Obviously, while optional, use of a thermistor input for NiMH batteries is strongly recommended.

In addition to these chemistry-specific measures, the LTC4011 applies some generic charge profile techniques. Battery open-circuit voltage is measured at the beginning of a new charge cycle to determine the state of charge of the attached pack. If the pack is initially heavily discharged, the IC applies a smaller conditioning current for a fixed period of time to recover the battery to a point of suitable fast charge acceptance. If the pack is initially discharged, the LTC4011 applies a –ΔV termination hold-off period to allow the internal chemistry—and hence terminal potential—to stabilize after applying full charge current. This avoids premature termination. However, if the pack is already moderately charged, the initial terminal voltage is well-behaved and –ΔV processing begins immediately to avoid accidental overcharging of the battery. If enabled, ΔT/Δt detection is always active.

Automatic Recharge Keeps Batteries Ready for Use

Nickel batteries exhibit a high self-discharge rate of up to 3% per day. Once a charge cycle has completed, the LTC4011 continues to monitor the open-circuit terminal voltage of the battery for as long as an input power source is connected. If the battery voltage indicates a loss of more than about 15% capacity, a refresh fast charge cycle is initiated to bring the stored energy level back to 100%. The duration of the recharge cycle is normally only a few minutes. This technique replaces more traditional continuous trickle charge methods. Trickle charge operates the battery in a constant state of overcharge, which can reduce the cycle life of some NiMH cells, generates continuous heat, and is somewhat less efficient that the LTC4011 automatic recharge approach.

Multiple Safety Features

Many safety features are built into the LTC4011. It monitors important voltage and temperature parameters during all charging phases.

If the VTEMP input has been enabled, the sensed temperature is required to lie between 0°C and 45°C, or charging is suspended. After fast charge begins, the battery temperature is allowed to rise to 60°C. If this limit is exceeded, however, the sensed temperature must fall below 45°C before charging can resume. The LTC4011 also tracks its own die temperature and disables charging if it rises above an acceptable limit.

Charging is not allowed to begin until the necessary voltage headroom to operate the PWM (about 500mV) has been established between the VCC and BAT pins. The battery voltage is also continuously monitored for overvoltage. If the average cell voltage on VCELL exceeds 1.95V, charging is disabled and a fault is indicated. The LTC4011 also profiles the battery voltage during charging to ensure proper charge acceptance, checking open-circuit voltage at the beginning of precharge and fast charge, and in-circuit voltage after about 20% of the fast charge cycle has been completed.

Finally, the LTC4011 contains a safety timer that limits the length of time any single charge can continue. This timer is easily programmed with an external resistor connected between TIMER and GND according the formula RTIMER (Ω) = tMAX (hours)/30µs.

Timing Can Be Everything

The LTC4011 uses the programming of the safety timer to a variety of purposes by inferring a relation between the set time limit, the programmed charge current and the capacity of the battery being charged. It assumes the period of this timer is set to 150% of the time normally required to deliver 100% charge to a fully discharged battery at the programmed current of RSENSE/100mV. The safety checkpoints discussed above, along with top-off charge duration, are then determined by intermediate intervals of the safety timer. Table 1 shows suitable values for RTIMER for a range of programmed fast charge rates.

| RTIMER (Ω) | Typical Fast Charge Rate | Precharge Limit (minutes) | Fast Charge Stabilization (minutes) | Fast Charge Limit (hours) | Top-Off Charge (minutes) |

| 24.9k | 2C | 3.8 | 3.8 | 0.75 | 15 |

| 33.2k | 1.5C | 5 | 5 | 1 | 20 |

| 49.9k | 1C | 7.5 | 7.5 | 1.5 | 30 |

| 66.5k | 0.75C | 10 | 10 | 2 | 40 |

| 100k | 0.5C | 15 | 15 | 3 | 60 |

A Smaller PWM Solution

The LTC4011 also embodies a complete PWM controller. Its buck regulator uses a synchronous pseudo-constant off-time architecture with high-side PFET power switch. This choice yields a PWM that is extremely easy to configure with a minimum number of external parts. Simply connect the external PFET power switch, optional NFET synchronous diode, the Schottky clamp and choke as shown in Figure 3. No external loop compensation is required, and the charge current is set by a single resistor connected between the SENSE and BAT pins. This resistor is in series between the inductor output and the battery with a value determined by the equation RSENSE = 100mV/IPROG.

The LTC4011 PWM uses a unique floating LV differential architecture to deliver 5% current accuracy and low cycle-to-cycle jitter with high inductor ripple current. That in turn allows use of space-efficient magnetics and a smaller output filter capacitor. The pseudo-constant off-time architecture eliminates the need for cumbersome slope compensation and allows full continuous operation over a wide VIN/VOUT range without generation of audible noise, even when using ceramic capacitors. Typical operating frequency is 550KHz. An example of the LTC4011 with a 2A PWM implementation is shown in Figure 5.

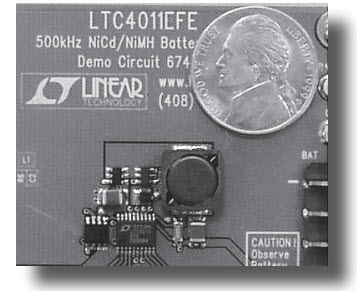

Figure 5. NiCD/NiMH charger layout.

PowerPath Control

PowerPath™ control is a vital part of proper termination when charging nickel batteries. Because the differences being sensed for –ΔV termination are so small, the series resistance of the battery can easily cause premature termination if varying load current is drawn from the battery during charging.

The LTC4011 provides integrated PowerPath support for an input PFET transistor between the DC input (DCIN) and the host’s unregulated system supply (VCC). This FET then acts as an ideal rectifier with a regulated forward drop as low as 50mV, requiring less operating head room and capable of producing less heat than a conventional blocking diode. The LTC4011 can provide up to 6V of gate drive to this pass device. Select an input FET with a low enough RDS(ON) at this gate drive level so that the combination of full charge current and full application load current does not cause excessive power dissipation.

As shown in Figure 4, the PFET between BAT and VCC then serves to automatically disconnect the battery from the system load as long as a DC input is present. A Schottky diode can be used in place of this MOSFET, if the additional voltage drop can be tolerated when running the application from the battery.

Micropower Features Support Extended Battery Use

The LTC4011 has a typical shutdown supply current of 3µA and normally draws much less than 1µA from the SENSE/BAT pin combination when the DC input supply has been removed. In addition, the VCDIV pin offers a means of disconnecting the VCELL resistor divider in the shutdown state, eliminating the current drawn by that circuit when charging is not possible. These features greatly minimize the load applied to the battery by the charger when disconnected from a DC power source, increasing the useable run time of the battery in portable applications.

Conclusion

The LTC4011 is a nickel chemistry charger that integrates a complete high voltage PWM controller, allowing it to efficiently charge batteries from a 34V input without the need for additional current source control ICs. True standalone operation and flexible control greatly simplify charger design. The PWM operates at a high frequency, enabling the use of surface mount components to save space. Reliable, robust charge termination algorithms backed by solid safety features make the LTC4011 an excellent choice for a wide range of fast charge implementations, providing long life for rechargeable nickel batteries.