Designing a High Performance TEC Controller

In optical telecommunication systems, diode lasers are mostly used either as the signal source in the transmitters or as the energy source in the optical amplifiers, their operations affect the performance of the whole system directly. Only under constant temperatures, diode lasers can perform stably, otherwise, their output wavelengths and power efficiencies will change dramatically.

In particular, Dense Wavelength Division Multiplexing (DWDM) systems combine a large number of laser beams of different wavelengths and inject the combined laser beams into a single fiber. The wavelength of each laser needs to be evenly placed within the low attenuation wavelength window of the fiber, so that an optical de-multiplexer at the other end of the fiber can distinguish each laser beam from the other laser beams without cross talks. Since the wavelength of the laser beam changes with the laser temperature, maintaining an accurate and stable laser temperature is a critical task for these DWDM systems.

In Erbium Doped Fiber Amplifiers (EDFA), diode lasers are used as the energy source, so called pump lasers. The laser temperature needs to be kept at a constant value so that the laser power is stable and the noise is minimized.

In addition, numerous passive optical components used in telecommunication systems, such as filters, Array Wave Guides (AWG), are sensitive to their temperatures. Good control of the temperatures for these components is needed in order to stabilize their optical parameters.

Therefore, temperature control is an important and critical task in the design of today’s optical telecommunication systems.

TEC – The Heat/Cold Generator

TEC, Thermoelectric Cooler, can produce both heat and cold by using the Peltier effect. Comparing it with other heat/cold generators, TEC has many advantages: easy to control the temperature, small size, noise free, no moving parts, long life, etc. All of these are important and critical for telecommunication components.

A TEC has two sides, when applying a DC voltage to the TEC, causing a DC current to flow in one direction, one of the two sides will get hot, and the other get cold; reversing the voltage will reverse the thermal transfer direction—the first side will now get cold and the second side get hot. In practice, the “hot” side and the “cold” side are named by the manufacturers in such a way that when the current flows into the designated positive terminal of the TEC (another terminal is designated as the negative terminal), the side that gets hot is called the “hot” side, and the other, that gets cold, is called the “cold” side. In this way, one side is always called the “hot” side, even though, it is sometimes used to produce “cold”. The same applies to the “cold” side. Usually, the side on which the two terminal leads are mounted is the hot side and is often mounted onto a heat sink, while the other side, the cold side, is often used for mounting the target of which its temperature needs to be controlled.

When generating cold, the TEC moves the heat away from its cold side to its hot side as the current flows into the positive terminal. The higher the current, the larger the amount of the heat is moved. During this process, heat is generated on both sides. When the current is increased to a certain level, the heat generated by the current on the cold side equals the heat being moved away from the cold side, the temperature on the cold side stops dropping, i.e. the TEC’s thermal output power becomes zero.

Two of the main parameters of a TEC is its maximum current and the maximum voltage. They are defined as: thermally shortening the hot side and the cold side of the TEC, the current which makes the TEC output the maximum thermal flow is the maximum current. The voltage across the TEC at the maximum current is the maximum voltage.

When the TEC’s current is less than the maximum value, the larger the current, the more thermal power it output to the thermal load. Thus, the temperature of the target device can be controlled by the magnitude and the direction of the current flowing through the TEC.

The size of a TEC ranges from 2mm×2mm×1.5mm to 50mm×50mm×4mm. Most TECs found in telecommunication components have the sizes of from 5mm×5mm×2mm to 10mm×10mm×3mm. The thermal output power ranges from 0.5W to 16W. In telecommunication systems, the maximum TEC voltage ranges from 1 volt to 5 volts.

The temperature on the target could be kept within 0.00001°C assuming that every component in the system is ideal. In optical transmitters applications, the required temperature stability ranges from ±0.02°C to ±0.1°C, depending on the laser and the wavelength spacing requirement. In EDFA applications, the required temperature stability is usually ±0.2°C to ±0.5°C. For passive optical components, the stability requirement range is wider: ±0.001°C to ±5°C.

Controlling a TEC

Figure 1 shows basic functional blocks required for controlling a TEC. The first element is a temperature sensor, which measures the temperature of the target mounted on the cold side of the TEC. The most commonly used temperature sensor in telecommunication components is a temperature sensitive resistor, so called thermistor. The resistance of the thermistor decreases as its temperature increases. The resistance of the thermistor is converted into a voltage, representing the measured target temperature. An external voltage, representing the set point temperature, i.e. the desired target temperature, is compared by an op-am with the target temperature voltage, resulting in an error voltage. This error voltage is amplified by a high gain amplifier, compensated for the phase lag caused by the thermal mass of the target and the TEC cold side plate, and then drives the H-bridge output. The H-bridge controls both the magnitude and the direction of the TEC current. When the target temperature is below the set-point temperature, the H-bridge drives the TEC in a direction and magnitude such that the target temperature is increased. When the target temperature is above the set-point temperature, the H-bridge will decrease the target temperature by reducing or even reversing the TEC current. When the control loop is stabilized, the TEC current magnitude and direction are just right, thus that the target temperature equals the set-point temperature.

Figure 1. The Block Diagram of a TEC Controller.

The thermistor has the advantages of high sensitivity, small size, and low cost. While for high absolute accuracy applications, the thermistor has the disadvantages of high long-term drift (±0.1°C/year) and high absolute errors (±1%). Other types of temperature sensors, such as RTD, a platinum resistor based device, can be used for the applications requiring lower drift and smaller errors.

TEC controllers can be categorized by the working mode of the output stage: linear mode and switch mode. A linear mode TEC controller is simpler to design and manufacture but has the shortcoming of very low power efficiency, ranging from 20% to 40%. A switch mode H-bridge for the TEC controller has the advantage of high power efficiency, but requires two high power inductors and low ESR capacitors to form the output filter. ADN8830, made by Analog Devices, Inc., uses one linear mode and one switch mode output stage in the H-bridge. This structure reduces the high power bulky filtering component count by half, and, at the same time, increases the power efficiency to above 90%. In addition, ADN8830 contains all the control function blocks shown in Figure 1, resulting in a one IC TEC controller solution.

High efficiency TEC controllers bring multiple advantages to the system:

- Generate less heat – easing the need for dumping the heat to the outside.

- Consume less power – lowering the power requirements for the power supply and lowering the cost.

- Operate at lower temperature – increasing the reliability of the controller.

- No need for a heat sink – reducing the package size and lowering the cost.

Designing a High Performance TEC Controller

An optimal TEC controller should have the best combination for these major specifications: high temperature stability, high power efficiency, low TEC ripple current, easy interfacing and monitoring, small PCB area required, fault detection and indication, and low cost. To achieve such a design, trade-offs among all these major parameters must be well understood and made.

Switching Frequency

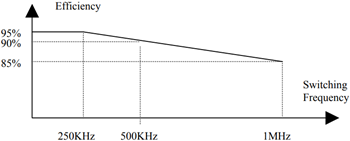

Choosing a switch mode output stage is a must for achieving the high efficiency. The switching frequency needs to be set properly. Setting the switching frequency high allows using smaller inductor and capacitor in the output filter, reducing the cost and the PCB space required. Figure 2 shows how the system cost decreases as the switching frequency increases. Figure 3 shows how the PCB area decreases as the switching frequency increases. A higher switching frequency, however, will yield higher EMI (Electro-Magnetic Interference) noise and lower power efficiency.

Figure 2. PCB Space vs. Switching Frequency.

Figure 3. System Cost vs. Switching Frequency.

Efficiency

As mentioned above, high efficiency brings many advantages to the system. However, for a switch mode TEC controller, the high efficiency is achieved at certain cost.

Several factors determine the efficiency. These are the power loss contributors limiting the efficiency:

- Drive power loss. This is the power needed for driving the gates of the two switchers at the switch mode output stage. It is proportional to the switching frequency, i.e. the drive power loss will be doubled when the switching frequency is doubled. It can be decreased by lowering the switching frequency and/or choosing the switchers of low input capacitance.

- Output capacitive load loss in the inductor and the switching MOSFET, i.e., the loss caused by driving the output capacitor at output of the switch mode stage. This loss is also proportional to the frequency and can be reduced by using a low input capacitance inductor and low output capacitance switching MOSFET.

- Iron loss. It is consisted of the hysteresis loss and the eddy current loss in the inductor core. For a high frequency power inductor using a ferrite core, these two losses are low at the frequency of below 500kHz, but it increases rapidly as the switching frequency approaches 1MHz. Choosing an inductor of using a high frequency ferrite core can decrease this loss.

- Switcher Ron loss. The loss caused by the resistance of the switch when it is conducting the current. Use low Ron MOSFET will lower this loss.

- Output inductor DCR loss. The loss caused by the DC resistance of the output filtering inductor when it is conducting the AC and DC current. Use the inductor of low DCR will decrease this loss, but the size of the inductor will go up.

Figure 4. Efficiency vs. Switching Frequency Increases.

Unlike switching output architectures that use a completely symmetrical H-bridge, new product design strategies like the one used with Analog Devices’ ADN8830 TEC controller (patented) use one side of the bridge in linear mode and the other in switch mode for higher output efficiency. This combination of linear and switching output stages reduces output ripple current by a factor of two, reduces external component count, yet improves the efficiency. When in large signal operation, the linear mode output stage will operate in a “switch mode”, saturated to one of the power rails, depending on whether the TEC is working at the heating mode or the cooling mode, to boost efficiency. In small signal operation, the linear mode output stage will operate in the linear mode to provide a smooth transition between the heating mode and the cooling mode. Most of single chip TEC Controllers use external MOSFET’s, which gives designers the flexibility to address a wide range of drive current requirements yet to maximize the efficiency.

Accuracy and Long Term Stability

If the thermistor were an ideal error-free device, the temperature accuracy would depend only on the offset of the input error amplifier.

There are two temperature stabilities to consider: short-term stability and long-term stability. The short-term stability is defined as the target temperature change with respect to the ambient temperature change of the TEC controller (in °C/°C). The target temperature change results from the input offset voltage drift caused by the ambient temperature change. The long-term stability is defined as the target temperature change vs. time (in °C/year). The same as above, this target temperature change originates in the offset voltage change vs. time, often over a period of years.

If a single chip TEC Controller uses an auto-zero amplifier in the front end with an offset voltage on the order of 1µV and does not drift over time or temperature, it can achieve a final temperature accuracy and a long term stability better than ±0.01°C.

Noise Performance – Ripple Current

Reducing the switching frequency increases the power efficiency, also increases the ripple current going through the TEC controller if the output filtering capacitor and the output inductor remain the same values. To cap the ripple current below a certain limit, the switching frequency has to be high enough and thus some TEC controller efficiency has to be sacrificed. Figure 5 shows that for a given ripple current, the required inductance and capacitance decrease as the switching frequency increases.

Figure 5. Inductance and Capacitance vs. Switching Frequency.

For most of applications, a typical inductance value of 4µH can maintain less than 1% output voltage ripple, with a sustained 1.5A TEC current and the default switching frequency of 500KHz. TEC controllers designed using an asymmetrical architecture (i.e. ADN8830), cut the ripple current in half.

Compensation Network Optimization—Stability vs. Response Speed

The compensation network affects the response speed and the temperature stability. To achieve high response speed, i.e., short settling time, and high temperature stability, the network needs to match the thermal load precisely. Doing this, however, is not an easy job. A precisely matched compensation network leaves less margin for the stability of the thermal control loop. A conservatively compensated network results in a longer settling time, but can tolerate more variations in the thermal transfer characteristics between the TEC drive current and the temperature sensor.

Some single chip TEC Controllers use external compensation network, and require only a few resistors and capacitors. Designers can adjust the compensation network according to their thermal load characteristics, thus achieving optimum temperature settling time and the stability margin.

Multi-TEC Operation—Interfacing with Other TEC Controllers

TEC controllers can be grouped together for controlling multiple TEC’s—multi- controller operation. The switching frequencies need to be synchronized, yet the switching phases need to be interleaved. Interleaving the switching phases can minimize the switching ripple voltages imposed onto the power supply lines.

In multi-controller operation, the power up procedure should be sequential. Turn one TEC controller on, and wait for temperature ready pin to become TRUE, indicating that the target temperature equals the set-point temperature. Then turn on the next TEC. In this way, the power supply will not see large current spikes. Therefore the frequency synchronization and phase interleaving control functions will definitely add value for such kind of system design. The temperature ready is another useful feature for almost all applications.

Control, Monitoring and Protection

TEC controllers can be left alone or controlled and monitored extensively. The controlling and monitoring scales need to be set according to system needs. These are the parameters that are frequently controlled: target temperature, TEC maximum current, TEC controller shut down, etc. These are the parameters that can be monitored: target temperature, TEC current, TEC voltage, temperature ready indication, etc.

For a reliable system operation, it is important to have effective indication of system failures. Protection from open or short circuits of the thermistor and of the TEC is critically important. Current limiting and voltage limiting functions are also important to ensure a reliable system.

Conclusion

Controlling a TEC presents the designer with many challenges. A system chip includes most of the functions needed to control a TEC, and therefore minimizes many of these challenges. At the same time, it reduces cost and PCB space, increases the efficiency and reliability, resulting in an optimum TEC control function. Choosing a right TEC Controller chip will help engineer to achieve a high performance design.