Current-Limited DC/DC Converter Simplifies USB Power Supplies

Introduction

Many portable Universal Serial Bus (USB) devices power themselves from the USB host or hub power supply when plugged into the USB port. Several requirements must be met to ensure the integrity of the bus: the USB specification dictates that the input capacitance of a device must be less than 10µF to minimize inrush currents when the device is plugged into the USB port; when first plugged in, the device must draw less than 100mA from the port and, for high power devices, the current drawn from the port can increase to 500mA only after it is given permission to do so by the USB controller. These requirements can be easily met using the LT1618 DC/DC converter, which provides an accurate input current control ideal for USB applications. The LT1618 combines a traditional voltage feedback loop with a unique current feedback loop to operate as a constant-current, constant-voltage source.

In addition to providing an accurate input current limit, the LT1618 can also be used to provide an accurately regulated output current for current-source applications. Driving white LEDs is one application for which the device is ideally suited. With an input voltage range of 1.6V to 18V, the LT1618 works from a variety of input sources. The 36V switch rating allows output voltages of up to 35V to be generated, easily driving up to eight white LEDs in series. The 1.4MHz switching frequency allows the use of low profile inductors and capacitors, which, along with the LT1618’s MSOP-10 package, helps to minimize board area.

USB to 12V Boost Converter

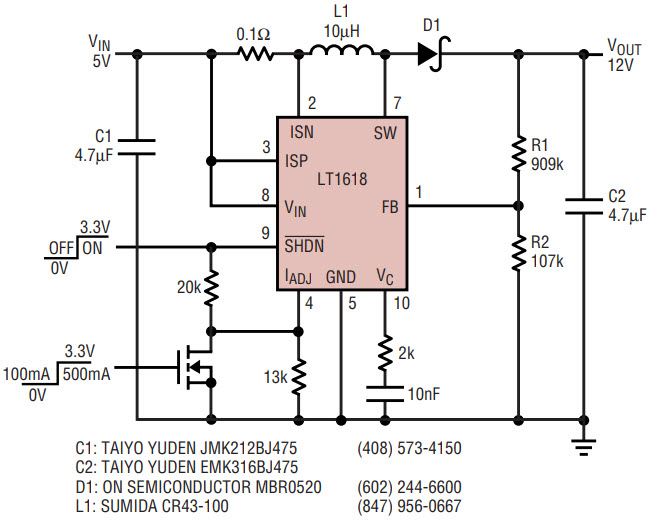

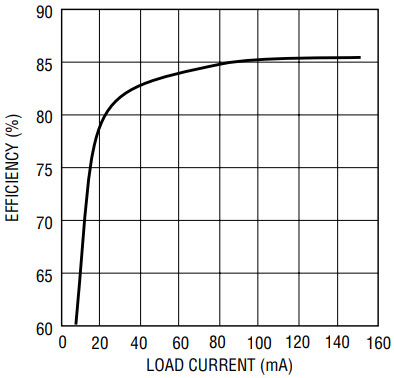

Figure 1 shows a 5V to 12V boost converter ideal for USB applications. The converter has a selectable 100mA/500mA input current limit, allowing the device to be easily switched between the USB low and high power modes. Efficiency, shown in Figure 2, exceeds 85%. If the load demands more current than the converter can provide with the input current limited to 100mA (or 500mA), the output voltage will simply decrease and the LT1618 will operate in constant-current mode. For example, with an input current limit of 100mA, about 35mA can be provided to the 12V output. If the load increases to 50mA, the output voltage will reduce to approximately 8V to maintain a constant 100mA input current.

Figure 1. USB to 12V boost converter with selectable 100mA/500mA current limit.

Figure 2. USB to 12V boost efficiency.

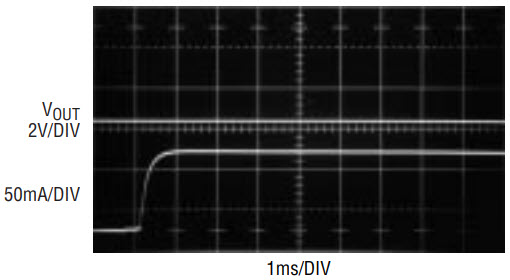

USB to 5V SEPIC Converter with Short-Circuit Protection

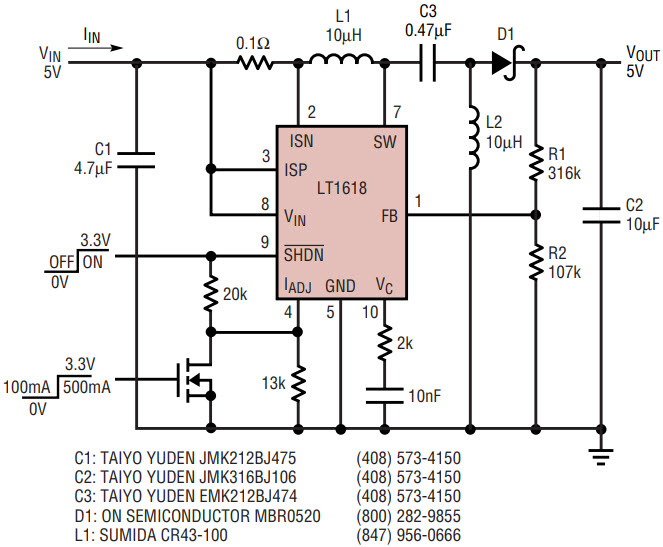

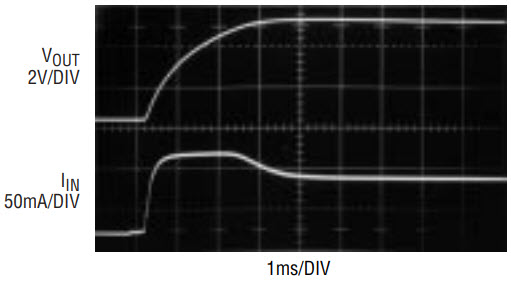

Unlike boost converters, SEPICs (single-ended primary inductance converters) have an output that is DC-isolated from the input, so an input current limit not only helps soft start the output, but also provides excellent short-circuit protection. The 5V SEPIC converter shown in Figure 3 is ideal for applications that need the output voltage to go to zero during shutdown. The accurate input current limit ensures USB device compliance even under output fault conditions. Figure 4 shows the start-up characteristic of the SEPIC converter with a 50mA load. By limiting the input current to 100mA, the output is effectively soft started, smoothly increasing and not over-shooting its final 5V value. Figure 5 shows that the input current does not exceed 100mA even with the output shorted to ground (thus the flat output voltage waveform in the oscilloscope photo). Efficiency is shown in Figure 6. This converter also has a selectable input current limit of either 100mA or 500mA, making it ideal for high power USB applications.

Figure 3. USB to 5V SEPIC converter.

Figure 4. USB to 5V SEPIC during start-up.

Figure 5. USB to 5V SEPIC start-up with shorted output.

Figure 6. USB to 5V SEPIC efficiency.

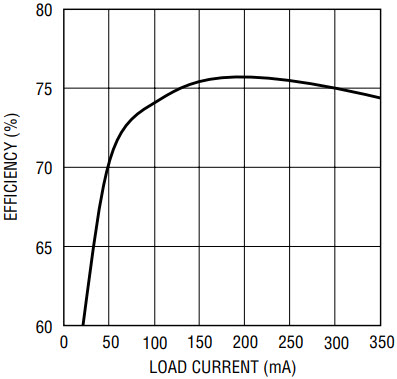

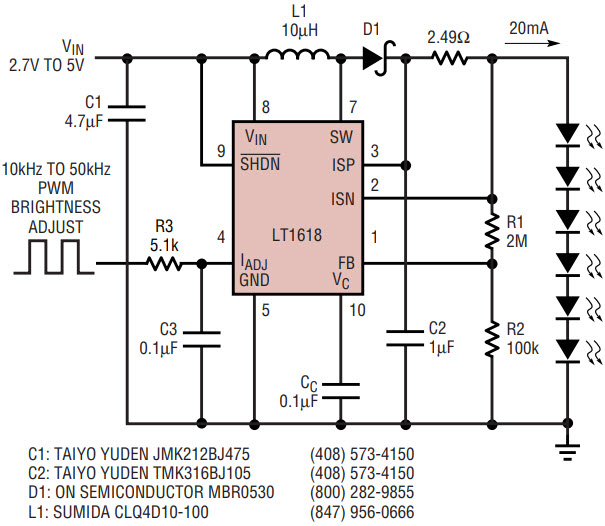

Li-Ion White LED Driver

The circuit in Figure 7 is capable of driving six white LEDs from a single Li-Ion cell. LED brightness can be easily adjusted using a pulse width modulated (PWM) signal, as shown, or using a DC voltage to drive the IADJ pin directly, without the R3, C3 low-pass filter. If brightness control is not needed, simply connect the IADJ pin to ground. The typical output voltage is about 22V and the R1, R2 output divider sets the maximum output voltage to around 26V to protect the LT1618 if the LEDs are disconnected. The LT1618’s constant current loop regulates 50mV across the 2.49Ω sense resistor, setting the LED current to 20mA. Efficiency for this circuit, shown in Figure 8, exceeds 70%, which is significantly higher than the 30% to 50% efficiencies obtained when using a charge pump for LED drive. No current flows in the LEDs when the LT1618 is turned off. Their high forward voltages prevent them from turning on, ensuring a true low current shutdown with no excess battery leakage or light output.

Figure 7. Li-Ion white LED driver.

Figure 8. Li-Ion white LED driver efficiency.

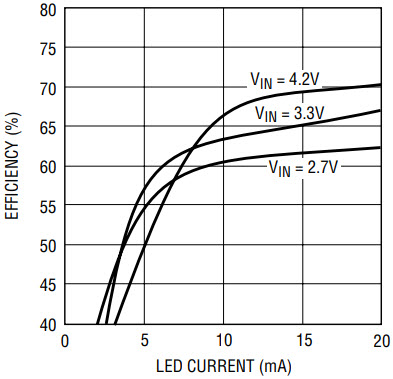

High Power White LED Driver

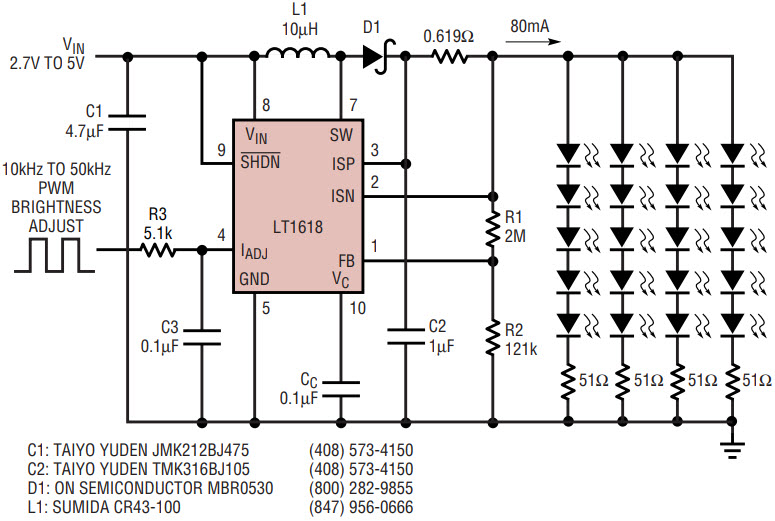

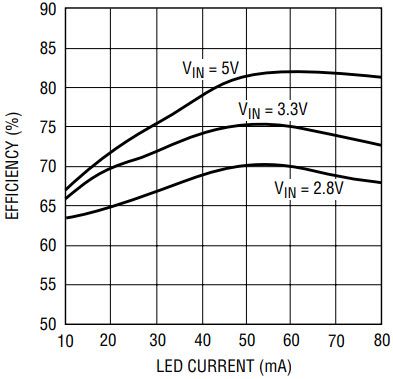

For larger LCD displays where a greater amount of light output is needed, multiple strings of LEDs can be driven in parallel. When driving parallel strings, ballast resistors should be added to compensate for LED forward voltage variations. The amount of ballasting needed depends on the LEDs used and how well they are matched. The circuit in Figure 9 is ideal for larger displays, providing constant current drive for twenty white LEDs from a single Li-Ion cell. Efficiency reaches a respectable 82%, as seen in Figure 10.

Figure 9. High power white LED driver.

Figure 10. High power white LED driver efficiency.

Conclusion

The constant-current/constant-voltage operation of the LT1618 makes the device an ideal choice for a variety of constant-current designs. The device provides accurate output current regulation or input current limiting, along with excellent output voltage regulation. With a wide input voltage range and the ability to produce outputs up to 35V, the LT1618 works well in many different applications.