3-Phase Synchronous Step-Down DC/DC Controller with Stage Shedding, Active Voltage Positioning and Nonlinear Control for High Efficiency and Fast Transient Response

3-Phase Synchronous Step-Down DC/DC Controller with Stage Shedding, Active Voltage Positioning and Nonlinear Control for High Efficiency and Fast Transient Response

2011-10-01

The LTC3829 is a feature-rich single-output 3-phase synchronous buck controller with on-chip drivers, remote output voltage sensing, inductor DCR temperature compensation, Stage Shedding™ mode, active voltage positioning (AVP) and nonlinear control. It is suitable for input from 4.5V to 38V and output from 0.6V up to 5V. The LTC3829 provides high efficiency, high power density and versatile power solutions for computers, telecom systems, industrial equipment and DC power distribution systems. The LTC3829 is available in 38-pin 5mm × 7mm QFN and 38-pin FE packages.

LTC3829 Features

The LTC3829 is a current mode PolyPhase® controller, similar to the LTC3850, but with an integrated a high speed differential amplifier for remote output voltage sensing, which can eliminate regulation errors due to PCB voltage drops at heavy loads. Figure 1 shows a typical 7V~14V input, 1.5V/60A output application schematic.

Figure 1. A 1.5V/60A, 3-phase converter featuring the LTC3829.

PolyPhase Operation and High Step-Down Ratios at High Frequency

The LTC3829’s three channels run 120° out-of-phase, reducing input RMS current ripple, as well as the required input capacitance. The CLKOUT and PLLIN pins enable up to 6-phase operation with multiple LTC3829s.

Figure 2 shows the tightly balanced DC current sharing between stages. Dynamic current sharing is also well balanced cycle-by-cycle due to the LTC3829’s peak current mode architecture.

Figure 2. Current sharing performance.

The LTC3829’s constant-frequency peak current mode control architecture allows a phase-lockable frequency of up to 770kHz. Even at this high frequency, high step-down ratios are possible, thanks to the LTC3829’s ability to operate at low duty cycle due to its small minimum on-time (90ns).

Accurate DCR Current Sensing Over Temperature

The LTC3829’s maximum current sense voltage is selectable—30mV, 50mV or 75mV—allowing the use of either the inductor DCR or a discrete sense resistor as the current sensing element. The inductor winding resistance (DCR) changes over temperature. So to improve accuracy, the LTC3829 can sense the inductor temperature via the ITEMP pin and maintain a constant current limit over a broad temperature range. This makes high efficiency inductor DCR sensing more reliable for high current applications.

Stage Shedding for Improved Light Load Efficiency

At heavy loads, the LTC3829 operates in constant frequency PWM mode. At light loads, it can operate in any of three modes: Burst Mode operation, forced continuous mode and Stage Shedding mode. Burst Mode operation switches in pulse trains of one to several cycles, with the output capacitors supplying energy during internal sleep periods. This provides the highest possible efficiency at very light load. Forced continuous mode offers continuous PWM operation from no load to full load, providing the lowest possible output voltage ripple.

In addition, Linear Technology’s proprietary programmable Stage Shedding feature can further improve the power supply efficiency in loads up to ~30% of full load as shown in Figure 3. At light loads, two of the three channels can be shut down in order to reduce switching-related losses.

Figure 3. Efficiency with and without Stage Shedding mode enabled.

When the MODE pin is tied to INTVCC, the LTC3829 enters Stage Shedding mode. This means that the second and third channels stop switching when the ITH pin voltage is below a certain programmed threshold. This threshold voltage, VSHED, on the ITH pin is programmed according to the following formula:

Connecting a single resistor from the ISET pin to SGND sets VISET by way of the precision 7.5μA current source from ISET.

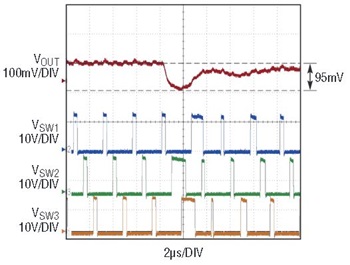

Stage Shedding mode in the LTC3829 features smooth transitions when dropping from 3-phase to 1-phase operation and likewise when increasing from 1-phase to 3-phases, with minimum ripple on the output, as shown in Figures 4 and 5. The smooth transition is a direct result of current mode control—a voltage mode, multiphase supply would have trouble achieving this performance.

Figure 4. Stage Shedding mode: 3-phase to 1-phase transition.

Active Voltage Positioning (AVP)

Transient performance is a priority in high current power supply designs. To minimize the voltage deviation during load steps, the LTC3829 includes two features that lower peak-to-peak output voltage deviation for a given load step: one is the programmable active voltage positioning (AVP); the other is the programmable nonlinear control.

The AVP scheme modifies the regulated output voltage depending on its current loading. The LTC3829 senses inductor current information by monitoring voltage across the sense resistor, RSENSE or the DCR sensing network of all three channels. The voltage drops are added together and applied as VPRE-AVP between the AVP and DIFFP pins, which are connected through resistor RPRE-AVP. Then VPRE-AVP is scaled through RAVP and added to the output voltage as the compensation for the load voltage drop. As shown in Figure 6, the load slope (RDROOP) is:

Figure 6. Programmable AVP.

With proper design, AVP can reduce the magnitude of transient induced peak-to-peak voltage spikes by 38%, as shown in Figures 7 and 8.

Figure 7. Transient performance without AVP.

Figure 8. Transient performance with AVP.

Nonlinear Control

The LTC3829 features a unique nonlinear control loop that can improve transient response dramatically. In the nonlinear control loop, an internal circuit monitors the output of the error amplifier. If the amplifier is sinking or sourcing large output currents (level programmable), the supply output voltage has significant overshoot or undershoot. This is when nonlinear control takes over: the controller simultaneously turns all of the TG signals on at a load step up, or off at a load step down to avoid control loop or PWM switching cycle delays.

This feature is enabled and programmed through the IFAST pin. When the IFAST pin is tied to INTVCC, the nonlinear control loop is disabled. The IFAST pin sources a precision 10μA, so connecting a resistor from IFAST to SGND sets VIFAST. When VIFAST is set below 0.5V, the difference of 0.5V and VIFAST sets the threshold voltage that triggers nonlinear control. Nonlinear control is only enabled when the feedback voltage VFB is within the UV and OV window.

Once nonlinear control is enabled, the top gate of all channels is turned on if:

The top gate of all channels is turned off if:

where VREF is the reference voltage (0.6V).

With proper design, nonlinear control can improve transient response by 21% during the load step up transient, as shown in Figures 9 and 10.

Figure 9. Transient performance without nonlinear control.

Conclusion

The LTC3829 3-phase step-down controller fits an outsized feature set into a small 5mm × 7mm 38-pin QFN. It offers high efficiency with strong integrated drivers and Stage Shedding/Burst Mode operation. It supports temperature compensated DCR sensing for high reliability. Its AVP and nonlinear control can improve transient response with minimum output capacitance. Output tracking, multi-device current sharing and external sync capability fill out its menu of features. The LTC3829 is ideal for high current applications, including telecom and datacom systems, industrial and high performance computers.