Mastering the Thermal Challenges of Advanced Defense Subsystems

With the continued drive for smaller form factor, such as smaller munitions and unmanned systems, the defense world is pushing the boundaries of electronic system integration and processing densities. Although smaller and smaller footprints are now becoming a reality, the challenge of thermal dissipation is often not considered; yet, meeting the thermal challenges to ensure long-term reliably and repeatable system performance is now becoming a more significant part of the system design, particularly when considering the extreme temperature ranges in which many aerospace and defense systems must operate. To meet future system size, weight, and power (SWaP) needs, an increasing proportion of system design time needs to be allocated to the thermal challenges.

Integration Drives Thermal Challenges

To review the challenge further, consider a typical RF receiver and transmitter that could be the basis for a military radio, element digitization for a radar system, or a communications link for an UAV or advanced munition, similar to that shown in Figure 1. Depending on the frequency of operation and specific application, the system requires the integration of a number of key functions and technologies to achieve optimum performance.

The RF front end requires power and low noise amplifiers, most likely based upon GaAs or GaN. The mixing stages, intermediate amplifiers, and synthesizers will be developed upon GaAs or SiGe with the digitizers and FPGA nodes developed on CMOS. This may result in four or five different technologies being used across the signal chain with many more variations of process geometries. Highly integrating these can result in the need to dissipate 50 W or more in a few square inches with limited thermal pathways.

Figure 1. ADI integrated RF and digital receiver module—3.25" × 0.5 × 1.4"

GaN-based power amplifiers (PAs), widely used in radar and electronic warfare systems, present other challenges with their system requirements and scale of power density. For example, the two GaN MMICs shown in Figure 2 dissipate 80 W each and with multiple PAs grouped close together.

Figure 2. GaN power amplifier utilizing dual 80 W PAs.

To optimize SWaP and cost, a thorough understanding of the thermal design is necessary to keep critical components’ temperature within their operating bounds. Each technology and application has its own challenges from a thermal perspective, but the drive to reduced SWaP concentrates heat densities. The heat dissipation, therefore, needs to be reviewed from multiple perspectives, as the heat generated in the gate of a MMIC flows in a continuous chain through numerous layers and interfaces until it ultimately reaches the connection point to the ambient environment. The entire chain must be reviewed for system thermal optimization, SWaP, and cost.

Although the focus on system size reduction is certainly making the thermal challenges more complex, some immediate relief is available from advanced process nodes and increased device integration. Advanced SiGe and CMOS nodes are enabling significant power reduction with increased integrated digital signal processing enabling increased integration. This supports increased functionality, often at power parity with previous generation architectures. The higher junction temperatures of GaN devices reduce the cooling requirements for these individual components. However, process node migration is not enough to meet the thermal challenges with system miniaturization seemingly moving faster.

Simulation Is Key

While prototype build and test continue to be critical in confirming design assumptions, the development times and high costs preclude efficient optimization based on hardware testing. Detailed simulation is therefore essential and enables the rapid evaluation of multiple system variations. The system trade-offs need to be evaluated from the entire system perspective. Multiple model levels and tools are required, as the geometry can scale six orders of magnitude from submicron gates to meter housings and the heat generating and transfer mechanisms in play can include conduction, convection, radiation, and EM energy. The modeling and simulation approach enables fast performance and cost trade-offs, optimizing from the device gate level to system level component placement, part design and material selection, or fan and heat sink specification.

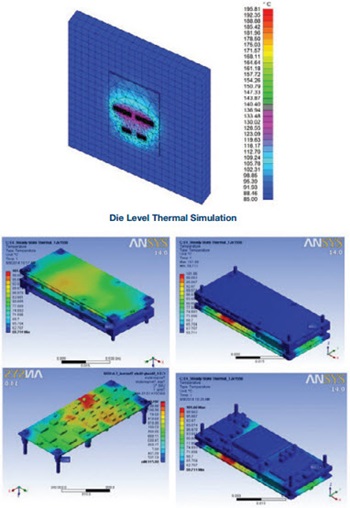

The maximum degrees of freedom come from systems designers who have design control over the entire system chain, from the MMIC gate level to the ambient environment, enabling comprehensive trade-offs. Figure 3 illustrates an example of system, board, and die level simulations enabling a complete systematic approach to the thermal challenges, the results of the simulation possibly impacting both device location and device modifications.

Figure 3. Simulating in two dimensions, board, and die level simulation.

Accomplishing this systolic analysis often requires multiple models and software packages. Specialized analysis techniques such as computational fluid dynamics (CFD) code for convection to fluids/air or electromagnetic simulations for RF losses with a handoff needed between each.

For example, a rack mounted, air cooled, high power solid state amplifier used in radar or electronic warfare systems, may need the following:

- Finite element analysis (FEA) with micron scale meshing including die level and heat spreader analysis

- Electromagnetic loss analysis to determine the power generated in RF lines

- FEA at the chassis level

- CFD analysis for airflow and convection to the ambient conditions

The greatest temperature deltas will typically occur at the locations of greatest heat concentrations, which are ultimately near the gates. In Figure 2, typically 70% of the temperature rise from ambient to junction is within the MMIC. In some cases power densities in radar systems now go beyond 6 W/mm, which makes simulating the trade-offs even more critical.

Selecting the Right Materials

The choice and use of very high thermal conducting materials used to spread the heat are obviously critical. For example, high power density GaN die used in the latest power amplifiers for radar—the substrate is typically SiC and the first attach layer is AuSn solder. Over 0.005" of material, the heat flux density may reduce from 13,000 W/mm² to 24 W/mm². As the heat continues to flow through the system its spreading will continue to reduce its flux density. However, the choice of materials is severely limited by coefficient of thermal expansion (CTE) matching, electrical conductivity to ground, and the cost and ability to manipulate the material.

CTE mismatches can result in cracking of substrates or delamination of bonding layers such as solder and epoxy. Cold storage and operating temperatures, critical aspects of aerospace and defense system performance criteria, tend to cause the greatest CTE driven stresses, as the solders and epoxy are designed for processing at elevated temperature. Even mild delamination can have catastrophic effects on the thermal performance of a die if the separation is in an area of high heat concentration—directly under a high power FET, for example. Comparing the hot spot temperatures on IR images of a design under test to known good images of the same design is a useful method for identifying early delamination when evaluating new materials. Epoxy and sintered silver manufacturers are developing products with lower modulus of elasticity to absorb the CTE stresses while still retaining relatively good thermal performance. Heat conductivity close to the die is a key material research area with extremely high thermal conductivity materials such as diamond being reviewed.

Material Optimization for Cost and SWaP

As defense systems continue to look for reduced SWaP and cost, performance trade-off decisions for cost, weight, and size goals are always intertwined in system architecture and thermal trade-offs. The use of materials such as diamond composites may seem hard to justify, however, even small pieces of these materials, as heat spreaders, in areas of high heat concentrations near the die can substantially reduce device temperatures and enable cost and weight savings in other parts of the system.

Figure 4 compares 60 W GaN die modeled with CuW carrier on an aluminum base compared to a diamond aluminum matrix material carrier on a copper insert in an aluminum base. The latter reduced the junction temperature by over 37°C, providing improved system performance and life while also enabling other SWaP and cost trade-offs elsewhere in the system.

Figure 4. 60 W GaN die with alternate stack ups.

In other examples convection cooled systems, such as rack-mounted systems, can be challenged with large temperature deltas across the heat sink base and from the heat sink fins to the ambient air. The heat sink and the fan choices have significant cost and performance impacts and also need to be specified from a system-level perspective. For a given heat sink volume, better performance is driven by a higher convective heat transfer rate that requires greater backpressure, such as from tighter channels or staggered/slotted fins that break up boundary layers, which in turn requires larger and more power hungry fans. The choice of fans also impacts the performance with axial fans typically the easiest to design in and providing high volume for low pressure systems while centrifugal fans or blowers are able to push against higher pressure but with lower volumes.

Lastly, the range of heat sink material choices can significantly impact cost but in many cases the use of skived copper heat sinks seems to provide a good performance and cost balance. Embedded heat pipes can also be excellent low weight devices for greatly enhancing effective thermal conductivity of heat sink baseplates, although they do not work in all environments with high gforces environments as a particular issue.

Solving Today’s Challenges

Although it may seem that the thermal challenges are ominous with many trade-offs, using a systematic approach can achieve solutions that balance cost, size, and performance. Advanced simulations provide the backbone for quick decisions, enabling detailed analysis from the gate level in the die to the overall system, as well as the impact of the heat sinks and heat spreaders. Using these advanced simulations, other trade-offs can then be made, from material choices to cooling techniques and optimal layout.

Making design decisions at the MMIC level and system level, makes high heat concentration systems possible. The KHPA-0811W 2 kW solid-state power amplifiers and the HMC7056 integrated upconverters and PA illustrate examples where optimized system-level thermal solutions were achieved. Both examples utilize the latest MMIC processes, with the MMIC design, substrate, and layout all influenced from full system thermal analysis. Both required detailed simulation analysis, careful component integration, and layout as well as material selection to balance performance and cost with the HMC7056 designed for man-portable systems.

Clearly having the system and MMIC design all under the control of the same design team aids these trade-offs and ultimately enables the highest reliability, cost, and performance optimized solutions for tomorrow’s aerospace and defense systems.

Figure 5. ADI 2 kW high power amplifier and integrated upconverter and power amplifier.