LT1306: Synchronous Boost DC/DC Converter Disconnects Output in Shutdown

LT1306: Synchronous Boost DC/DC Converter Disconnects Output in Shutdown

著者

Bing Ma

1999年11月01日

Introduction

Step-up or boost DC/DC converters traditionally suffer from a lack of true shutdown capability. The output of a boost converter is connected to the input through the inductor and diode; when the device is powered down, the load is still connected to the input source, presenting a possible discharge path. Even some synchronous boost converters suffer from this limitation. The unique configuration of the LT1306’s internal 2 ampere switch and rectifier overcomes this limitation. When the LT1306 is shut down, the output is disconnected from the input, eliminating the discharge path.

Additionally, the LT1306 can regulate the output when the input voltage exceeds the output voltage. This is useful for generating a 5V supply from a 4-cell alkaline battery. When fresh, the battery voltage measures about 6.5V, but when depleted, the battery voltage is only 4V. A simple boost converter output will follow the input voltage only when the battery voltage exceeds 5V, while a step-down, or buck converter will lose regulation when the battery voltage falls below 5V. The LT1306 regulates the output to 5V in both situations.

Lastly, the LT1306 controls inrush current. A user installing a new battery need not worry about high inrush current as the battery initially charges the output capacitor. The LT1306 provides a clean solution to a difficult problem.

The LT1306 packs all these features in an SO-8 package. The constant frequency, current mode PWM device runs at 340kHz and features Burst Mode™ operation to maintain high efficiency at light loads. No-load quiescent current is 160μA, while the device consumes just 9μA in shutdown. The device can be externally synchronized to frequencies between 425kHz and 500kHz.

Circuit Description

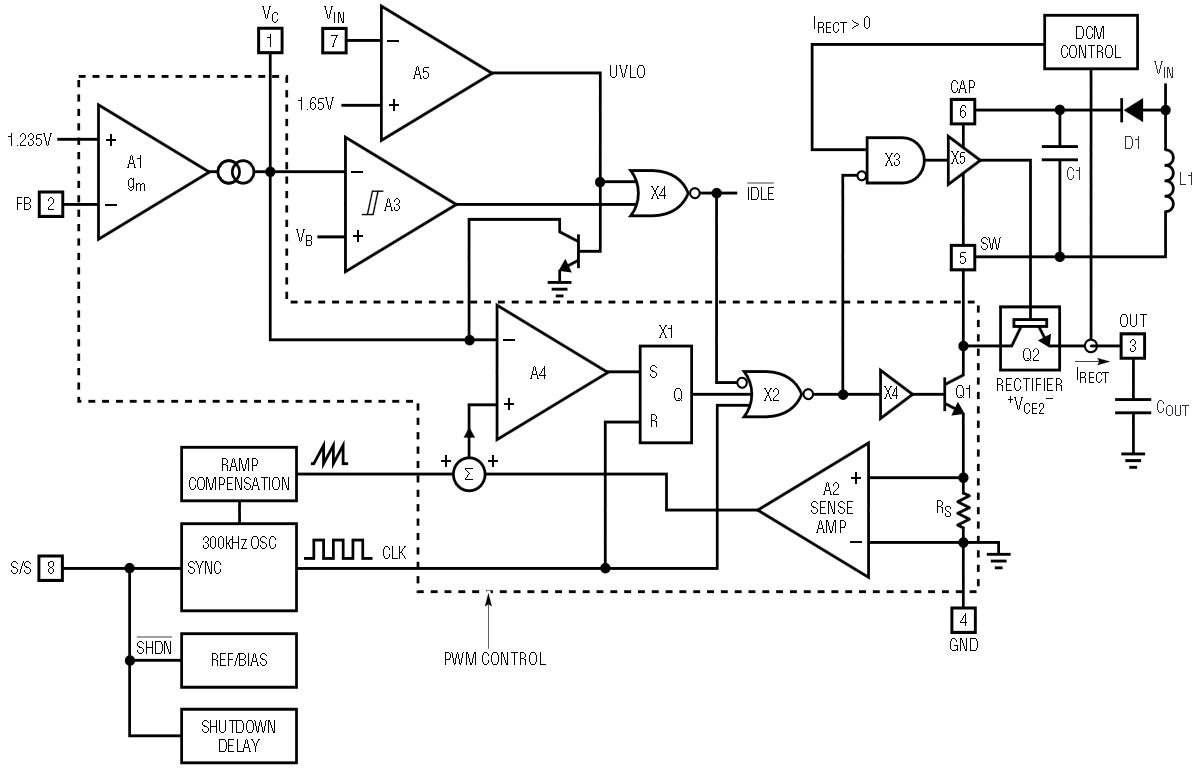

In the block diagram of Figure 1, the PWM control path is shown enclosed within the dashed line. The free-running frequency of the oscillator is trimmed to 340kHz. The main power switch, Q1, is turned on at the trailing edge of the clock pulse. Q1 is switched off when the switch current (sensed across resistor RS) exceeds a programmed level set by the error amplifier output, VC, and the compensation ramp. This is current mode control. The switch current limit is reached when VC clamps at 1.28V.

Figure 1. LT1306 block diagram.

The error amplifier output determines the peak switch current required to regulate the output voltage. VC is therefore a measure of the output power. At heavy loads, the peak and average inductor current are both high. The LT1306 operates in continuous-conduction mode (CCM) as VC increases. As the load decreases, the average inductor current moves lower with an accompanying decrease in the peak inductor current. If the inductor current returns to zero within each switching cycle, the converter is said to operate in discontinuous-conduction mode (DCM). Further reduction in load moves VC towards its lower operating range.

Hysteretic comparator A3 determines if VC is too low for the LT1306 to operate efficiently. As VC falls below the Burst Mode threshold, VB, comparator A3 turns off Q1. Any energy stored in the inductor is delivered to the output through the synchronous rectifier. The LT1306 draws only 160μA from the input in this idle state. As the output voltage droops, VC rises above the upper trip point of A3. The LT1306 again wakes up and delivers power to the load. If the load remains light, the output voltage will rise and VC will fall, causing the converter to idle again. Power delivery therefore occurs in bursts. The burst frequency is dependent on the input voltage, the inductance, the load current and the output filter capacitance. The output voltage ripple in Burst Mode operation is higher than those in CCM and DCM operation. Burst operation increases light load efficiency because the higher peak switch current characteristic of Burst Mode operation allows the converter to deliver more energy in each switching cycle than possible with cycle-skipping DCM operation. Thus, fewer switching cycles are required to maintain a given output. Chip supply current also becomes a small fraction of the total input current.

The synchronous rectifier is represented as an NPN transistor, Q2, in the block diagram. A rectifier driver, X5, supplies variable base drive to Q2 and controls the voltage across the rectifier. The supply voltage for driver X5 is generated locally with the bootstrap circuit comprising D1 and C1. When switch Q1 is on, the bootstrap capacitor C1 is charged from the input to the voltage VIN – VD1(ON) – VCESAT1. The charging current flows from the input through D1, C1 and Q1 to ground. After Q1 is switched off, the node SW goes above VO by the collector–emitter saturation voltage of Q2. D1 becomes reverse biased and the CAP pin voltage is approximately VO + VIN – VD1(ON). The capacitor C1 supplies the Q2 base drive. The charge consumed is replenished during Q1’s on-interval.

In boost operation, X5 drives the rectifier Q2 into saturation with constant forced β. X5 ceases supplying base current to Q2 when the inductor current falls to zero. If VIN is greater than VO, Q2 will not be driven into saturation. Instead, the collector–emitter voltage of Q2 increases so that the inductor voltage reverses polarity as Q1 switches. Since the inductor voltage is always bipolar, volt-second balance can be maintained regardless of the input voltage. The LT1306 can therefore operate as a step-down converter.

During start-up, the inductor voltage of a boost converter with a diode rectifier remains positive until the output voltage rises to one diode voltage below the input voltage. A high input-transient current spike invariably results. In the LT1306, the inductor voltage reverses polarity every switching cycle. This, with cycle-by-cycle current limit, eliminates the inrush current spike.

The rectifier voltage drop depends on both the input and output voltages. Efficiency in step-down operation is approximately that of a linear regulator. For sustained step-down operation, the maximum output current will be limited by the package thermal characteristics.

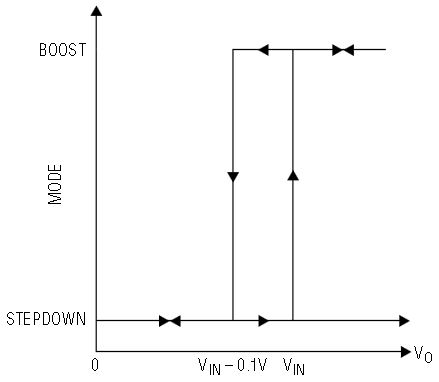

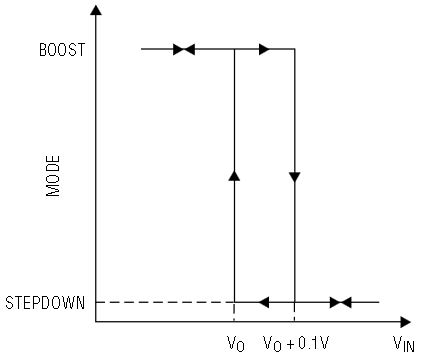

A hysteretic comparator inside driver X5, which detects the cross-over between the input and the output voltages, signals the driver to provide appropriate base current to the rectifier. DC transfer characteristics of this comparator are illustrated in Figures 2 and 3.

Figure 2. DC transfer characteristics of the mode control comparator plotted with VO as an independent variable; VIN is considered fixed.

Figure 3. DC transfer characteristics of the mode control comparator plotted with VIN as an independent variable; VO is considered fixed.

When shutdown is activated (VS/S < 0.45V), all circuits except synchronous rectifier Q2 and its driver X5 are shut off. If VO is above VIN, Q2 will be driven into saturation. Stored inductive energy flows to the output through the saturated rectifier. As VO falls below VIN, X5 reduces the base drive to Q2, which increases the rectifier voltage. The inductor voltage is now negative. The inductor current continues to fall to zero. The driver X5 then turns off and the rectifier Q2 becomes an open circuit. The LT1306 consumes 9μA from the input in shutdown.

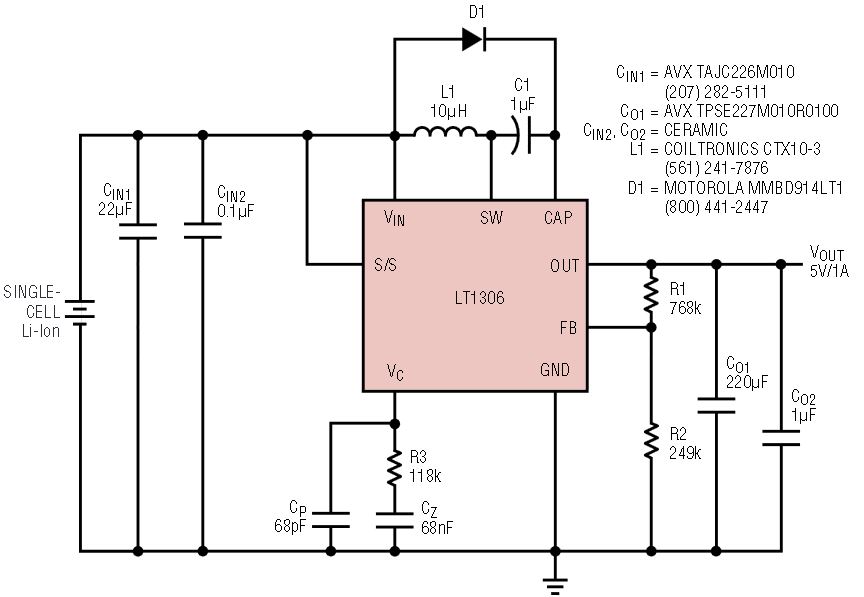

Single Li-ion Cell to 5V Converter

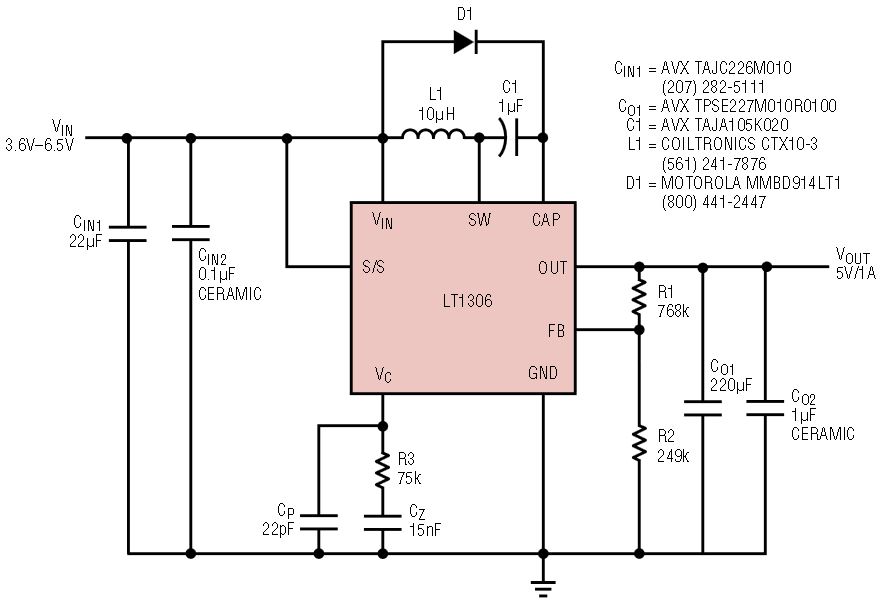

The LT1306 is ideally suited for generating 5V output from a single Li-ion cell. The circuit shown in Figure 4 is capable of supplying 1A of DC output current. The value of resistor R3 is chosen so that the overall feedback loop gain crosses 0dB before the right-half plane (RHP) zero. The capacitor CZ and the resistor R3 form a low frequency zero in the loop response. CP ensures adequate gain margin beyond the RHP zero. The value of R3 is inversely proportional to the error amplifier gm. Low gm and high R3 improve converter load-transient response.

Figure 4. Single Li-Ion cell to 5V converter.

In applications where high pulse current (>1A) is drawn from the output, a large electrolytic capacitor (>1000μF) is typically used to hold up the output voltage during the load pulse. Higher output filter capacitance lowers the dominant pole frequency of the gain response so that higher loop gain (that is, a higher value of R3) is required in the compensation network to give the same loop crossover frequency.

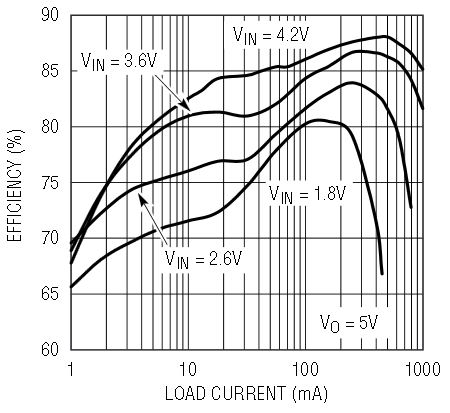

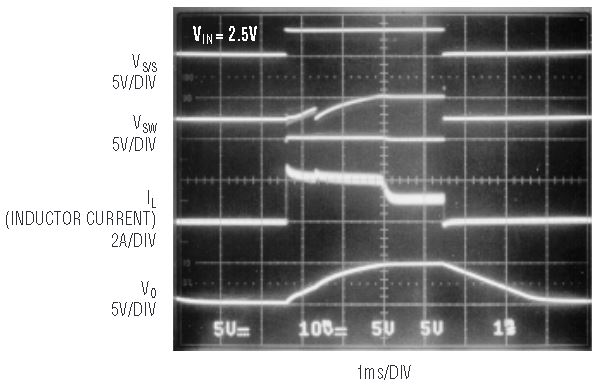

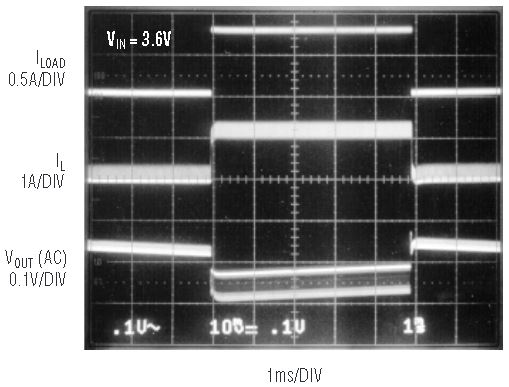

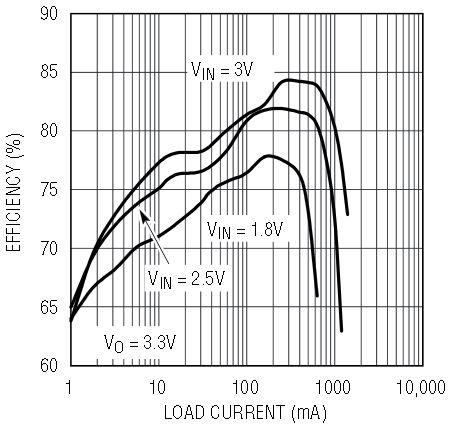

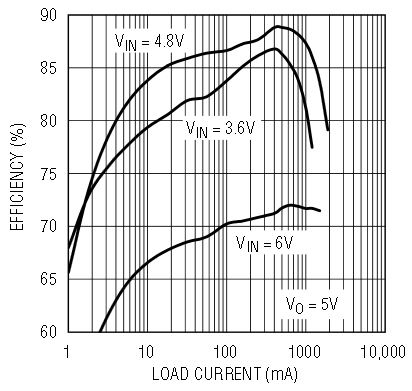

Efficiency curves of the converter are shown in Figure 5. Figure 6 shows a start-up-to-shutdown transient. The converter operates in step-down mode until the output voltage exceeds the input voltage (2.5V). The mode switching is evidenced by the sudden decrease in the SW node voltage. The input start-up current is well controlled at the switch current limit of 2.2A. The converter then produces a steady state output of 5V. Pulling the S/S pin low for at least 33μs disconnects the load. Figure 7 shows the load transient response of the converter.

Figure 5. Efficiency of Figure 4’s circuit.

Figure 6. Start-up to shutdown transient response: note that the input start-up current is well controlled and that the output falls to zero in shutdown (IL is also the input current, as the inductor is at the input).

Figure 7. Transient response of the converter in Figure 4 with a 50mA to 800mA load step.

2-Cell to 3.3V Converter

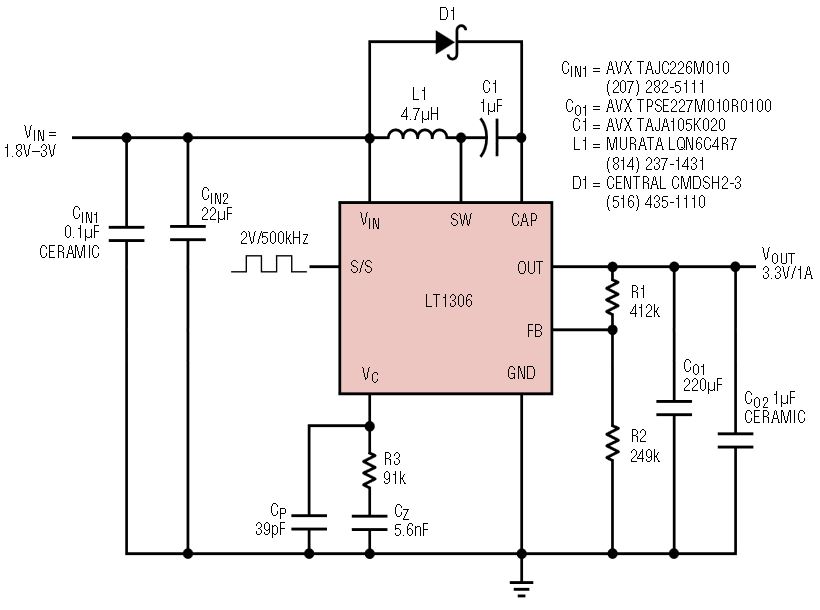

Figure 8 depicts an externally synchronized 2-cell to 3.3V converter running at 500kHz. A 4.7μH inductor is used to take advantage of the higher switching frequency. Driving the S/S pin with a clock generator, which has a 2V amplitude and less than 20ns of rise time, synchronizes the LT1306. Synchronization is positive-edge triggered. Diode D1 is a CMDSH2-3 Schottky diode. Compared to a junction diode, a Schottky diode increases the bootstrap voltage and affords higher operating headroom for rectifier Q2. In situations where reduced headroom is acceptable (such as over the commercial temperature range), a 1N4148 or 1N914 diode can also be used. The converter efficiency is plotted in Figure 9.

Figure 8. 2-cell to 3.3V output converter.

Figure 9. Efficiency of Figure 8’s circuit.

4-Cell to 5V Converter

Due to its ability to establish volt-second balance with VIN greater than VO, the LT1306 is also suited for applications where the battery voltage straddles the desired output voltage. One such example is the 4-cell to 5V converter shown in Figure 10.

Figure 10. 4-cell to 5V output converter.

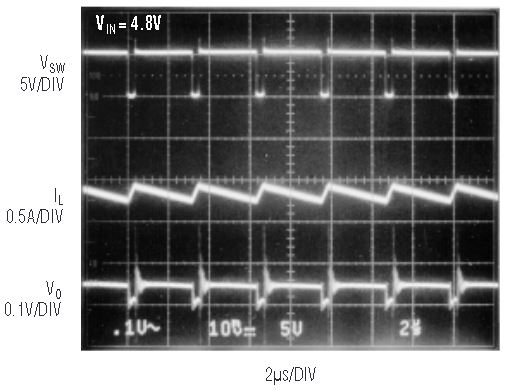

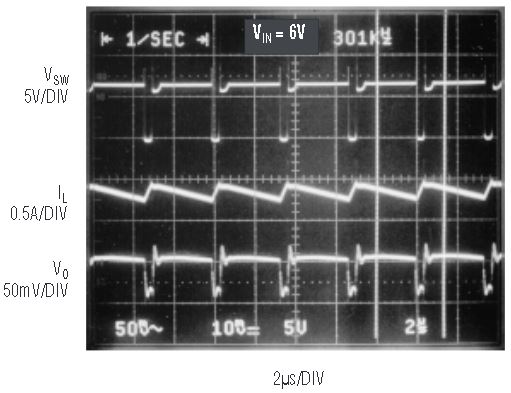

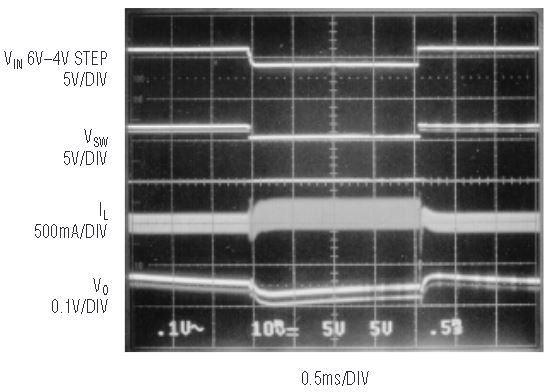

The continuous-conduction mode switch-node voltage and the inductor current for step-down operations (Figure 12) are contrasted with those of boost operation in Figure 11. Note that in step-down mode, when the rectifier is conducting, the switch voltage exceeds VIN. Input step (from 4V to 6V) transient response is illustrated in Figure 13. The converter efficiency is plotted in Figure 14.

Figure 11. Continuous conduction mode switching waveforms in boost mode; VIN = 4.8V, VO = 5V.

Figure 12. Continuous conduction mode switching waveforms in step-down mode; VIN = 6V, VO = 5V.

Figure 13. Transient response of the circuit in Figure 10 with step input (4V–6V).

Figure 14. Efficiency of Figure 10’s circuit.

Conclusion

The LT1306 is a complete synchronous boost DC/DC converter offering a set of features that few competing devices are able to match. The unique rectifier design results in a boost/step-down converter that disconnects the load in shutdown and controls input current during startup.