36V, 2A LED Driver with 5000:1 PWM Dimming Meets CISPR 25 Class 5 EMI Limits with Silent Switcher Architecture

36V, 2A LED Driver with 5000:1 PWM Dimming Meets CISPR 25 Class 5 EMI Limits with Silent Switcher Architecture

2017年11月02日

Design Note DN570: Introduction

The LED backlights in automotive heads-up displays, infotainment systems, and dashboard lighting must be bright enough to compete with direct sunlight streaming into a car during the day, yet capable of reducing brightness by several orders of magnitude to avoid blinding a driver at night. Generic LED drivers struggle to achieve such high dimming ratios.

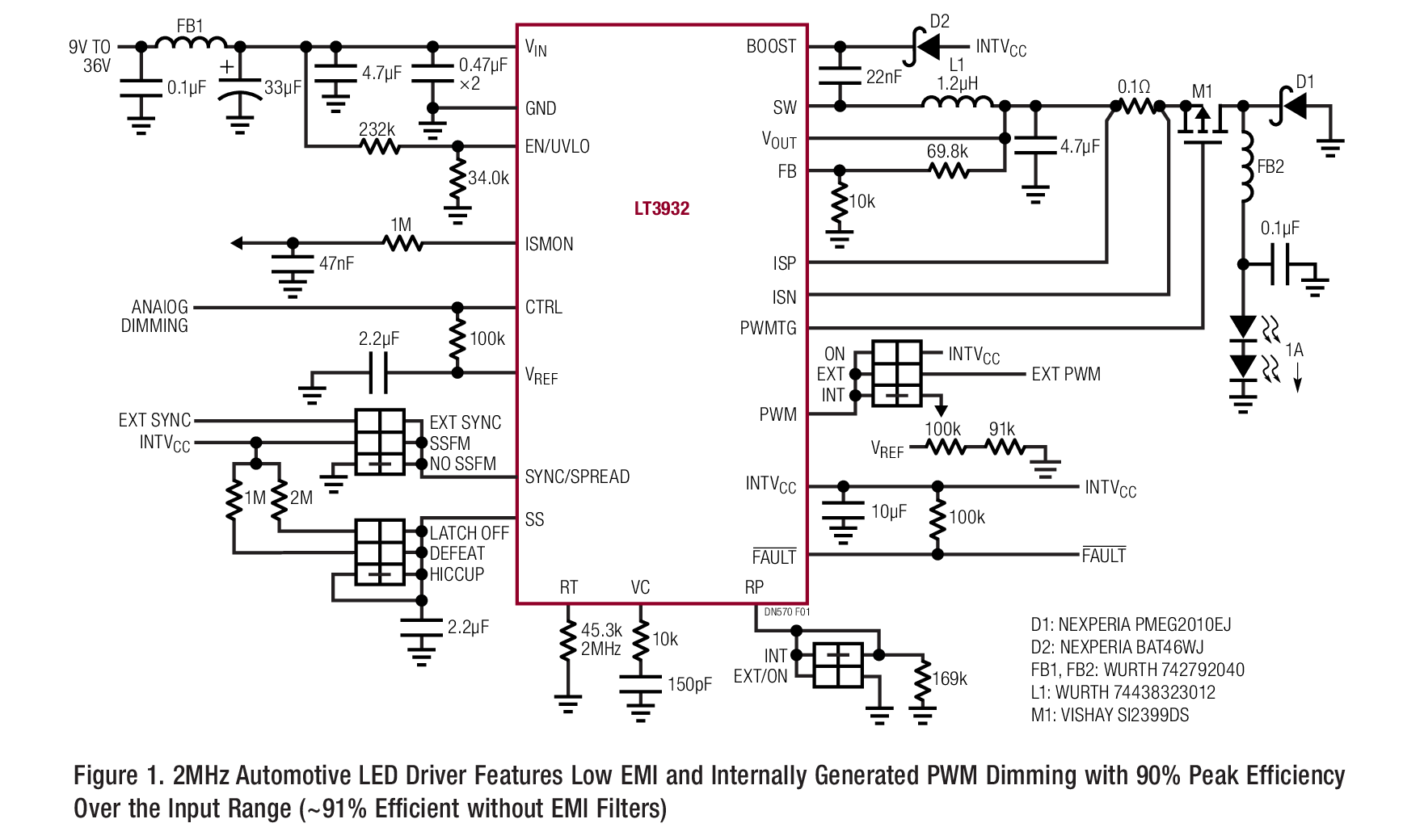

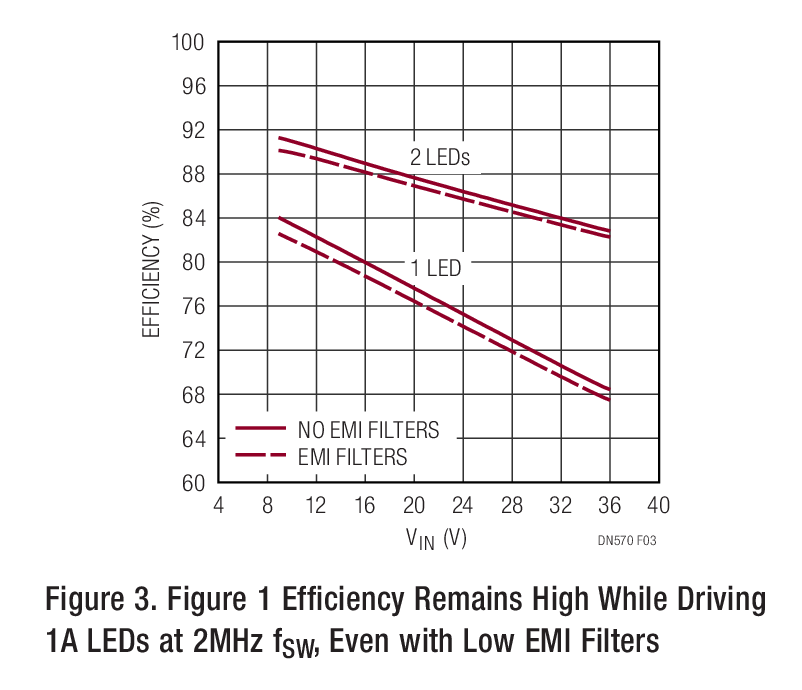

The LT3932 synchronous step-down LED driver with integrated 36V, 2A switches features high ratio PWM dimming. The LT3932 houses its high efficiency integrated power switches inside a small 4mm × 5mm QFN package, and can be run at up to 2MHz switching frequency for a compact, high bandwidth design. When high dimming ratio capability is not needed, and simplicity is paramount, its internal PWM generator can be used to produce 128:1 PWM dimming controlled by a simple DC voltage. With built-in fault protection to handle open and short LEDs, and spread spectrum frequency modulation to aid in reducing EMI, the LT3932 meets the demanding requirements of automotive and industrial LED lighting applications (Figure 1).

High PWM Dimming Ratio

With the LT3932 operating at a dimming frequency of 100Hz and a switching frequency of 2MHz, a high current LED design can achieve 5000:1 PWM dimming with well regulated LED current. Furthermore, PWM and analog dimming can be combined to push dimming ratios to 20,000:1. For applications requiring PWM dimming ratios surpassing 5000:1, the LT3932‑1, a variant of LT3932, enables higher dimming performance with no part-defined limitation of minimum PWM on-time vs switching frequency. With the latest in-car automotive displays requiring minimum dimming ratios of 10,000:1, the LT3932/-1 makes it easy to meet otherwise daunting dimming specs.

Low EMI Silent Switcher

The extreme LED dimming requirements in automobile applications can make it difficult to meet CISPR EMI standards without adding costly noise-mitigating components and complexity. The LT3932 makes it possible to achieve both a high dimming ratio and low EMI by incorporating a number of built-in EMI‑minimizing features:

- EMI is minimized by its Silent Switcher® architecture for low EMI hot loops.

- Built-in spread spectrum frequency modulation (SSFM) helps to reduce both conducted and radiated EMI.

- The slew rate of the LT3932 is controlled to optimize efficiency while maintaining low noise performance.

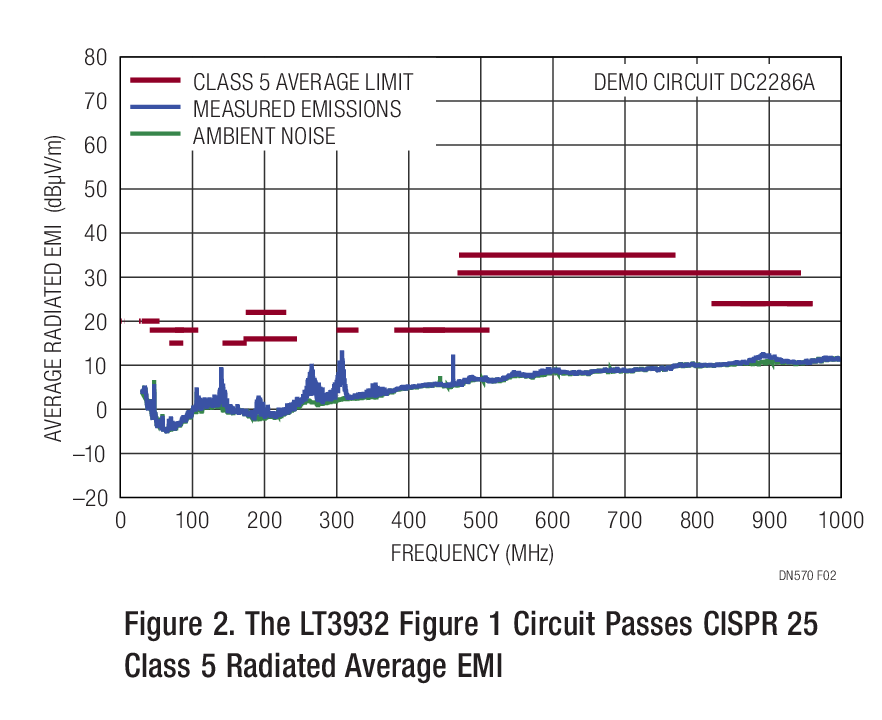

The efficacy of the LT3932’s low EMI technology is shown in Figure 2—a radiated EMI scan of the production demo circuit for the LT3932 (DC2286A). It passes CISPR 25 Class 5 average limits, as well as peak limits.

Machine Vision Applications

Modern industrial assembly line production utilizes machineassisted automated optical inspection to ensure that the fast moving parts on an assembly line meet defined specifications. Defective parts that fail optical inspection are tagged and automatically removed from the assembly line, ensuring part-to-part consistency. The high speed cameras used on these types of assembly lines require a photoflash system capable of consistently reproducing a fixed on-time pulse of light with a variable off-time defined by the speed of the assembly line, as well as the spacing of the parts.

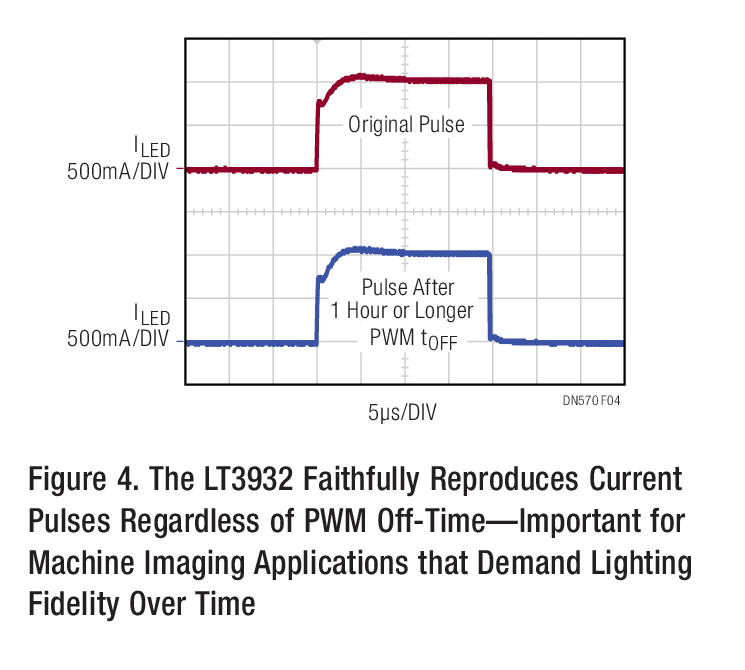

The LT3932 can reproduce a fixed on-time pulse of LED current with an indefinite off-time by maintaining its output charge while PWM is held low—no additional circuitry is required. Figure 4 shows two fixed-length on-time pulses of LED current produced by the LT3932, separated by one hour of off-time, demonstrating the LED driver’s ability to maintain its output charge during arbitrarily long PWM off-times. By preserving the state of the output, the LT3932 produces consistently shaped current pulses, regardless of the PWM off-time.

Conclusion

The LT3932 enables compact, high current LED driver designs with excellent dimming performance. It includes a number of built-in features to simplify the design process of high performance automotive and industrial LED driver applications.