AN-1078: ADXL346 Quick Start Guide

Physical Mounting

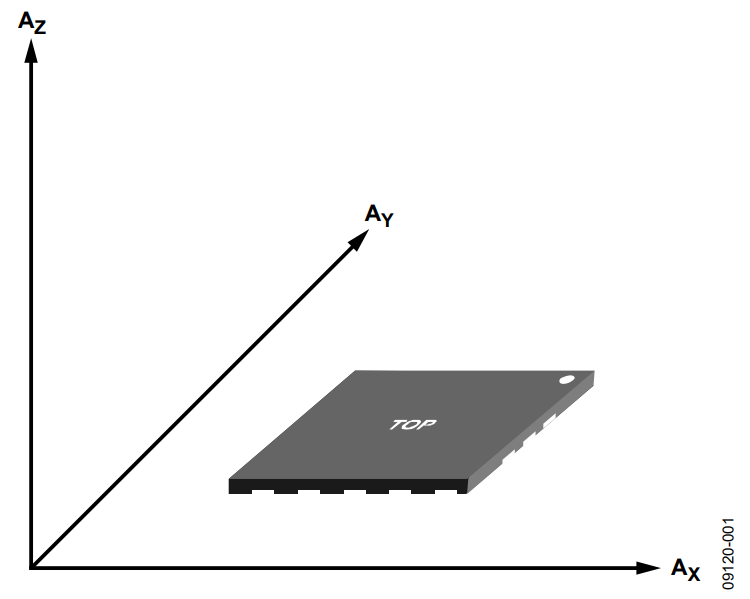

The ADXL346 is 3-axis accelerometer. The sensing axes are shown in Figure 1.

Figure 1. Sensing Axes of ADXL346.

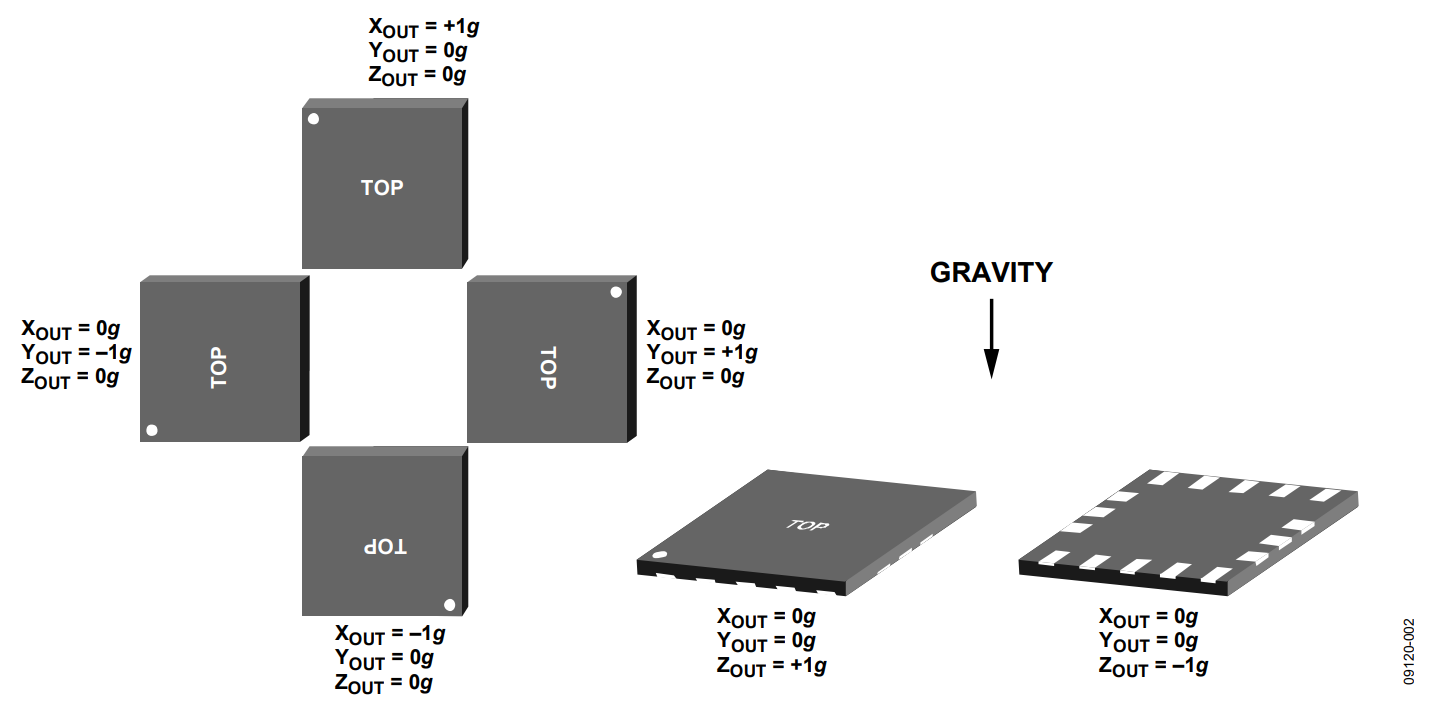

The ADXL346 senses positive acceleration when it is accelerated in the positive direction of the sensing axes. The user must be careful when sensing gravity because positive acceleration is sensed when the direction of the sensing axis is opposite to gravity. Figure 2 shows the output response to gravity.

Figure 2. Output Response vs. Orientation to Gravity.

The ADXL346 is supplied in a small, thin, 3 mm × 3 mm × 1 mm, 16-lead, plastic package. Refer to the ADXL346 data sheet for recommended printed circuit board land pattern.

Electrical Connection

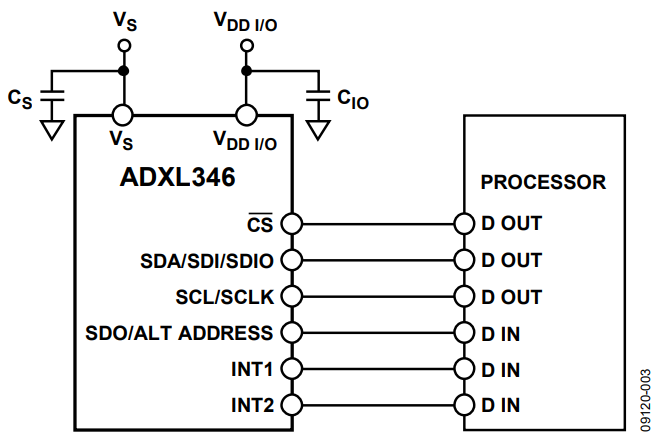

ADXL346 communication is done via either I2C or SPI (3- or 4-wire). Figure 3 shows the recommended electrical connections for 4-wire SPI mode. Note that the SDO pin can be disconnected when using 3-wire SPI mode.

Figure 3. Recommended Connection for 4-Wire SPI Mode.

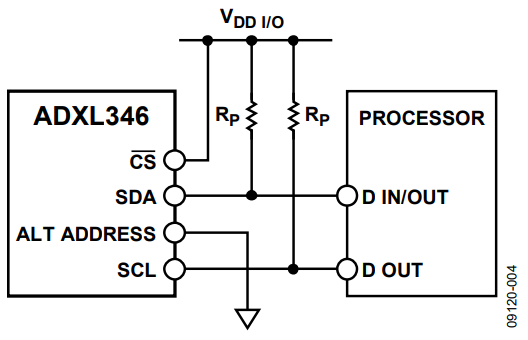

Figure 4 shows the recommended electrical connection for I2C mode. The 7-bit I2C address for the device is 0x53, followed by the R/W bit. The user can select alternate I2C address by connecting an SDO/ALT ADDRESS pin to the VDD I/O pin. The 7-bit I2C address for that configuration is 0x1D, followed by the R/W bit.

Figure 4. Recommended Connection for I2C Mode.

Refer to the ADXL346 data sheet for details on power supply decoupling.

Communication Interface

Table 1 gives the list of typical configuration settings for the master processor requirements for SPI communication with the ADXL346. These settings are normally in control registers. Refer to the ADXL346 data sheet for timing specification and command sequence.

| Processor Setting | Description |

| Master | ADXL346 operates as slave |

| SPI Mode | Clock polarity (CPOL) = 1 Clock phase (CPHA) = 1 |

| Bit Sequence | MSB first mode |

For I2C communication, refer to the ADXL346 data sheet and UM10204 I2C-Bus Specification and User Manual, Rev. 03—19 June 2007 for processor settings as well as timing specifications and command sequence.

Sometimes it is important to confirm the validity of communication before going to the next design stage. This can be done by reading the DEVID register (Address 0x00). It is a read only register that contains 0xE6. If the data read from DEVID is not 0xE6, it is the indication that either the physical connection or command sequence is incorrect.

Initialization

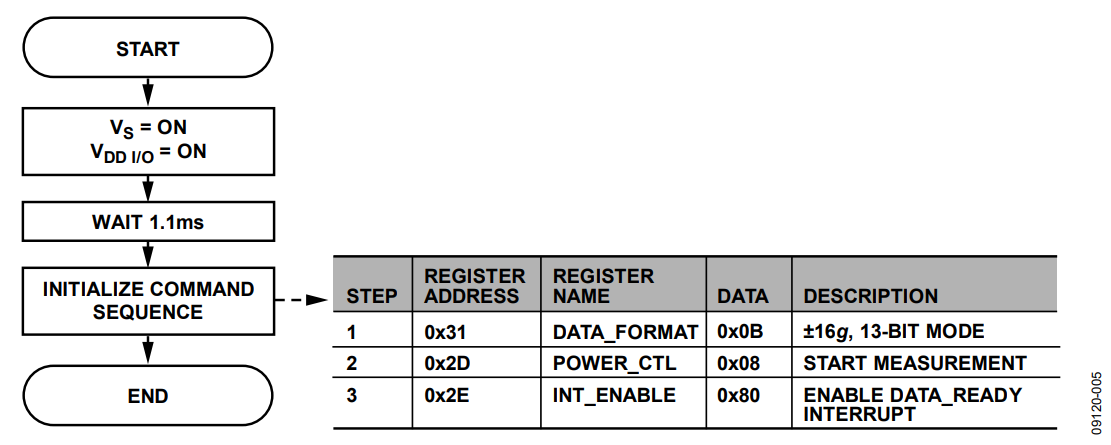

Figure 5 shows the minimum initialization sequence. The ADXL346 operates in a 100 Hz ODR with the DATA_READY interrupt on the INT1 pin during this start-up sequence. When setting other interrupts or using the FIFO, it is recommended that those registers used are set before the POWER_CTL and INT_ENABLE registers. Refer to the ADXL346 data sheet and AN-1025 Application Note for other operation modes of the ADXL346 and details about FIFO.

Figure 5. Minimum Initialization Sequence.

Reading Output Data

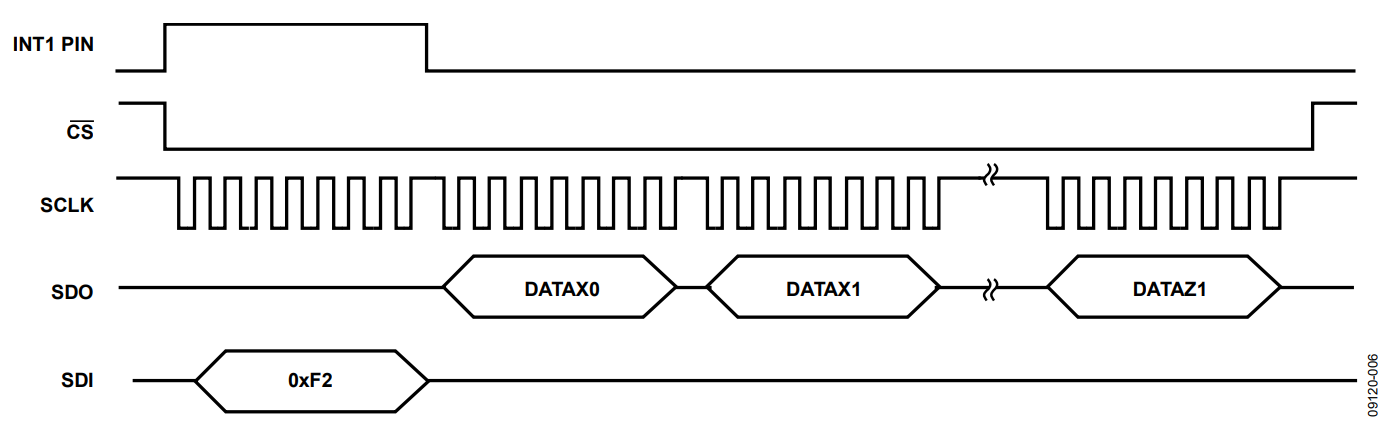

The DATA_READY interrupt signal indicates that 3-axis acceleration data is updated in the data registers. It is latched high when new data is ready. (The interrupt can be configured to be latched from low-to-high through the DATA_FORMAT register. Refer to the ADXL346 data sheet for details.) Use the low-to-high transition to trigger action on an interrupt service routine. Data is read from DATAX0, DATAX1, DATAY0, DATAY1, DATAZ0, and DATAZ1 registers. To ensure data coherency, it is recommended that multibyte reads are used to retrieve data from ADXL346. Figure 7 shows the read sequence example for 4-wire SPI.

Data Format

The data format of the ADXL346 is 16 bits. Once acceleration data is acquired from data registers, the user must reconstruct the data. DATAX0 is the low byte register for X-axis acceleration and DATAX1 is the high byte register. In 13-bit mode, the upper 4 bits are sign bits (see Figure 6). Note that other data formats are available by setting the DATA_FORMAT register. See the ADXL346 data sheet for more details.

Figure 6. Data Construction.

Figure 7. Data Read Timing Sequence for 4-Wire SPI Connection.

The ADXL346 uses twos complement data format. When in 13-bit mode, 1 LSB represents about 3.9 mg.

| 16-Bit Code (Hex | Twos Complement Representation (Dec) | Acceleration (mg) |

| 0FFF | 4095 | +1599 |

| … | … | … |

| 0002 | +2 | +7.8 |

| 0001 | +1 | +3.9 |

| 0000 | 0 | 0 |

| FFFF | −1 | −3.9 |

| FFFE | −2 | −7.8 |

| … | … | … |

| F000 | −4095 | −1600 |

Using The Self-Test Feature

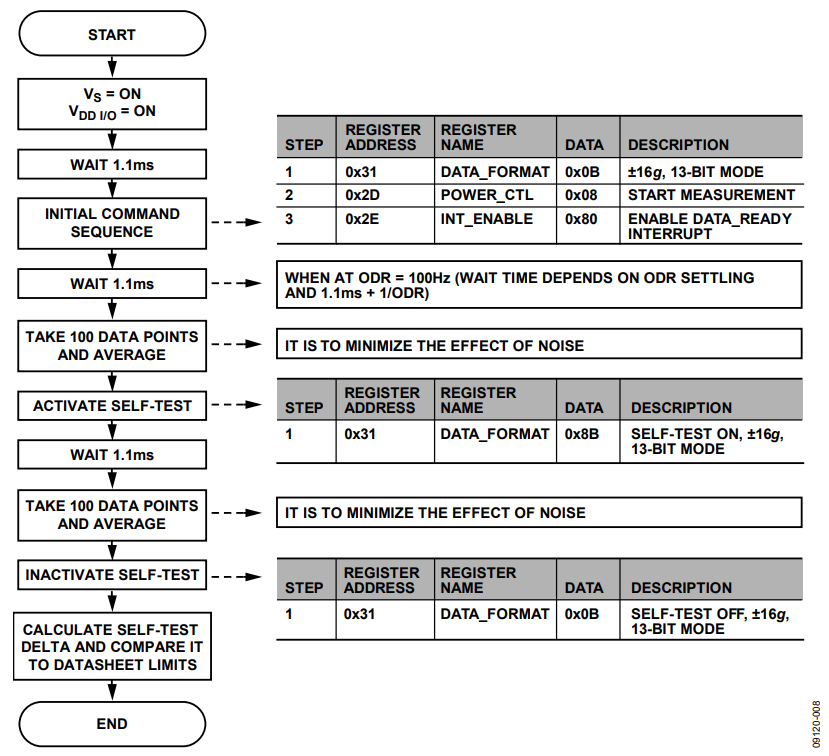

The ADXL346 provides a self-test feature that enables an electromechanical test on the device without external mechanical stimulus. Figure 8 outlines a recommended self-test sequence. Note that the ADXL346 should be placed in a stable environment when conducting the self-test sequence.

Figure 8. Self-Test Sequence.

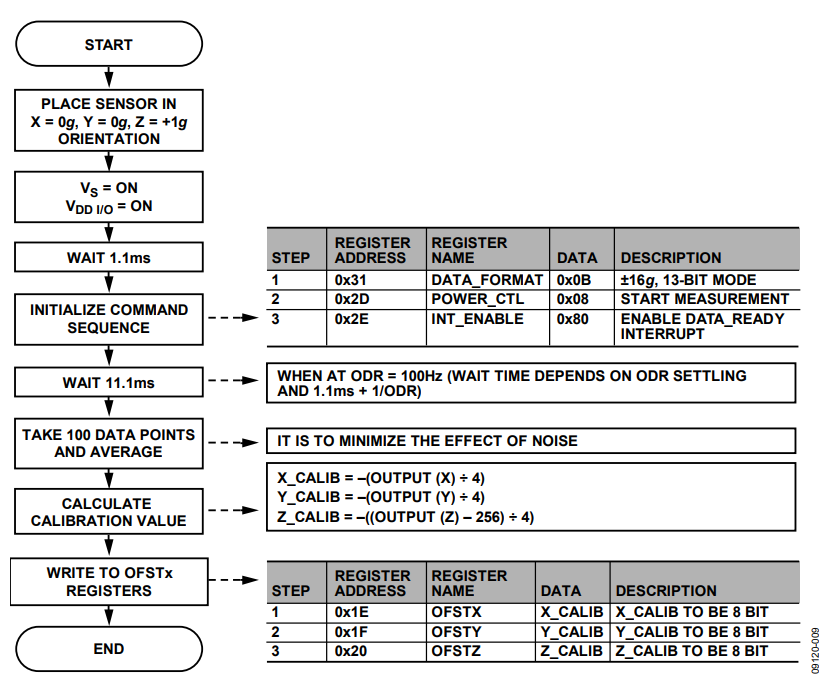

Using Offset Registers

The ADXL346 has offset registers that facilitate offset calibration. The data format for the offset registers is 8-bit, twos compliment. The resolution of the offset registers about 15.6 mg/LSB. If the offset calibration must be finer than 15.6 mg/LSB, the calibration needs to be done at the processor. The offset register adds the value written in the register to measured acceleration. For example, if the offset is +156 mg, then −156 mg should be written to offset register. Figure 9 shows the typical offset calibration sequence.

Figure 9. Offset Calibration Sequence.

For this routine, X-/Y-axes errors are zero when 0 g input is applied, whereas Z-axis errors are zero when 1 g input is applied. Greater accuracy can be achieved if it is possible to rotate the ADXL346 at calibration.