SC70 LED Driver Drives Six White LEDs from a Single Li-Ion Battery

SC70 LED Driver Drives Six White LEDs from a Single Li-Ion Battery

by

Mayur Kenia

Mar 1 2006

Introduction

The highly integrated LT3491 provides a compact, simple solution for driving backlight circuits in battery-powered portable devices, such as cellular phones, PDAs, and portable GPS devices. It features internal compensation, open-LED protection, a 32V power switch and a 32V Schottky diode all inside a tiny SC70 package.

Specifically, the LT3491 is a fixed frequency step-up DC/DC converter that drives up to six white LEDs in series from a Li-Ion cell. Series connection of the LEDs provides identical LED currents resulting in uniform brightness without the need for ballast resistors. In addition, the 2.3MHz switching frequency allows the use of tiny inductors and capacitors.

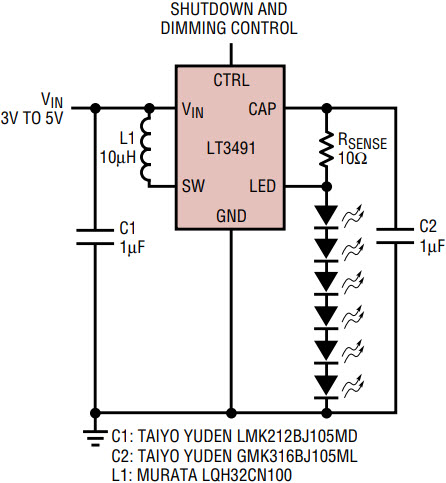

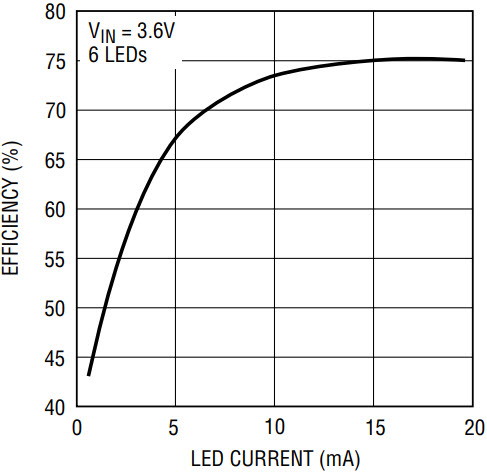

Figure 1 shows how easy it is to drive six white LEDs from a Li-Ion battery. Figure 2 shows the efficiency of the six white LED application circuit.

Figure 1. Li-Ion powered driver for six white LEDs.

Figure 2. Efficiency of the circuit in Figure 1.

High Side Sense

The LT3491 features a unique high side LED current sense that enables the part to function as a “one wire” current source—one side of the LED string can be returned to ground anywhere, allowing a simpler “one wire” LED connection. Traditional LED drivers use a grounded resistor to sense LED current requiring a 2-wire connection to the LED string. High side sense moves the sense resistor to the top of the LED string.

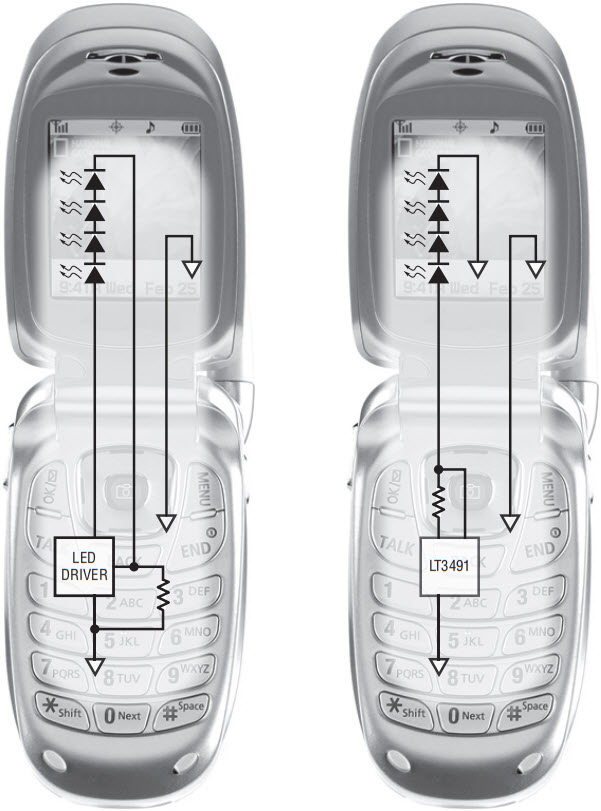

Figure 3 shows the advantage of high side sense in a cell phone where the LEDs are placed some distance away from the driver. The technique eliminates the return wire thereby reducing the number of wires running through the hinge. Also, it allows the LEDs to be placed further away from the converter without compromising performance.

Figure 3. Traditional sense (left) and high side sense (right) implemented solutions in a cell phone. The high side solution reduces the number of connections through the hinge.

Dimming & Shutdown Control

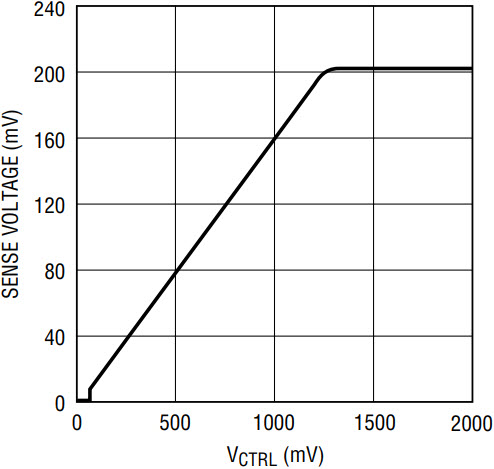

A single pin performs both shutdown and accurate LED dimming control. The dimming range of the part extends from 1.5V at the CTRL pin for full LED current down to 100mV. The CTRL pin directly controls the regulated sense voltage across the sense resistor that sets the LED current. Figure 4 shows the regulated sense voltage versus CTRL pin voltage.

Figure 4. LED sense voltage versus CTRL pin voltage.

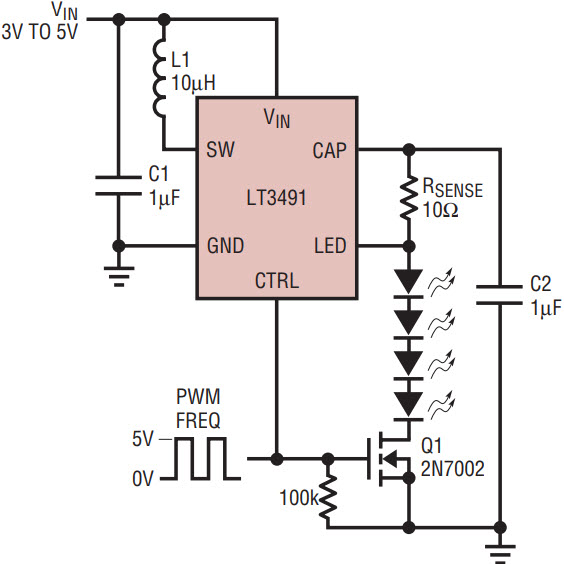

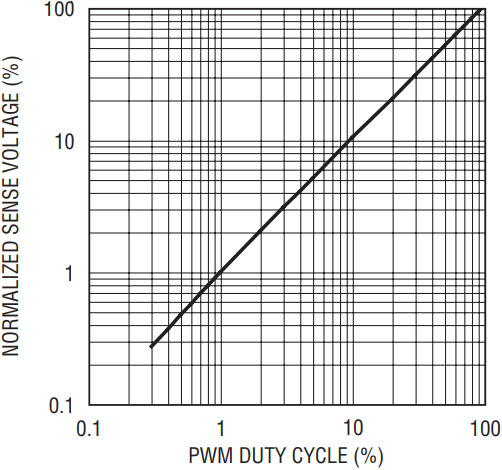

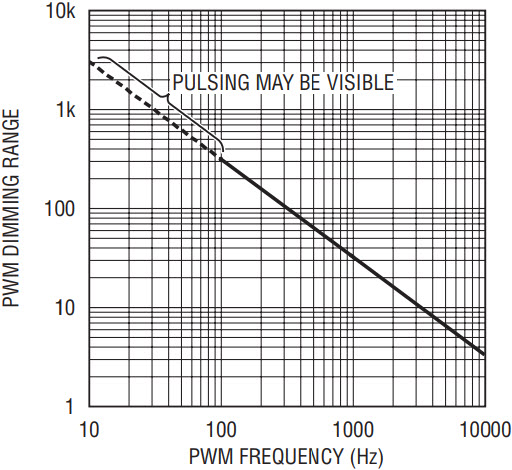

In addition to using a DC voltage at the CTRL pin, either a filtered PWM signal or a direct PWM signal can be used to control the LED current. Direct PWM dimming achieves wider dimming compared to using a filtered PWM or a DC voltage. Direct PWM dimming uses a MOSFET in series with the LED string to quickly connect and disconnect the LED string. Figure 5 presents direct PWM dimming in a Li-Ion to four white LED application. The PWM signal controls both the turn on and turn off of the part through the CTRL pin and the MOSFET. Figure 6 shows the linearity of PWM dimming. The available dimming range depends on the settling time of the application and the PWM frequency used. The application in Figure 5 achieves a dimming range of 300:1 using a 100Hz PWM frequency. Figure 7 shows the available dimming range for different PWM frequencies.

Figure 5. Li-Ion to four white LEDs with direct PWM dimming.

Figure 6. Linearity of PWM dimming for a 100Hz PWM frequency and the application of Figure 5.

Figure 7. Dimming range vs frequency.

Torch and Flash Mode LED Control

White LEDs are quickly gaining popularity as the illumination source for camera phones. White LEDs provide a simple compact solution for flash and torch lighting in cell phone applications. The LT3491 provides a small overall solution to flash and torch control.

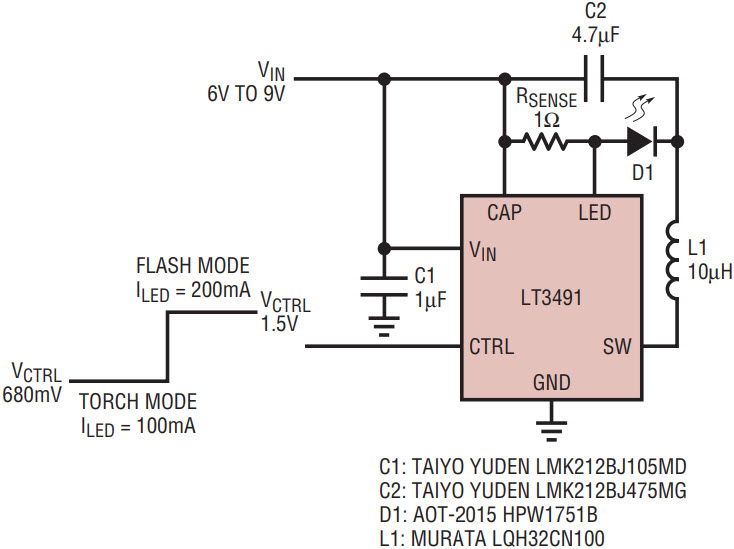

Torch and flash applications typically use a single high power white LED. The LED driver cannot be setup as a boost because the input voltage in camera phones is very close to, if not higher, than the forward voltage of the LED. A higher input voltage creates a DC path to ground that will drain the battery. High side sensing allows the LT3491 to drive a single LED from higher inputs, thus avoiding this problem. Figure 8 shows the application circuit for torch and flash control powered from two Li-Ion cells. The voltage at the control pin can be moved between two DC levels to toggle between torch and flash operation.

Figure 8. A 2-Cell Li-Ion driver for torch and flash mode control.

Conclusion

The LT3491 provides a highly integrated solution to drive backlight applications up to six LEDs from a Li-Ion cell input with the added advantage of high side sense in a tiny SC70 package.