LTC1733: Thermal Regulation Maximizes Lithium-Ion Battery Charging Rate Without Risk of Overheating

LTC1733: Thermal Regulation Maximizes Lithium-Ion Battery Charging Rate Without Risk of Overheating

May 1 2002

Introduction

Linear battery chargers are typically smaller, simpler and less expensive than switcher-based solutions, but they have one major disadvantage: excessive power dissipation. When the input voltage is high and the battery voltage is low (discharged battery) a linear charger could generate enough heat to damage itself or other components. Typically, such conditions are temporary—as the battery voltage rises with its charge—but it is worst case situations that one must account for when determining the maximum allowable values for charge current and IC temperature. To solve this problem, the LTC1733 employs internal thermal feedback to regulate the charge current and limit the die temperature. This feature translates to faster charge times, because a designer can program a high charge current (to minimize charging time) without the risk of damaging the LTC1733 or any other components. The need for thermal over-design is also eliminated. To further improve heat transfer, the LTC1733 is housed in a thermally enhanced 10-pin MSOP package. For simplicity, the LTC1733 provides a complete lithium-ion charger solution requiring only three external components, as shown in Figure 1.

Figure 1. Standalone Li-Ion battery charger.

An internal power MOSFET allows charge current to be programmed up to 1.5A, with 7% accuracy, to ensure a fast and complete charge. The internal MOSFET also eliminates the need for an external current sense resistor or blocking diode. The final float voltage is pin selectable to either 4.1V or 4.2V with 1% accuracy to prevent dangerous overcharging or reduced battery capacity due to undercharging.

Following battery manufacturers’ guidelines, the LTC1733 includes a programmable charge termination timer and thermistor input for temperature qualified charging. Status outputs include C/10 charge detection to indicate a near end-of-charge condition, wall adapter present detection to determine whether charging may proceed or not, charge current monitoring for gas gauging, and fault detection for identifying bad cells. Low battery charge conditioning (trickle charging) safely charges an over-discharged cell, and automatic recharge ensures that the battery is always fully charged. To conserve battery power, the LTC1733 battery drain current drops to less than 5μA when a wall adapter is not present or when the part is shutdown.

Charging a Battery

To charge a single cell Li-ion battery, the user must apply an input voltage (typically, a wall adapter) of at least 4.5V to the VCC pin. The ACPR pin will subsequently pull low to indicate that the input voltage condition has been met. Furthermore, a 1% resistor must be connected from PROG to GND to program the nominal charge current to 1500V/RPROG. The CHRG pin will then pull low to indicate that a charge cycle has commenced. A capacitor connected between the TIMER pin and GND will program the charge termination time to 3 hours per 100nF.

If the BAT pin voltage is below 2.48V at the beginning of a charge cycle then the charge current will be one-tenth of the programmed value in order to safely bring the cell voltage high enough to allow full charge current. If the cell is damaged, and the voltage does not rise above 2.48V within one-quarter of the programmed termination time, the charge cycle will terminate, and the FAULT status output will latch low indicating a bad cell. All three of these status output pins, ACPR, CHRG and FAULT, have enough current sinking capability to light an LED.

Once the battery voltage rises above 2.48V (which typically occurs soon after the start of a charge cycle), the LTC1733 will provide a constant current to the battery as programmed by RPROG. The LTC1733 will remain in constant-current mode until the BAT pin voltage approaches the selected final float voltage (4.1V for SEL = 0V and 4.2V for SEL = VCC). At this point the part enters constant-voltage mode.

In constant-voltage mode, the LTC1733 begins to decrease the charge current to maintain a constant voltage at the BAT pin rather than a constant current out of the BAT pin. When the current drops to 10% of the full-scale programmed charge current, an internal comparator latches off the strong pull-down at the CHRG pin and connects a weak current source (about 25μA) to ground to indicate a near end-of-charge (C/10) condition.

Unlike battery chargers that terminate when the current reaches C/10, the LTC1733 continues to charge the battery after the C/10 point, as long as the termination time has not elapsed, to ensure that the battery is fully charged. Terminating charging at C/10 can leave a battery charged to only 90% to 95% capacity, while charging past C/10 and terminating based on time can charge a battery to 100% capacity. Upon termination, the CHRG pin assumes a high impedance state.

Recharging a Battery

The LTC1733 has the ability to recharge a battery assuming that the battery voltage has been charged above 3.95V (SEL = 0V) or 4.05V (SEL = VCC) during the initial charge cycle. Once above these thresholds, a new charge cycle begins if the battery voltage drops below 3.9V (SEL = 0V) or 4.0V (SEL = VCC) due to either a load on the battery, or the self-discharge current of the battery. The recharge circuit integrates the BAT pin voltage for a few milliseconds to prevent transients from restarting the charge cycle. This feature ensures that the battery remains charged even if left connected to the powered charger for very long periods of time.

Thermal Regulation

An additional key feature of the LTC1733 is the internal thermal regulation loop. If high power operation and/or high ambient temperature conditions cause the junction temperature of the LTC1733 to approach 105°C, the charge current is automatically reduced to maintain the junction temperature at roughly 105°C (board temperatures typically remain below about 85°C). This is called constant-temperature mode. This feature allows the user to program a charge current based on typical operating conditions and eliminates the need for the complicated thermal over-design necessary in many linear charger applications. Worst-case conditions are automatically taken care of by the LTC1733. In addition to protecting the LTC1733, this feature eliminates “hot spots” on the board, thereby protecting surrounding components. The thermal shutdown features of other battery chargers simply turn off the charger at very high temperatures (typically, in excess of 130°C). This junction-temperature-based type of shutdown allows both the battery charger and the surrounding board to get extremely hot, so even though the shutdown “protection” exists, the application must be painstakingly designed to avoid reaching the thermal shutdown temperature under all scenarios. The LTC1733 simplifies thermal design by automatically balancing charge current, power dissipation and operating temperature.

To further improve the thermal performance of the LTC1733, it is packaged in a 10-pin thermally enhanced MSOP package. The application board pictured in Figure 2 occupies just 76mm2 of board space and can dissipate over 2W of power at room temperature. That equates to a maximum charge current of about 1.5A, with a 5V input supply. This assumes that a Li-ion battery spends most of its time at 3.7V during charge. In fact, this is a conservative assumption, since a typical Li-ion battery will rise above 3.8V within the first few minutes of charging. The powerful thermal features of the LTC1733 and the 7% accuracy of the programmed charge current allow very fast and accurate charging of single cell Li-ion batteries.

Figure 2. Full featured single cell Li-Ion charger.

PROG Current Monitor

For gas gauging applications, the PROG pin provides very accurate information regarding the current flowing out of the BAT pin. The relationship is given by:

During constant-current mode, the PROG pin voltage is always 1.5V, indicating that the programmed charge current is flowing out of the BAT pin. In constant-temperature or constant-voltage mode, the BAT pin current is reduced and can be determined by measuring the PROG pin voltage and applying the above formula. The PROG pin, along with the three open-drain status outputs (ACPR, CHRG, and FAULT), inform the user of exactly what the LTC1733 is doing at all times.

NTC Thermistor

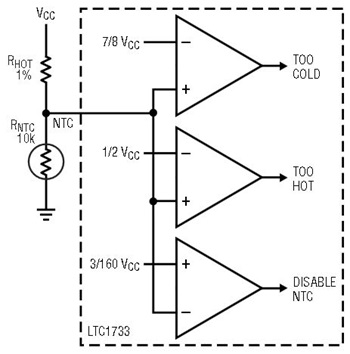

In addition to the programmable timer and low battery charge qualification, the LTC1733 adds temperature qualified charging to the list of battery manufacturer recommended safety features. The battery temperature is measured by placing a negative temperature coefficient (NTC) thermistor close to the battery pack. Using the circuitry shown in Figure 3, the LTC1733 can temporarily suspend the internal timer and stop charging when the battery temperature falls below 0°C or rises above 50°C. To perform this function, RHOT should be chosen to be the value of the selected NTC thermistor at 50°C. This will ensure that the internal comparator’s trip point of 1/2VCC corresponds to an NTC temperature of 50°C. Furthermore, the selected NTC thermistor should have a value at 0°C that is as close to seven times the value at 50°C as possible. A 7:1 cold to hot NTC ratio ensures that the internal comparator’s trip point of 7/8VCC corresponds to an NTC temperature of 0°C. The hot and cold comparators each have approximately 2°C of hysteresis to prevent oscillation about the trip point. In addition, the NTC function can be disabled without any external components by simply grounding the NTC pin.

Figure 3. Temperature qualification circuitry.

Conclusion

The LTC1733 is a full-featured, standalone Li-ion battery charger. In its simplest form, the LTC1733 only requires three external components and can safely and accurately charge high-capacity batteries very quickly with up to 1.5A of charge current. An NTC thermistor and a few LEDs can be added to take advantage of the safety and status features.

About the Authors

Trevor Barcelo has over 15 years of experience at Linear Technology as an analog IC design engineer, design manager and product line manager. He began his career at Linear Technology’s headquarters in Milpitas, CA by...